Beruflich Dokumente

Kultur Dokumente

Bioaffinity Sensing Using Biologically Functionalized Conducting-Polymer Nanowire

Hochgeladen von

junep42Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Bioaffinity Sensing Using Biologically Functionalized Conducting-Polymer Nanowire

Hochgeladen von

junep42Copyright:

Verfügbare Formate

Published on Web 12/23/2004

Bioaffinity Sensing Using Biologically Functionalized Conducting-Polymer

Nanowire

Kumaran Ramanathan, Mangesh A. Bangar, Minhee Yun, Wilfred Chen,

Nosang V. Myung,*, and Ashok Mulchandani*,

Department of Chemical and EnVironmental Engineering, and Center for Nanoscale Science and Engineering,

UniVersity of California-RiVerside, RiVerside, California 92521, and Jet Propulsion Laboratory,

California Institute of Technology, 4800 Oak GroVe DriVe, Pasadena, California 91109

Received September 11, 2004; E-mail: adani@engr.ucr.edu; myung@engr.ucr.edu

Recent advances in electronic detection based on nanowires

(NWs) and nanotubes (NTs) has revolutionized our ability to provide label-free and real-time, yet sensitive and selective detection

of a wide range of chemical and biological species using the NW

or NT as the gate of a planar field effect transistor (FET).1 Unlike

two-dimensional FETs, one-dimensional nanowires avoid the reduction in conductance changes caused by lateral current shunting to

the point that even single-molecule detection is possible. The selectivity of the nanosensors can be further enhanced by modification

with specific bioreceptors such as antibodies. Examples of silicon

nanowire (SiNWs) and carbon nanotubes (CNT) functionalized with

biotin and human autoantigen (U1A), respectively, for label-free,

sensitive, and real-time detection have been reported.1,2 The

suggested mechanism for the resulting high sensitivity, potentially

to single molecule, is the extremely sensitive modulation of the

electrical conductance/resistance of the NWs and NTs brought about

by the changes in the electrostatic charges from surface adsorption

of various molecules, leading to the depletion or accumulation of

carriers in the bulk of the nanometer diameter structure.

While these reports demonstrated the power of nanoengineered

materials as biosensors, the fabrication methods employed are

seriously limited. The techniques of manipulating individual carbon

nanotube onto prepatterned electrodes by an atomic force microscope,3 random dispersion of suspended carbon nanotubes onto

prepatterned electrodes,4,5 and lithographically patterning catalyst

(as CNT nucleation sites) on electrodes,6,7 while adequate for

demonstrating the operational characteristics of individual devices,

have low throughput and limited controllability and hence are

unattractive for scaling up to high-density sensor arrays. More

importantly, surface modifications, typically required to incorporate

bioreceptors, have to be performed post-synthesis and post-assembly. Attempts to improve fabrication controllability using either

electric field alignment8,9 or fluidic alignment followed by e-beam

lithography have been reported.1,10 However, no report to date has

demonstrated the ability to assemble these nanomaterials into a

functional sensor circuit and to individually address each nanostructured sensing element with the desired bioreceptor, a requirement necessary for the successful fabrication of nanosensor arrays.

Conducting polymers such as polypyrrole (Ppy) because of their

electronic conductivity, environmental stability, easy and controlled

processing by electrochemical polymerization, and biocompatibility

have emerged as promising materials in the development of planar

electrochemical biosensors.11,12 Biomolecules can be incorporated

into the conducting polymer in a single step during polymer

synthesis rather than the multiple steps needed for synthesis of

surface-modified silicon nanowires and carbon nanotubes. Recently,

Hernandez et al. reported a template method for synthesis of bio

496

University of California-Riverside.

California Institute of Technology.

9

J. AM. CHEM. SOC. 2005, 127, 496-497

logically functionalized Ppy nanowires.13 Although elegant, application of template-fabricated biologically functionalized nanowire

is limited by some of the same problems as those for SiNWs and

CNT. Because the nanowires synthesized in the template have to

be separated and collected by dissolving the template in a solution,

the nanowires are either floating or remain attached to the substrate,

forming a vertical array. For use in biosensors these nanowires will

need a time-consuming and arduous method for adhering to

patterned electrodes. Additionally, the harsh conditions, 25% nitric

acid followed by 3 M sodium hydroxide, required to dissolve the

alumina template might not be suitable for many biological

molecules of interest. We report herein for the first time a simple,

biomolecular friendly, single-step protocol for the fabrication of a

polypyrrole nanowire biosensor of controlled dimension and composition, large aspect ratio, and most of all, site-specific positioning

and its application to label-free bioaffinity sensing.

We recently demonstrated the feasibility of fabricating single

and multiple individually addressable polypyrrole and polyaniline

nanowires of controlled dimension (100 nm wide and up to 13 m

long) and location by electrodeposition within a channel between

two electrodes on the surface of a silicon wafer and their application

as pH sensors.14 A similar electrode structure with a channel 100

or 200 nm wide by 3 m long was employed for the entrapment of

the model protein, avidin, during electrochemical polymerization

of polypyrrole in a single step. The initial investigations on

biomolecular functionalization of Ppy nanowires by entrapment in

a single-step during electropolymerization were performed using

avidin-conjugated ZnSe/CdSe quantum dots (Aqd). This was done

to facilitate microscopic characterization and establishment of the

location of the biomolecule in the nanowire.

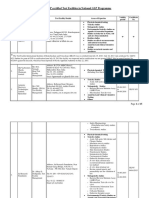

Scanning electron micrograph images of the Aqd-functionalized

Ppy nanowire demonstrated that the nanowire was continuous, well

defined, dendrite free, spanning the entire length of the channel,

and making a good contact with both electrodes. Energy-dispersive

X-ray (EDX) analysis of the nanowires confirmed the presence of

Cd within the nanowire, an indication of the presence of quantum

dot and thereby streptavidin within the Ppy nanowire (Figure 1).

The integrity and good ohmic contact with the two electrodes

of the biomolecule-modified Ppy nanowire was further confirmed

by the linear dependence of current as a function of the applied

potential (see Supporting Information Figure S2).

To demonstrate the utility of functionalized nanowires as sensors,

biotin conjugated to a 20-mer DNA oligo (biotin-DNA) was

applied. Figure 2 shows that the resistance of the 200 nm wide

avidin-functionalized nanowires increased rapidly to a constant

value upon addition of 1 nM of the biotin-DNA conjugate, and

the resistance change increased with increasing concentrations up

to 100 nM. Increasing the concentration further to 1 M resulted

in only a 4% increase over 100 nM, indicating saturation of recog10.1021/ja044486l CCC: $30.25 2005 American Chemical Society

COMMUNICATIONS

Figure 3. AFM phase images for a 50 nm thick film on an area for (A)

polypyrrole and (B) polypyrrole with entrapped Aqd.

Figure 1. (A) SEM image of an Aqd-embedded polypyrrole nanowire (200

nm wide). The EDX analysis of polypyrrole nanowire with embedded Aqd

(B) and without embedded Aqd (C).

Figure 2. Electrical responses of an unmodified nanowire (A) to 100 nM

biotin-DNA (single stranded) and avidin-embedded polypyrrole (200 nm)

nanowires to 1 nM (B) and 100 nM (C) biotin-DNA. The responses were

recorded on two separate polypyrrole-avidin nanowires. Polypyrrole

nanowire containing entrapped avidin were grown using 25 nM pyrrole in

10 mM NaCl and of avidin.

nition sites. In contrast, addition of buffer and/or DNA oligo without

conjugated biotin to the functionalized nanowires did not result in

any observable changes in resistance. These observations together

with the absence of any response to the addition of biotin-DNA

to an unmodified Ppy nanowire confirmed that the changes in

resistance were due to the binding of biotin-DNA with avidin in

the functionalized nanowires. A similar response of a 100 nm PpyAqd nanowire upon exposure to similar concentrations of biotinDNA further validated the sensing strategy. While the % changes

were very similar to those of the 100 nm Ppy-Aqd nanowire as

expected, the absolute resistance values in 200 nm nanowires were

lower due to the higher cross-sectional area of such nanowires.

For the detection of larger target analytes that cannot diffuse

into the Ppy pores and a fast response of small molecules, the

entrapped biomolecule should be on the surface of the nanowire.

To determine the location of the Aqd in the Ppy, AFM PhaseImaging was performed on a 50 nm thick (the depth of the channel

used for nanowire formation) Aqd-Ppy film electrochemically

deposited on a gold electrode. AFM PhaseImaging is an extension

of tapping mode which allows detecting variation in composition

and hardness. As shown in Figure 3, Aqd-Ppy film shows a much

higher contrast compared to Ppy film, demonstrating the composite

nature of Aqd-Ppy film and presence of Aqd on the film surface.

In conclusion, a facile yet powerful method for fabrication of

biologically functionalized nanowires of controlled dimension and

high aspect ratio in confined channels and its application to

bioaffinity sensing were demonstrated. The one-step incorporation

of functional biological molecules into the conducting-polymer

nanowire during its synthesis and built-in electrical contacts is the

major advantage of the new fabrication method over the reported

silicon nanowire and carbon nanotube biosensors that require post-

synthesis modification and positioning. Combined with the already

demonstrated ability to make individually addressable nanowires

that are a few micrometers apart sequentially, one at a time, this

will enable fabrication of high-density biosensor nanoarrays. While

the concept has been demonstrated for biological modification of

Ppy nanowires, other monomers such as aniline and thiophene that

can be electropolymerized from an aqueous environment benign

to biomolecules can also be employed. The nanomolar sensitivity

of the present biosensor, while lower than that for SiNW and CNT,

was obtained with nanowires that were not optimized with respect

to the conductivity. A sensitivity of potentially single-molecule

detection is possible by adjusting the nanowires conductivity to a

value closer to the lower end of a semiconductor. Wrightons group

has already demonstrated that the conductivities of Ppy or polyaniline can be modulated by simply controlling the oxidation state

of these polymers.11,12,15 Additionally, the diversity of monomers,

dopants, and electropolymerization conditions and modes adds many

dimensionalities to the reported technique in terms of the ability to

design tailor-made nanowire biosensors. These are currently being

investigated.

Acknowledgment. This work was supported by grants from

DOD/DARPA/DMEA and Jet Propulsion Laboratory.

Supporting Information Available: Experimental procedure for

fabrication of biologically functionalized Ppy nanowires, chronopotentiogram during nanowire growth, and I-V plot. This material is

available free of charge via the Internet at http://pubs.acs.org.

References

(1) Cui, Y.; Wei, Q.; Park, H.; Lieber, C. M. Science 2001, 293, 1289-1292.

(2) Chen, R. J.; Bangsaruntip, S.; Drouvalakis, K. A.; Kam N. W. S.; Shim,

M.; Yiming, L.; Kim, W.; Utz, P. J.; Dai, H. Proc. Natl. Acad. Sci. U.S.A.

2003, 1000, 4984-4989.

(3) Roschier, L.: Pentilla, J.; Martin, M.; Hakonen, P.; Paalanen, M.; Tapper,

U.; Kauppinen, E. I.; Journet, C.; Bernier, P. Appl. Phys. Lett. 1999, 75,

728-730.

(4) Tans, S. J.; Verscheren, A. R. M.; Dekker, C. Nature 1998, 393, 49-52.

(5) Bezryadin, A.; Verschueren, A. R. M.; Tans, S. J.; Dekker, C. Phys. ReV.

Lett. 1998, 80, 4036.

(6) Franklin, N. R.; Wang, Q.; Tombler, T. W.; Javey, A.; Shim, M.; Dai, H.

Appl. Phys. Lett. 2002, 81, 913-915.

(7) Guillorn, M. A.; Haile; M. D.; Merkulov; V. I.; Simpson, M. L.; Eres, G.

Y.; Cui, H.; Puretzky, A. A.; Geohegan, D. B. Appl. Phys. Lett. 2002, 81,

2860-2862.

(8) Smith, P. A.; Nordquist, C. D.; Jackson, T. N.; Mayer, T. S.; Martin, B.

R.; Mbindyo, J.; Mallouk, T. E. Appl. Phys. Lett. 2000, 77, 1399-1401.

(9) Duan, X.; Huang, Y.; Cui, Y.; Wang, J.; Lieber, C. M. Nature 2001, 409,

66-69.

(10) Huang, Y.; Duan, X.; Cui, Y.; Lauhon, L. J.; Kim, K.-H.; Lieber, C. M.

Science 2001, 294, 1313-1317.

(11) White, H. S.; Kittlesen, G. P.; Wrighton, M. S. J. Am. Chem. Soc. 1984,

106, 5375-5377.

(12) Kittlesen, G. P.; White, H. S.; Wrighton, M. S. J. Am. Chem. Soc. 1984,

106, 7389-7396.

(13) Hernandez, R. M.; Richter, L.; Semanick, S.; Stranick, S.; Mallouk, T. E.

Chem. Mater. 2004, 16, 3431-3438.

(14) Ramanathan, K.; Bangar, M.; Yun, M.; Chen, W.; Mulchandani, A.;

Myung, N. V. Nano Lett. 2004, 4, 1237-1239. Yun, M.; Myung, N. V.;

Vasquez, R. P.; Lee, C.; Menke, E.; Penner, R. M. Nano Lett. 2004, 4,

419-422.

(15) Paul, E. W.; Ricco, A. J.; Wrighton, M. S. J. Phys. Chem. 1985, 89,

1441-1447.

JA044486L

J. AM. CHEM. SOC.

VOL. 127, NO. 2, 2005 497

Das könnte Ihnen auch gefallen

- International Symposium on Selective Ion-Sensitive Electrodes: International Union of Pure and Applied ChemistryVon EverandInternational Symposium on Selective Ion-Sensitive Electrodes: International Union of Pure and Applied ChemistryG. J. MoodyNoch keine Bewertungen

- Heat, Apr 2011Dokument5 SeitenHeat, Apr 2011emediageNoch keine Bewertungen

- Electrochimica ActaDokument7 SeitenElectrochimica ActaTaher KhanNoch keine Bewertungen

- CNT Abs PDFDokument7 SeitenCNT Abs PDFLaurentiu-Florin MosinoiuNoch keine Bewertungen

- Effect of Solution Concentration and Applied Volta PDFDokument8 SeitenEffect of Solution Concentration and Applied Volta PDFAtiko Nur OktaVianiNoch keine Bewertungen

- Vrouw, Jun 2011Dokument6 SeitenVrouw, Jun 2011emediageNoch keine Bewertungen

- Carbon Nanotube Transistors For Biosensing ApplicationsDokument13 SeitenCarbon Nanotube Transistors For Biosensing Applicationsrjc030012939Noch keine Bewertungen

- Mechanical and Electrical Properties of Electrospun PVDF/MWCNT Ultrafine Fibers Using Rotating CollectorDokument7 SeitenMechanical and Electrical Properties of Electrospun PVDF/MWCNT Ultrafine Fibers Using Rotating CollectorRana Sabouni TabariNoch keine Bewertungen

- Polyaniline/single-Walled Carbon Nanotube Composite Electronic DevicesDokument6 SeitenPolyaniline/single-Walled Carbon Nanotube Composite Electronic DevicesDebarchan BasuNoch keine Bewertungen

- Dielectrophoretically Assembled Polymer Nanowires For Gas SensingDokument5 SeitenDielectrophoretically Assembled Polymer Nanowires For Gas SensingMuhammad Tayyab ZahoorNoch keine Bewertungen

- 2012 Goyal Surface Modification ReviewDokument21 Seiten2012 Goyal Surface Modification ReviewkeyachemNoch keine Bewertungen

- Seventeen, Sep 2011Dokument6 SeitenSeventeen, Sep 2011emediageNoch keine Bewertungen

- Adma 200803865Dokument6 SeitenAdma 200803865RACHIT DOBHALNoch keine Bewertungen

- Effect of Concentration and Nozzle-Collector Distance On The Morphology of NanofibersDokument5 SeitenEffect of Concentration and Nozzle-Collector Distance On The Morphology of NanofibersMuhammad Shafiz DanialNoch keine Bewertungen

- Meg PbsDokument9 SeitenMeg PbsmolkuNoch keine Bewertungen

- 2017 Effect of Polyaniline On MWCNTs Supercapacitor Properties Prepared byDokument7 Seiten2017 Effect of Polyaniline On MWCNTs Supercapacitor Properties Prepared bymudalagi73Noch keine Bewertungen

- A Novel Methanol Sensor Based On Gas-Penetration Through A Porous Polypyrrole-Coated Polyacrylonitrile Nanofiber MatDokument5 SeitenA Novel Methanol Sensor Based On Gas-Penetration Through A Porous Polypyrrole-Coated Polyacrylonitrile Nanofiber MatMuhammad RashidNoch keine Bewertungen

- Hetero-Nanojunctions With Atomic Size Control Using A Lab-On-Chip Electrochemical Approach With Integrated MicrofluidicsDokument14 SeitenHetero-Nanojunctions With Atomic Size Control Using A Lab-On-Chip Electrochemical Approach With Integrated Microfluidicsanon_666754590Noch keine Bewertungen

- Fibre Optic P H Sensors Prepared by Immobilisation TechniqueDokument3 SeitenFibre Optic P H Sensors Prepared by Immobilisation TechniqueSemanu TcheyiNoch keine Bewertungen

- Improve and Extend The Range Wavelength of The Photodetector Based On PVP Polymer by Doping It With Manganese Dioxide Via Electrospinning TechniqueDokument15 SeitenImprove and Extend The Range Wavelength of The Photodetector Based On PVP Polymer by Doping It With Manganese Dioxide Via Electrospinning TechniqueCentral Asian StudiesNoch keine Bewertungen

- Biosensors To Improve Output SensitivityDokument20 SeitenBiosensors To Improve Output SensitivitydebmallyNoch keine Bewertungen

- Accepted Manuscript: Sensors and Actuators BDokument30 SeitenAccepted Manuscript: Sensors and Actuators BSamsouma BkNoch keine Bewertungen

- Letters: Ultrasensitive Solution-Cast Quantum Dot PhotodetectorsDokument4 SeitenLetters: Ultrasensitive Solution-Cast Quantum Dot PhotodetectorsPetru ApostolNoch keine Bewertungen

- Control of Thickness of PEDOT Electrodeposits On GlassITODokument8 SeitenControl of Thickness of PEDOT Electrodeposits On GlassITOGonzalo FenoyNoch keine Bewertungen

- MicroTAS2020 IzadoraTanimotoDokument2 SeitenMicroTAS2020 IzadoraTanimotoIzadora Mayumi Fujinami TanimotoNoch keine Bewertungen

- Nanomaterials 03 00498 PDFDokument26 SeitenNanomaterials 03 00498 PDFFarvin FleetNoch keine Bewertungen

- Applied Surface Science: Full Length ArticleDokument6 SeitenApplied Surface Science: Full Length ArticleDiego ChaparroNoch keine Bewertungen

- SiNW Sensor FabricatDokument10 SeitenSiNW Sensor FabricatSergey OstapchukNoch keine Bewertungen

- 2006 - (1) - Electrochemical Sensors Based On Conducting Polymer-PolypyrroleDokument14 Seiten2006 - (1) - Electrochemical Sensors Based On Conducting Polymer-Polypyrroletrandafir16Noch keine Bewertungen

- (2001) A Conductive Polypyrrole Based AmmoniumDokument13 Seiten(2001) A Conductive Polypyrrole Based AmmoniumVĩ PhùngNoch keine Bewertungen

- Electrospinning Fabrication of High Strength and Toughness Polyimide NanofiberDokument8 SeitenElectrospinning Fabrication of High Strength and Toughness Polyimide NanofiberRonak VaghaniNoch keine Bewertungen

- A Novel Technique For Optical Fiber PH Sensing Based On Methylene Blue Adsorption-2Dokument8 SeitenA Novel Technique For Optical Fiber PH Sensing Based On Methylene Blue Adsorption-2liton_kabirNoch keine Bewertungen

- Long Distance Electron Transfer in Cytochrome C Oxidase Immobilised On Electrodes. A Surface Enhanced Resonance Raman Spectroscopic StudyDokument8 SeitenLong Distance Electron Transfer in Cytochrome C Oxidase Immobilised On Electrodes. A Surface Enhanced Resonance Raman Spectroscopic StudyEdward PittsNoch keine Bewertungen

- 1 Au NPs Thin Films Fabricated by Electrophoretic Deposition Method For Highly Sensitive SERS Application Odi YesDokument7 Seiten1 Au NPs Thin Films Fabricated by Electrophoretic Deposition Method For Highly Sensitive SERS Application Odi Yesben0706Noch keine Bewertungen

- 2017 Novel Concept For Fabricating A Flexible Transparent Electrode (The JOURNAL of PHYSICAL CHEMISTRY C)Dokument7 Seiten2017 Novel Concept For Fabricating A Flexible Transparent Electrode (The JOURNAL of PHYSICAL CHEMISTRY C)최요민Noch keine Bewertungen

- Integration of Nanochannels With Electrodes To Control Single Molecule DNA MovementDokument2 SeitenIntegration of Nanochannels With Electrodes To Control Single Molecule DNA MovementArash IraniNoch keine Bewertungen

- AppSurfSci Scotto-Et-Al PEDOT-graphite-biosensing 2020 Compressed PDFDokument9 SeitenAppSurfSci Scotto-Et-Al PEDOT-graphite-biosensing 2020 Compressed PDFROJITAS90Noch keine Bewertungen

- Magisetty2018Dokument17 SeitenMagisetty2018Riston SinagaNoch keine Bewertungen

- Electrocative Carbon Nanotube ActuatorsDokument8 SeitenElectrocative Carbon Nanotube ActuatorsSean PontNoch keine Bewertungen

- Tatler, Jan 2011Dokument4 SeitenTatler, Jan 2011emediageNoch keine Bewertungen

- Synthesis of Au/Graphene Oxide Composites For Selective and Sensitive Electrochemical Detection of Ascorbic AcidDokument6 SeitenSynthesis of Au/Graphene Oxide Composites For Selective and Sensitive Electrochemical Detection of Ascorbic Acidjaum_camposcostaNoch keine Bewertungen

- Detection of Phenol at Boron-Doped Nanocrystalline Diamond Electrodes (2011)Dokument8 SeitenDetection of Phenol at Boron-Doped Nanocrystalline Diamond Electrodes (2011)DanielNoch keine Bewertungen

- 6 17 2016 ElectrocheDokument13 Seiten6 17 2016 ElectrocheBHOOMINoch keine Bewertungen

- Psi LBR ElectrophysiologyDokument4 SeitenPsi LBR ElectrophysiologyElena Iulia CucoleaNoch keine Bewertungen

- Kompakt, Jan 2011Dokument5 SeitenKompakt, Jan 2011emediageNoch keine Bewertungen

- Experimental Investigation On Thermal Electric and Dielectric Characterization For PolypropyleneDokument12 SeitenExperimental Investigation On Thermal Electric and Dielectric Characterization For PolypropyleneIAEME PublicationNoch keine Bewertungen

- Electrospun Nanofibrous Membranes For Highly Sensitive Optical SensorsDokument3 SeitenElectrospun Nanofibrous Membranes For Highly Sensitive Optical Sensorsgovardhan50Noch keine Bewertungen

- 02 Apl 5Dokument3 Seiten02 Apl 5Vinita ChoudharyNoch keine Bewertungen

- Mobarak 2013Dokument7 SeitenMobarak 2013pao18476Noch keine Bewertungen

- Measuring The Ionic Conductivity of Solid - 2023 - International Journal of EleDokument10 SeitenMeasuring The Ionic Conductivity of Solid - 2023 - International Journal of EleWilliam Rolando Miranda ZamoraNoch keine Bewertungen

- Electrical Conductivity Improvement of PDokument7 SeitenElectrical Conductivity Improvement of PHenry LauNoch keine Bewertungen

- Zeghina2014Dokument10 SeitenZeghina2014Riston SinagaNoch keine Bewertungen

- Single-Step in Situ Synthesis of Polymer-Grafted Single-Wall Nanotube CompositesDokument2 SeitenSingle-Step in Situ Synthesis of Polymer-Grafted Single-Wall Nanotube CompositesGaruda Sastha ArunNoch keine Bewertungen

- Mixed Ionic Electronic ConductorsDokument7 SeitenMixed Ionic Electronic ConductorsJennyNoch keine Bewertungen

- A Summary of DOI10.1021 - La9021273Dokument3 SeitenA Summary of DOI10.1021 - La9021273Huỳnh ChâuNoch keine Bewertungen

- 1 s2.0 S1566119924000065 MainDokument7 Seiten1 s2.0 S1566119924000065 MainABDELKHALK ABOULOUARDNoch keine Bewertungen

- MIP Com Nanoparticulas de Ouro Na Determinação de ValganciclovirDokument44 SeitenMIP Com Nanoparticulas de Ouro Na Determinação de ValganciclovirLeticia Caroline CesárioNoch keine Bewertungen

- Optimization of Light Source Wavelength For Ammonia Detection in WaterDokument7 SeitenOptimization of Light Source Wavelength For Ammonia Detection in WaterTELKOMNIKANoch keine Bewertungen

- Preparation of Pvdf-Based Electrospun Membranes and Their Application As SeparatorsDokument5 SeitenPreparation of Pvdf-Based Electrospun Membranes and Their Application As SeparatorsRana Sabouni TabariNoch keine Bewertungen

- Nanostructured Electrodes Improve The Fill FactorDokument7 SeitenNanostructured Electrodes Improve The Fill FactoralexNoch keine Bewertungen

- Hymns For Next WeektDokument2 SeitenHymns For Next Weektjunep42Noch keine Bewertungen

- Start of The Year PacketDokument12 SeitenStart of The Year Packetjunep42Noch keine Bewertungen

- Global SocietiesOnline Syllabus Fall 2017Dokument5 SeitenGlobal SocietiesOnline Syllabus Fall 2017junep42Noch keine Bewertungen

- Eng122 Course SyllabusDokument6 SeitenEng122 Course Syllabusjunep42Noch keine Bewertungen

- Start of The Year Packet 2017-18 FINALDokument12 SeitenStart of The Year Packet 2017-18 FINALjunep42Noch keine Bewertungen

- Biology 102 Syllabus Summer 2017-CvGDokument12 SeitenBiology 102 Syllabus Summer 2017-CvGjunep42Noch keine Bewertungen

- Fall EventsDokument2 SeitenFall Eventsjunep42Noch keine Bewertungen

- Lively&Jokela EerDokument8 SeitenLively&Jokela Eerjunep42Noch keine Bewertungen

- KH - Keyboard Harmony ExercisesDokument51 SeitenKH - Keyboard Harmony Exercisesjunep42100% (4)

- Sluggish Data 11 4Dokument5 SeitenSluggish Data 11 4junep42Noch keine Bewertungen

- Tgas 1961Dokument283 SeitenTgas 1961junep42Noch keine Bewertungen

- Shafer@udel - Edu: The Assessment PageDokument6 SeitenShafer@udel - Edu: The Assessment Pagejunep42Noch keine Bewertungen

- 420-530 PDF PDFDokument7 Seiten420-530 PDF PDFjunep42Noch keine Bewertungen

- SOAR Snail FolioDokument8 SeitenSOAR Snail Foliojunep42Noch keine Bewertungen

- Topology Control Problems Under Symmetric and Asymmetric Power ThresholdsDokument12 SeitenTopology Control Problems Under Symmetric and Asymmetric Power Thresholdsjunep42Noch keine Bewertungen

- Is The Export-Lead Growth Hypothesis Valid For Canada?: Titus AwokuseDokument25 SeitenIs The Export-Lead Growth Hypothesis Valid For Canada?: Titus Awokusejunep42Noch keine Bewertungen

- The Nanokernel: David L. Mills University of Delaware and Poul-Henning Kamp Freebsd ProjectDokument8 SeitenThe Nanokernel: David L. Mills University of Delaware and Poul-Henning Kamp Freebsd Projectjunep42Noch keine Bewertungen

- Nomination Deadlines For Officer Elections in Fall 2015: What's InsideDokument50 SeitenNomination Deadlines For Officer Elections in Fall 2015: What's Insidejunep42Noch keine Bewertungen

- Enzymes Lab ReportDokument11 SeitenEnzymes Lab ReportAra Alibasa75% (4)

- New List of GLP Approved LabsDokument15 SeitenNew List of GLP Approved LabsMulayam Singh YadavNoch keine Bewertungen

- Routine and Special Core AnalysisDokument33 SeitenRoutine and Special Core AnalysisInfinix UserNoch keine Bewertungen

- Sgs Port Klang Ann Joo Integrated Steel 03653-03731 (79samples)Dokument8 SeitenSgs Port Klang Ann Joo Integrated Steel 03653-03731 (79samples)Jasni JalaludinNoch keine Bewertungen

- Amol Raj PDFDokument10 SeitenAmol Raj PDFGaurav SinghNoch keine Bewertungen

- ವಿಜ್ಞಾನ ಪ್ರಯೋಗಾಲಯ ಉಪಕರಣಗಳುDokument4 Seitenವಿಜ್ಞಾನ ಪ್ರಯೋಗಾಲಯ ಉಪಕರಣಗಳುghshmkadiwalinamNoch keine Bewertungen

- Advantages and Disadvantages of Hydraulic SystemsDokument3 SeitenAdvantages and Disadvantages of Hydraulic SystemsTina MilovanovićNoch keine Bewertungen

- 2-7-Totally Gel-Free Fiber Optical Cables Manufactured With PBTDokument6 Seiten2-7-Totally Gel-Free Fiber Optical Cables Manufactured With PBTDursunNoch keine Bewertungen

- 175 023400Dokument2 Seiten175 023400Abu Anas M.SalaheldinNoch keine Bewertungen

- DSC Products With CodesDokument6 SeitenDSC Products With CodesmelvinkuriNoch keine Bewertungen

- Wolfson Eup3 Ch15 Test BankDokument16 SeitenWolfson Eup3 Ch15 Test Bankifghelpdesk100% (1)

- Poro Die Casting MethologyDokument3 SeitenPoro Die Casting Methologypurushothaman1234566Noch keine Bewertungen

- Bigdye Terminator V3.1 Cycle Sequencing Kit: User GuideDokument50 SeitenBigdye Terminator V3.1 Cycle Sequencing Kit: User GuidePham ThanhTungNoch keine Bewertungen

- Tablas TermodinámicasDokument5 SeitenTablas TermodinámicasSarahí CabreraNoch keine Bewertungen

- Laboratory Worksheet: Pre-Lab QuestionsDokument2 SeitenLaboratory Worksheet: Pre-Lab QuestionsKelee DeWittNoch keine Bewertungen

- Forensic Assignment Muhammad Asghar Roll No. 2357Dokument5 SeitenForensic Assignment Muhammad Asghar Roll No. 2357Faisal AwanNoch keine Bewertungen

- MSM Unit 4Dokument10 SeitenMSM Unit 4YAZI 77Noch keine Bewertungen

- 010 - Permit To Work Procedure Feb 2013Dokument61 Seiten010 - Permit To Work Procedure Feb 2013vdeviv100% (1)

- 1267497350933Dokument18 Seiten1267497350933anon_166797875Noch keine Bewertungen

- Insoluble Ions EssayDokument2 SeitenInsoluble Ions EssayDarshan Meghji100% (1)

- Ecomax Front Loading DishwashersDokument4 SeitenEcomax Front Loading Dishwashersrichard9982Noch keine Bewertungen

- Welding Metallurgy - Unit 12 - WEEK 11 PDFDokument3 SeitenWelding Metallurgy - Unit 12 - WEEK 11 PDFDilipNoch keine Bewertungen

- Effects of Zinc and Linoleic Acid Supplementation On The Skin and Coat Quality of Dogs Receiving A Complete and Balanced Diet (PagesDokument8 SeitenEffects of Zinc and Linoleic Acid Supplementation On The Skin and Coat Quality of Dogs Receiving A Complete and Balanced Diet (PagesjenNoch keine Bewertungen

- NMDTM PhosphoricAcidDokument10 SeitenNMDTM PhosphoricAcidacas35Noch keine Bewertungen

- Done By: Neha Jain Priya Upadhyay Saanchi AroraDokument13 SeitenDone By: Neha Jain Priya Upadhyay Saanchi AroraPriya UpadhyayNoch keine Bewertungen

- Chapter 20 Exercise Short QuestionsDokument2 SeitenChapter 20 Exercise Short Questionssaifullah629Noch keine Bewertungen

- Operation Manual - IDU - FXFQ-PVEDokument5 SeitenOperation Manual - IDU - FXFQ-PVEJM ArcillaNoch keine Bewertungen

- 715 1Dokument155 Seiten715 1Aniculaesi MirceaNoch keine Bewertungen

- BT Crops - Review PaperDokument12 SeitenBT Crops - Review Paperrajiv pathakNoch keine Bewertungen

- Water VapourDokument11 SeitenWater VapourivanmjwNoch keine Bewertungen

- A Brief History of Time: From the Big Bang to Black HolesVon EverandA Brief History of Time: From the Big Bang to Black HolesBewertung: 4 von 5 Sternen4/5 (2193)

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseVon EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseBewertung: 3.5 von 5 Sternen3.5/5 (69)

- The Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionVon EverandThe Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionBewertung: 4 von 5 Sternen4/5 (812)

- A Beginner's Guide to Constructing the Universe: The Mathematical Archetypes of Nature, Art, and ScienceVon EverandA Beginner's Guide to Constructing the Universe: The Mathematical Archetypes of Nature, Art, and ScienceBewertung: 4 von 5 Sternen4/5 (51)

- Alex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessVon EverandAlex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessNoch keine Bewertungen

- The Lives of Bees: The Untold Story of the Honey Bee in the WildVon EverandThe Lives of Bees: The Untold Story of the Honey Bee in the WildBewertung: 4.5 von 5 Sternen4.5/5 (44)

- The Rise and Fall of the Dinosaurs: A New History of a Lost WorldVon EverandThe Rise and Fall of the Dinosaurs: A New History of a Lost WorldBewertung: 4 von 5 Sternen4/5 (596)

- Giza: The Tesla Connection: Acoustical Science and the Harvesting of Clean EnergyVon EverandGiza: The Tesla Connection: Acoustical Science and the Harvesting of Clean EnergyNoch keine Bewertungen

- Summary and Interpretation of Reality TransurfingVon EverandSummary and Interpretation of Reality TransurfingBewertung: 5 von 5 Sternen5/5 (5)

- Knocking on Heaven's Door: How Physics and Scientific Thinking Illuminate the Universe and the Modern WorldVon EverandKnocking on Heaven's Door: How Physics and Scientific Thinking Illuminate the Universe and the Modern WorldBewertung: 3.5 von 5 Sternen3.5/5 (64)

- Lost in Math: How Beauty Leads Physics AstrayVon EverandLost in Math: How Beauty Leads Physics AstrayBewertung: 4.5 von 5 Sternen4.5/5 (125)

- The Best American Science And Nature Writing 2021Von EverandThe Best American Science And Nature Writing 2021Bewertung: 4 von 5 Sternen4/5 (8)

- Fire Season: Field Notes from a Wilderness LookoutVon EverandFire Season: Field Notes from a Wilderness LookoutBewertung: 4 von 5 Sternen4/5 (142)

- When You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsVon EverandWhen You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsBewertung: 3.5 von 5 Sternen3.5/5 (13)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingVon EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingBewertung: 5 von 5 Sternen5/5 (5)

- The Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorVon EverandThe Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorBewertung: 4.5 von 5 Sternen4.5/5 (137)

- Spoiled Rotten America: Outrages of Everyday LifeVon EverandSpoiled Rotten America: Outrages of Everyday LifeBewertung: 3 von 5 Sternen3/5 (19)

- The Other End of the Leash: Why We Do What We Do Around DogsVon EverandThe Other End of the Leash: Why We Do What We Do Around DogsBewertung: 5 von 5 Sternen5/5 (65)

- Come Back, Como: Winning the Heart of a Reluctant DogVon EverandCome Back, Como: Winning the Heart of a Reluctant DogBewertung: 3.5 von 5 Sternen3.5/5 (10)

- Quantum Spirituality: Science, Gnostic Mysticism, and Connecting with Source ConsciousnessVon EverandQuantum Spirituality: Science, Gnostic Mysticism, and Connecting with Source ConsciousnessBewertung: 4 von 5 Sternen4/5 (6)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingVon EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingBewertung: 3.5 von 5 Sternen3.5/5 (35)