Beruflich Dokumente

Kultur Dokumente

03-TA-07 Rev-B

Hochgeladen von

WawanCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

03-TA-07 Rev-B

Hochgeladen von

WawanCopyright:

Verfügbare Formate

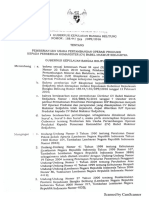

UPGRADING UNIT PRODUKSI PELUMAS JAKARTA

PROCESS LOAD SHEET FOR

ADDITIVE TANK

03-TA-07

DOC. NO.

DS-03-018-128

CLIENT

PT. PERTAMINA (Persero)

PROJECT TITLE

UPGRADING UNIT PRODUKSI PELUMAS JAKARTA PROJECT

LOCATION

TANJUNG PRIOK - JAKARTA

CONTRACT NO.

LATER

JOB. NO

2F1002

11-Mar-11

REV

DATE

Issued for Information

DESCRIPTION

SM/NK

AM/IRJ

IRJ

Prep'd

Check'd

Appr'd

By

Date

Client Approval

PROCESS - DATASHEET

ADDITIVE TANK

REV

B

ENGINEERING PROCUREMENT

CONSTRUCTION

DESCRIPTION

BY

CHK'D

SM/NK AM/IRJ

Issued for Information

APP'D

DATE

IRJ

11-Mar-11

UUPPJ PROJECT

1

2

3

4

5

TAG NUMBER

SERVICE

NUMBER

P&ID

DOCUMENT NO

:

:

:

:

:

03-TA-07

ADDITIVE TANK

1 (ONE) UNIT

DS-03-018-128

OPERATING

PROCESS DESIGN

N3

7

8

9

Pressure

Temperature

ATM

Full of Liquid

37 oC

47 oC

N4

N5

MW 2

N 11

N6

10

11

12

13

Materials

Corrosion allow

Carbon Steel

Fluid

Viscosity

Specific Gravity

Vapor Pressure

Additive A20

2400 cSt @ 40oC

0.971 @ 15.6 oC

Insulation

Lining

Working Capacity

Nominal Capacity

Dimension (ID X H)

Addition :

- Flame Arrestor

- Breather Valve

Yes (Full)

N/A

575

m3

644

m3

8.21

m x

N7

14

15

16

17

18

19

MW1

20

22

23

24

25

26

27

28

29

N9

N1

21

N10

N8

12.17

N2

No

Yes

30

31

32

Vessel Heating

Suction Heater c/w Hot Insulation

LIQUID LEVEL

NOZZLE DATA

33

Level (mm)

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

LLLL

LLL

HLL

500

550

11365

Notes :

1. Inlet nozzle size based on 400 m3/h (max. loading arm capacity)

Ref

Nb

MW1

MW2

N1

N2

N3

N4

N5

N6

N7

N8

N9

N10

N11

1

1

1

1

1

1

1

1

1

1

1

1

1

inch

24

24

10 (*1)

2

2

2

4 B

2

2

6

2

2

3

Rating-Facing

Service

150# - RF

150# - RF

150# - RF

150# - RF

150# - RF

150# - RF

150# - RF

150# - RF

150# - RF

150# - RF

150# - RF

150# - RF

150# - RF

Man Hole

Man Hole

Liquid Inlet

Manual Drain

Level Transmitter

Level Switch

Vent

Overflow

Temperature Transmitter

Liquid Outlet

Steam Coil Inlet

Steam Coil Outlet

Return Line

ATTACHMENT

1.

Basis of Calculation

2.

Calculation Sheet

3.

Nozzle Calculation

4.

Venting Calculation

UPGRADING UNIT PRODUKSI PELUMAS JAKARTA

BASIS OF CALCULATION - ADDITIVE TANK

CLIENT

Page

PT. PERTAMINA (Persero)

LOCATION

TANJUNG PRIOK - JAKARTA

PROJECT

UPGRADING UNIT PRODUKSI PELUMAS JAKARTA PROJECT

PROJECT NO.

2F1002

DOC. NO.

DS-03-018-128

Prp.

Chk.

Apr.

Date

SM/NK

AM/IRJ

IRJ

11-Mar-11

BASIS OF CALCULATION - ADDITIVE TANK

2

3

4

5

Objective

To size the Additive Tank

6

7

Basis

1. Density of Additive

2. Additive Filling rate capacity

970

kg/m3

=

400

m3/hr

(Max. Marine Loading Arm transfer rate capacity)

10

11

Assumption

12

1. Additive supply

25

13

2. Estimated holding time is

23.0

m3/hr

hr

14

15

Calculations

16

1. Size of the Additive Tank

17

Required working volume

575.0

m3

18

Margin 0%

575.0

m3

19

20

The Working Volume of the Additive Tank Provided

575

m3

21

Tank Volume / Capacity

644

m3

22

23

24

25

26

27

28

29

30

31

32

of

Rev.

UPGRADING UNIT PRODUKSI PELUMAS JAKARTA

ADDITIVE TANK - CALCULATION

CLIENT

PT. PERTAMINA (Persero)

LOCATION

TANJUNG PRIOK - JAKARTA

PROJECT

UPGRADING UNIT PRODUKSI PELUMAS JAKARTA PROJECT

PROJECT NO.

2F1002

DOC. NO.

DS-03-018-128

Page

of

Rev.

Prp.

Chk.

Apr.

Date

SM/NK

AM/IRJ

IRJ

11-Mar-11

Calculations

2

3

4

H.L.L

h3

h3 =

vapor space

h2 =

height of working volume

6

7

8

h2

12170 mm

L.L.L

10

11

h1c

12

h1

13

h1 =

h1b

h1a

14

bottom to L.L.L space

Outlet nozzle

15

8210 mm

16

17

1.

h1 (Bottom to L.L.L space) calculation

(defined as per API 650)

6 in. NPS

18

Outlet nozzle diameter

19

h1a

200 mm

(From Table 3.6 API 650)

20

h1b

76.2 mm

( = 0.5 * Nozzle OD)

21

h1c

152.4 mm

428.6 mm

h1

22

( = 1 * Nozzle OD)

Take

h1

500 mm

23

24

2.

h2 (Height of working volume) calculation

Est. working volume

575.0 m3

27

H/D Ratio

1.385

28

Diameter

8210 mm

29

Height

25

Take

26

11367 mm

3.

h3 (vapor space)

800 mm

32

33

Final Dimension

34

Diameter

35

Height

36

H/D check

37

Total Capacity

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

8210 mm

h2

10867 mm

Calc. working vol.

575.29 m3

OK !

30

31

1.324

8210 mm

12170 mm

1.48

644.3 m3

UPGRADING UNIT PRODUKSI PELUMAS JAKARTA

Page 3

ADDITIVE TANK - NOZZLE AND LIQUID LEVEL CALCULATION

CLIENT

LOCATION

PROJECT

PROJECT NO.

DOC. NO.

PT. PERTAMINA (Persero)

TANJUNG PRIOK - JAKARTA

UPGRADING UNIT PRODUKSI PELUMAS JAKARTA PROJECT

REV

BY

SM/NK

2F1002

DS-03-018-128

CHECK

AM/IRJ

APPR.

IRJ

Liquid Inlet

of

DATE

11-Mar-11

Liquid Outlet

Mass Flow =

Density =

Act Vol. Flow =

388,000 kg/hr

Mass Flow =

970.0 kg/m3

400.00 m3/hr

24,250 kg/hr

970.0 kg/m3

25.00 m3/hr

27.50 m3/hr

Density =

Actual Vol. Flow =

Design Pump Flow =

Design For One Tank:

Holding Time =

Liquid Volume =

LLLL =

(LLLL~HLL)/D =

23.0 hours

575.0 m3

0.500 m

Tank Diameter =

8.21 m

LLLL~HLL =

10.865 m

Vapour space Height =

6.86 %

0.80 m

Tank Height =

12.17 m

Tank Volume =

H/D =

644 m3

1.48

LLL Calculation

working vol. : 575 m3

HLL

0.80

1.324

10.87

dL (in)

12.17

LLL

0.05 m

LLLL

h1c

0.50

h1b

h1a (mm) =

200

h1b (mm) =

76.2

h1c (mm) =

152.4

h1

428.6

(mm) =

Take LLLL(mm)

500

dL

h1a

LLLL~LLL Calc

8.21

#REF!

in

Hold time (min)

Liquid Inlet Nozzle diameter :

dF =

10 in

ID =

AF =

vF =

vF =

FvF2 =

Take (mm)

10.039

0.0511 m2

2.1756 m/s

4591.4116 kg/m.s2

FvF2 =

Liquid Outlet Nozzle diameter :

dF =

6 in

ID =

AF =

LLLL~LLL (mm)

OK!

6.063

0.0186 m2

0.4101 m/s

163.1434 kg/m.s2

OK!

5

43.30

50

UPGRADING UNIT PRODUKSI PELUMAS JAKARTA

ADDITIVE TANK 03-TA-07 - VENT SIZE CALCULATION

CLIENT

PT. PERTAMINA (Persero)

LOCATION

TANJUNG PRIOK - JAKARTA

Page

PROJECT

UPGRADING UNIT PRODUKSI PELUMAS JAKARTA PROJECT

PROJECT NO.

2F1002

DOC. NO.

DS-03-018-128

of

Rev.

Prep.

Chk.

Apr.

Date

SM/NK

AM/IRJ

IRJ

11-Mar-11

Vent Nozzle Size Calculation (Based on API 2000)

1

2

Tank Capacity (Nominal)

644

m3

Liquid flash point

200

Liquid normal boiling point

Wetted surface area

100

293.18

3

4

m2

8

9

1.

Inbreathing

10

11

Q1 (Maximum Movement Out of Tank)

5.6

SCFH of Air

per

CFH of Liquid Outflow

12

(per section 4.3.2.1.1)

0.94

Nm3/hr of Air

per

m3/hr of Liquid Outflow

13

Outflow

14

Air inlet

(Table A.1 of API-2000 Ed 2009)

27.5 m3/hr

25.9 Nm3/hr

15

16

Q2 (Thermal Inbreathing)

17

(per section 4.3.2.1.2)

3836 Nm3/hr

108.6 Nm3/hr

(Interpolation Table A.3 of API-2000 ed. 2009)

18

Total Vacuum Relief Required (Q)

19

20

21

Q1

25.9 Nm3/hr

134.5 Nm3/hr

Q2

108.6 Nm3/hr

22

23

24

2.

Outbreathing - Pressure Relief

25

26

Q1 (Maximum Movement IntoTank)

SCFH of Air

per

CFH of Liquid Outflow

27

(per section 4.3.2.1.1)

1.01

Nm3/hr of Air

per

m3/hr of Liquid Outflow

28

Inflow

29

Air outlet

(Table A.1 of API-2000 Ed 2009)

400.0 m3/hr

404.0 Nm3/hr

30

31

Q2 (Thermal Outbreathing)

32

(per section 4.3.2.1.2)

2300 ft3/hr

65.2 Nm3/hr

(Interpolation Table A.3 of API-2000 ed. 2009)

33

Total Vacuum Relief Required (Q)

34

35

36

Q1

404.0 Nm3/hr

469.2 Nm3/hr

Q2

65.2 Nm3/hr

37

38

39

3.

Take the largest from (1) and (2) :

40

469.2

262.7

41

Maximum velocity at nozzle

42

Pipe size

Nm3/hr

Am3/hr

10.0 m/s

Q x4

0.8 x x 3600

43

44

45

96

mm

46

3.7961

in

in

47

48

49

50

51

Take pipe size

(minimum 2 in)

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Tank Blanketing BasicsDokument47 SeitenTank Blanketing BasicsHamdan Sidek100% (2)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Drilling Hydraulics ADokument63 SeitenDrilling Hydraulics Asryn89100% (3)

- Lecture-08 - Properties of Reservoir Fluid LiquidsDokument70 SeitenLecture-08 - Properties of Reservoir Fluid LiquidsJoy Prokash RoyNoch keine Bewertungen

- Separators: Advantages DisadvantagesDokument46 SeitenSeparators: Advantages DisadvantagesMahmoud Ahmed Ali Abdelrazik100% (1)

- Urea Production Flow DiagramDokument8 SeitenUrea Production Flow DiagramAyatNoch keine Bewertungen

- Flare Gas Recovery & Zero Flare SolutionsDokument16 SeitenFlare Gas Recovery & Zero Flare SolutionsEddie TaiNoch keine Bewertungen

- Lyophilization of Parenterals FinalDokument25 SeitenLyophilization of Parenterals FinalMostofa RubalNoch keine Bewertungen

- Intake Sistem 875,000,000: Uraian Pekerjaan Jumlah Harga Total Grand TotalDokument5 SeitenIntake Sistem 875,000,000: Uraian Pekerjaan Jumlah Harga Total Grand TotalWawanNoch keine Bewertungen

- Ohio Brass Surge Arresters PDFDokument48 SeitenOhio Brass Surge Arresters PDFomh129Noch keine Bewertungen

- CNG LPG Supply Scope Summary To Be Filled Up by Vendor (Check List), 220120Dokument4 SeitenCNG LPG Supply Scope Summary To Be Filled Up by Vendor (Check List), 220120WawanNoch keine Bewertungen

- FEMCO Support LetterDokument1 SeiteFEMCO Support LetterWawanNoch keine Bewertungen

- 005 2 Sets ZS Type Load Cell, CC 07 TPMDokument1 Seite005 2 Sets ZS Type Load Cell, CC 07 TPMWawanNoch keine Bewertungen

- MDS For ZA Weigher Feeder (81-WQ-316)Dokument2 SeitenMDS For ZA Weigher Feeder (81-WQ-316)WawanNoch keine Bewertungen

- Po BBM Zarindo BeltimDokument1 SeitePo BBM Zarindo BeltimWawanNoch keine Bewertungen

- Babel 1Dokument1 SeiteBabel 1WawanNoch keine Bewertungen

- MDS For Filler Weigher Feeder (81-WQ-317)Dokument2 SeitenMDS For Filler Weigher Feeder (81-WQ-317)WawanNoch keine Bewertungen

- Magnetic Fluid Seals for Sea MachineryDokument11 SeitenMagnetic Fluid Seals for Sea MachineryWawanNoch keine Bewertungen

- CBU-summary Manday Services-8Dokument1 SeiteCBU-summary Manday Services-8WawanNoch keine Bewertungen

- TB - Kietrans 61, TK - Star Marine 2561Dokument2 SeitenTB - Kietrans 61, TK - Star Marine 2561WawanNoch keine Bewertungen

- Process Load Sheet For: Additive Tank 03-TA-02Dokument7 SeitenProcess Load Sheet For: Additive Tank 03-TA-02WawanNoch keine Bewertungen

- Upgrading Unit Produksi Pelumas Jakarta Project Additive Tank Process DatasheetDokument7 SeitenUpgrading Unit Produksi Pelumas Jakarta Project Additive Tank Process DatasheetWawanNoch keine Bewertungen

- 03-TA-08 Rev-BDokument7 Seiten03-TA-08 Rev-BWawanNoch keine Bewertungen

- 03-TA-03 Rev-ADokument7 Seiten03-TA-03 Rev-AWawanNoch keine Bewertungen

- UPGRADING UNIT PRODUKSI PELUMAS JAKARTA PROCESSDokument7 SeitenUPGRADING UNIT PRODUKSI PELUMAS JAKARTA PROCESSWawanNoch keine Bewertungen

- Process Load Sheet For: Additive Tank 03-TA-01Dokument7 SeitenProcess Load Sheet For: Additive Tank 03-TA-01WawanNoch keine Bewertungen

- UPGRADING UNIT PRODUKSI PELUMAS JAKARTA PROCESSDokument7 SeitenUPGRADING UNIT PRODUKSI PELUMAS JAKARTA PROCESSWawanNoch keine Bewertungen

- Process Load Sheet For: Additive Tank 03-TA-02Dokument7 SeitenProcess Load Sheet For: Additive Tank 03-TA-02WawanNoch keine Bewertungen

- 03-TA-03 Rev-ADokument7 Seiten03-TA-03 Rev-AWawanNoch keine Bewertungen

- UPGRADING UNIT PRODUKSI PELUMAS JAKARTA PROCESSDokument7 SeitenUPGRADING UNIT PRODUKSI PELUMAS JAKARTA PROCESSWawanNoch keine Bewertungen

- 03-TH-06 Rev-ADokument7 Seiten03-TH-06 Rev-AWawanNoch keine Bewertungen

- Process Load Sheet For: Additive Tank 03-TA-01Dokument7 SeitenProcess Load Sheet For: Additive Tank 03-TA-01WawanNoch keine Bewertungen

- 03-TH-11 Rev-ADokument7 Seiten03-TH-11 Rev-AWawanNoch keine Bewertungen

- UPGRADING UNIT PRODUKSI PELUMAS JAKARTA PROCESSDokument7 SeitenUPGRADING UNIT PRODUKSI PELUMAS JAKARTA PROCESSWawanNoch keine Bewertungen

- UPGRADING UNIT PRODUKSI PELUMAS JAKARTA PROCESSDokument7 SeitenUPGRADING UNIT PRODUKSI PELUMAS JAKARTA PROCESSWawanNoch keine Bewertungen

- Process Load Sheet For: Abb Swing Holding Tank 03-TH-05Dokument7 SeitenProcess Load Sheet For: Abb Swing Holding Tank 03-TH-05WawanNoch keine Bewertungen

- UPGRADING UNIT PRODUKSI PELUMAS JAKARTA PROCESSDokument7 SeitenUPGRADING UNIT PRODUKSI PELUMAS JAKARTA PROCESSWawanNoch keine Bewertungen

- Chapter 4 Bonding Ionic-Metalli and GeometryDokument106 SeitenChapter 4 Bonding Ionic-Metalli and GeometryPaula IscarNoch keine Bewertungen

- Equipo1 Surface-Sampling-Bench Data-Sheet en WebDokument2 SeitenEquipo1 Surface-Sampling-Bench Data-Sheet en WebEladio Daniel Aquino ChanNoch keine Bewertungen

- Emulsification of Heavy Crude Oil in Water For Pipeline Transportation PDFDokument7 SeitenEmulsification of Heavy Crude Oil in Water For Pipeline Transportation PDFJesus AlbertoNoch keine Bewertungen

- VLE MeOH/H2O 1 atm xy dataDokument1 SeiteVLE MeOH/H2O 1 atm xy dataAjay TulpuleNoch keine Bewertungen

- Stage Separation of Gas-CondensateDokument2 SeitenStage Separation of Gas-CondensateRifka AisyahNoch keine Bewertungen

- Crystal BondingDokument12 SeitenCrystal BondingSuyogNoch keine Bewertungen

- Chapter 3 - Conservation of EnergyDokument79 SeitenChapter 3 - Conservation of EnergyBananaliksNoch keine Bewertungen

- WinOpi RefMan Ed5 303028ENDokument2 SeitenWinOpi RefMan Ed5 303028ENAndrei TaranuNoch keine Bewertungen

- Projet Proposal For The Construction of A Marcet BoilerDokument5 SeitenProjet Proposal For The Construction of A Marcet BoilerOjiSofttouchCharlesNoch keine Bewertungen

- Distillation Column EfficienciesDokument32 SeitenDistillation Column EfficienciesJesus GarcíaNoch keine Bewertungen

- PHY4221 (2020) Assignment 2Dokument2 SeitenPHY4221 (2020) Assignment 2MainzaNoch keine Bewertungen

- Vapor Pressure Lowering Solutions ExplainedDokument10 SeitenVapor Pressure Lowering Solutions ExplainedMelvin CabonegroNoch keine Bewertungen

- Experiment No-4: Mass Transfer Lab IIT KGPDokument5 SeitenExperiment No-4: Mass Transfer Lab IIT KGPSiddharth MohapatraNoch keine Bewertungen

- C-MIBK rev8.hsc distillation simulationDokument11 SeitenC-MIBK rev8.hsc distillation simulationAsh YehiaNoch keine Bewertungen

- Anderol 555Dokument1 SeiteAnderol 555rewindingidsNoch keine Bewertungen

- Reservoir Engineering Exercise Set 1Dokument9 SeitenReservoir Engineering Exercise Set 1Mohammad HaqNoch keine Bewertungen

- Melting and Boiling Point DeterminationDokument5 SeitenMelting and Boiling Point DeterminationVanessa ValdezNoch keine Bewertungen

- Hysys Oil ManagerDokument43 SeitenHysys Oil ManagerKarim Kholeif50% (2)

- VLE Calculations for Distillation DesignDokument4 SeitenVLE Calculations for Distillation Designsandeep lal0% (1)

- Fatih Bilingual School EdunavDokument2 SeitenFatih Bilingual School EdunavZian hafisNoch keine Bewertungen

- General Chemistry 1 Atomic Structure and Electron ConfigurationDokument44 SeitenGeneral Chemistry 1 Atomic Structure and Electron ConfigurationMaria AnnaNoch keine Bewertungen

- Gas Absorption Lab ReportDokument12 SeitenGas Absorption Lab ReportGracylla RoseNoch keine Bewertungen

- PME 112 Laboratory Manual (2023)Dokument11 SeitenPME 112 Laboratory Manual (2023)Abu SayeedNoch keine Bewertungen