Beruflich Dokumente

Kultur Dokumente

Ms 1210 Part 11991 Specification For Fire Hydrant Systems Equipment Part 1 Landing Valves For Wet Risers-710265

Hochgeladen von

aaaaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ms 1210 Part 11991 Specification For Fire Hydrant Systems Equipment Part 1 Landing Valves For Wet Risers-710265

Hochgeladen von

aaaaCopyright:

Verfügbare Formate

MALAYSIAN

STANDARD

MS 1210: PART 1:1991

SPECIFICATION FOR FIRE HYDRANT

SYSTEMS EQUIPMENT PART 1: LANDING

VALVES FOR WET RISERS

ICS: 13.220.20

Descriptors: fire hydrant, systems equipment, wet risers

Copyright 1991

DEPARTMENT OF STANDARDS MALAYSIA

DEVELOPMENT OF MALAYSIAN STANDARDS

The Department of Standards Malaysia (STANDARDS MALAYSIA) is the national

standards and accreditation body of Malaysia.

The main function of STANDARDS MALAYSIA is to foster and promote standards,

standardisation and accreditation as a means of advancing the national economy,

promoting industrial efficiency and development, benefiting the health and safety of

the public, protecting the consumers, facilitating domestic and international trade and

furthering international cooperation in relation to standards and standardisation.

Malaysian Standards (MS) are developed through consensus by committees which

comprise balanced representation of producers, users, consumers and others with

relevant interests, as may be appropriate to the subject at hand. To the greatest

extent possible, Malaysian Standards are aligned to or are adoption of international

standards. Approval of a standard as a Malaysian Standard is governed by the

Standards of Malaysia Act 1996 [Act 549]. Malaysian Standards are reviewed

periodically. The use of Malaysian Standards is voluntary except in so far as they are

made mandatory by regulatory authorities by means of regulations, local by-laws or

any other similar ways.

STANDARDS MALAYSIA has appointed SIRIM Berhad as the agent to develop,

distribute and sell the Malaysian Standards.

For further information on Malaysian Standards, please contact:

Department of Standards Malaysia

OR

Ministry of Science, Technology and Innovation

Level 1 & 2, Block 2300, Century Square

Jalan Usahawan

63000 Cyberjaya

Selangor Darul Ehsan

MALAYSIA

SIRIM Berhad

(Company No. 367474 - V)

1, Persiaran Dato Menteri

Section 2, P.O. Box 7035

40700 Shah Alam

Selangor Darul Ehsan

MALAYSIA

Tel: 60 3 8318 0002

Fax: 60 3 8319 3131

http://www.standardsmalaysia.gov.my

Tel: 60 3 5544 6000

Fax: 60 3 5510 8095

http://www.sirim.my

E-mail: central@standardsmalaysia.gov.my

E-mail: msonline@sirim.my

MS 1210 : Part 1: 1991

This Malaysian Standard, which had been approved by the Mechanical

Engineering Industry

Standards Committee and endorsed by the Council of the Standards and Industrial Research

Institute of Malaysia (SIRIM) was published under the authority of the SIRIM Council in

February, 1991.

SIRIM wishes to draw attention to the fact that this Malaysian Standard does not purport to

include all the necessary provisions of a contract.

The Malaysian

Standards are subject to periodical review to keep abreast of progress in the

industries concerned. Suggestions for improvements will be recorded and in due course brought

to the notice of the Committees charged with the revision of the standards to which they refer.

The following references relate to the work on this standard:

Committee reference : SIRIM 406/2/6-2

Draft for comment : D159 (JSC F)

Amendments issued since publication

Amd. No.

Date of issue

Text affected

MS 1210 : Part 1: 1991

CONTENTS

Page

Committee representation

Foreword

SECTION ONE: GENERAL

1

Scope

Definitions

Valve types

Classification by pressure rating

Nominal inlet sizes

Temperature rating

Marking

SECTION TWO: DESIGN

8

Materials

Valve bodies

10

Valve inlets

11

Valve outlets

10

12

Bonnets

10

13

Stems

10

14

Stem sealing on globe valves

13

15

Glands on globe valves

13

16

Disks and disk facings

13

17

Handwheels and operation

13

18

Bolting

13

19

Pressure retention

14

20

Strap

14

21

Blank cap and chain

14

22

Water flow rate and outlet pressure

14

23

Outlet pressure at restricted flow (high pressure valves only)

15

24

Resistance to high temperature (diaphragm valves only)

15

MS 1210 : Part 1: 1991

CONTENTS (Contd.)

Page

SECTION THREE: PRODUCTION TESTING REQUIREMENTS

AND TEST CERTIFICATE

25

1-lydrostatic tests

16

26

Pressure control test (high pressure valves only)

16

27

Test certificate

16

Figure 1

Valve types

Choice of materials for components and parts

11

Bolting for valves

13

Body test pressures and durations

17

Seat test pressures and durations

18

Test methods

17

Recommendations for the information to be supplied by the

purchaser to the manufacturer

21

Tables

Appendices

Publications

22

MS 1210 : Part 1: 1991

Committee representation

The Mechanical Engineering Industry Standards Committee under whose supervision this Malaysian Standard was prepared,

comprises representatives from the following Government Ministries, trade, commerce and manufacturer associations and

scientific and professional bodies.

Malaysian Motor Vehicle Assemblers Association

Ministry of Works and Utilities (Public Works Department)

Ministry of Manpower (Factory and Machinery Department)

Malaysian Industrial Development Authority (MIDA)

Universiti Teknologi Malaysia

Institution of Engineers(Malaysia)

Ministry of Defence (Defence Science and Technology Centre)

The Technical Committee on Fire Prevention and Protection comprising which prepared this Malaysian Standard consists of

the following representatives:

Encik M. Chelliah (Chairman)

Kapt. Kamaruddin Abu Hassan

Jr. Dr. Ow Chee Sheng

BOMBA

Kementerian Pertahanan

JEM

Encik Anthony Dibble/Encik Lim Chia Fook

Encik Loh Aik Eng

Jr. Thin Choon Chai

Encik P. Sivakumaran

Jr. Ahmad Fauzi Hassan

Encik Khalid Hassan (Secretary)

Persatuan Insuran Am Malaysia

PAM

MFPA

Persatuan Keselamatan Perindustrian Malaysia (MSI5)

.IKJ

Standards and Industrial Research Institute of Malaysia

The Technical Sub-Committee on Equipment for Fire Prevention and Protection which prepared this Malaysian Standard

consists of

Encik M. Chelliah (Chairman)

Mejar Akbar Din

Encik Yusof Sidek/Encik Pauzan Ahmad

Cik Patsy Chia

BOMBA

Kementerian Pertahanan

BOMBA

MSIS

Jr. Wong See Foong

Encik Mustafah Jamaludin (Secretary)

JEM

Standards and Industrial Research Institute of Malaysia

Co-opted members

Encik William Kong

Encik Michael Toh

Encik Allen Wong/

Encik Desmond De Rozaria

Encik Y.S. Ong

Encik T.W. Chow

Encik L.K. Ong

Encik Mat Khajr Salbin

Kolling Eng. Sdn. Bhd.

Nelton Eng. Sdn. Bhd.

Lianyeu Mfg. Sdn. Bhd.

S.R.I. Sdn. Bhd.

Eversafe Sdn. Bhd.

MFPA

Standards and Industrial Research Institute of Malaysia

MS 1210 : Part 1: 1991

FOREWORD

This Malaysian Standard was prepared by the Technical Sub-committee on Equipment for Fire

Prevention and Protection formed by the Technical Committee on Fire Prevention and Protection

under the authority of the Mechanical Engineering Industry Standards Committee.

This standard was based on BS 5041 : Part I : 1987 Fire hydrant systems equipment, Specification

for landing valves for wet risers, which specifies requirements for valves suitable for use on wet

risers of either high or low pressure installations.

The subjects of the other Parts in the MS 1210 series of general specifications for fire hydrant

systems equipment are as follows.

Part 2.

Part 3.

Part 4.

Part 5.

Landing valves for dry risers

Inlet breechings for dry riser inlets

Boxes for landing valves for dry risers

Boxes for foam inlets and dry riser inlets

These Parts give detailed requirements for most of the other special items required for wet and

dry risers described in *BS 5306 : Part 1.

The Malaysian Standard version under preparation,

i.e. MS 566 : Part _________

MS 1210 : Part 1: 1991

FIRE HYDRANT SYSTEMS EQUIPMENT

PART 1: LANDING VALVES FOR WET RISERS

SECTION ONE: GENERAL

1.

SCOPE

This Part of MS 1210 specifies requirements for copper alloy globe valves generally complying

with BS 5154 and diaphragm valves generally complying with BS 5156, both suitable for

installation as landing valves on wet risers. The valves have screwed or flanged inlets and also

delivery hose connections complying with *Bs 336. This standard covers valves of nominal

pressure (PN) designations 1500 kPa and 2000 kPa and nominal inlet sizes DN 40 to DN 65 for

flanged ends and 1 1/2 and 2 1/2 for screwed ends.

NOTE 1. Information which the purchaser is recommended to supply to the manufacturer is given in appendix B and does

not form part of the specification.

NOTE 2. The titles of the publications referred to in this standard are listed in appendix C.

2.

DEFINITIONS

For the purposes of this Malaysian Standard, the following definitions apply.

2.1

Wet riser (wet rising main). A vertical pipe installed in a building for fire fighting

purposes, permanently charged with water from a pressurized supply, and fitted with valves and

outlet connections at specified points.

2.2

riser.

Landing valve. An assembly comprising a valve and outlet connection from a wet or dry

3.

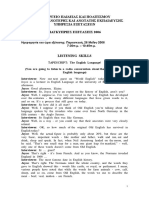

VALVE TYPES

Valves, whether globe or diaphragm, shall be of the horizontal, bibnosed, oblique or rightangle

type, the general forms being illustrated in fig. 1.

4.

CLASSIFICATION BY PRESSURE RATING

4.1

General. Valves shall be classified as low pressure or high pressure according to the

nominal inlet working pressure for which they are suitable.

4.2

Low pressure valves.

pressures up to 1500 kPa.

*

Low pressure valves shall be suitable for use at nominal inlet

Malaysian Standard version under preparation.

MS 1210 : Part 1: 1991

4.3

High pressure valves.

pressures up to 2000 kPa.

High pressure valves shall be suitable for use at nominal inlet

5.

NOMINAL INLET SIZES

5.1

Flanged end valves. The nominal inlet size (DN) shall be 40, 50 or 65.

5.2

Screwed end valves. The nominal inlet size (DN) shall be 1, 2 or 2.

6.

TEMPERATURE RATING

Both low pressure and high pressure valves shall be suitable for continuous use at their nominal

pressure rating throughout the temperature range from 10C to 38C.

7.

MARKING

7.1

General. Each valve shall be marked with the following:

(a) the letters LP (for low pressure valves) or HP (for high pressure valves) in a position which

will be visible after the valve has been installed;

(b) the nominal size;

(c) the manufacturers name or trademark;

(d) the number of this standard, i.e. MS 1210 : Part 1.

7.2

Diaphragm valves. The diaphragm shall be marked FIRE HYDRANT, FIRE HYD or

with the manufacturers grade reference for the particular material. The marking shall be visible

on the assembled valve.

NOTE. When required by the local authority, it shall incorporate the preferred language(s).

MS 1210 : Part 1: 1991

Figure 1. Valves types

MS 1210 : Part 1: 1991

SECTION TWO: DESIGN

8.

MATERIALS

Each component or part of the valve shall be made from one of the materials given in table I or

other materials of equivalent properties.

9.

VALVE BODIES

9.1

Body wall thickness. The body wall thickness at any point shall be as follows.

(a) For low pressure valves: not less than shown in table 6 of BS 5154 : 1983 for PN 16 for the

appropriate size of valve.

(b) For high pressure valves: not less than shown in table 6 of BS 5154 :1983 for PN 20 for the

appropriate size of valve.

9.2

Body seat. The body seat shall be either integral with the body or inserted in the form of

a securely fitted but renewable ring. The shape of the seating surface shall be suited to the type

of disk used (see clause 16).

9.3

Seating face. The seating face shall be not less than 3 mm wide.

10.

VALVE INLETS

10.1

Gciieral. Valve inlets shall be either flanged (see 10.2) or screwed (see 10.3).

10.2

Flanged ends

10.2.1 Inlet flanges shall be in accordance with the following tables in BS 4504 : Part 2 : 1974,

with the possible exception of drilling (see 10.2.2):

(a) for low pressure valves: table 16/21 for the appropriate size of valve;

(b) for high pressure valves: table 25/21 for the appropriate size of valve.

The casting surrounding the bolt holes on the flange shall be case smooth and level or machined

or spot faced to ensure satisfactory bolting.

Holes shall be equally spaced on the pitch circle diameter and shall be drilled off centres.

If a flange is fitted with an 0 ring seal then the seal shall comply with BS 1806 or BS 4518.

10.2.2 If the purchaser does not specify drilling requirements for the flanges, they shall be

drilled in accordance with table 16/21 (low pressure valves) or table 25/21 (high pressure valves)

of BS 4504: Part 2 :1974.

MS 1210 : Part 1: 1991

10.3

Screwed ends

10.3.1 Body ends shall be hexagonal or of shape suitable for a hook or C spanner to facilitate

tightening.

10.3.2 Screwed ends shall have male or female threads complying with BS 21.

10.3.3 The thickness of male ends shall be not less than 3 mm from the root diameter of the

thread to the bore of the inlets.

11.

VALVE OUTLETS

Outlet end connections shall be either integral or screwed on,

and shall be of female

instantaneous pattern complying with *BS 336.

12.

BONNETS

12.1

Diaphragm valves. The bonnet to body connection shall be bolted.

12.2

Globe valves. The bonnet to body connection shall be screwed or union or bolted. The

surfaces forming the bonnet and body joint shall be machined. The joint may be metal to metal,

or made with a gasket or 0 ring of non-shrinking material and complying with BS 1806 or BS

4518.

12.3

Bonnet wall thickness. The bonnet wall thickness at any point shall be as follows:

(a) for low pressure valves: not less than shown in table 6 of BS 5154 : 1983 for PN 16 for the

appropriate size of valve;

(b) for high pressure valves: not less than shown in table 6 of BS 5154 : 1983 for PN 20 for the

appropriate size of valve.

13.

STEMS

13.1

General. Valves shall be of the rising stem inside screw type, having the actuating thread

within the bonnet or otherwise protected from damage and the external environment. They shall

be formed in one piece, and shall be of sufficient length to ensure a minimum clearance of 40

mm between the handwheel and any part of the valve vertically below the periphery of the

handwheel, and between the handwheel and the plunger release lug on the outlet.

~BS 336, Specification for fire hose couplings and ancillary equipment.

10

MS 1210 : Part 1: 1991

Table 1. Choice of materials for components and parts

Component

Material

British Standard

number

Grade or

designation

Low pressure and high pressure valves

Body

Copper alloy

1400

LG2 or LG4

Bonnet

Copper alloy

1400

2872

2874

LG2 or LG4

CZ1I4 or CZ122

Stem

Copper alloy

2874

Disk

Copper alloy

1400

2872 or 2874

LG2 or LG4

CZ1 14 or CZI22

Handwheel

Copper alloy

1400

2872

LG2 or LG4

CZll4orCZl22

Malleable cast

iron

Grey cast iron

Spheroidal

graphite cast iron

Aluminium alloy*

6681

1452

2789

1490

CZll2, CZll3,

CZ1I4 or CZI2I

150 or 180

LM6 or LM25

Renewable

disk facing

Rubber

Chioroprene

1154

2752

70 IRHD minimum

nominal hardness

Diaphragm

Rubber

Manufacturers standard

Blank cap

Copper alloy

1400

2872

LG2 or LG4

CZ1I4orCZ122

Aluminium

alloy*

1490

LM5 condition M

LM6 condition M

LM16 condition TF

LM25 condition TB or TF

Carbon steel**,

tensile

strength not

less 390 N/mm2

Aluminium

bronze

1506

162

2872

CA 104

Bolting:

globe valves

diaphragm

valves

*The surface shall have an anodized finish of thickness not less than grade AA15 of BS 1615:1987, and the anodic oxidation

coating shall be sealed (see clause 7 of that standard).

**Free cutting steels shall not be used.

MS 1210 : Part 1: 1991

Table 1. Choice of materials for components and parts (Contd.)

Component

Material

British Standard

number

Grade or

designation

Compressor

Grey cast iron

Copper alloy

1452

1400

150

LG2 or LG4

1154

2752

85 IRHD minimum nominal

hardness

Hardness HV 5 to I-IV 12

when measured in

accordance with

BS 427 : Part I

High pressure valves only

Relief valve

seating

Rubber

Chloroprene

Nylon

Relief valve

spring

Copper alloy

Stainless

steel

Pressure

regulating

spring

Chrome vanadium

steel

BS 970:Part 5

735 A50

13.2

Stein sizes. The diameter of the stem shall be not less than 16 mm where the stem is

made from CZII4, or 19 mm where the stem is made from any other copper alloy (see table 1).

The size of any square or drive on the stem shall be not less than 12 mm across flats. Where the

handwheel is attached to the stem using a pin, the minimum cross-sectional dimension at that

point shall be not less than 14.5 mm.

13.3

Threads on stems. The actuating thread shall be either Acme form or V form. The root

diameter of the thread shall be not less than the following:

(a) 16 mm for stems of CZII4;

(b) 19mm for stems of CZII2, CZI13 or CZI2I.

13.4

Retention of stein. It shall not be possible for the spindle to pass completely through the

gland nut.

12

MS 1210 : Part 1: 1991

14.

STEM SEALING ON GLOBE VALVES

Globe valves shall be provided with one of the following means of sealing the stems:

(a) an 0 ring complying with BS 1806 or BS 4518; or

(b) a rubber gland seal; or

(c) a stuffing box gland.

It shall be possible to replace the seal or repack the gland when under pressure with the valve

fully closed.

15.

GLANDS ON GLOBE VALVES

Glands globe valves shall be either screwed or bolted Screwed glands shall consist of a gland and

gland nut when used as a stuffing box. Bolted glands shall be either a solid type or a two-piece

selfaligning type.

16.

DISKS AND DISK FACINGS

Disks shall be provided with resilient facings which may be renewable or bonded.

17.

HANDWHEELS AND OPERATION

The valve shall be closed by turning the handwheel in a clockwise direction when facing the

handwheel. The number of complete turns of the handwheel to fully open a completely closed

valve shall be not less than four nor more than 10.

Flandwheels shall be marked with the OPEN and CLOSE direction.

I-Iandwheels shall have a diameter of not less than 100 mm.

18.

BOLTING

Bolting shall be in accordance with one of the standards given in table 2.

Table 2. Bolting for valves

Metric

Inch

BS

BS

BS

BS

BS 1 69

BS 2693:Part I

BS 48~2

3692

4190

4439

4882

13

MS 1210 : Part 1: 1991

19.

PRESSURE RETENTION

19.1

Body test. A valve shall show no sign of leakage or distortion of the body when tested in

accordance with Al.l (see also 25.1).

NOTE. This requirement is for the integrity of the valve body, not the strength of the release mechanism of the valve outlet

connection (see clause 11). *BS 336 requires connectors including the release mechanism to withstand a test pressure of 2250

kPa. The test method in A1.1 is such that the requirements of 19.1 and *BS 336 are not contradictory.

19.2

Seat test. A valve shall show no sign of leakage or distortion of the body when tested in

accordance with A1.2 (see also 25.2).

20.

STRAP

The valve shall be provided with a means for attaching a strap, so that the handwheel can be

secured to counter unauthorized use.

NOTE. If specified by the purchaser the following should also be provided (see **BS 5306

Part 1):

(a) a strap made of leather or reinforced plastics material not less than 12 mm wide or less than 2 mm thick, and with ends

suitable for linking by a padlock;

(b) a small non-ferrous padlock to secure the two ends of the strap.

The provision of a strap is not usually considered necessary where the valve is to be enclosed in a box.

21.

BLANK CAP AND CHAIN

A blank cap complying with *BS 336 shall be provided. The cap shall be provided with a

pressure relief hole having a flow area of not less than 2 mm2.

The blank cap shall be attached to the body by a suitable lug, 5 hook and chain.

22.

WATER FLOW RATE AND OUTLET PRESSURE

NOTE. Manufacturers customarily quote a flow coefficient for valves. The requirements in 22.1 will be met by low pressure

valves with a flow coefficient C (as defined and measured by the method given in BS 5793 : Section 2.1) of not less than 42.

The requirements in 22.2 will b~met by high pressure valves which have a flow coefficient of not less than fully open and

which limit the outlet pressure to not more than 450 ~50 kPa.

22.1

Low pressure valves. Tile water flow rate through the valve shall be not less than 8.5 L/s

and the outlet pressure shall be not less than 400 kPa when the inlet pressure is 470 kPa, when

measured in accordance with A2.

22.2

Fligh pressure valves. The water flow rate through tile valve shall be not less than 8.5 L/s

at an outlet pressure of 450 50 kPa and at inlet pressures from 570 kPa up to an including 2000

kPa, when tested in accordance with A3.

*BS 336, Specification for fire hose couplings and ancillary equipment.

**BS 5306 : Part 1, Code of practice for fire extinguishing installations and equipment on premises. Part 1 Hydrant systems,

hose reels and foam inlets.

14

MS 1210 : Part 1: 1991

23.

OUTLET PRESSURE AT RESTRICTED FLOW (high pressure valves only)

23.1

High pressure valves shall be fitted with a device which, when tile outlet is restricted,

limits the outlet pressure to a value not exceeding 700 kPa, when tested in accordance with A4.l

and A4.2.

23.2

Where the means of pressure limitation is a pressure relief valve, it shall not open at an

outlet pressure of less than 500 kPa when tested in accordance with A4.l and A4.3.

23.3

Where tile means of pressure limitation is a pressure regulating mechanism, any means of

adjustment shall be fitted with a locking/clamping device to maintain the initial setting. The

valve shall comply with all tile operational requirements of this specification without alteration of

tile initial setting (see also clause 26).

24.

RESISTANCE TO HIGH TEMPERATURE (diaphragm valves only)

Diaphragm valves shall not leak at a rate exceeding 23 L/min when tested in accordance with A5.

15

MS 1210 : Part 1 : 1991

SECTION THREE: PRODUCTION TESTING REQUIREMENTS AND TEST CERTIFICATE

25.

HYDROSTATIC TESTS

25.1

Body test. Each valve shall be tested in accordance with A1.i and shall comply with 19.1.

25,2

Seat test. Each valve shall be tested in accordance with A1.2 and shall comply with 10.2.

26.

PRESSURE CONTROL TEST (high pressure valves only)

Each higil pressure valve shall be tested in accordance with A4 and shall comply with clause 23.

27.

TEST CERTIFICATE

The manufacturer shall supply a test certificate to certify that each valves in question have been

tested and have satisfactorily complied with clause 19 (applicable to the type of valve). It shall

also state the medium used in each test.

16

MS 1210 : Part 1: 1991

Appendix A

Test methods

NOTE. Where the tests in Al, A3 and A4 are carried out for type approval purposes, it may be sufficient to carry out each

appropriate test once only.

Warning note. Where hydrostatic pressure testing is required, safety precaution shall be taken.

Al.

PRESSURE RETENTION TEST

(see clauses 19 and 25)

A1.1 Body test.

Blank off the outlet of tile valve. Render any pressure relief valve

inoperative. With the valve in the open or partly open position, connect tile inlet to a hydraulic

pressure test rig. Vent any trapped air. Subject tile valve body to the appropriate hydrostatic test

pressure for the appropriate test duration in accordance with table 3. Apply the test pressure

without significant hydraulic shock. Use no external restraint on tile valve body.

NOTE. The test may be carried out before the connector is fitted to valves with screwed-on connectors. When testing high

pressure valves with integral connectors, or with screwedon connectors fitted, additional means of retaining the outlet

blanking the outlet blanking piece may be used to prevent distortion of the release mechanism. When testing low pressure

valves with the connector fitted additional means may not be used to retain the outlet blank: only the release mechanism

may be used.

Table 3. Body test pressures and durations

Valve type

Minimum hydrostatic test pressure

Test duration

kPa

mm

Low pressure

2250

High pressure

3000

A1,2 Seat test. Render any pressure relief valve inoperative. Connect the inlet to a hydrostatic

pressure test rig. Vent any trapped air. With the outlet open to the atmosphere and tile valve in

the closed position, subject tile valve to the appropriate hydrostatic test pressure and appropriate

test duration in accordance with table 4. Apply the test pressure without significant hydraulic

shock.

17

MS 1210 : Part I : 1991

Table 4. Seat test pressures and durations

Valve type

Minimum hydrostatic test pressure

Test duration

kPa

mm

Low pressure

1650

High pressure

2200

FLOW AND PRESSURE DROP TEST (low pressure valves only)

A2.

(see 22.1)

Apparatus. A test rig of pipework of a size appropriate for the landing valve under test

A2.1

and having the following features shall be used:

(a)

pressure measuring devices, accurate to 5 kPa, fitted close to the inlet and outlet of the

valve;

(b) two control valves fitted upstream and downstream of the pressure measuring devices;

(c) a means of supplying water at both a suitable pressure and 8.5 L/s;

(d) a means of measuring the water flow rate through tile rig, accurate to 0.5 L/s.

A2.2 Procedure. Mount the landing valve in tile test rig fully opened. With water flowing

through the rig adjust the control valves to give a flow rate of 8.5 L/s and an iniet pressure at the

landing valve of 470 kPa. If necessary, successively adjust the two control valves: opening the

upstream valve will increase pressure and flow while opening tile downstream valve will decrease

pressure and increase flow. Measure and record the outlet pressure.

A3.

FLOW AND PRESSURE CONTROL (high pressure valves only)

(see 22.2)

A3.1

Apparatus. A test rig in accordance with A2.1 shall be used except that tile water supply

shall be at 2000 kPa and 8.5 L/s.

A3.2

Procedure. Carry out the test as follows.

(a) Mount the landing valve in tile test rig fully opened.

(b) With water flowing through the rig and at an inlet pressure of approximately 750 kPa, adjust

the control valves to give a flow rate of 8.5 0.5 L/s. Measure and record the water flow rate

and inlet and outlet pressures.

18

MS 1210

Part 1: 1991

(c) Open the upstream control valve to increase the inlet pressure to approximately 1250 bar. Do

not adjust the downstream control valve unless tile outlet pressure is outside the limits of 450

50 kPa and the flow rate is outside the limits 8.5 0.5 L/s. In that case adjust only the

downstream valve and by small increments only until tile flow rate of pressure falls within the

limits. Measure and record and flow rate and pressures.

(d) Repeat (c) at inlet pressures of approximately 1750 kPa and 2000

kPa.

10

(e) Close the upstream control valve to give an inlet pressure of approximately 1500 kPa. Adjust

tile downstream control valve only if necessary, as above. Measure and record the flow rate and

inlet pressures.

(f) Repeat (e) at an inlet pressure of 1000 kPa and at as low and inlet pressure as is possible

without tile outlet pressure dropping below 400 kPa.

S

A4.

PRESSURE RELIEF TESTS (high pressure valves only)

(see clauses 23 and 26)

A4.1

Apparatus.

Apparatus in accordance with A2.l with tile means of measuring flow

upstream from tile landing valve shall be used.

Since valves with a pressure regulating device do not release water to relieve tile pressure, a

means of relieving excessive inlet pressure should be fitted when testing this type.

For testing high pressure valves fitted with a pressure relief valve, provision shall be made for

disposal of the water which will be released through tile relief valve.

A4.2 Procedure for verification of compliance with 23.1. Mount tile landing valve in the test

rig fully opened. With water flowing through the rig, adjust the contro valves to give a flow

rate of 8.5 L/s at an inlet pressure of 2000 kPa.

Close the downstream control valve slowly. Observe and record whether the outlet remains below

700 kPa until it is fully closed.

NOTE. It may be necessary to adjust the upstream control valve to control any increase in the inlet pressure.

Repeat the test at inlet pressure of 1000 kPa and 1500 kPa.

A4.3 Procedure for verification of compliance with 23.2 (pressure relief types only). Mount

tile landing valve in the test rig fully opened. With water flowing through the valve, adjust the

control valves to give a water flow rate of 8.6 L/s, or tile maximum possible if this rate cannot be

attained, at an inlet pressure of 500 kPa. Slowly close the downstream control valve. Observe

and record tile outlet pressure at whicil tile pressure relief valve opens.

19

MS 1210 : Part 1 : 1991

AS.

HIGH TEMPERATURE RESISTANCE TEST (diaphragm valves only)

(see clause 24)

A5.1

Apparatus

A5.1.1 Oven or furnace capable of maintaining an air temperature of 540 10C during tile test.

A5.1.2 Suitable pipework for connection to the valve inlet, to provide a water supply at a

pressure equal to tile nominal inlet pressure of 1500 kPa (low pressure valves) or 2000 kPa (high

pressure valves) and for connection to the outlet to dispose of water passing through the valve.

This pipework shall be selfdraining.

A5.2

Procedure. Remove any outlet hose connection and blank cap.

Place the valve in the oven, fill the valve with water and close it. Adjust the water pressure to

the valve equal to the nominal inlet pressure of the valve under test. Heat the oven to 540 10C

and maintain at this temperature for 20 mm. Measure the rate of any water flow from tile valve

outlet at the end of this time.

20

MS 1210 : Part 1: 1991

Appendix B

Recommendations for the information to be supplied by the

purchaser to the mnamiufacturer

It is recommended that tile purchaser provide the following information with his or her order:

(a) tile valve type (see clause 3);

(b) whether a high pressure or low pressure valve is required (see clause 4);

(c) the nominal size (see clause 5);

(d) whether a screwed or flanged valve inlet is required (see clause 10);

(e) if a flanged inlet is required, whether tile flange is to be supplied undrilled (see 10.2.2);

(f) whether a strap and padlock is required (see clause 20).

21

MS 1210 : Part 1: 1991

Publications referred to

BS 21

Specification for pipe threads for tubes and fittings where pressuretight joints are

made on the threads (metric dimensions)

*BS 336

Specification for fire hose couplings and ancillary equipment

BS 427

Method for Vickers hardness test

Part 1. Testing of metals

BS 970

Wrought steels (blooms, billets, bars and forgings)

Part 5. Carbon and alloy spring steels for the manufacture of hot formed springs

BS 1154

Specification for natural rubber compounds

BS 1400

Specification for copper alloy ingots and copper alloy and high conductivity

copper alloy castings

BS 1452

Specification for grey iron castings

BS 1490

Aluminium and aluminium alloy ingots and castings

BS 1506

Specification for carbon, low alloy and stainless steel bars and billets for bolting

material to be used in pressure retaining applications

BS 1615

BS 1769

Method for specifying anodix coatings on aluminium and its alloys

Unified black hexagon bolts, screws and nuts (UNC and UNF threads).

Heavy

series

BS 1806

Dimensions of toroidal sealing rings (0 seals and their housings)

BS 2693

Screwed studs

Part I. General purpose studs (obsolescent)

BS 2752

Specification for chloroprene rubber compounds

BS 2789

Specification for spheroidal graphite or nodular graphite cast iron

BS 2872

Copper and copper alloys. Forging stock and forgings

BS 2874

Specification for copper and copper alloy rods and sections (other than forging

stock)

BS 3692

ISO metric precision hexagon bolts, screws and nuts. Metric units

BS 4190

ISO metric black hexagon bolts, screws and nuts

BS 4439

Screwed studs for general purposes. Metric series

BS 4504

Flanges and bolting for pipes, valves and fittings. Metric series

Part 2. Copper alloy and composite flanges

22

MS 1210

BS 4518

Part 1: 1991

Specification for metric dimensions of toroidal sealing rings (0 rings) and their

housings

BS 4882

Bolting for flanges and pressure containing purposes

BS 5154

Specification for copper alloy globe, globe stop and check, check and gate valves

BS 5156

Specification for diaphragm valves

*B5 5306

Code of practice for fire extinguishing installations and equipment on premises

Part 1. Hydrant systems, hose reels and foam inlets

BS 5793

Industrial-process control valves

Part 2. Flow capacity

Section 2.1 Sizing equations for incompressible fluid flow under installed

conditions

BS 6681

Specification for malleable cast iron

The Malaysian Standard version under preparation,

i.e. MS 566 : Part _________

23

Das könnte Ihnen auch gefallen

- ms1447 2Dokument7 Seitenms1447 2zul ireanaNoch keine Bewertungen

- Malaysian Standard: Fire Detection and Fire Alarm Systems - Part 5: Heat Detectors - Point DetectorsDokument9 SeitenMalaysian Standard: Fire Detection and Fire Alarm Systems - Part 5: Heat Detectors - Point DetectorsmarkNoch keine Bewertungen

- Ms 1210 PT 3 1991 Confirmed 2011 PrepdfDokument6 SeitenMs 1210 PT 3 1991 Confirmed 2011 PrepdfmarkNoch keine Bewertungen

- MS 1525 2007 Prev PDFDokument7 SeitenMS 1525 2007 Prev PDFguy69oiNoch keine Bewertungen

- Fire MS StandardDokument1 SeiteFire MS StandardMichael Tan100% (1)

- MS 1745-Part 14-2009Dokument71 SeitenMS 1745-Part 14-2009Von Jin100% (13)

- Ms 1183 Part 2 1993-Code of Practice For Fire Precautions-730104Dokument92 SeitenMs 1183 Part 2 1993-Code of Practice For Fire Precautions-730104Sivanesan Kupusamy50% (2)

- UBBL Fire Requirements - Law & PracticeDokument53 SeitenUBBL Fire Requirements - Law & PracticeAnonymous eRprq4m91% (11)

- Red Book - Guide-to-Fire-Protection-in-Malaysia-2006 PDFDokument274 SeitenRed Book - Guide-to-Fire-Protection-in-Malaysia-2006 PDFvictor_92100% (1)

- 1745 10 05preDokument10 Seiten1745 10 05premarkNoch keine Bewertungen

- MS1590 - 2003 CO2 Ext Sys DesignDokument59 SeitenMS1590 - 2003 CO2 Ext Sys DesignShaffiq100% (1)

- MS 1183 2015 - PrepdfDokument8 SeitenMS 1183 2015 - PrepdfHisyam Shahril0% (1)

- MS - 1489!1!2012 - F Hose Reel and FoamDokument17 SeitenMS - 1489!1!2012 - F Hose Reel and FoamShaffiqNoch keine Bewertungen

- Smoke Control in Protected Escape Routes Using Pressurisation (MS 1472-1999)Dokument64 SeitenSmoke Control in Protected Escape Routes Using Pressurisation (MS 1472-1999)Alex Chin50% (2)

- General Requirements For DBKL Bomba (English)Dokument3 SeitenGeneral Requirements For DBKL Bomba (English)Andrea WongNoch keine Bewertungen

- UBBL 2012 and MS 1183 For PG 20180526Dokument189 SeitenUBBL 2012 and MS 1183 For PG 20180526Tan Bak PingNoch keine Bewertungen

- Guide To Fire Protection in MsiaDokument260 SeitenGuide To Fire Protection in Msiacookienut85% (13)

- Fire Protection in MalaysiaDokument37 SeitenFire Protection in MalaysiaCastiel Arumugam50% (2)

- Bomba Requirements PDFDokument149 SeitenBomba Requirements PDFEmily Ong75% (12)

- UBBL 1984 As at Feb 2011 (Resized)Dokument189 SeitenUBBL 1984 As at Feb 2011 (Resized)Alex Sia Hong Rui100% (2)

- TechDokument4 SeitenTechcliffordtanNoch keine Bewertungen

- BombaDokument18 SeitenBombasyafikalzahraqi90% (10)

- Bomba SubmissionDokument17 SeitenBomba SubmissionDean KayreeNoch keine Bewertungen

- Ubbl 1984Dokument34 SeitenUbbl 1984Yoke Shu100% (1)

- MS 1780 2017 PDokument5 SeitenMS 1780 2017 PMuhammad Rizal Ismail0% (6)

- Smoke Control Practice in MalaysiaDokument5 SeitenSmoke Control Practice in MalaysiaZacharul Shah100% (1)

- Guide To Fire Protection in MalaysiaDokument137 SeitenGuide To Fire Protection in MalaysiaWilliam Ball96% (28)

- Senarai Rujukan Bomba Sijil Rujukan Bahan MS StandardDokument21 SeitenSenarai Rujukan Bomba Sijil Rujukan Bahan MS Standardredisme09Noch keine Bewertungen

- MS 1471 Part 5 - 1999Dokument8 SeitenMS 1471 Part 5 - 1999KHA120096 StudentNoch keine Bewertungen

- Fire Fighting - Intepretation of Passive Fire Requirement Ubbl 1984Dokument63 SeitenFire Fighting - Intepretation of Passive Fire Requirement Ubbl 1984Veron ET100% (1)

- Fire Requirements - UBBLDokument47 SeitenFire Requirements - UBBLchipon3150% (2)

- Building Plan Submission - What Bomba WantsDokument15 SeitenBuilding Plan Submission - What Bomba WantsYoke Shu90% (20)

- Ms 1073 3 1996 Prepdf PDFDokument1 SeiteMs 1073 3 1996 Prepdf PDFMohd ShahidNoch keine Bewertungen

- uBBl 19 Feb 2012Dokument20 SeitenuBBl 19 Feb 2012Kayelvili Krishnamoorthy100% (2)

- MS 982 1985preDokument5 SeitenMS 982 1985preEncik LaLa50% (2)

- Guide To Fire Protection in MalaysiaDokument3 SeitenGuide To Fire Protection in MalaysiaFadilah Ansari0% (2)

- Need Statement Guide JKRDokument89 SeitenNeed Statement Guide JKRKhairuddin Ismail67% (12)

- MS 1539 PT3 2003 Portable Fire Extinguisher PDFDokument31 SeitenMS 1539 PT3 2003 Portable Fire Extinguisher PDFLee GP100% (3)

- Malaysian Standard: Fire Detection and Alarm Systems - Part 1: IntroductionDokument5 SeitenMalaysian Standard: Fire Detection and Alarm Systems - Part 1: IntroductionHamza MukhtarNoch keine Bewertungen

- BOMBA Building RegulationsDokument13 SeitenBOMBA Building RegulationsEmily Ong86% (7)

- Research On Understanding UBBL Schedule 6 by Ar Ridha RazakDokument63 SeitenResearch On Understanding UBBL Schedule 6 by Ar Ridha RazakRidha Razak80% (5)

- Buku UBBL 21Dokument232 SeitenBuku UBBL 21ismail ibrahim100% (1)

- Panduan Teknik Mekanikal ACDokument77 SeitenPanduan Teknik Mekanikal ACahmad harith100% (2)

- JKR-Internal Water Line & Sanitary SystemDokument49 SeitenJKR-Internal Water Line & Sanitary Systemfaizal aziz91% (11)

- BCM 503 Building Services Engineering IDokument34 SeitenBCM 503 Building Services Engineering IMohd Azmil Mohd Rohani88% (16)

- JKR Mech DRWG PDFDokument117 SeitenJKR Mech DRWG PDFFelix Semion100% (1)

- 6.fire Safety Systems SlidesDokument147 Seiten6.fire Safety Systems SlidesHan Jian Goh100% (2)

- Malaysian Standard: Portable Fire Extinguishers - Part 5: Fire Extinguisher For Use On Class F FiresDokument5 SeitenMalaysian Standard: Portable Fire Extinguishers - Part 5: Fire Extinguisher For Use On Class F Fireskellyt111979100% (1)

- By Law Ubbl MalaysiaDokument224 SeitenBy Law Ubbl MalaysiaLaney Low100% (2)

- 11M013R0 PCDokument29 Seiten11M013R0 PCdaveleyconsNoch keine Bewertungen

- 34 Samss 117Dokument9 Seiten34 Samss 117naruto256Noch keine Bewertungen

- Sans 347.2010Dokument47 SeitenSans 347.2010madodandembe100% (1)

- 34 Samss 515Dokument13 Seiten34 Samss 515naruto256Noch keine Bewertungen

- Flow Measurement Criteria - PIPDokument16 SeitenFlow Measurement Criteria - PIPKarthik ChockkalingamNoch keine Bewertungen

- STD 153Dokument15 SeitenSTD 153Shriram AvasarkarNoch keine Bewertungen

- Ms 30 Part 8 1995 Prepdf Confirmed 2011Dokument6 SeitenMs 30 Part 8 1995 Prepdf Confirmed 2011Munirah HassanNoch keine Bewertungen

- ASTM B117: SD-11 Closeout Submittals Energy Efficient Equipment For Motors Reduce Volatile Organic Compounds (VOC)Dokument5 SeitenASTM B117: SD-11 Closeout Submittals Energy Efficient Equipment For Motors Reduce Volatile Organic Compounds (VOC)JamesNoch keine Bewertungen

- Preview Only: Malaysian StandardDokument4 SeitenPreview Only: Malaysian StandardSyamim kerrrNoch keine Bewertungen

- Nzqa 31141Dokument4 SeitenNzqa 31141Hitesh ShahNoch keine Bewertungen

- Dental Compressed Air and Vacuum Systems: Health Technical Memorandum 2022 Supplement 1Dokument44 SeitenDental Compressed Air and Vacuum Systems: Health Technical Memorandum 2022 Supplement 1احمد الجزار2007Noch keine Bewertungen

- MR SunilDokument5 SeitenMR SunilaaaaNoch keine Bewertungen

- 26 5 2006 English Listening KeyDokument1 Seite26 5 2006 English Listening KeyaaaaNoch keine Bewertungen

- New Microsoft PowerPoint PresentationDokument1 SeiteNew Microsoft PowerPoint PresentationaaaaNoch keine Bewertungen

- 26 5 2006 English Listening KeyDokument1 Seite26 5 2006 English Listening KeyaaaaNoch keine Bewertungen

- Test 5g54hDokument1 SeiteTest 5g54haaaaNoch keine Bewertungen

- 26 5 2006 English Listening KeyDokument1 Seite26 5 2006 English Listening KeyaaaaNoch keine Bewertungen

- Max Life-TermsAndConditions CommonDokument6 SeitenMax Life-TermsAndConditions CommonaaaaNoch keine Bewertungen

- Literature Review of Information Technology Adoption Models at Firm LevelDokument12 SeitenLiterature Review of Information Technology Adoption Models at Firm LevelMegat Shariffudin Zulkifli, DrNoch keine Bewertungen

- HttpsDokument1 SeiteHttpsaaaaNoch keine Bewertungen

- Time Taken To Sort 100,000 Data: GraphsDokument1 SeiteTime Taken To Sort 100,000 Data: GraphsaaaaNoch keine Bewertungen

- Adoption 2Dokument13 SeitenAdoption 2thao nhiNoch keine Bewertungen

- Imagine Tab by John LennonDokument4 SeitenImagine Tab by John LennonaaaaNoch keine Bewertungen

- Basic Intro To ModelsDokument4 SeitenBasic Intro To ModelsaaaaNoch keine Bewertungen

- Strength and Safety Verification of Piping System Exposed To VibrationsDokument4 SeitenStrength and Safety Verification of Piping System Exposed To VibrationsaaaaNoch keine Bewertungen

- Utility Scale 1 MW Solar Power Generation-LibreDokument34 SeitenUtility Scale 1 MW Solar Power Generation-LibreSandy6050% (1)

- Psa 5 Product OverviewDokument26 SeitenPsa 5 Product OverviewAlfonso José García LagunaNoch keine Bewertungen

- BS1710 BS4800+colours 1Dokument1 SeiteBS1710 BS4800+colours 1ozkanumurhan100% (3)

- BP Chart For AdultsDokument2 SeitenBP Chart For AdultssultanudNoch keine Bewertungen

- Autopipe New User Tips 9aDokument51 SeitenAutopipe New User Tips 9aLuisRiosQNoch keine Bewertungen

- Class 1 FatigueDokument11 SeitenClass 1 FatiguecohenfuNoch keine Bewertungen

- 26 5 2006 English KeyDokument2 Seiten26 5 2006 English KeyaaaaNoch keine Bewertungen

- Design by Analysis Versus Design by Formula of A PWR Reactor Pressure VesselDokument5 SeitenDesign by Analysis Versus Design by Formula of A PWR Reactor Pressure VesselaaaaNoch keine Bewertungen

- Wish You Were Here (Fingerstyle) Tab by Pink Floyd - Songsterr Tabs With RhythmDokument5 SeitenWish You Were Here (Fingerstyle) Tab by Pink Floyd - Songsterr Tabs With RhythmaaaaNoch keine Bewertungen

- Risk Based Inspection ApplicationDokument12 SeitenRisk Based Inspection Applicationelvis hidalgoNoch keine Bewertungen

- Performance of Solar Power PlantsDokument43 SeitenPerformance of Solar Power PlantsSanju DevNoch keine Bewertungen

- 26 5 2006 English ListeningDokument4 Seiten26 5 2006 English ListeningaaaaNoch keine Bewertungen

- Everybody Wants To Rule The World TabDokument11 SeitenEverybody Wants To Rule The World TabaaaaNoch keine Bewertungen

- Accessing PromptDokument1 SeiteAccessing PromptaaaaNoch keine Bewertungen

- IGive Information FlyerDokument2 SeitenIGive Information FlyeraaaaNoch keine Bewertungen

- Attachment 4 - BLS Information For Clinical Staff 2016Dokument1 SeiteAttachment 4 - BLS Information For Clinical Staff 2016aaaaNoch keine Bewertungen

- Mechanical Power FormulaDokument9 SeitenMechanical Power FormulaEzeBorjesNoch keine Bewertungen

- Rubber DamDokument78 SeitenRubber DamDevanshi Sharma100% (1)

- Biology Concepts and Applications 9th Edition Starr Solutions ManualDokument9 SeitenBiology Concepts and Applications 9th Edition Starr Solutions Manualscarletwilliamnfz100% (31)

- Anin, Cris Adrian U. Experiment Water Flirtation ELECTIVE 103Dokument2 SeitenAnin, Cris Adrian U. Experiment Water Flirtation ELECTIVE 103Cris Adrian Umadac AninNoch keine Bewertungen

- The Morning Calm Korea Weekly - August 22,2008Dokument24 SeitenThe Morning Calm Korea Weekly - August 22,2008Morning Calm Weekly NewspaperNoch keine Bewertungen

- Asin URL Index URL/keyword DomainDokument30 SeitenAsin URL Index URL/keyword DomainStart AmazonNoch keine Bewertungen

- TMIS07 - Kalam Internship - S7 Tesla MindsDokument3 SeitenTMIS07 - Kalam Internship - S7 Tesla MindsDMJ JonesNoch keine Bewertungen

- Strategy Guide To Twilight Imperium Third EditionDokument74 SeitenStrategy Guide To Twilight Imperium Third Editioninquartata100% (1)

- PTEG Spoken OfficialSampleTest L5 17mar11Dokument8 SeitenPTEG Spoken OfficialSampleTest L5 17mar11Katia LeliakhNoch keine Bewertungen

- Dr. Muhammad Mumtaz: Thesis TitleDokument10 SeitenDr. Muhammad Mumtaz: Thesis TitleDr. Muhammad MumtazNoch keine Bewertungen

- Nodal Mesh AnalysisDokument20 SeitenNodal Mesh Analysisjaspreet964Noch keine Bewertungen

- The Division 2 - Guide To Highest Possible Weapon Damage PvE BuildDokument18 SeitenThe Division 2 - Guide To Highest Possible Weapon Damage PvE BuildJjjjNoch keine Bewertungen

- Where Business Happens Where Happens: SupportDokument19 SeitenWhere Business Happens Where Happens: SupportRahul RamtekkarNoch keine Bewertungen

- Surge Protection Devices GuidesDokument167 SeitenSurge Protection Devices GuidessultanprinceNoch keine Bewertungen

- Mechanical Vibration and Oscillation in Transmission LinesDokument27 SeitenMechanical Vibration and Oscillation in Transmission LinesChhatrapal SinghNoch keine Bewertungen

- Cover Sheet: Online Learning and Teaching (OLT) Conference 2006, Pages Pp. 21-30Dokument12 SeitenCover Sheet: Online Learning and Teaching (OLT) Conference 2006, Pages Pp. 21-30Shri Avinash NarendhranNoch keine Bewertungen

- Practice Problems For Modulus and Logarithm Section-I: FiitjeeDokument8 SeitenPractice Problems For Modulus and Logarithm Section-I: FiitjeePratham SharmaNoch keine Bewertungen

- Role of ACT, S & WHO Guidlines For The Treatment of MalariaDokument34 SeitenRole of ACT, S & WHO Guidlines For The Treatment of MalariasalmanNoch keine Bewertungen

- E10.unit 3 - Getting StartedDokument2 SeitenE10.unit 3 - Getting Started27. Nguyễn Phương LinhNoch keine Bewertungen

- Cavitation in Francis PDFDokument373 SeitenCavitation in Francis PDFAlberto AliagaNoch keine Bewertungen

- Wilson v. Baker Hughes Et. Al.Dokument10 SeitenWilson v. Baker Hughes Et. Al.Patent LitigationNoch keine Bewertungen

- Financial/ Accounting Ratios: Sebi Grade A & Rbi Grade BDokument10 SeitenFinancial/ Accounting Ratios: Sebi Grade A & Rbi Grade Bneevedita tiwariNoch keine Bewertungen

- VISCOLAM202 D20 Acrylic 20 Thickeners 202017Dokument33 SeitenVISCOLAM202 D20 Acrylic 20 Thickeners 202017Oswaldo Manuel Ramirez MarinNoch keine Bewertungen

- User Manual - Wellwash ACDokument99 SeitenUser Manual - Wellwash ACAlexandrNoch keine Bewertungen

- Amplifier Frequency ResponseDokument28 SeitenAmplifier Frequency ResponseBenj MendozaNoch keine Bewertungen

- Digital-To-Analog Converter - Wikipedia, The Free EncyclopediaDokument8 SeitenDigital-To-Analog Converter - Wikipedia, The Free EncyclopediaAnilkumar KubasadNoch keine Bewertungen

- Zoomlion Gulf FZE Introduction: 1.1 ME Service Support 1.2 Construction CasesDokument13 SeitenZoomlion Gulf FZE Introduction: 1.1 ME Service Support 1.2 Construction CasesArk TradingNoch keine Bewertungen

- CP R80.10 Installation and Upgrade GuideDokument246 SeitenCP R80.10 Installation and Upgrade GuideAlejandro OrtìzNoch keine Bewertungen

- Esp 1904 A - 70 TPH o & M ManualDokument50 SeitenEsp 1904 A - 70 TPH o & M Manualpulakjaiswal85Noch keine Bewertungen

- Unknown 31Dokument40 SeitenUnknown 31Tina TinaNoch keine Bewertungen