Beruflich Dokumente

Kultur Dokumente

H09095 - SuperFill Surge Reduction Equip

Hochgeladen von

AQUILES CARRERAOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

H09095 - SuperFill Surge Reduction Equip

Hochgeladen von

AQUILES CARRERACopyright:

Verfügbare Formate

CEMENTING

SuperFill Surge Reduction Equipment

Achieving safe trip velocities by optimizing the balance between operational efficiencies and surge

pressure when tripping casing into the hole.

With new frontiers such as ultra deepwater and slimhole

well designs, downhole pressure management is increasingly

challenged by ever narrowing margins between pore pressure and

fracture gradients. When running and landing casing to depth,

operating outside this safe pressure window, even if just for a

short period of time, has historically led to costly well problems.

These are problems such as fluid loss from a fractured formation,

contamination of the mud either by flow of formation fluids or

excessive formation debris due to sloughing, or even a pressure

kick. Float equipment is imperative for mitigating damaging surge

pressures. Halliburtons SuperFill surge reduction equipment

helps casing to be run in at an optimum speed and stay within the

window between pore pressure and fracture gradient.

Benefits

Complete and compatible surge reduction components

designed for use together that include:

Surge Reduction Float Equipment

SSR Plug Sets

Drill Pipe Diverter Tool

Commander 1000 Top Drive Cementing Heads

Reliable auto fill equipment that cannot be

inadvertently deactivated

Allows increased pipe running speeds

Reduces surge pressures on weak formations

Reduces costly mud losses when running tubular through

tight clearance wellbores

Configuration designs available that allow for

multiple circulations

High LCM fluid systems compatible

PDC drillable

Applications

Conventional cement to surface full-bore casing jobs

Sub sea completions

Running a liner and cementing the wellbore

HAL39937

Running casing in the well at an operationally efficient speed

without damaging the formation due to surge pressure is a

long-standing challenge in the oil and gas industry. The pipe

velocity has to be calculated according to variables such as mud

properties, hole diameter size, and clearance; and unless the

weighted drilling fluids are allowed to flow freely into and up the

casing itself, the casing acts as a piston, pushing the fluids into

weak formations. Hours of rig time can be consumed filling the

casing conventionally or through slow running speeds. However,

running speeds can be optimized while protecting the formation

with Halliburtons SuperFill surge reduction equipment, a reliable

auto-fill system.

CEMENTING

SuperFill Float Collars and Float Shoes

Halliburton offers several SuperFill auto-fill assemblies that allow wellbore fluids to enter the casing as it is being run into the wellbore. The

SuperFill family of products is Halliburtons most versatile pressure deactivated auto-fill system for use in almost any wellbore configuration.

Equipment can be supplied for use with most casing sizes (4-in. and larger), weight, grade or thread in either shoe or collar assemblies.

Double SuperFill valve options are available and are standard in some configurations. The specific configurations available are listed below

with their unique features.

SuperFillTM Type FV (Flapper Valve)

SuperFillTM Type FVB (Flapper Valve; Ball Retained)

Allows multiple circulations without auto

fill deactivation while running casing

Deactivation of auto fill feature occurs with first circulation

Single valve equipment as standard

For applications where neither plugs nor deactivation balls can

be dropped or circulated from the surface

Double valve equipment available in

sizes 7-in. and larger

Retained deactivation ball is carried

in with tool

Two deactivation ball sizes available:

1 3/8-in. and 2 3/8-in. balls

Suitable for use with conventional

SSR plug sets (two plugs)

or VersaFlex liner plug assemblies

Drop ball option available with surface

launch applications or with a bottom plug

displacement option

Available with an NR plug seat

(7-in. through 20-in.) is an

optional feature for surface launch

or sub-service applications

Available in double valve float collar

configuration only

Available in Float Shoes

and Float Collars

HAL39946

Utilizes a compatible full open

guide shoe

HAL39948

HAL39949

Drop ball option compatible with

SSR -II two plug or SSR top plug

assemblies with small deactivation

ball assuming deviation is no greater

than 30 at the SuperFill FV assembly

Suitable for horizontal subsurface release

applications

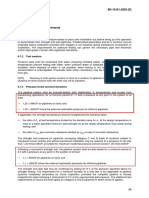

CEMENTING

SuperFillTM Type FVB Plus (Flapper Valve; Ball

Retained: Plus Multiple Circulation Feature)

Reduces surge pressures on weak formations

Allows multiple circulations without auto fill deactivation while

running casing

Reduces formation damage caused by mud losses

Tool cannot be inadvertently deactivated

For applications where neither plugs nor deactivation balls can

be dropped or circulated from the surface

Tool is permanently closed with free fall activation ball

or full bore rupture tube

Retained deactivation ball

with circulation option

The ball drop version can be set up to carry in the ball, on the

ball seat while running in hole, in case of well control issues

Allows circulation while running in hole

without deactivating auto-fill feature

Full bore ID after closure when configured for the full bore

rupture tube

Increasing circulation rate

deactivates auto-fill feature

Torque Ring allows LH and RH Torque up to 80,000 ft/lbs

Circulation rates up to 4 BPM can

be achieved without deactivation

Load rated to 750 US ton at 10,000 psi

Available in 6 5/8 drill pipe configuration.

Circulation rates and time are

determined by wellbore fluid

rheological properties and cumulative

total time of multiple circulations

Other sizes available on request

HAL39947

Retained deactivation ball option

required for conventional SSR plug

sets (two plugs)

Reduces costly mud losses when running tubular

Available with an NR plug seat (7-in. through 20-in.) is an

optional feature for surface launch or sub-service applications

Available in double valve float collar configuration only

Utilizes a compatible full open guide shoe

Used in subsurface applications

Provides flow path from inside the drill pipe to the annulus

outside the drill pipe

Reduces frictional pressure loss

Enables Increased pipe running speeds

HAL39938

The SuperFill diverter is the final component that completes the

surge reduction package available from Halliburton. This tool

enhances the SuperFill float valve systems by relieving additional

pipe running surge pressures caused by frictional pressures inside

the work string. Halliburtons SuperFill diverter is designed to be

run just above the liner or subsea wellhead running tool to provide

a flow path for the wellbore fluids inside the liner to exit the work

string into the annular space around the work string and not up the

smaller restricted diameter of the drill pipe.

HAL39941

SuperFillTM Diverter Tool

a. Allows fluid to exit into annular space between working string

and previous casing while running in.

Ball can be carried in on the seat for quick deactivation in case of well

control issues.

b. Tool closes at approximately 300 psi and provides a 1200-1800 psi

spike when the ball extrudes.

CEMENTING

SuperFillTM Confirmation Sub

Designed to be run in conjunction with the SuperFill

diverter tool

Run in the drill pipe work string, and positioned 1-2 stands

below the diverter tool

Load rated to 750 US ton at 10,000 psi and matches the

performance of the SuperFill diverter tool

Available in 6 5/8-in. drill pipe configuration.

Other sizes available on request

Designed for confirmation that the diverter tool has been closed

Temporarily detains diverter tool activation ball after closing the

diverter sleeve

Allows for second 1200-1800 psi pressure spike to be seen

at surface

Torque Ring allows LH and RH Torque up to 80,000 ft/lbs

HAL39940

Ball is discharged down the drill pipe to be retained in the

liner plug set

HAL39939

Halliburton offers a complete string of compatible surge reduction components designed for use together,

from the CommanderTM 1000 Top-Drive Cementing Head to the Guide Shoe.

For more information on SuperFill Surge Reduction Equipment,

please call you local Halliburton representation or email us at cementing@halliburton.com.

2012 Halliburton. All rights reserved. Sales of Halliburton products and services will be in accord solely with the terms and conditions contained in the contract

between Halliburton and the customer that is applicable to the sale.

H09095 06/14

www.halliburton.com

Das könnte Ihnen auch gefallen

- ElastiCem Resilient Slurry SystemsDokument2 SeitenElastiCem Resilient Slurry Systemsbagus918Noch keine Bewertungen

- Designing Urea ReactorDokument20 SeitenDesigning Urea ReactordcobasbNoch keine Bewertungen

- How To Run and Cement Liners Part 3Dokument4 SeitenHow To Run and Cement Liners Part 3Anwar SaeedNoch keine Bewertungen

- 2 Bridge PlugsDokument9 Seiten2 Bridge PlugsmahsaNoch keine Bewertungen

- Spe 96810 MS PDokument10 SeitenSpe 96810 MS PSlim.BNoch keine Bewertungen

- Fundamentals and Applications of Bionic Drilling FluidsVon EverandFundamentals and Applications of Bionic Drilling FluidsNoch keine Bewertungen

- 001 Refrigeration BasicsDokument24 Seiten001 Refrigeration BasicsRotaru SebastianNoch keine Bewertungen

- YCAB ManDokument44 SeitenYCAB Manttt44967% (3)

- H03729Dokument4 SeitenH03729AQUILES CARRERANoch keine Bewertungen

- 06 Openhole IsolationDokument24 Seiten06 Openhole IsolationMuhammad ShahrukhNoch keine Bewertungen

- Successfully Drills Through Total Losses Zones, Saves 17.6 DaysDokument2 SeitenSuccessfully Drills Through Total Losses Zones, Saves 17.6 DaysAriel Della TorreNoch keine Bewertungen

- SFT 644 Fishing KItDokument13 SeitenSFT 644 Fishing KItgeo840% (1)

- 3-Consideration On Cement PlugsDokument9 Seiten3-Consideration On Cement PlugsAry RachmanNoch keine Bewertungen

- 00087167Dokument11 Seiten00087167JohnSmith100% (1)

- Trackmaster OhcDokument5 SeitenTrackmaster OhcCharles DesmazuresNoch keine Bewertungen

- VAREL RC Comparison Chart Final 2012Dokument2 SeitenVAREL RC Comparison Chart Final 2012Baitaw WanwarangNoch keine Bewertungen

- Top-Co - AutoFill - BV & HF ValvesDokument4 SeitenTop-Co - AutoFill - BV & HF ValvesJuan LacorteNoch keine Bewertungen

- Tubulars and Tubular Services Catalog: DrilcoDokument29 SeitenTubulars and Tubular Services Catalog: DrilcoDoni KurniawanNoch keine Bewertungen

- PolarProp ApplicationDokument4 SeitenPolarProp ApplicationCristian BarbuceanuNoch keine Bewertungen

- Casing Running and Drilling ToolsDokument33 SeitenCasing Running and Drilling Toolsfffggg777Noch keine Bewertungen

- 3 - Arenas Curables y ActivadoresDokument52 Seiten3 - Arenas Curables y ActivadoresPablo SotoNoch keine Bewertungen

- Downhole ProblemsDokument15 SeitenDownhole Problemsnasr yassinNoch keine Bewertungen

- Champ Ion PackerDokument2 SeitenChamp Ion PackerCHO ACHIRI HUMPHREYNoch keine Bewertungen

- Hydraquaker: Hydraulic Drilling Jar Delivers High ImpactDokument4 SeitenHydraquaker: Hydraulic Drilling Jar Delivers High ImpactPavin PiromNoch keine Bewertungen

- Gryphon Product OverviewDokument51 SeitenGryphon Product OverviewTaras ByloNoch keine Bewertungen

- CHAMP® XHP PackerDokument2 SeitenCHAMP® XHP PackerservicemenruNoch keine Bewertungen

- CPST Pressure Setting Tool PDFDokument1 SeiteCPST Pressure Setting Tool PDFmahsaNoch keine Bewertungen

- Whipstock 9.625 Mechanical Running ProceduresDokument16 SeitenWhipstock 9.625 Mechanical Running ProceduresTudor virgil100% (1)

- Maintenance Steps of Mud Gas SeparatorDokument1 SeiteMaintenance Steps of Mud Gas SeparatorNumbWong100% (1)

- Santrol Pocket Guide InternationalDokument2 SeitenSantrol Pocket Guide Internationalintoyou2007Noch keine Bewertungen

- Halliburton: VR Safety JointDokument2 SeitenHalliburton: VR Safety Jointsaeed65Noch keine Bewertungen

- DRILPLEX - Casing MillingDokument5 SeitenDRILPLEX - Casing MillingPablo Martínez BerenguerNoch keine Bewertungen

- Homco Casing Patch: Restoring Casing Integrity With A Permanent Steel SealDokument8 SeitenHomco Casing Patch: Restoring Casing Integrity With A Permanent Steel SealHamed NazariNoch keine Bewertungen

- Davis-FET CatalogDokument19 SeitenDavis-FET CatalogfarajNoch keine Bewertungen

- Introduction To Cementing ClientsDokument59 SeitenIntroduction To Cementing ClientsSlim.BNoch keine Bewertungen

- 03 Tuned CementsDokument8 Seiten03 Tuned Cementshamora33100% (1)

- A1 001 Wireline Unit PTO SwapBody 24ftDokument2 SeitenA1 001 Wireline Unit PTO SwapBody 24ftRio de MarioNoch keine Bewertungen

- 2014 DeepAssurance Cementing - OverviewDokument32 Seiten2014 DeepAssurance Cementing - OverviewAQUILES CARRERANoch keine Bewertungen

- 1PackerSystem PackerAccessories&tools PDFDokument21 Seiten1PackerSystem PackerAccessories&tools PDFAnand aashishNoch keine Bewertungen

- Side Pocket MandrelDokument3 SeitenSide Pocket MandrelSyameer109Noch keine Bewertungen

- Pressure Rating For SSII Float EquipmentDokument2 SeitenPressure Rating For SSII Float EquipmentMahmoud Ahmed Ali AbdelrazikNoch keine Bewertungen

- Davis Lynch Cementing PDFDokument30 SeitenDavis Lynch Cementing PDFWilliam0% (1)

- Janki Oil ToolsDokument55 SeitenJanki Oil ToolsInderjeet HoodaNoch keine Bewertungen

- Drilltech Services (USA) Inc: Spiro-TorqDokument10 SeitenDrilltech Services (USA) Inc: Spiro-TorqDante Cabrera GuzmanNoch keine Bewertungen

- Packer Testing Program Design and Management: August 2013Dokument7 SeitenPacker Testing Program Design and Management: August 2013wily784Noch keine Bewertungen

- Case Hole PDFDokument11 SeitenCase Hole PDFyazidNoch keine Bewertungen

- 2014 TUBING Reference Tables: Listings For Pipe Sizes To 5 - In. OdDokument28 Seiten2014 TUBING Reference Tables: Listings For Pipe Sizes To 5 - In. OdOMSD-01 OPMNoch keine Bewertungen

- Drilling Tools - 1Dokument269 SeitenDrilling Tools - 1berrouiNoch keine Bewertungen

- H00707Dokument2 SeitenH00707AQUILES CARRERANoch keine Bewertungen

- Technical Manual Mecanical Bumper SubDokument6 SeitenTechnical Manual Mecanical Bumper SubYeisson Rubio100% (1)

- RTTS Packer: Technical Data SheetDokument5 SeitenRTTS Packer: Technical Data SheetHamid Reza Babaei100% (1)

- Brochure - NCS Multistage-Unlimited-Pin-point Fracturing - CompressedDokument8 SeitenBrochure - NCS Multistage-Unlimited-Pin-point Fracturing - CompressedNightNoch keine Bewertungen

- 2003 Liner Hangers CatalogDokument104 Seiten2003 Liner Hangers CatalogFABGOILMAN100% (1)

- BHA and Running ProcedureDokument5 SeitenBHA and Running ProcedureRANJITH K PNoch keine Bewertungen

- Armada SamplingDokument2 SeitenArmada SamplingDavid RuizNoch keine Bewertungen

- Peco CatalogDokument152 SeitenPeco CatalogClaudio Israel Godinez SomeraNoch keine Bewertungen

- Hydraulic Whipstock CHDokument1 SeiteHydraulic Whipstock CHAnonymous kEC3kiyNoch keine Bewertungen

- 4 - in and 5-In. Posiset Thru-Tubing Plug (1 - In. Od) : Description FeaturesDokument1 Seite4 - in and 5-In. Posiset Thru-Tubing Plug (1 - In. Od) : Description Featureshamed1725Noch keine Bewertungen

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsVon EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNoch keine Bewertungen

- Measurement While Drilling: Signal Analysis, Optimization and DesignVon EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNoch keine Bewertungen

- FS Valve HalliburtonDokument2 SeitenFS Valve HalliburtonAlexandruAndreiNoch keine Bewertungen

- Rci-01059 Corrosion Inhibitor: ChemicalsDokument1 SeiteRci-01059 Corrosion Inhibitor: ChemicalsAQUILES CARRERANoch keine Bewertungen

- ST FerrotrolDokument2 SeitenST FerrotrolAquiles CarreraNoch keine Bewertungen

- Sim Els74st5Dokument9 SeitenSim Els74st5AQUILES CARRERANoch keine Bewertungen

- Foam Wiper Balls PDFDokument2 SeitenFoam Wiper Balls PDFAQUILES CARRERANoch keine Bewertungen

- RF BJ ProductDokument1 SeiteRF BJ ProductAQUILES CARRERANoch keine Bewertungen

- Five Wiper Pugs Tapered CasingDokument1 SeiteFive Wiper Pugs Tapered CasingAQUILES CARRERANoch keine Bewertungen

- Poly Plug 1Dokument4 SeitenPoly Plug 1AQUILES CARRERANoch keine Bewertungen

- ST EnvirosolDokument2 SeitenST EnvirosolAQUILES CARRERANoch keine Bewertungen

- ST SuperRheoGelDokument2 SeitenST SuperRheoGelAQUILES CARRERANoch keine Bewertungen

- Foam Wiper Balls PDFDokument2 SeitenFoam Wiper Balls PDFAQUILES CARRERANoch keine Bewertungen

- Mud CleanSystemsDokument1 SeiteMud CleanSystemsAQUILES CARRERANoch keine Bewertungen

- CE FlowGuardLDokument1 SeiteCE FlowGuardLAQUILES CARRERANoch keine Bewertungen

- Aqua ConDokument2 SeitenAqua ConAQUILES CARRERANoch keine Bewertungen

- Badger Resieved NormalDokument1 SeiteBadger Resieved NormalAQUILES CARRERANoch keine Bewertungen

- FP 6LDokument1 SeiteFP 6LAQUILES CARRERANoch keine Bewertungen

- Cementing: BJ Services Comp BJ Services Comp BJ Services Comp BJ Services Comp BJ Services Company ANY ANY ANY ANYDokument2 SeitenCementing: BJ Services Comp BJ Services Comp BJ Services Comp BJ Services Comp BJ Services Company ANY ANY ANY ANYAQUILES CARRERANoch keine Bewertungen

- CD 31LDokument2 SeitenCD 31LAQUILES CARRERANoch keine Bewertungen

- Ba 86LDokument2 SeitenBa 86LAQUILES CARRERA100% (1)

- Cementing: BJ Services Comp BJ Services Comp BJ Services Comp BJ Services Comp BJ Services Company ANY ANY ANY ANYDokument1 SeiteCementing: BJ Services Comp BJ Services Comp BJ Services Comp BJ Services Comp BJ Services Company ANY ANY ANY ANYAQUILES CARRERANoch keine Bewertungen

- Ba 58LDokument2 SeitenBa 58LAQUILES CARRERANoch keine Bewertungen

- Ba 56Dokument1 SeiteBa 56AQUILES CARRERANoch keine Bewertungen

- Cementing: Charts Charts Charts Charts ChartsDokument3 SeitenCementing: Charts Charts Charts Charts ChartsAQUILES CARRERANoch keine Bewertungen

- A 3LDokument4 SeitenA 3LAQUILES CARRERANoch keine Bewertungen

- All Area Equipment ListDokument16 SeitenAll Area Equipment ListMOHSIN HASNAINNoch keine Bewertungen

- Mid-Statyes - Carbon Steel Pipe Fitting - Straight TEEDokument2 SeitenMid-Statyes - Carbon Steel Pipe Fitting - Straight TEETamer BannaNoch keine Bewertungen

- 3488Dokument8 Seiten3488Dolly PriyaNoch keine Bewertungen

- A Biokinetic Model For Treatment of DistilleryDokument17 SeitenA Biokinetic Model For Treatment of DistilleryLong ThuậnNoch keine Bewertungen

- Bel-Ray Slide and Cam LubricantDokument2 SeitenBel-Ray Slide and Cam LubricantdhowardjNoch keine Bewertungen

- Progress Tracker-HVAC & BVDokument11 SeitenProgress Tracker-HVAC & BVInfant VelladuraiNoch keine Bewertungen

- Meshless Methods in LS-DYNA: An Overview of EFG and SPHDokument43 SeitenMeshless Methods in LS-DYNA: An Overview of EFG and SPHLe Anh TuanNoch keine Bewertungen

- 1963 - Becker - Mixing and Flow in Ducted Turbulent JetsDokument14 Seiten1963 - Becker - Mixing and Flow in Ducted Turbulent JetslucasphpNoch keine Bewertungen

- NotesDokument179 SeitenNotesz_artist95Noch keine Bewertungen

- Wind Pressure Calculation For 3 Sec Gust Extreme StormDokument5 SeitenWind Pressure Calculation For 3 Sec Gust Extreme StormChinnaraja GandhiNoch keine Bewertungen

- Hydraulic CircuitDokument2 SeitenHydraulic CircuitJohn Louie Mazon100% (1)

- Steam Hydrocarbon Reforming, Hydrogen Reformer, Steam Methane Reformer - Products and Services - SELAS FLUID A Linde Engineering Division MemberDokument1 SeiteSteam Hydrocarbon Reforming, Hydrogen Reformer, Steam Methane Reformer - Products and Services - SELAS FLUID A Linde Engineering Division Membernizam17100% (1)

- Assignment Week 1Dokument4 SeitenAssignment Week 1Radhakrishnan SreerekhaNoch keine Bewertungen

- 14OTC Tech Sess 25106MSDokument12 Seiten14OTC Tech Sess 25106MSamrNoch keine Bewertungen

- Coldspell Manual Rev2Dokument25 SeitenColdspell Manual Rev2ipl200910Noch keine Bewertungen

- Panaflow Meter System: Panametrics Ultrasonic FlowmeterDokument4 SeitenPanaflow Meter System: Panametrics Ultrasonic FlowmeterRuben Dario Mamani ChoqueNoch keine Bewertungen

- Design and Operation of Membrane Bioreactors in EuropeDokument21 SeitenDesign and Operation of Membrane Bioreactors in EuropePremchandrahas SastryNoch keine Bewertungen

- Fluid Properties Assignment QuestionsDokument1 SeiteFluid Properties Assignment Questionsshalom_pkl100% (1)

- BSEN201461 ExtractDokument1 SeiteBSEN201461 ExtractKumudana AdhikariNoch keine Bewertungen

- Journal Bearing LubricationDokument5 SeitenJournal Bearing LubricationYorman Hernandez100% (1)

- Pigging & Water FlushingDokument1 SeitePigging & Water FlushingAlmario SagunNoch keine Bewertungen

- Introduction To Cavitation in Hydraulic MachineryDokument12 SeitenIntroduction To Cavitation in Hydraulic MachineryBen100% (1)

- Nsport Phenomena in Materials Engineering PDF Book - Mediafile Free File SharingDokument3 SeitenNsport Phenomena in Materials Engineering PDF Book - Mediafile Free File SharingSanjeev Sahu0% (1)

- WCFX-E Series 60Hz: Water Cooled Rotary Screw Water Chillers Cooling Capacity: 70 To 990 TR (246 To 3482 KW)Dokument36 SeitenWCFX-E Series 60Hz: Water Cooled Rotary Screw Water Chillers Cooling Capacity: 70 To 990 TR (246 To 3482 KW)Linder Rimac HuillcaNoch keine Bewertungen

- TB8102.8 PGDokument8 SeitenTB8102.8 PGAlberto LazzarettiNoch keine Bewertungen

- Incompressible Flow Over Finite Wings IIIDokument30 SeitenIncompressible Flow Over Finite Wings IIIrevandifitroNoch keine Bewertungen

- CT - Thermodynamics - Module Heat & Thermodynamics - 03012022 - 14. Heat & Thermodynamics ModuleDokument105 SeitenCT - Thermodynamics - Module Heat & Thermodynamics - 03012022 - 14. Heat & Thermodynamics ModuleAnita Akhilesh YadavNoch keine Bewertungen