Beruflich Dokumente

Kultur Dokumente

Design and Experimental Analysis of Composite Grating

Hochgeladen von

IJSTECopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Design and Experimental Analysis of Composite Grating

Hochgeladen von

IJSTECopyright:

Verfügbare Formate

IJSTE - International Journal of Science Technology & Engineering | Volume 3 | Issue 06 | December 2016

ISSN (online): 2349-784X

Design and Experimental Analysis of Composite

Grating

Mr. Akash H. Barhe

PG Student (Design Engineering)

Department of Mechanical Engineering

S.N.D. College of Engineering & Research Center, Yeola

(Nasik), India

Prof. Bhamre V.G.

Head of Dept.

Department of Mechanical Engineering

S.N.D. College of Engineering & Research Center, Yeola

(Nasik), India

Abstract

Steel grating has been the standard industrial foot walk products and has been a popular grating choice for many years. The steel

grating is widely used in refineries on landing and operating platforms. These industries has great interest in a cheaper, but

quality alternative for steel grating since it offers great techno-commercial advantage to them. In this paper the design and

experimental analysis of composite grating is carried out. The numerical design of composite grating is conducted as per IS

guidelines used in industrial practices for grating design. The model prepared for composite grating is evaluated in finite element

analysis. For experimental testing, Composite grating plate is fabricated from hand lay-up process. This grating plate is analyzed

experimentally against predefined load test. Finally the results are discussed to conclude the paper.

Keywords: Grating Platform, Gratings

________________________________________________________________________________________________________

I.

INTRODUCTION

The gratings are widely used in factories, workshops, mining, ports of various platforms, refineries, power plants and

petrochemical industries on landing and operating platforms. Gratings are used at different walkways, access zones in to take live

and/or dead loads depending on application. These industries has great interest in a cheaper, but quality alternative for steel

grating since it offers great techno-commercial advantage to them.

Fig. 1: Typical Grating Platform Made of Carbon Steel

Typically manufactured from mild carbon steel, aluminum and stainless steels, bar gratings are also available in specialty

metal alloys to suit nearly any application. The metallic gratings used in industrial applications are having certain limitations as

listed below.

1) The metallic gratings are made from stainless steel, aluminum, carbon steel which have high density and hence the grating

is heavy. This directly effect on the design of supporting structure and civil foundation of the plant.

2) The carbon steel grating is corrosion prone. Therefore they cannot be used in corrosive atmosphere without galvanizing

treatment.

The introduction of composite gratings will help in designing structural platform with same strength at lesser cost and equal

quality and reliability. Being corrosion resistant, the grating will not require additional galvanizing or painting. This will further

save the cost of project.

II. DESIGN CALCULATIONS

Following sections will provide the design and sizing of composite grating.

All rights reserved by www.ijste.org

163

Design and Experimental Analysis of Composite Grating

(IJSTE/ Volume 3 / Issue 06 / 030)

Loading on Grating Platform

As the composite grating is being designed as an alternative to steel grating, the composite grating shall be suitable to withstand

the equal load which is applicable for carbon steel grating. Therefore imposed loads in this case will remain same as that of steel

grating.

Sr. No.

1

a.

b.

c.

Table 1

IS 875 Parts 2, 1987, Imposed Floor Loads for Different Occupancies

Occupancy Classification

Uniformly Distributed Load (UDL), kN/nm3

Industrial Building

Work area without machinery / equipment

2.5

Work area with machinery / equipment

Light Duty

5.0

Medium Duty

7.0

Heavy Duty

10.0

Boiler rooms and plant rooms

5.0

Concentrated Load, kN

4.5

4.5

4.5

4.5

6.7

Accordingly,

Total imposed load on the grating [10] = = 5.0 = 5000

Total dead load on the grating = = 400

= 5400

Total number of flats in 1m X 1m grating platform is given by,

1000

=

=

40

= 25

Total load taken by single flat is given by,

5400

=

=

25

= 216

Each bearing bar will carry equal load of 216 N. This load will be uniformly distributed on the complete span. The bearing

bars are simply supported on side plates.

Now,

Total length of each flat = Lflat = 1000 mm or 1 m.

Uniform Distributed Load (UDL) on each flat is given by,

216

=

=

1000

= 0.216 /

Design of Grating for Bending Stresses

Maximum bending moment for simply supported beam having uniform load distribution is given by,

2

=

8

Therefore,

2

=

8

0.21610002

=

8

= 27000 .

The material of construction for composite grating is Fibre Reinforced Plastic (FRP). It has ultimate tensile strength in the

range of 480 to 1650 MPa depending upon the properties of parent materials.

Sr. No.

1

2

3

Reinforcing Material

Steel

Glass FRP

Basalt FRP

Table 2

Mechanical Design Properties of FRP

Yield Strength ksi (MPA) Tensile Strength ksi (MPA)

40-75 (276-517)

N/A

N/A

70-230 (480-1,600)

N/A

150-240 (1,035-1,650)

Elastic Modulus ksi (MPA)

29,000 (200)

5,100-7,400 (35-51)

6,500-8,500 (45-59)

Therefore we will take the lowest UTS for glass FRP i.e. 480 MPa to design the grating bearing bars. The maximum allowable

stress in bending is given as below:

= 0.66

= 0.66 480

= 316.8 /2

All rights reserved by www.ijste.org

164

Design and Experimental Analysis of Composite Grating

(IJSTE/ Volume 3 / Issue 06 / 030)

The section modulus of the beam is given by,

27000

=

316.8

= 853

Since the bearing bars for composite grating will be rectangular shaped, it will have section modulus which is given by,

2

=

6

Therefore,

2

0.085 =

6

Here we can select either height or width and then the remaining dimension can be derived. Lets consider the thickness of flat

as 5mm for ease of manufacturing and higher strength.

Therefore,

5 2

0.085 =

6

= 10

Since the height of the bearing bar is derived from the opted thickness, will select 20.0 mm height for bearing bar for

composite grating.

=

Design of Grating for Deflection due to Loading

Maximum deflection for simply supported beam having uniformly distributed load across the span is given by,

4

5

=

384

Where,

w = Uniformly Distributed Load (UDL)on beam, N/mm

l = Total length of beam over which load is distributed, mm

E = Modulus of Elasticity for glass FRP = 35 N/mm2

bh3

IXX = Moment of Inertia, mm4 =

12

Therefore,

bh3

IXX =

12

5203

IXX =

12

IXX = 3334 mm4

Maximum deflection can be obtained as,

0.216 10004

5

max =

3

35 10 3334 384

max = 24 mm

Allowable deflection for any load carrying member is given by,

Lflat

allowable =

400

1000

allowable =

400

allowable = 2.5 mm

Comparing the deflections,

Hence the bearing bar is failing for deflection which is the most commonly observed failures in composites. In order to

overcome this failure, we will increase the flat height to 50mm.

Rechecking the deflection,

5503

=

12

= 52083 4

Maximum deflection can be obtained as,

0.216 10004

5

=

3

384

35 10 52083

All rights reserved by www.ijste.org

165

Design and Experimental Analysis of Composite Grating

(IJSTE/ Volume 3 / Issue 06 / 030)

= 1.54

Comparing the deflections,

Now, the deflection of bearing bar is within the permissible limit under given loading conditions.

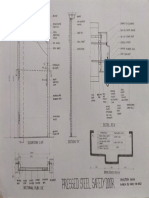

Fig. 2: Composite Grating Drawing

III. FABRICATION OF GRATING

For fabrication of composite grating, combination of fibers and matrix shall be used. Glass fiber reinforcement with Epoxy resin

is used as major constituents. Continuous Fibre Reinforced Plastic (FRP) strings are used as reinforcement. In preparation of

matrix two solution are used namely resin and hardener.

First the sufficiently thin layer of gelcoat is applied on the mould. The FRP strings are arranged in two handles from opposite

ends. Two operators lay down the strings in zig-zag manner overlapping each other inside the square mesh grooves provided on

the mould surface. Matrix is then applied on this reinforcement by hand brush. Then air is removed by pressing the laminate b y

metal plate.

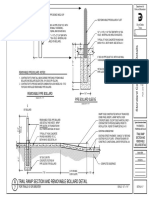

Fig. 3: Mould for Composite Grating

Same process is repeated several times until the desired thickness of grating plate is achieved. After applying matrix the

arrangement is kept to dry at least for next 24 hours as the curing time of this matrix is 24 hrs. After this curing, the grating plate

is removed from mould by manual hammering. The grating plate is then deburred by portable electric operated grinding

machine. The ends of grating plates are trimmed by portable cutting machine to obtain desired outer dimensions.

All rights reserved by www.ijste.org

166

Design and Experimental Analysis of Composite Grating

(IJSTE/ Volume 3 / Issue 06 / 030)

Fig. 4: Measurement of Composite Grating

IV. EXPERIMENTAL VALIDATION AND RESULTS

Composite grating plate is analysed against pre-defined load conditions by using Universal Testing machine.

Experimental Procedure

1)

2)

3)

4)

5)

6)

7)

Arrange grating with help of fixture on the base of machine.

Adjust the actuator on the center of grating with loading plate.

Arrange the strain gauges on both side of grating.

Start the machine & apply the load of 5400 N on center of grating.

Record the reading of load, deflection & stress.

Store the data in computer to generate the graph of load Vs deflection & stress.

Release the load, so that actuator moves in original position.

Sr. No.

1

2

3

4

5

6

7

Table 3

Observation Table for UTM Readings

Description

Min

Max

Flat Thickness, mm

Span Length, mm

Span Width, mm

Grating Area, m2

Applied Load, kN

Shear Stress, kN/m2

192 X 10^3

Deflection, mm

2.5

Set 1

5

1000

1000

1

5.4

538

2.3

Set 2

5

1000

1000

1

5.5

537

2.7

Results from Experimental Analysis

The results obtained in analytical design calculations and experimental testing for composite grating are summarized below.

Sr. No.

1

2

3

Table - 4

Test Results for Composite Grating

Result Description

Analytical Calculations

Total Load Applied on Grating, N

5400

Deflection due to loading, mm

1.54

Induced shear force, kN/m2

432

Experimental Testing

5400

2.3

538

1) The weight of the composite grating for equivalent area and strength is 13.8 kg as compared to 24.5 kg of metallic grating.

This will have a significant impact on the supporting structural design.

2) The composite grating is limited to use for ambient temperature conditions only. Use of grating at elevated temperatures i.e.

above 60 degree has direct impact on the strength of the plates.

3) Since the composite grating is completely made of non-corrosive substances, it is purely corrosion resistance. This gives

advantage over metallic grating which needs galvanizing treatment before using in saline atmosphere.

4) The grating is giving 2.3 mm deflection when loaded with 5400 N. However this deflection is within acceptable limit of 2.5

mm.

5) The flexibility of composite grating absorbs the shock or impact loads which metallic grating cannot absorb and will bend

permanently.

6) FRP Composite is purely non-conductive in nature and hence the grating can be used for electrical machinery platforms

where metallic grating cannot be used for safety reasons.

All rights reserved by www.ijste.org

167

Design and Experimental Analysis of Composite Grating

(IJSTE/ Volume 3 / Issue 06 / 030)

REFERENCES

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

[15]

[16]

[17]

[18]

[19]

[20]

Mr. Kumar D, Mr. Rajendra Boopathy, Mechanical and Thermal Properties of Horn FRP Composites (2014) Global Congress on Manufacturing and

Management, pp-1-12.

Mr. Luke O. Dandy, Mr. Gary A. Leeke, Current Status of Recycling of FRP (2009) Journal of Progress in Material Sciences, pp-1-8.

Mr. Robert Sonnenschein, Miss Katarina Gadjosova, FRP Composites and Their Using in the Construction of Bridges (2016) World Multidisciplinary

Urban Planning Symposium, pp-1-9.

Mr. Hom Nath Dhakal, Mr. Ivan Popov, Comprehensive Study on Machinability of Sustainable and Conventional FRP Composites (2016) Journal of

Engineering Science and Technology, pp-1-10.

Mr. Madhav Morbale, Mr. Vock Rose, A Vessel Circular Platform Details (2015) Journal of UOP Standard Structural Calculations, pp-5-18.

Mr. James B Chang, Mr. Vinay K Goyal, Composite Structures Damage Tolerance Analysis Methodologies (2012), NASA Center for Aero Space

Information, pp-38-40.

Structural Composite Materials, F.C. Campbell, ASM International, Issue 1, pp 10-18.

Design of Machine Elements, V.B. Bhandari, Tata McGraw Hill, Third edition.pp 323-340,566-576,740-757.

PSG Design Data Book, PSG Publications. pp 213-216;250-255;441.

Process Equipment Design, M.V. Joshi, V.V. Mahajani, pp 223-240.

Lab Test Report for FRP grating at Heat Fabs, Bhosari, Pune.

Machine Design, R.S.Khurmi, J.K.Gupta, S.Chand Publication.pp 509-557,1101-1124.

Metal Bar Grating Manual, MBG-531-09, (2009), Issue 7, ANSI, pp-4-17.

Grating Design Guide, PIP STE05530, (2007), pp-2-8

Vessel Circular Platform Details, PIP STF05535, (2005), pp-2-6

Details for Pipe Railing for Walking and Working Surfaces, PIP STF05520, (2003), pp-6-9

Standard Grating Detail Type-I to Type-III, Engineers India Limited, (2001), pp-1-6

Code of Practices for Design Loads for Buildings and Structures, IS 875-2 1987, Bureau of Indian Standards, (1998), pp-11.

General Construction in Steel - Code of Practice, IS 800: 2007, Bureau of Indian Standards, pp-32.

Composite Manufacturing, the Official Magazine of The American Composites Manufacturers Association, (2015), Vol. 31, pp-22.

All rights reserved by www.ijste.org

168

Das könnte Ihnen auch gefallen

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionVon EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNoch keine Bewertungen

- Friction Stir Welding of High Strength 7XXX Aluminum AlloysVon EverandFriction Stir Welding of High Strength 7XXX Aluminum AlloysNoch keine Bewertungen

- Concrete Rock InterfaceDokument7 SeitenConcrete Rock Interfacedyc123Noch keine Bewertungen

- FalseworkManual PDFDokument456 SeitenFalseworkManual PDFRenu UpadhyayNoch keine Bewertungen

- Structural Analysis 1: Statically Determinate StructuresVon EverandStructural Analysis 1: Statically Determinate StructuresNoch keine Bewertungen

- Concrete-Filled Double-Skin Steel Tubular Columns: Behavior and DesignVon EverandConcrete-Filled Double-Skin Steel Tubular Columns: Behavior and DesignNoch keine Bewertungen

- High Density Concrete - Properties For Structural - Shielding - OKDokument13 SeitenHigh Density Concrete - Properties For Structural - Shielding - OKhadianatyaNoch keine Bewertungen

- Investigation of the Chirajara Bridge CollapseVon EverandInvestigation of the Chirajara Bridge CollapseNoch keine Bewertungen

- USDA Forest Service Floating Trail Bridges and DocksDokument31 SeitenUSDA Forest Service Floating Trail Bridges and DocksRockWagonNoch keine Bewertungen

- Concrete Model in AdinaDokument28 SeitenConcrete Model in AdinaAdolfo Gálvez VillacortaNoch keine Bewertungen

- Ferro Final 12052015Dokument550 SeitenFerro Final 12052015Valentina Roncancio GuizaNoch keine Bewertungen

- Economics For Structural Steel Lattice GirdersDokument10 SeitenEconomics For Structural Steel Lattice Girdersthomas kilian100% (2)

- Code For Awning DesignDokument38 SeitenCode For Awning DesignmdeenkNoch keine Bewertungen

- Skid ResistanceDokument7 SeitenSkid Resistanceebinsams007Noch keine Bewertungen

- Seismology: Body Waves and SourcesVon EverandSeismology: Body Waves and SourcesBruce BoltNoch keine Bewertungen

- CIV4235 stm1Dokument58 SeitenCIV4235 stm1benzhuNoch keine Bewertungen

- Design of Piles Under Cyclic Loading: SOLCYP RecommendationsVon EverandDesign of Piles Under Cyclic Loading: SOLCYP RecommendationsAlain PuechNoch keine Bewertungen

- Nonlinear Finite Element Analysis and Adina: Proceedings of the 4th ADINA ConferenceVon EverandNonlinear Finite Element Analysis and Adina: Proceedings of the 4th ADINA ConferenceNoch keine Bewertungen

- Portal Frames With SwayDokument9 SeitenPortal Frames With SwayArun SunnyNoch keine Bewertungen

- Public Ferry Wharf Safety AssessmentDokument85 SeitenPublic Ferry Wharf Safety Assessmentgreg westNoch keine Bewertungen

- Brooklyn Bridge Park Preventative Maintenance Plan ReportDokument77 SeitenBrooklyn Bridge Park Preventative Maintenance Plan ReportcrainsnewyorkNoch keine Bewertungen

- ICE Paper - Nonlinear Finite Element Analysis of ConcreteDokument11 SeitenICE Paper - Nonlinear Finite Element Analysis of ConcreteASHOK SINHA KARANAMNoch keine Bewertungen

- High Density ConcreteDokument15 SeitenHigh Density Concretevolmink100% (2)

- Hitec TMS 40626 PDFDokument30 SeitenHitec TMS 40626 PDFPetrucio José Dos Santos JuniorNoch keine Bewertungen

- Mechanics of Material Interfaces: Proceedings of the Technical Sessions on Mechanics of Material Interfaces Held at the ASCE/ASME Mechanics Conference, Albuquerque, New Mexico, June 23-26, 1985Von EverandMechanics of Material Interfaces: Proceedings of the Technical Sessions on Mechanics of Material Interfaces Held at the ASCE/ASME Mechanics Conference, Albuquerque, New Mexico, June 23-26, 1985Noch keine Bewertungen

- Hot Rolled Structural Brochure 2016Dokument16 SeitenHot Rolled Structural Brochure 2016LNoch keine Bewertungen

- Irc 6 2010Dokument82 SeitenIrc 6 2010suvraNoch keine Bewertungen

- Probabilistic service life model of RC structures subjected to the combined effect of chloride-induced corrosion and cyclic loadingVon EverandProbabilistic service life model of RC structures subjected to the combined effect of chloride-induced corrosion and cyclic loadingNoch keine Bewertungen

- Rebar - Wikipedia, The Free EncyclopediaDokument7 SeitenRebar - Wikipedia, The Free EncyclopediajnmanivannanNoch keine Bewertungen

- Seismic Design of Bridges - Equivalent Cantilever MethodDokument14 SeitenSeismic Design of Bridges - Equivalent Cantilever MethodJosue LewandowskiNoch keine Bewertungen

- AD 293 - Web Panel Zones in Vierendeel Girders (Part 1)Dokument2 SeitenAD 293 - Web Panel Zones in Vierendeel Girders (Part 1)symon ellimacNoch keine Bewertungen

- SP 17M (14) Student PreviewDokument12 SeitenSP 17M (14) Student PreviewPrasanth B0% (1)

- DM Reinforced Earth WallDokument76 SeitenDM Reinforced Earth Wallbkswain2003Noch keine Bewertungen

- Structural Engineering SoftwareDokument2 SeitenStructural Engineering SoftwareYusak Santoso UseNoch keine Bewertungen

- DFJDec2013Vol7No2 FinalDokument88 SeitenDFJDec2013Vol7No2 FinalThaung Myint OoNoch keine Bewertungen

- Prying ActionDokument4 SeitenPrying ActionNguyen Quoc Vu100% (1)

- Wire Rope (Trawl Rope) - Galvanized, Bright, Stainless, IWRC, Fillerwire & RDokument6 SeitenWire Rope (Trawl Rope) - Galvanized, Bright, Stainless, IWRC, Fillerwire & RralishNoch keine Bewertungen

- Sharma Et Al-2017-Structural Concrete As PublishedDokument9 SeitenSharma Et Al-2017-Structural Concrete As PublisheddebiNoch keine Bewertungen

- SDNF File Format PDFDokument48 SeitenSDNF File Format PDFMark OglesbyNoch keine Bewertungen

- Sci P342Dokument111 SeitenSci P342VijayNoch keine Bewertungen

- Earthquake isolation method with variable natural frequencyVon EverandEarthquake isolation method with variable natural frequencyNoch keine Bewertungen

- Vulcanhammer - Info: The Website About Vulcan Iron Works Inc. and The Pile Driving Equipment It ManufacturedDokument152 SeitenVulcanhammer - Info: The Website About Vulcan Iron Works Inc. and The Pile Driving Equipment It ManufacturedSid KhanNoch keine Bewertungen

- Application of FRP Composites For Underwater PilesDokument9 SeitenApplication of FRP Composites For Underwater Pileswendydy6Noch keine Bewertungen

- CSCWorld Tedds Calculations British Standards and Eurocodes 20140826Dokument3 SeitenCSCWorld Tedds Calculations British Standards and Eurocodes 20140826shawnmckenzie840% (1)

- Model Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionVon EverandModel Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNoch keine Bewertungen

- Methodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsVon EverandMethodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsNoch keine Bewertungen

- TSLAB V3.0 User GuidanceDokument68 SeitenTSLAB V3.0 User GuidanceJohn R100% (1)

- Design and Analysis of Magneto Repulsive Wind TurbineDokument7 SeitenDesign and Analysis of Magneto Repulsive Wind TurbineIJSTENoch keine Bewertungen

- Effect of RIB Orientation in Isogrid Structures: Aerospace ApplicationsDokument9 SeitenEffect of RIB Orientation in Isogrid Structures: Aerospace ApplicationsIJSTENoch keine Bewertungen

- Development of Relationship Between Saturation Flow and Capacity of Mid Block Section of Urban Road - A Case Study of Ahmedabad CityDokument6 SeitenDevelopment of Relationship Between Saturation Flow and Capacity of Mid Block Section of Urban Road - A Case Study of Ahmedabad CityIJSTENoch keine Bewertungen

- Partial Replacement of Fine Aggregate With Iron Ore Tailings and Glass PowderDokument7 SeitenPartial Replacement of Fine Aggregate With Iron Ore Tailings and Glass PowderIJSTENoch keine Bewertungen

- A Mixture of Experts Model For ExtubationDokument4 SeitenA Mixture of Experts Model For ExtubationIJSTENoch keine Bewertungen

- An Implementation and Design A Customized Advanced Image Editor Using Image Processing in MatlabDokument5 SeitenAn Implementation and Design A Customized Advanced Image Editor Using Image Processing in MatlabIJSTENoch keine Bewertungen

- Onerider The Bike TaxiDokument3 SeitenOnerider The Bike TaxiIJSTENoch keine Bewertungen

- Technology Advancement For Abled PersonDokument9 SeitenTechnology Advancement For Abled PersonIJSTENoch keine Bewertungen

- Using The Touch-Screen Images For Password-Based Authentication of IlliteratesDokument6 SeitenUsing The Touch-Screen Images For Password-Based Authentication of IlliteratesIJSTENoch keine Bewertungen

- Wireless Information Process and Power Transfer in Single-User OFDM SystemDokument6 SeitenWireless Information Process and Power Transfer in Single-User OFDM SystemIJSTENoch keine Bewertungen

- Privacy Preserving: Slicer Based SchemeDokument3 SeitenPrivacy Preserving: Slicer Based SchemeIJSTENoch keine Bewertungen

- Research On Storage Privacy Via Black Box and Sanitizable SignatureDokument6 SeitenResearch On Storage Privacy Via Black Box and Sanitizable SignatureIJSTENoch keine Bewertungen

- An Implementation of Maximum Power Point Tracking Algorithms For Photovoltaic Systems Using Matlab and Arduino Based RTOS SystemDokument5 SeitenAn Implementation of Maximum Power Point Tracking Algorithms For Photovoltaic Systems Using Matlab and Arduino Based RTOS SystemIJSTENoch keine Bewertungen

- Duplicate Detection Using AlgorithmsDokument3 SeitenDuplicate Detection Using AlgorithmsIJSTENoch keine Bewertungen

- An Implementation of Matlab Based Platform For The Evaluation of Modulation Techniques Using Multiuser MIMO-OFDM For Visible Light Communications Using MatlabDokument5 SeitenAn Implementation of Matlab Based Platform For The Evaluation of Modulation Techniques Using Multiuser MIMO-OFDM For Visible Light Communications Using MatlabIJSTENoch keine Bewertungen

- Study On The Properties of Aerated Concrete Incorporating Fly Ash and Rubber PowderDokument6 SeitenStudy On The Properties of Aerated Concrete Incorporating Fly Ash and Rubber PowderIJSTENoch keine Bewertungen

- Coupled Shear Wall: A ReviewDokument2 SeitenCoupled Shear Wall: A ReviewIJSTE100% (1)

- DSR 2010-11Dokument285 SeitenDSR 2010-11bolsamirNoch keine Bewertungen

- TQM Reporting Group 7 1Dokument42 SeitenTQM Reporting Group 7 1Alvin SantosNoch keine Bewertungen

- Feritic Stainless SteelDokument27 SeitenFeritic Stainless SteelAngga Kurnia Darma SastrodikromoNoch keine Bewertungen

- Technical Information Technical Information: General Information R2 R15Dokument42 SeitenTechnical Information Technical Information: General Information R2 R15safat parNoch keine Bewertungen

- Piping Marking ProcedureDokument14 SeitenPiping Marking ProcedureKelvin ThengNoch keine Bewertungen

- C. Pressure On Silo Walls Due To Stored Material: Primary Load 109: Seismic Load Along +Z Direction (+ezDokument1 SeiteC. Pressure On Silo Walls Due To Stored Material: Primary Load 109: Seismic Load Along +Z Direction (+ezdantevariasNoch keine Bewertungen

- Silo Data SheetDokument4 SeitenSilo Data SheetZoran Danilov100% (1)

- DSR 2007Dokument319 SeitenDSR 2007Nabendu LodhNoch keine Bewertungen

- Typical Foundation Layout Plan at Expansion Gap at Every 30MtrDokument1 SeiteTypical Foundation Layout Plan at Expansion Gap at Every 30Mtrnazi1945Noch keine Bewertungen

- Astm A 681Dokument14 SeitenAstm A 681talhadikenNoch keine Bewertungen

- 2012 FWP Steps BrochureDokument12 Seiten2012 FWP Steps BrochureFort Wayne PoolsNoch keine Bewertungen

- Flow-Tek Part Number Selection GuideDokument18 SeitenFlow-Tek Part Number Selection GuideAmanda50% (2)

- Powder Metallurgy: Introduction ToDokument268 SeitenPowder Metallurgy: Introduction ToBhavya SumaNoch keine Bewertungen

- Pressed Steel Safety DoorDokument1 SeitePressed Steel Safety DoorAshutosh SinghNoch keine Bewertungen

- IS 2095 - 1gypsum Plaster Boards PDFDokument7 SeitenIS 2095 - 1gypsum Plaster Boards PDFRushikant ManeNoch keine Bewertungen

- Tyvek Installation Guide - Residential-WRB-Install PDFDokument24 SeitenTyvek Installation Guide - Residential-WRB-Install PDFDavid TorskeNoch keine Bewertungen

- Studying The Effect of Tramp Elements in Scrap On Industrial Recycled Steel Processing and QualityDokument8 SeitenStudying The Effect of Tramp Elements in Scrap On Industrial Recycled Steel Processing and QualityDominic TanNoch keine Bewertungen

- Adhesive Compounds'2 Component For Sealing Wire and Light in PavementDokument4 SeitenAdhesive Compounds'2 Component For Sealing Wire and Light in PavementDevrim GürselNoch keine Bewertungen

- Ic-M700pro SM 5Dokument202 SeitenIc-M700pro SM 5backup mailNoch keine Bewertungen

- Enclosures: Practical Guide To Electrical Enclosures For Industrial ApplicationsDokument24 SeitenEnclosures: Practical Guide To Electrical Enclosures For Industrial ApplicationsMohamed ElnahNoch keine Bewertungen

- Standard Dimension Ratio (SDR) : HDPE Pressure Pipes According To EN 12201, EN 13244 and DIN 8074/75Dokument1 SeiteStandard Dimension Ratio (SDR) : HDPE Pressure Pipes According To EN 12201, EN 13244 and DIN 8074/75Arunprasad MurugesanNoch keine Bewertungen

- Rebar Drawing Check ListDokument1 SeiteRebar Drawing Check Listalok100% (1)

- Wall Bracing To Slab-On-Ground FloorsDokument7 SeitenWall Bracing To Slab-On-Ground Floorsmurdicks0% (1)

- Testing The Hardness of MetalsDokument5 SeitenTesting The Hardness of MetalsAwanNoch keine Bewertungen

- Corrosion HDBK S2Dokument296 SeitenCorrosion HDBK S2Aleksandra AleksicNoch keine Bewertungen

- Structural Notes: Construction WorkmanshipDokument1 SeiteStructural Notes: Construction WorkmanshipSamuel RamonesNoch keine Bewertungen

- Can The Anchor Bolts Type ASTM F1554 Grade 36 Be Replaced With ASTM A307 Grade 36?Dokument2 SeitenCan The Anchor Bolts Type ASTM F1554 Grade 36 Be Replaced With ASTM A307 Grade 36?Jovito EdillonNoch keine Bewertungen

- BollardDetail 3Dokument1 SeiteBollardDetail 3aishahrahmanNoch keine Bewertungen

- Lecture # 5Dokument5 SeitenLecture # 5Ch. Muhammad UsamaNoch keine Bewertungen