Beruflich Dokumente

Kultur Dokumente

Job Safety Analysis SEG 6.1 - Rebar and Formwork Fabrication and Installation Carpentry Works Rev.0

Hochgeladen von

Jayvee Baradas ValdezOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Job Safety Analysis SEG 6.1 - Rebar and Formwork Fabrication and Installation Carpentry Works Rev.0

Hochgeladen von

Jayvee Baradas ValdezCopyright:

Verfügbare Formate

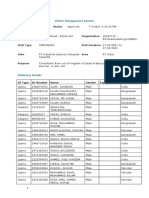

JOB SAFETY ANALYSIS # 2

Control Measures Example Table

Controls

Most Effective

Elimination

(Remove

the hazards)

Least

Effective

Engineering/Isolation

(Design people

effective

control

measures to protect

and

the environment)

Warning

(Alert people

of the hazards)

Administrative

(Provide training,

Procedures etc)

PPE Equipment)

(Personal Protective

Critical

Major

Moderate

Minor

1

6

Remove

damage

machine

fromtrailing

servicecords.

Provide power

outlets

to avoid

Use water-based

latex rather than

oil-based

paintsof organic solvents

Use

detergents

instead

Ventilation

Machine Guard

Enclosure

Signs

Backup Alarms

Work Rotation

Equipment

inspection

Safety Glasses

Hearing

Protection

Severity Table

ELCB

LOTO

Platform/Guardrail

Horns

Labels

Beepers

Tags

MD 510

F000-HS-HSSTA-2002

Examples

Make

connections

at ground

structure

to eliminate

height.level before erecting a

Substitution

(Replace the materials/process

hazardous

one) with a less

Severity

Level

Catastroph

ic

000.653.F0100

Form Job

Safety Analysis

Reduce energy,

such as speed, force, amperage,

pressure

and temperature.

Secondary Containment

Barriers

Improved

Lighting

High Visibility

Paint

Good housekeeping Practices

Harness and lanyard

Gloves

Respirator

High visibility vest

People

Multiple

or

single

fatality

Impact

Environment/Community

Long term

impact

to publicity/media

air,

surface/ground

water,

or soil;

or area/

Wide

spread

areas

including

offsite

community

affected;

orExtensive

adverse

coverage

Equipment/Property

Extensiveimpacts;

losses

oforLosses

high

value

equipment/property;Major

schedule

exceeding

1M

USD;

orSignificant

unplanned

financial

impacts to

business unit.

table

Likeliho

Proba

Chances

od Likelihood

bility

of100

Level

Occurren

ce

Very

2

1 in

Likely

5 1x10

Injury

or illness

resulting

in total

permanent

or

impartial

disability

Injury or illness

resulting

in

temporary

disability

or loss

of

function.

Injury

or illness

requiring

medical

attention.

Injury

or illness

requiring

first

aid only.

Lasting

(upto

toregulatory

one

year)impact

toOffsite

air,

surface/ground

water,

or authorities;

soil;

or

area/community

affected;

or events

that

reportable

or are

some

adverse

publicity/media

coverage.

Temporary

(up

towater,

one

impacts

to air,

surface/

ground

or

soil;

or or

significant

area

of the

project

sitemonth)

affected,

Breach

of

regulatory

requirement

or limit;

or

potential

for

adverse

Short-term

(up

to

onepublicity/media.

day)

impact

toand

air,

surface/

ground

water,

or

soil;

or

very

small

are

within

the

project

site

affected;

no

potential

for

adverse

publicity

or

media

coverage.

No

direct

impact

to

air,

surface/ground

water,

or

soil;

or

effects

restricted

within

the buildings

or containment

structures;

and

no potential

for adverse publicity/media

coverage.

Losses

of exceeding

equipment/property

that

cannot

be readily

replaced;

or losses

100k

USDon

or

significant

unplanned

impact

project

budget/schedule.

Loss of replaced;

equipment

that

can be

readily

or

losses

exceeding

10k

USD,

or

significant

unplanned

impact

on

project

budget.

Damage

to

equipment/

property

that

can

be

repaired

within

a

reasonable

timeframe;

exceeding

1k

USD

or

minor

impact

on the

budget. or losses

No

impact

on

equipment

functionality;

minor

cosmetic

damage;by

or

repair cost

easily

covered

normal

project

operation

budget.

Likely

Possibl

e

Unlikel

y

Very

Unlikel

y

4

3

2

1

3

1x10

4

1x10

5

1x10

6

1x10-

1 in 1,000

1 in 10,000

1 in 100,000

1 in

1,000,000

Seve

rity

Ver

Me

Ver

Ver

VerOverall Risk Rating

Hig

y

RiskPos

Matrix

y

Unli

Like

y

diu

sibl

ly

Like

y

Low

h

Hig

Catast Unli kely

e

m

kely

2

4

ly

rophic 16

3

32 48

64 80

Critica

Low 4-7

16h

1

5

8

16

24

32

40

Major

8-l -16

Note: Site/Construction

8

4

8 12 16 20

Moder

0-3

31 324

000.653.F0100

Form Job

MD 510

F000-H

Safety

Analysis

STA-2002

2

4

6

8

10

15

JOB

SAFETY

ANALYSIS

#

2

Minor

Manager

must

ate - 2

1

2

3

4

5

80Date:

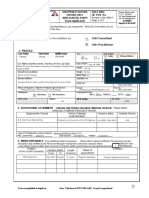

Section

1 General

Information

Emergency Contact Name

Prepared

Jesus

B. Valdez

New __ Revised

By:

__

-1

Primary:

Liu Lian

JSA TITLE: personally review any

Job

Safety

Analysis

SEG

6.1

- Rebar a

Formwork

fabrication

and

installatio

Carpentry

works

Rev.0

Contact

Description:

Rebar and Formwork preparations for concrete pouring acti

Number:

items with a High or

Project HSE:

Jesus B. Valdez

High

risk

Contact

Location: Very Umm

Wualresidual

Package 6.15 TLUL

Laydown and Site.

Number:

Tools

Rebar Cutting and Bending

Machine,

Electric

wood

saw,

hammer,

steel fixer,by

grinders, drill, boom

Equipment

truck/crane,

trailer

truck

and

portable

generators.

Used:and

score,

and

approve

Section

this job requires any

operations?

Yes 2 Does

Yesof the following

Yes

Areal Lift

Hazardous

Energy

Lead

Work

Respiratory

Control

hazards

signing

this

form.

Asbestos

work

Hazardous

Materials

Limited

Roof

work

communication

Confined

Space

Hazardous

waste

Loading/Unloading

X

Site/Vehicle

traffic

operations

Material

Electrical Hazards

X

Heavy Equipment

X

Noise exposure

X

Extreme

temperature

Emergency

Shutdown

High

Energy

Potentials

Powered

Industrial

X

Trucks

Excavation/Trenching

X

Hoisting

Rigging

and

Process

Cranes

instability/upset

First Line

Break

Hot

work

Radiation

area work

Grating/Floor

plate/Guardrail

Ladders

and

X

Remote

Location

Removal

Scaffolding

Section 3 AreYes

any of Task

these

Human Factors

to the Job?X

Human

Nature

Yes

Organizational

Demands

Yes Applicable

Work

Yes

Factors

Environment

Assumptions

X

Emphasis

on

High

workload

Changes

(inaccurate

schedule

(memory

departures

from

mental

picture)

requirement)

routine

Complacency

/

X

Lack

of

support

Interpretation

Confusing

Overconfidence

for

stop

work

requirement

display

or

authority

controls

Distraction

X

Personality

Irrecoverable

Hidden

system

Conflicts

acts

response

Habit Patterns

X

Poor

X

Lack

of or

Lack of

Communication

Unclear

Alternative

with

peers/

standards

indication

Supervisor

Inaccurate

risk

Unclear

goals,

Unexpected

X

perception

roles and

equipment

responsibilities

conditions

Limited

short

Workarounds/

term

memory

OOS

instruments

Mental

Shortcuts(bias

es)

Mindset(turne

d to see)

Stress(Limits

attention)

Maintenance/Chan

gesalone

Working

Work

at

height(1.5m)

Others

Individual

Capabilities

Hazardous

attitude

for

critical

task

Illness

fatigue

Imprecise

communication

habits

Indistinct

problem-solving

skills

Lack

of

knowledge

(Mental

Lackmode)

of

proficiency/

inexperience

Unfamiliarity

with

the

task/

first

time

JOB SAFETY ANALYSIS # 2

Activity/Step

1. Toolbox

Talk

2.

Preparations

Hazards

1.1

Unclear

information

1.2

Incomplete

STA

2.1

Sharp

Objects

2.22.3

Broken

tools

Broken

Equipment

2.4

Unauthorized

Personnel

3.

Rebar

Cutting

and

bending

3.1

Pinch

Points

3.2No

Equipment

Failure

3.3

Deadman

Switch

/Emergency

Stop

3.4

Hand

Injuries

3.5

Fire

Hazards

3.6 hazard

Ergonomic

4. Carpentry

work

4.1

Fire

Hazards

4.2 4.3

Pinch

Points

Sharp

objects

4.4

Eye

injuries

4.5No

Ergonomic

hazards

4.6

Deadman

Switch

/Emergency

Stop

Transportatio

n5.

of

Materials

6. and

Installation

of

rebars

formworks

5.1

Falling

objects

5.2

Trafficand

Hazards

5.3

Loading

Unloading

of

materials

6.1

Slips/Trips/

Fall

hazards

6.2

Sharp

objects

6.3

Broken

tools

6.4

Fall

from

height

6.5

Unsafe

access

6.6

Points

6.7Pinch

Protruding

objects

7.

Housekeepin

71 Trip/

Slip/

Fall

hazards

Section 4 Job Safety Analysis

English

Control

Measures

1.1.1

Permit

to work

must

beexecuting

secured

and

1.

11

discussed

to

workers

before

the

activity.

The

activities

hazards

and

control

measures

must

be

known

to

the

workers.

1.2

STA

1.2.1

Foreman

everyday

shall

discussed

3

points

activity

Construction/Quality

and

on for

topthe

of it

Safetyin

and

shall

be written

the

details

the

STA.

2.1.1

Use

hand

protection

to

prevent

sharp

2

2.1

objects

to

cut

through

your

skin.

Safeguard

materials

(i.e.

rebar

caps,

plastic

covers

etc.)

in2.2.1

which

suspected

to

be

sharp.(I.e.

rebars,

wood

etc.)

2.2

Inspect

tools

before

using;

look

for

2.3

damage,

cracks,

or

loose

parts

before

2.4

2.2.2

Colour

code

tools

according

to using.

the

month.

2.3.1

Equipment

checklist

shall

be filled

upto

by

the party

operator

on daily

basis.

2.3.2

Third

certification

shall

be

up

date

if

applicable.

2.4.1

Equipment

operators

details

shall

be

posted

on

the

equipment.

3.1.1

Do not

remove

machine

on

3.

3.1

equipments

/ Install

additional

ifguards

necessary.

3.1.2

Identify

the

Pinch

points

before

using

3.2

equipment.

3.3

3.2.1

Proper

grounding

of equipment

is

necessary

for

the

avoidance

of shock.

3..4

3.2.2

Inspection

of

equipment

prior

to use.

3.5

3.2.3

Install

GFCI

and

ELCB.

3.6

3.3.1 and

Inspect

the

equipment

for

deadman

switch

emergency

stop,

install

if

not

yet

available.

3.4.1Do

Using

protection

isguarding.

a must.

3.4.2

not hand

remove

machine

3.5.1

Fire

extinguisher

shall

be

at

least

7.5

m

maximum

from

the

equipment.

3.5.2 m

Isolate

the equipment

and

remove

the

combustible

material

from

distance

of 10.7

from

the aequipment.

3.6.1

Elevate

the

work

piece

and platform

to

0.9

m3.6.2

to minimum

lessen

the

bending

movements

can

strain

the

back.

Work

rotation

shall

be done. that

1.1

1.2

2.1

2.2

2.2

2.3

2.4

3.1

3.1

3.2

3.2

3.2

3.3

3.4

3.4

3.5

3.5

10

3.6

3.6

4.1.1

extinguisher

shall

be

atremove

least 7.5

m

maximum

the

equipment.

4.1.2Fire

Isolate

the from

equipment

and

the

combustible

material

from

distance

ofon

10.7

m

minimum

from

the aequipment.

4.2.1

Do

not

remove

machine

equipments

/ Install

additional

ifguards

necessary.

4.2.1

Identify

the

Pinch

points

before

using

equipment.

4.3.1

Use

hand

protection

to

prevent

sharp

objects

to

cut

through

your

skin.

Safeguard

materials

(i.e. rebar

caps,

plastic covers

etc.)

in which

suspected

to be

sharp.(I.e.

rebars,

wood

etc.)

4.4.1

Use

safety

glasses

and

faceboards.

shield

while

cutting

through

wood

and

4.5.1

the

work

piece

and

platform

to .

9 m Elevate

to

lessen

the

bending

movements

can

strain

the

back.

4.5.2

Work

rotation

shall

be done. that

5.1.1

Secure

the

rebar/formworks

on the

trailer

bed by

using

tie

ropes

or slings.

5.2.1

Flagmen

shall

guide

the trailer/boom

truck

on

site.

5.3.1

Proper

rigging

procedure

must

be

followed (SEE LIFTING AND RIGGING MS)

6.1.1

Maintain

aatidy

area

free

fromcan

scattered

materials

and

tools.

6.1.2

Allocate

space

where

you

place

yourAccess

materials

properly

stacked.

6.1.3

shall

be tools

free

from

any materials/

doand

notand

block

the

access.

6.1.4

Materials

and

tools

stacked

shall

be

barricaded

signages

shall

be

installed.

6.1.5

Materials

near

the

road

shall

have

blinking

lights

attached

to

the

barricade.

6.1.6

Proper

access

shall

bebe

provided

forarea.

the

workers

especially

inside

the

excavation

6.2.1

Hand

gloves

shall

used

while

working.

6.3.1

Tools

must

be

inspected

before

using

and

shall

be

color

coded

by

month

color.

6.4.1 working

Steel a

fixing

and

formworks

that

required

at height

shall

be provided

safe

scaffold.

6.4.2 Use

body

harness

and

lanyard

while

working

on

elevated

area

on

safe

scaffolding/

ensure

100%

tie off.

6.5.1 Access

shall

be

made

byaccessible

qualified

scaffolder

and

shall

be

easily

without

anystart

blockage

and

tripping

6.6.1

Identify

the

in the

between

material

points

before

the

of

activity,

thishazards.

will

let

workers

aware

of

the

danger.

6.7.1

Rebar

caps

shall

be

each

protruding

object

(rebars

/installed

tapered

rebars

/

formwork

shuttering

locks).on

7.1.1

Proper

material the

arrangements

must

be

observed;

barricade

material and

place

4.1

4.1

10

4.2

4.2

4.3

4.4

4.5

4.5

5.1

5.2

5.3

6.1

6.1

6.1

6.1

6.1

6.1

6.2

6.3

6.4

6.4

6.5

6.6

6.7

7.1

4.

4.1

4.2

4.3

4.4

4.5

4.6

5.

6.

5.1

5.2

5.3

6.1

6.2

6.3

6.4

6.5

6.6

6.7

7.

7.1

7.2 Protruding

objects

signage. materials on site.

7.2

7.1.2

unnecessary

7.1.3

Disposed

trash

inside

the waste

skip

and Remove

properly

segregate

according

to

type

(biodegradable,

non-bio,

hazardous,

chemical

waste).

7.2.1

Install

rebar

caps

rebars.

7.2.2

remove

the

nails

onon

wood

after

dismantling

the

formworks.

8.

Working

8.1

8.1.1 Take

Provide

heat

shelters

andwork

cold drinking

8.

8.1

/

under

the

heatFatigue

stress /

water

on site.

sun,

humid

and

other

8..2

Heat

8.1.2

frequent

breaks

and

8.2

Adverse

related

weather

sickness(

skin

8.1.3 Drink

See

Heat

stress

program

for rotation.

more

condition

rash/

sunburn/

details.

Heat

cramps

8.3

/

8.2.1

plenty

of

water

(7 days)

glasses

of

//

8.3 Extreme

water

or

more

for

hotter

Cold

weather/

/

Heavy

rains/

8.2.2

Shower

more

often

Sandstorms/

8.2.3

bring

extra

clothings

Heavy

Snow/

High

winds

8.3.1 Suspend

the

work

in

case

of

seriously

harsh weather condition.

9.

Extended

9.1

Poor

9.1.1

The

light

intensity

shall

be measured

on

9.

9.1

Hours

Work

Illumination

hourly

basis

and

shall

have

a shelter/

minimum

of 110

lux

(5shall

ft-cd).

9.2

Indigenous

fauna

on site

9.1.2

way/

patio/

rest

toilets

9.2

andWalk

access

areas

have

adequate

lighting.

9.2.1

Do

not

wander

around

dark

places.

Snakes

and

other

animals

mostly

stay

out

of

the

light.

9.2.2

Do

not

interact

with

any

animals

on

site.

For more info

(EXTENDED

HOURS WORK

ANDsee

FRIDAY

OVERTIME).

Section 5 Approvals and Signature

SEG Management

Name

Position

Signature

Name

Lu Hongxing

Project

Manager

Scott

Clark

Wang

Haitao

HSE Manager

Dick

Trembath

7.1

7.1

7.2

7.2

8.1

8.1

8.1

8.2

8

8.2

8.2

8.3

9.1

9.1

9.2

9.2

Das könnte Ihnen auch gefallen

- JHA PlumberDokument3 SeitenJHA PlumberEko Susanto100% (1)

- JSA ScaffoldingDokument2 SeitenJSA ScaffoldingHrishikesh UnnikrishnanNoch keine Bewertungen

- JSA WeldingDokument2 SeitenJSA WeldingSigint Sides0% (3)

- Plumbing Work JSA HSE ProfessionalsDokument1 SeitePlumbing Work JSA HSE ProfessionalsStansilous Tatenda NyagomoNoch keine Bewertungen

- JHA PaintingDokument9 SeitenJHA Paintingperquino oasan100% (1)

- 0 JsaDokument54 Seiten0 JsaRavi AmarlapudiNoch keine Bewertungen

- Part-A: Jsa Date: 23.11.16 Work Permit No: HW-: Civil Works Inside The Tank DykeDokument4 SeitenPart-A: Jsa Date: 23.11.16 Work Permit No: HW-: Civil Works Inside The Tank DykevivekaramanaNoch keine Bewertungen

- JSA Finishing Temporary FacilitiesDokument6 SeitenJSA Finishing Temporary Facilitiesjet Louis Magallones100% (1)

- Civil JSA Form Application of Protective Coating On Sump PitsDokument1 SeiteCivil JSA Form Application of Protective Coating On Sump PitsdrmuhsinNoch keine Bewertungen

- JSA Excavation PDFDokument6 SeitenJSA Excavation PDFmohamedamine.zemouriNoch keine Bewertungen

- Jsa Installing BracketDokument3 SeitenJsa Installing BracketHow Chin Engineering Sdn Bhd100% (1)

- Confined Spaces Toolbox TalkDokument3 SeitenConfined Spaces Toolbox TalkWaSim AKramNoch keine Bewertungen

- JSA PlumberDokument2 SeitenJSA PlumberSyed Yousuf AliNoch keine Bewertungen

- JHA - Survey WorksDokument3 SeitenJHA - Survey WorksNazirul Syazwan100% (3)

- Job Hazard Analysis FormDokument10 SeitenJob Hazard Analysis FormJayson Escamillan100% (1)

- 02-Job Safety Analysis - Excavation WorkDokument2 Seiten02-Job Safety Analysis - Excavation Workkhaja asifuddinNoch keine Bewertungen

- Excavation and TrenchingDokument2 SeitenExcavation and TrenchingvikasNoch keine Bewertungen

- (Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)Dokument3 Seiten(Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)krisNoch keine Bewertungen

- JSA Erection of Gathering TentDokument12 SeitenJSA Erection of Gathering TentMuhammad Tariq100% (2)

- Jsa-Jha For Using of Hand ToolsDokument2 SeitenJsa-Jha For Using of Hand ToolsKamran Khan50% (2)

- Excavations JSA Final 2015Dokument5 SeitenExcavations JSA Final 2015jithin shankarNoch keine Bewertungen

- Removing Staircase with Crane Lifts SteelDokument3 SeitenRemoving Staircase with Crane Lifts Steelmarvin100% (1)

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7Dokument4 SeitenThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7abhijit janaNoch keine Bewertungen

- Job Safety Analysis PlumbersDokument5 SeitenJob Safety Analysis Plumbersallen2912100% (1)

- JSA Epoxy Coating Machine ShopDokument10 SeitenJSA Epoxy Coating Machine ShopMarhendra100% (1)

- INSTALLATION SAFETY ANALYSISDokument22 SeitenINSTALLATION SAFETY ANALYSISSyed Yousuf Ali100% (1)

- Monsoon Safety PlanDokument24 SeitenMonsoon Safety Planarka raheemNoch keine Bewertungen

- Job Safety Analysis: Night Work at SiteDokument2 SeitenJob Safety Analysis: Night Work at SiteSaiyad RiyazaliNoch keine Bewertungen

- Kimanis Power Project: Job Safety AnalysisDokument6 SeitenKimanis Power Project: Job Safety AnalysisLuqman OsmanNoch keine Bewertungen

- JHA Scaffolding - ApprovedDokument15 SeitenJHA Scaffolding - ApprovedLuqman OsmanNoch keine Bewertungen

- Chipping Work (Manually)Dokument1 SeiteChipping Work (Manually)ChandruNoch keine Bewertungen

- Job Safety Analysis - Cone ErectionDokument7 SeitenJob Safety Analysis - Cone ErectionMohammed MinhajNoch keine Bewertungen

- Job Safety Analysis (JSA) - CONCRETE WORKS - DateDokument2 SeitenJob Safety Analysis (JSA) - CONCRETE WORKS - DatenabeelNoch keine Bewertungen

- JSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingDokument4 SeitenJSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingMohammed Minhaj100% (1)

- JSA For Demobilization WorksDokument2 SeitenJSA For Demobilization WorksIanne Dee85% (13)

- Job Safety Analysis (JSA) : Description Hazard ControlDokument2 SeitenJob Safety Analysis (JSA) : Description Hazard ControlRidha Bennasr100% (2)

- Summer Plan Rev ADokument10 SeitenSummer Plan Rev AKhaled Ismail100% (1)

- Jha RebarsDokument7 SeitenJha RebarsJaycee QuinNoch keine Bewertungen

- King Faisal Air Academy Carpentry JSADokument1 SeiteKing Faisal Air Academy Carpentry JSAnabeelNoch keine Bewertungen

- PTW JHA Prayer Garment Hanging Rack InstallationDokument2 SeitenPTW JHA Prayer Garment Hanging Rack InstallationPHH9834Noch keine Bewertungen

- Job Safety Analysis for PCC WorkDokument6 SeitenJob Safety Analysis for PCC WorkCICON EngineersNoch keine Bewertungen

- Exavation Works PipercksDokument4 SeitenExavation Works PipercksHRTYR100% (1)

- Assess and Manage Construction RisksDokument1 SeiteAssess and Manage Construction RisksAnonymous goXrLOI33% (3)

- 04 Jsa For Camp Constn & Associated FacilitysDokument5 Seiten04 Jsa For Camp Constn & Associated FacilitysHilbrecht De Pedro100% (1)

- Jha of PaintingDokument3 SeitenJha of PaintingAllan Camacho Regalado100% (1)

- JSA For Vegetation ClearingDokument4 SeitenJSA For Vegetation ClearingSawLaiBoyan33% (3)

- Job Hazard Analysis - Granite Surface PlateDokument2 SeitenJob Hazard Analysis - Granite Surface PlateRaziellia Nor SaafriNoch keine Bewertungen

- Pha ExcavationDokument13 SeitenPha ExcavationirshadNoch keine Bewertungen

- 7 - Civil WorkDokument12 Seiten7 - Civil WorkPerwez21100% (1)

- Tbam: Dikkowita Fisheries HarbourDokument8 SeitenTbam: Dikkowita Fisheries HarbourkskahatadeniyaNoch keine Bewertungen

- Job Safety AnalysisDokument6 SeitenJob Safety Analysiskehamchoi100% (3)

- DOCUMENT Piping Insulation Installation and Dismantle Work JHADokument12 SeitenDOCUMENT Piping Insulation Installation and Dismantle Work JHAAmirHakimRusli100% (1)

- Concrete Surface Coating JSA-027Dokument5 SeitenConcrete Surface Coating JSA-027shivgovind pal100% (1)

- Jha RoofingDokument4 SeitenJha Roofingahmadhatake100% (1)

- JSA For Piping-Hydro TestDokument10 SeitenJSA For Piping-Hydro TestMuthu AlaguRajNoch keine Bewertungen

- Electrical Works Safety AnalysisDokument6 SeitenElectrical Works Safety AnalysisShaikh Abu bakarNoch keine Bewertungen

- Job Safety Analysis SEG 6.1 - Hotwork (Grinding, Cutting, and Welding) Rev.0Dokument1 SeiteJob Safety Analysis SEG 6.1 - Hotwork (Grinding, Cutting, and Welding) Rev.0Jayvee Baradas ValdezNoch keine Bewertungen

- Engineering & Technology PathwayDokument110 SeitenEngineering & Technology PathwayNaveen S BasandiNoch keine Bewertungen

- Construction Safety - Part 3 (Ppe)Dokument27 SeitenConstruction Safety - Part 3 (Ppe)Henry TuraldeNoch keine Bewertungen

- CCPS - PHA For Combustible Dusts - FinalDokument29 SeitenCCPS - PHA For Combustible Dusts - FinalHemendra Jani100% (2)

- Sinopec-Tr-Safety Training Attendance SheetsDokument2 SeitenSinopec-Tr-Safety Training Attendance SheetsJayvee Baradas ValdezNoch keine Bewertungen

- Request# Status: Visitor Management SystemDokument3 SeitenRequest# Status: Visitor Management SystemJayvee Baradas ValdezNoch keine Bewertungen

- SINOPEC - RTR SOC Attendance Sheet 24-08-2021Dokument3 SeitenSINOPEC - RTR SOC Attendance Sheet 24-08-2021Jayvee Baradas ValdezNoch keine Bewertungen

- HSE VIOLATION NOTIFICATION SINOPEC 001 - Mass Toolbox MeetingDokument4 SeitenHSE VIOLATION NOTIFICATION SINOPEC 001 - Mass Toolbox MeetingJayvee Baradas ValdezNoch keine Bewertungen

- Sinopec Status of Firstaid BoxDokument1 SeiteSinopec Status of Firstaid BoxJayvee Baradas ValdezNoch keine Bewertungen

- SA ID Cancellation ReceiptDokument1 SeiteSA ID Cancellation ReceiptJayvee Baradas ValdezNoch keine Bewertungen

- Smoke Detector Test and Inspection ReportDokument1 SeiteSmoke Detector Test and Inspection ReportJayvee Baradas ValdezNoch keine Bewertungen

- SDM 023 Attendance SheetDokument1 SeiteSDM 023 Attendance SheetJayvee Baradas ValdezNoch keine Bewertungen

- Sinopec: Company Work Locations Manpower Work Activities Supervisors Name & Contact No#Dokument2 SeitenSinopec: Company Work Locations Manpower Work Activities Supervisors Name & Contact No#Jayvee Baradas ValdezNoch keine Bewertungen

- Job Safety Analysis Work SheetDokument10 SeitenJob Safety Analysis Work SheetJayvee Baradas ValdezNoch keine Bewertungen

- 0002 Rev 00 Jsa TR Seg Piping ErectionDokument11 Seiten0002 Rev 00 Jsa TR Seg Piping ErectionJayvee Baradas ValdezNoch keine Bewertungen

- T40 RattlerDokument3 SeitenT40 RattlerDeo MananganNoch keine Bewertungen

- ADA-third Party NEWDokument1 SeiteADA-third Party NEWJayvee Baradas ValdezNoch keine Bewertungen

- Drinking WaterDokument1 SeiteDrinking WaterJayvee Baradas ValdezNoch keine Bewertungen

- 6th Central Pay Commission Salary CalculatorDokument15 Seiten6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- RPB Astro Instruction ManualDokument20 SeitenRPB Astro Instruction ManualJayvee Baradas ValdezNoch keine Bewertungen

- Sinopec Status of Firstaid BoxDokument1 SeiteSinopec Status of Firstaid BoxJayvee Baradas ValdezNoch keine Bewertungen

- FGP SEG TR JSA 20 - Man Lift Operation Rev. 02Dokument15 SeitenFGP SEG TR JSA 20 - Man Lift Operation Rev. 02Jayvee Baradas ValdezNoch keine Bewertungen

- Application Form OSH PractitionerDokument3 SeitenApplication Form OSH PractitionerJayvee Baradas Valdez100% (4)

- Good Practices Guide To Dark Rooms OperationsDokument3 SeitenGood Practices Guide To Dark Rooms OperationsJayvee Baradas Valdez0% (1)

- Guidelines DO16Dokument77 SeitenGuidelines DO16Marlo ChicaNoch keine Bewertungen

- Visio Miguel ProjectDokument1 SeiteVisio Miguel ProjectJayvee Baradas ValdezNoch keine Bewertungen

- Using the Ladder UnsafelyDokument14 SeitenUsing the Ladder UnsafelyJayvee Baradas ValdezNoch keine Bewertungen

- Powerline Pre Board Ree Sept 2010 PDFDokument14 SeitenPowerline Pre Board Ree Sept 2010 PDFJayvee Baradas ValdezNoch keine Bewertungen

- Saes T 555Dokument21 SeitenSaes T 555Jayvee Baradas ValdezNoch keine Bewertungen

- Powder Actuated ToolsDokument1 SeitePowder Actuated ToolsJayvee Baradas ValdezNoch keine Bewertungen

- Content:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualDokument8 SeitenContent:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualJayvee Baradas ValdezNoch keine Bewertungen

- NEMA Enclosure Types 11-05-2Dokument9 SeitenNEMA Enclosure Types 11-05-2Duron SaavedraNoch keine Bewertungen

- S2 Recruitment Guide - SuikosourceDokument4 SeitenS2 Recruitment Guide - SuikosourceJayvee Baradas ValdezNoch keine Bewertungen

- JSA Template 2017-05-30 Powder Actuated ToolsDokument19 SeitenJSA Template 2017-05-30 Powder Actuated ToolsJayvee Baradas Valdez100% (2)

- Robotics SyllabusDokument52 SeitenRobotics SyllabusManoj Kumar100% (1)

- Karnataka Housing Board Suvarna Karnataka Housing Programme: Detaails of Completed ProjectsDokument3 SeitenKarnataka Housing Board Suvarna Karnataka Housing Programme: Detaails of Completed ProjectsRavi KumarNoch keine Bewertungen

- Computer Network by Kanodia PublicationDokument30 SeitenComputer Network by Kanodia PublicationNeha BhavsarNoch keine Bewertungen

- What Is Ambari - Introduction To Apache Ambari ArchitectureDokument5 SeitenWhat Is Ambari - Introduction To Apache Ambari ArchitectureMario SoaresNoch keine Bewertungen

- Sahara Laptops FinalDokument27 SeitenSahara Laptops Finalethen999Noch keine Bewertungen

- 50 Liberty / Fan Pier: BCDC Presentation 4/2015Dokument17 Seiten50 Liberty / Fan Pier: BCDC Presentation 4/2015The Fort PointerNoch keine Bewertungen

- Door Schedule Door TypesDokument1 SeiteDoor Schedule Door TypesPau LlenaNoch keine Bewertungen

- Xilinx - Pci DatabookDokument258 SeitenXilinx - Pci Databookstargreen1001Noch keine Bewertungen

- TL-SG3210 V2 DatasheetDokument5 SeitenTL-SG3210 V2 DatasheetFelipe LagaresNoch keine Bewertungen

- Building Permit FormDokument2 SeitenBuilding Permit FormJohnNoch keine Bewertungen

- Slackware PKG PresentationDokument33 SeitenSlackware PKG PresentationAlexandru-Marian CiotlosNoch keine Bewertungen

- Concrete Mix Ratio GuideDokument3 SeitenConcrete Mix Ratio GuideAj SarsonaNoch keine Bewertungen

- Manual de Programacao MP-4200-THDokument112 SeitenManual de Programacao MP-4200-THJoão AntônioNoch keine Bewertungen

- RPA Course ContentDokument3 SeitenRPA Course ContentUday KiranNoch keine Bewertungen

- Report and DesignDokument53 SeitenReport and Designkiran raghukiranNoch keine Bewertungen

- Abhishek Kumar Srivastava: Curriculum VitaeDokument3 SeitenAbhishek Kumar Srivastava: Curriculum VitaeAbhishek SrivastavaNoch keine Bewertungen

- York YHJF Series - Fin & Tube 14.5 SEER Heat Pump (R-410A) (STYLE A) Generation 1 & 2Dokument4 SeitenYork YHJF Series - Fin & Tube 14.5 SEER Heat Pump (R-410A) (STYLE A) Generation 1 & 2Michael MartinNoch keine Bewertungen

- Bhopal CircleDokument18 SeitenBhopal CircleChristina HarmonNoch keine Bewertungen

- Workflow overview and development in Microsoft Dynamics AXDokument23 SeitenWorkflow overview and development in Microsoft Dynamics AXsiriluck_s6826100% (1)

- CATALOGO AnclajesDokument12 SeitenCATALOGO AnclajessergioNoch keine Bewertungen

- Shura IslandDokument7 SeitenShura IslandMohamed ElbanaNoch keine Bewertungen

- Programmable Logic DevicesDokument12 SeitenProgrammable Logic Devicesrobinpt100% (1)

- Unconsolidated Undrained Triaxial Test On ClayDokument16 SeitenUnconsolidated Undrained Triaxial Test On Claygrantyboy8450% (2)

- Flash IIP Installation Guide 8-26-14Dokument10 SeitenFlash IIP Installation Guide 8-26-14label engineering companyNoch keine Bewertungen

- Apartment LiteratureDokument117 SeitenApartment LiteratureVenkat100% (8)

- Marconi SMA/MSH - Carritech TelecommunicationsDokument2 SeitenMarconi SMA/MSH - Carritech TelecommunicationsCarritech TelecommunicationsNoch keine Bewertungen

- FS 8700 21 LonWorksDokument72 SeitenFS 8700 21 LonWorksEric DunnNoch keine Bewertungen

- CPUID HWMonitor Report AnalysisDokument46 SeitenCPUID HWMonitor Report Analysisshivam12312Noch keine Bewertungen

- Visigoths Siege Rome Salarian Gate 410 ADDokument2 SeitenVisigoths Siege Rome Salarian Gate 410 ADMaria Laura RomeroNoch keine Bewertungen

- OSR 35b Technical Fire ProtectionDokument36 SeitenOSR 35b Technical Fire Protectioncsharpplus100% (1)