Beruflich Dokumente

Kultur Dokumente

Water Circulation

Hochgeladen von

سامح الجاسمCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Water Circulation

Hochgeladen von

سامح الجاسمCopyright:

Verfügbare Formate

Water Circulation

Pumps & Circulators

Family of Circulators

Taco LoadMatch series circulators are designed for quiet, efficient operation on LoadMatch fan

coil heating & cooling systems. Each circulator includes a removable Integral Flow Check (IFC)

to prevent gravity flow and reduce installation costs. An anti-condensate baffle prevents the

build up of condensate on the motor windings when pumping chilled water. The unique,

field serviceable cartridge contains all moving parts. Replacing the cartridge rebuilds the

circulator. With no mechanical seal, the self-lubricating, maintenance-free design provides

unmatched reliability.

Taco LoadMatch. Real world

hydronic system technology

for Green Building design.

Features and Benefits

Page 2

Unmatched reliability and

quiet, efficient operation:

Tacos LoadMatch circulators move

models of bronze or cast iron construc-

moving parts, allowing for easy

water in the direction it needs to go

tion, provide unmatched reliability

service instead of replacing the

in closed loop, single pipe systems of

and maintenance free operation.

entire circulator.

LoadMatch design. LoadMatch circula-

Each LoadMatch circulator comes with

tors reduce operating and mainte-

an integral flow check (IFC) to prevent

Connecting terminal unit secondary

nance costs by providing a lower pump

gravity flow and an exclusive anti-

piping circuits to their primary piping

head and less horsepower to match

condensate baffle to protect motor

circuits in a two pipe

separate loads in zoned applications.

windings against condensate build-up

LoadMatch system

With individual LoadMatch circulators

in chilled water systems.

is accomplished

in place for each zone in a building,

through the use of

and all loads operating separately from

Known for their quiet, efficient opera-

each other, water through the direct

tion, compact LoadMatch circula-

return LoadMatch system behaves

tors are self-lubricating and have no

LoadMatch circulators also feature

exactly the way it was intended.

mechanical seal. The unique, field

optional variable speed and priority

LoadMatch circulators, in fourteen

serviceable cartridge contains all

zoning models.

Taco Twin Tee fittings.

LoadMatch Twin Tee fittings

Secondary Circuit

Return

Primary

Circuit Flow

Supply

Primary

Circuit Flow

Internal

Baffle

To learn more see Taco Catalog# 100-6.8

Features and Benefits

Page 3

Integral Flow Check (IFC)

as possible. If they arent then the

housing. This condition is inherent in

Prevents Ghost Flows

path of least resistance for some of the

any wet rotor circulator, and is a result

An integral spring loaded flow check

water is through the secondary circuit

of direct metallic contact between the

prevents any ghost flowsor unwanted

and terminal unit.

motor housing and the volute containg

flows in the terminal unit secondary

circuit when the circulator is off.

cold chilled water.

This can result in overheating or over-

The anti-condensate baffle provides

cooling when the circulator is cycled

an air gap between these two compo-

The flow check

off by the room or zone thermostat.

nents effectively insulating the motor

prevents unwant-

The integral spring loaded flow check

housing from the cold volute.

ed flow. The

prevents these ghost flows.

Standard Pressure Rating is 200 PSI

spring provides

approximately

Anti-Condensate Baffle

The standard pressure rating of a

10 w.c. pressure

Prevents Condensation in

LoadMatch circulator is 200 psi.

drop in direction of flow to prevent

the Motor Housing

This enables the circulator to be used

unwanted or ghost flows when the

An anti-condensate baffle prevents

in medium and high rise construction

LoadMatch circulator is off.

condensation from collecting inside

without having to install hydraulically

the motor housing and shorting out

isolated subsystems.

Ghost flows can develop in the ter-

the motor windings.

minal unit secondary circuit when

It can also be used in integrated piping

the two tees to the secondary circuit

If the circulator is used in chilled water

systems utilizing fire protection piping

are not installed correctly. These tees

applications in humid climates con-

to meet NFPA Chapter 13 pressure

should be installed as close together

densation will occur inside the motor

ratings of 175 psi.

Features and Benefits

Page 4

11

10

9

8

1

15

7

14

13

12

6

5

4

3

2

(#1)

Integral Flow Check (IFC)

prevents gravity flow.

(#7)

Thrust Washer Prevents noise

and wear on rotor / front bearing.

(#2) Casing Cast iron or Bronze.

(#8) Spacer Washer.

(#3) Casing O-ring EPDM

(#9) Rotor / Shaft Steel rotor, hollow

ceramic impeller shaft.

(#13) Anti-Condensate Baffle

Allows for ambient air flow, prevents

build-up of condensate on motor.

(#14) Stator Permanent split capacitor.

(#4)

Impeller Polypropylene

30% glass filled

(#5) Dirt Barrier Keeps system dirt

away from bearings.

(#6)

Front Bearing Support Assembly

Brass with carbon bearings for

smooth operation and long life.

(#10) Rear Bearing Support Assembly.

(#11) Cartridge Sleeve Stainless Steel.

(#12) Cartridge Support Plate

Seals cartridge and casing O-ring.

(#15) Motor Housing/Capacitor

Box Assembly

Applications

Page 5

Part I Fundamentals

For larger and more complex buildings and systems, economic and

functional considerations are more

critical, and performance curves must

relate the hydraulic efficiency, the

power required,

the shaft speed,

and the net positive suction head

required in addition to the flow

and pressure produced (Fig. 1-2).

A centrifugal pump operated at constant speed delivers any capacity

from zero to maximum depending on

the head, design and suction conditions. Pump

performance

is most commonly shown

by means of

plotted curves

which are

graphical representations

of a pumps

Pump perforperformance

mance curves

Fig

1-1*

characteristics.

show this interrelaPump curves present the average

tion of pump head, flow and efficiency

results obtained from testing several

for a specific impeller diameter and

pumps of the same design under stancasing size. Since impellers of more

dardized test conditions. For a single

than one diameter can usually be fitted

family residential application, considerin a given pump casing, pump curves

ations other than flow and head are of

show the performance of a given

relatively little economic or functional

pump with impellers of various diamimportance, since the total load is

eters. Often, a complete line of pumps

small and the equipment used is relaof one design is available and a plot

tively standardized. For many smaller

called a composite or quick selection

circulators, only the flow and pressure

curve can be used, to give a complete

produced are represented on the perpicture of the available head and flow

formance curve (Fig. 1-1).

for a given pump line (Fig. 1-3). Such

FLOW-M3/H

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

50hz

5.5

6.0

20

18

12

TOTAL HEAD-FEET

16

10

14

10

12

10

11

12

13

13

5.5

5.0

4.5

4.0

3.5

3.0

1.0

2

0

6.0

1.5

6.5

2.0

7.0

2.5

11

6.5

L0205B

L0410F

L0410B

L0609

L0710

L0515F

L0515B

L0435

L1111

L1130

L1614

L1034

L1121

22

0.5

10

12

14

16

18

20

22

24

26

28

30

FLOW-GPM

0.0

TOTAL HEAD-METERS

LOADMATCH CIRCULATOR MODELS

0.0

24

charts normally give flow, head and

pump size only, and the specific performance curve must then be referred

to for impeller diameter, efficiency, and

other details. For most applications in

our industry, pump curves are based

on clear water with a specific gravity

of 1.0.

Part II The System Curve

Understanding a system curve, sometimes called a system head curve, is

important because conditions in larger,

more complex piping systems vary

as a result of either controllable or

uncontrollable changes. A pump can

operate at any point of rating on its

performance curve, depending on the

actual total head of a particular system.

Partially closing a valve in the pump

discharge or changing the size or

length of pipes are changes in system

conditions that will alter the shape of a

system curve and, in turn, affect pump

flow. Each pump model has a definite

capacity curve for a given impeller

diameter and speed. Developing a

system curve provides the means to

determine at what point on that curve

a pump will operate when used in a

particular piping system.

*See Page 16 for Larger 50Hz & 60Hz Performance Curves

Fig 1-2

25

20

NPSH

77%

30

24

18

12

6

0

10

8

6

4

2

0

200

20

70%

6.50"(165mm)

150

225

300

375

FLOW IN GALLONS PER MINUTE

HEAD IN METERS

)

HP KW

7.5 (5.6

75

50

P )

3H KW

.2

(2

)

P

2H .5KW

(1

CURVES BASED ON CLEAR WATER

WITH SPECIFIC GRAVITY OF 1.0

)

P

5H KW

.7

(3

15

100

10

55%

50%

5.50"(140mm)

30

450

525

600

JSA/MS 2-18-02 PC-2066 RevA ECN10627

HEAD IN KILOPASCALS

65%

6.00"(152mm)

60%

HEAD IN FEET

7.00"(178mm)

45

NPSH

35

79%

75%

77%

70%

65%

50%

55%

60%

7.50"(191mm)

30

KPa

15

REQUIRED

60

Curve no. 2066

Min. Imp. Dia. 5.50"

Size 4 X 3 X 7.0

1760 RPM

AUGUST 27, 2001

10

75%

75

FEET

Model 3007

FI & CI Series

L/SEC

Fig 1-3

Applications

Page 6

Pipes, valves and fittings create

represents the SYSTEM CURVE. By lay-

vary pump flow. Partially closing the

resistance to flow or friction head.

ing the system curve over the pump

valve shifts the operating point to a

Developing the data to plot a system

performance curve, the pump flow can

higher head or lower flow capacity.

curve for a closed Hydronic system

be determined (Fig. 21).

Opening the valve has the opposite

under pressure requires calculation of

effect. Working the system curve

the total of these friction head losses.

Care must be taken that both pump

against the pump performance curve

Friction tables are readily available

head and friction are expressed in feet

for different total resistance possibilities

that provide friction loss data for pipe,

and that both are plotted on the same

provides the system designer impor-

valves and fittings. These tables usu-

graph. The system curve will intersect

tant information with which to make

ally express the losses in terms of the

the pump performance curve at the

pump and motor selection decisions

equivalent length of straight pipe of the

flow rate of the pump because this is

for each system. A system curve is also

same size as the valve or fitting. Once

the point at which the pump head is

an effective tool in analyzing system

the total system friction is determined,

equal to the required system head for

performance problems and choosing

a plot can be made because this fric-

the same flow.

appropriate corrective action.

tion varies roughly as the square of

Fig. 22 illustrates the use of a discharge

the liquid flow in the system. This plot

valve to change the system head to

In an open Hydronic system, it may be

necessary to add head to raise the liquid from a lower level to a higher level.

Fig 2-1

Called static or elevation head, this

amount is added to the friction head

to determine the total system head

curve. Fig. 23 illustrates a system curve

developed by adding static head to the

friction head resistance.

Fig 2-3

Fig 2-2

Applications

Page 7

Part III

The LoadMatch Concept

The wet rotor circulator provides the

installation costs, energy, and money,

specified flow to each terminal unit

and can reduce pump head, and lower

A LoadMatch system is the marriage of

at all times. The simplicity of the

hp. When loops are carrying equal

two old ideas wrapped around a new

LoadMatch concept allows you to

loads and arranged symmetrically,

technology. The old ideas are single

specify one size of pipe for large por-

they will nearly self-balance. The

pipe distribution and primary-secondary

tions of the system. In single loop

resulting configuration will keep

pumping. The new technology con-

installations, there is no limit to the

balancing losses down and will

sists of the use of maintenance-free

number of fan coils you can install.

lower ongoing energy costs.

wet rotor circulators. A primary dis-

Final pipe size is determined by the

tribution system is a single pipe loop;

total load of the loop and T. If your

the secondary distribution system is a

loop is heavily loaded, its practical to

decoupled secondary piping loop for

split the system into two loops with

each terminal unit in the system.

smaller pipe sizes. This change saves

Fig 3-1

Fig 3-2

Terminal Unit

Secondary

Circulator

Expansion Tank

Single Pipe Loop

Primary

System Pump

Chiller

Air Separator

Multiple Loop Systems Reduce Pipe Size & Installation Costs

Applications

Page 8

Cutting Design Time

The simplicity of the Taco LoadMatch

Boilers, chillers, and terminal units

provides highly efficient BTU

system shaves hours of planning

are always sized based upon heat

transport between the generators

off the job. Tacos powerful new

gain and heat loss calculations, and

and the heating or cooling

Hydronic System Solutions intelligent

are selected to suit the loads. Unlike

terminal units.

CAD software reduces errors, typically

reverse return systems, LoadMatch

saving 30% in total design and

construction administration time.

LoadMatch

Building Blocks (See Fig. 3-3)

The run-out piping between the

single-pipe loop and the terminal unit

follows conventional design practice.

When a coil is farther away from

the loop, simply extend the run-out

length and adjust the circulator for

any increase in head.

Fig 3-3

Applications

Page 9

Managing Temperature

For design engineers the most cited

concern about LoadMatch systems that

arises is the temperature cascade of

the system. Because the water temperature in the loop changes, it would

appear that the terminal units at the

end of the loop are not going to be

able to provide the necessary BTUs

for the heating or cooling loads. So

they ask, In a cooling system, how is

your system able to provide the same

capacity, including dehumidification, at

the end of the loop experiencing 50 F

entering water when other units at the

start of the loop are experiencing 40F

entering water? This is a legitimate

question.

An examination of basic heat transfer

fundamentals will provide the answer.

Consider the single dimensional steady

state heat transfer form of the NavierStokes equation, shown below.

Q = U x A x T

Where:

Lets take a room that we want to

maintain at 70 F. If the room is at the

beginning of the loop we have a 40 F

water supply, so the T between the

water supply and the room is a 30 F

difference (70F 40F). However, at

the end of the loop the water is at 50

F, so now the T is 20 F (70F - 50F).

In order to maintain the heat transfer

of a terminal unit at constant capacity

with a decreased T, either the heat

transfer coefficient or U value, or area

A, or a combination of both, has to be

increased.

The heat transfer coefficient or U value

in a typical terminal unit is a function of

fluid velocity, and the area A is a function of rows. The answer lies in increasing the flow rate through the heat

exchanger or in adding more rows,

or a combination of both, in order

to compensate for the decreased T.

Following is an example of applying

this simple concept to a typical fan

coil unit (See Figure #3-4):

As the above graph shows, the sensible

and latent capacity of the terminal unit

can be achieved in several ways by

varying combinations of increased heat

transfer coefficient or U value (velocity)

or area A (number of rows).

At the beginning of the loop shown

by the point at the left of the graph at 40F entering water, utilizing a 2 row

coil at 1 gpm, yields a given sensible

and latent capacity. At the end of

the loop - as shown by the point at

the middle of the graph, we can

achieve the same sensible and latent

capacity (50F entering water

temperature) by increasing the U

value or velocity (50F entering water

temperature, 2 rows and 2.2 gpm).

As an alternative shown by the

point at the right of the graph - we

can achieve the same capacity by

increasing the area or number of rows

(50F entering water temperature,

3 rows, and 1.5 gpm).

Q is the heat transfer rate,

Fig 3-4

U is the heat transfer coefficient,

A is the surface area,

Fan Coil Cooling Capacity

T is the temperature difference

Capacity (MBH)

8.00

Sensible

Capacity

6.00

4.00

Latent

Capacity

2.00

0.00

40 / 2 / 1 50 / 2 / 2.2 50 / 3 / 1.5

EWT (Deg. F) / Rows (#) / Flow (GPM)

Applications

This is possible because the dew

point of the airstream on the coil at

ASHRAE room Comfort Zone conditions of 75F and 60% RH has a dewpoint of 60F. Therefore an entering

chilled water temperature of 50F is

certainly capable of dehumidifying

this air stream.

Despite concerns about the temperature cascade in a LoadMatch cooling

system, the use of basic principles of

thermodynamics and psychrometrics, as described above, will result

in comfortable room conditions,

including dehumidification, in

very humid climates.

Tacos Hydronic System Solutions

software is now available that will

calculate the temperature cascade

automatically and provide a flow diagram printout of the entering water

temperature at every terminal unit in

the system. Using the flow diagram

temperature cascade information, the

engineer selects the terminal unit for

the correct cascaded entering water

temperature at each terminal unit.

Another approach to selecting all the

terminal units at different entering

water temperatures is to select the

terminal units at the same entering

water temperature.

Page 10

A recommendation is to use a worst

case entering water temperature,

taking into account the diversity of the

system. Diversity is typically defined as

the actual load divided by the design

load. For our 10 F design T example,

and assuming a 70 percent diversity

factor, one can select all the units at

47F entering water temperature (47F

= 40 + 0.7 x 10). Therefore, using this

method, the process to select terminal

units for a single pipe system is no different than selecting terminal units for

a two pipe system.

A second concern about the temperature cascade that should be addressed

here is a common misconception that

the use of multiple terminal units on a

loop adversely affects the temperature

cascade.

Again, an examination of basic heat

transfer fundamentals will provide

the answer.

Take the steady state mass transfer

equation, shown below:

Q = M x Cp x T

Where:

Q is the heat transfer rate

M is the mass transfer rate

Cp is the specific heat

T is the temperature difference

In any loop the mass flow rate (M) is

a function of the total load of all the

terminal units, divided by the specific

heat and the design T for the system.

Because the Ts are determined by

the design, and not by the number

of terminal units, the flow will always

increase to match the load. Therefore

the last terminal unit on a loop will

never experience more than the

design T.

Interestingly, the more terminal units

on a loop the better the temperature

cascade will be at the last terminal

unit. This concept is admittedly counterintuitive, but is the result of the

diversity in the system. With more

terminal units, there will be more

diversity, and a better entering water

temperature at the last terminal unit.

Applications

Page 11

Variable Speed drive

The drive is available in a Variable

The Variable Voltage (VV) version

LoadMatch circulators are available

Speed Setpoint (VS) or Variable Speed

can be set up to operate the circula-

with an optional variable speed drive

Variable Voltage (VV) configuration.

tor at different speeds based on an

externally generated analog signal

to satisfy a variety of applications.

The drive is integral to the circulator

The Variable Speed Setpoint (VS)

input. Its reliable operation, ease of

in an all-in-one package.

version can be set up to deliver a fixed

installation and integration to DDC or

temperature, maintain a specific tem-

Building Management Systems allows

perature drop between sensor loca-

for a wide variety of HVAC applica-

tions (T), used as a bypass / shunt

tions, such as maintaining a room

pump or integrated into a fan coil

temperature or humidity setpoint.

package to vary the speed of

The control accepts a 0-10 V(dc),

the pump based on supply air

0-20 mA, 2-10 V(dc), or 4-20mA signal.

temperature. The setpoint

adjustment is integral to the

The variable speed drive also saves

onboard drive.

operating costs. Following is a graph

(fig. 3-5) of power consumption vs.

VS can be either direct

speed or flow rate of a typical circulator.

acting (speed increases on

a temperature decrease) or

reverse acting (speed increases

on a temperature increase).

0-10V

Input

Fig 3-5

90.0

80.0

Gpm or Watts

70.0

60.0

Power, watts

50.0

40.0

30.0

20.0

Flow rate, gpm

10.0

0.0

0

Input Signal, VDC

10

Applications

Turndown of the circulator is also

excellent. At low speeds the control

algorithm changes to a pulse control

operating the circulator in pulses of

100% torque or speed and varying the

time between pulses.

This eliminates the turndown limitation typical of control valves since the

turndown is now a function of the

accuracy of the external DDC controller

and sensor, not the construction of the

circulator (valve).

The turndown of a typical terminal unit

control valve is in the range of 30:1.

The turndown of a LoadMatch variable

speed circulator is over 100:1.

Dehumidification with

Variable Speed Drive

The VV drive can be used to provide

accurate room humidity control in

humid climates through the use of

local dehumidification reheat control.

To adequately dehumidify in humid

Page 12

climates humidity must be controlled

directly rather than indirectly, whenever an air conditioning unit runs. This

is because the sensible heat ratio of a

load in a humid climate (0.7 to 0.75) is

lower than the sensible heat ratio of a

typical cooling coil (0.8 to 0.85).

Psychrometrically this will result in

overcooling of the space to achieve the

humidity setpoint. The room or supply

air must then be reheated to satisfy the

rooms temperature setpoint using the

heating coils variable speed circulator.

Therefore, to adequately dehumidify,

the air conditioning unit must remain

on. However, a typical air conditioning

unit is cycled off by sensible heat or

dry bulb air temperature in the room

thermostat. Therefore indirect humidity control does not provide satisfactory

dehumidification in humid climates.

Direct humidity control requires the

use of a humidity sensor and humidity controller in the occupied spaces

controlling the air conditioning units

cooling coil to achieve humidity setpoint. The cooling coils variable speed

circulator is therefore controlled from

two sources, demand for space cooling

or demand for space dehumidification.

This can be done with larger 100%

dedicated outside air (DOAS) central air

handling units and space consuming

ductwork, or with no air handling unit

or ductwork by smaller room terminal

units.

Comfort and energy efficiency are optimized and cost reduced when dehumidification, and the associated reheat,

are accomplished with smaller terminal

units at the zone or room level, e.g. fan

coils. Both central air handling units

or room terminal units require a cooling and heating coil with the heating

coil in the reheat position as shown in

figure 3-6.

Fig 3-6

LoadMatch Thermostat

Cooling/Dehumidification

withe Variable Speed Circulators

Fan

Coil

Unit

Chilled Water

Coil

Hot Water

Coil

3-Speed Fan

Cooling

Circulator

See Taco Catalog# 100-14 to learn more.

Room Temperature/Humidity

Control Thermostat/ Humidistat

Heating

Circulator

Selection Procedure

Page 13

Selection Example

Selection Example

Example 1:

Problem:

Select LoadMatch circulators to provide heating and

cooling to a fan coil unit.

Example 2:

Problem:

Select LoadMatch circulators to circulator to provide

heating and cooling to a heat pump unit.

Conditions:

Heating coil requires 5 gpm at 5 ft. head.

Cooling coil requires 10 gpm at 8 ft. head.

The circulators will use flanged connections.

Conditions:

Condenser coil requires 5 gpm at 10 ft. head. The circulator

will use sweat connections.

Selection Procedure:

1. From the LoadMatch circulator family of curves select a

Model L0410F for the heating coil. The F suffix indicates

cast iron body with flanged connections.

2. From the LoadMatch circulator family of curves select

a Model L1121 for the cooling coil. The L1121 is

furnished standard cast iron body with flanged

connections.

Selection Procedure:

1. From the LoadMatch circulator family of curves select

a Model L0515B for the heating coil. The B suffix

indicates bronze body with sweat connections.

Technical Data

Page 14

Mounting Positions

Features

Integral Flow Check (IFC)

Prevents gravity flow

Eliminates separate

in-line flow check

Reduces installed cost,

easy to service

Improved performance vs.

In-line flow checks

Exclusive ACB Anti-Condensate

Baffle - protects motor windings

against condensate build-up

Unique replaceable cartridge

Field serviceable

Unmatched reliability

Maintenance free

Quiet, efficient operation

Direct drive-Low power

consumption

Self lubricating, No mechanical seal

Standard high capacity output

Compact design

Standard

Optional

Flange Orientation

Standard

L1111 only

For Indoor

use only

Materials of Construction

Performance Data

Casing (Volute): Cast Iron or Bronze

Integral Flow Check:

Body, Plunger.....Acetal

O-ring Seals.........EPDM

Spring......................Stainless Steel

Stator Housing:...... Steel or Aluminum

Cartridge:................... Stainless Steel

Impeller:..................... Non-Metallic

Shaft:............................ Ceramic

Bearings:.................... Carbon

O-Ring & Gaskets: EPDM

Minimum Fluid Temperature:

32F (0C)

Electrical Data

Model

HP

Maximum Fluid Temperature:

230F (110C) Cast Iron

220F (104C) Bronze

Maximum Working Pressure:

200 psi

Connection Sizes:

3/4, 1, 1-1/4, 1-1/2 Flanged

1/2, 3/4 Sweat

3250RPM, 60Hz, Single Phase

115V, Amps

208-230V, Amps

2750RPM, 50Hz, Single Phase

277V, Amps

100/110V, Amps

220V, Amps

0.19

0.33

0.55

0.85

0.46

0.52

0.22

0.21

0.29

0.31

0.57

0.50

0.79

0.63

0.90

0.64

0.50

0.52

0.71

0.79

1.60

1.60

1.76

1.70

2.00

1.80

0.39

0.42

0.50

0.50

0.72

0.77

0.80

0.75

1.00

0.82

BRONZE

L0410

L0515

1/40

1/25

0.55

0.84

0.37

0.51

L0410

L0609

L0710

L0515

L0435

L1111

L1130

L1614

L1034

L1121

1/40

1/35

1/25

1/25

1/8

1/8

1/8

1/8

1/6

1/8

0.52

0.52

0.71

0.79

1.40

1.10

1.90

1.57

2.00

1.45

0.36

0.42

0.42

0.46

0.70

0.55

0.90

0.70

1.00

0.73

CAST IRON

Dimensional Data

Page 15

Circulator Dimensions & Weights

A

Ship Wt.

Model

Connection in. mm in. mm in. mm in. mm in. mm in. mm lbs. Kg

BRONZE

L0410

L0515

1/2, 3/4 swt.

3/4 swt.

6

6-1/2

152

165

4-7/8

4-9/16

124

116

2-3/16

3-3/16

56

81

2-15/16

2-15/16

75

75

3-5/16

4-11/16

84

119

4-3/8

6-3/8

111

162

6

9

2.7

4.0

2-15/16

2-15/16

2-15/16

2-15/16

3-3/8

3-5/16

3-5/16

3-5/16

3-7/8

3-5/16

75

75

75

75

86

84

84

84

98

84

5

5

5

5

5-1/2

5-3/8

5-1/2

6

6

5-1/2

127

127

127

127

140

137

140

152

152

140

6-3/8

6-3/8

6-3/8

6-3/8

6-3/8

6-3/8

6-1/2

8-1/2

6-1/2

6-1/2

162

162

162

162

162

162

165

216

165

165

7

8

8

9

9.5

10

12

14

12.5

13

3.2

3.6

3.6

4.0

4.3

4.5

5.5

6.3

5.7

5.9

CAST IRON

L0410

L0609

L0710

L0515

L0435

L1111

L1130

L1614

L1034

L1121

6-1/4

5-5/8

5-7/8

5-15/16

7

7-1/4

7-1/2

8-1/16

7-1/2

7-1/4

Flanged

Flanged

Flanged

Flanged

Flanged

Flanged

Flanged

Flanged

Flanged

Flanged

159

143

149

151

178

184

191

205

191

184

4-3/8

4

4-1/2

4-1/2

5-11/16

5-5/16

6-1/8

6-3/8

6-3/8

5-3/4

111

102

114

114

144

135

156

162

162

146

3-3/16

3-3/16

3-3/16

3-3/16

3-3/16

3-3/16

3

4-1/4

3

3-1/4

81

81

81

81

81

81

76

108

76

83

D

F

C

E

A

Flanged Models

B

Sweat Connection Models

Performance Curves

Page 16

60 Hz Performance Curves

LOADMATCH CIRCULATOR MODELS

60hz

FLOW-M3/H

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

6.5

7.0

7.5

8.0

8.5

9.0

10.0

9.5

LEGEND

32

2

28

26

24

5

7

22

6

7

11

20

18

16

14

10

11

12

12

12

9.0

L0410F

L0410B

L0609

L0710

L0515F

L0515B

L0435

L1111

L1130

L1614

L1034

L1121

30

TOTAL HEAD-FEET

9.5 10.0 10.5

8.5

8.0

7.5

7.0

6.5

6.0

5.5

5.0

4.5

4.0

3.5

3.0

10

10

2.5

2.0

1.5

1.0

3

0.5

2

0

TOTAL HEAD-METERS

0.0

34

0.0

0

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

FLOW-GPM

50 Hz Performance Curves

50hz

FLOW-M3/H

0.0

24

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

7.0

LEGEND

22

1

2

20

18

4

11

16

TOTAL HEAD-FEET

6.5

6

7

10

14

8

9

12

10

10

11

12

12

L0410F

L0410B

L0609

L0710

L0515F

L0515B

L0435

L1111

L1130

L1614

L1034

L1121

6.5

6.0

5.5

5.0

4.5

4.0

3.5

3.0

2.5

10

6

2.0

2

4

1.5

1.0

2

0

0.5

0

10

12

14

16

FLOW-GPM

18

20

22

24

26

28

30

0.0

TOTAL HEAD-METERS

LOADMATCH CIRCULATOR MODELS

Mechanical Specifications

Page 17

Part I

General

1.1

by a professional engineer. This

schematic shall show the entering

and leaving temperature, load,

and flow at every terminal unit.

B.

In addition the prior approval

package shall include an owner

contact list for 50 single pipe

distribution jobs this manufacturer

has successfully installed over

the last five years. A system

performance guarantee shall

also be provided along with

manufacturers liability policy

cover page. This entire package

must be received 10 days

prior to bid. Only written approval

issued via addendum will be

notification of vendor approval.

No verbal approvals will

be acknowledged.

WORK INCLUDED

A. This Section governs the

materials and installation

of closed hydronic systems

associated with building

heating and cooling.

The following systems, where

applicable, shall be installed

as specified herein.

Hot Water Heating System

Chilled Water Cooling System

Dual Temperature Water System

Heat Pump Circulating System

Closed Circuit Cooling Tower System

Run-Around Heat Recovery System

1.3

1.2

TESTING & APPROVING AGENCIES

EQUIPMENT SUBSTITUTION

A.

A.

All items eligible for substitution

require submission of request for

substitution 10 days prior to

bid date. This submittal shall

include specific models and

capacities of equipment and

not just manufacturers literature.

The prior approval request

package shall also include

an engineered flow schematic

showing that the manufacturer

has a detailed understanding of

the temperature cascade.

This schematic shall be sealed

Where items of equipment are

required to be provided with

compliance to U.L., A.G.A., or

other testing and approving

agencies, the contractor may

submit a written certification

from any nationally recognized

testing agency, adequately

equipped and competent to

perform such services, that the

item of equipment has been

tested and conforms to the same

method of test as the listed

agency would conduct.

1.4

SUBMITTAL DATA

A. See Section 15000 for general

submittal requirements.

B.

Provide manufacturers literature

for all products specified in this

Section, which will be installed

under this project.

C.

Provide performance curves

for all pumps. Plot the specified

operating point for each pump

on its respective curve.

D.

Provide complete literature for

all components of packaged

systems. These include pump

performance, heat exchanger

calculations, expansion tank

capacity, data for all accessories

and valves and complete wiring

diagrams specific to the exact

unit to be supplied.

The wiring diagram shall indicate all

required field and factory wiring.

E.

The submittal package shall

include the engineered flow

schematic as described in the

substitution section.

Mechanical Specifications

Part 2

Products

2.1

SYSTEM

The LoadMatch distribution system

shall include circulators, twin tees,

design suite of software, and system

guarantee. All the components shall

be manufactured by a single source

and that company shall provide a

system guarantee. The manufacturer

shall have a minimum of 50 single

pipe distribution jobs installed

within the last five years.

4. The circulator shall incorporate a

removable integral spring loaded

flow check to eliminate fluid

circulation when the pump is off.

A. LoadMatch Circulator.

5. The circulator shall incorporate

an integral condensate baffle

to eliminate condensation

on the motor housing when

supplying chilled water.

Alternative manufacturing

processes that delay the effect

of condensation versus

preventing it shall not be

allowed. Specifically extra

coating on the windings

is not acceptable.

1. Circulators shall be Taco Model

LoadMatch circulator or

approved equal.

6. Circulator shall be rated for

200 psi working pressure

at 220F fluid temperature.

2. The circulator shall be

water lubricated, direct drive,

requiring no seals, couplers

or bearing assembly.

Ceramic shaft and carbon

bearing construction shall

be capable of running without

fluid for 10 days without

damage to shaft or bearings.

7. An integral variable speed drive

(VSD) shall accept a 0-10 VDC

or 4-20 MA modulating control

signal to control the speed of the

circulator motor. VSD shall

incorporate an exercise sequence

to run the pump for 20 seconds

if there has been no run signal

for 72 hours.

3. The circulator shall be repairable

in-line without removal of the

circulator from the piping using

a stainless steel replaceable

cartridge. Circulator shall be

provided with a 3 year warranty.

8. Circulator shall bear UL label.

9. The manufacturer shall guarantee

system operation for

one full heating season and

one full cooling season,

Page 18

to the extent that the HVAC system

shall deliver the heating and

cooling capacities as specified.

The value of the guarantee shall be

equal to the value of retrofitting the

system to a two-pipe system.

B. Twin Tee

1. Tee fittings for terminal unit

tie-in to system distribution

piping shall be Taco Twin-Tee.

2. Twin-Tee fittings shall be made

of ductile iron or bronze and

shall be rated for 200 psi.

3. The fitting shall be manufactured

with two system connections

and two terminal unit

connections. The system

connections shall be offered

in three types: sweat, threaded,

and grooved. Terminal unit

connections shall all be threaded.

4. The fitting shall include an

internal baffle that prevents

short circuiting of the terminal

unit fluid from inlet to outlet.

C. Design software for

temperature cascade

1. Manufacturer shall provide,

as part of the system, a software

package that allows the

construction team to design,

Mechanical Specifications

Page 19

document, and manage the

temperature cascade in a single

pipe distribution system. This

software shall produce a flow

diagram that sizes all equipment

and pipe based on input loads

and temperature differentials.

The software shall document all

of these design calculations in

a flow schematic. The flow

schematic shall show all loads,

entering and leaving

temperatures, and flow for

each terminal unit. In the case

of dual temperature systems

and heat pumps, it shall

document datafor both

heating and cooling modes.

D. System Guarantee

1. The manufacturer shall provide

a written letter of guarantee

certifying the performance of

the entire system.

This includes but is not limited

to terminal unit performance.

Part 3

Execution

3.1 PUMPS

A. General

1. All pumps, other than

circulators, shall be fitted

with a multi-purpose or

balancing valve or other

means of providing

system balance.

2. All pumps shall be fitted with

instrument test port on inlet and

outlet ports unless otherwise

indicated.

3. All pump groups (over one pump

in parallel) on a single system

shall utilize a check valve on the

outlet to prevent reverse flows.

B. Circulator

1.

Circulator shall be mounted with

motor in horizontal position.

It may be mounted vertically

with motor up provided the

system pressure is minimum

of 20 psig.

Taco Catalog #100-9.9

Supersedes: 01/10/08

Effective Date: 03/27/14

Printed in USA

Contact Us

Taco engineers are at the forefront of

Green Building hydronics, designing

components and systems to help you

meet the challenges of environmentally

sensitive and budget conscious

design and build. Visit our web site

at www.taco-hvac.com for more

information or call us to talk to a Taco

Green Building professional.

www.taco-hvac.com

Taco Inc., 1160 Cranston Street, Cranston, RI 02920 / (401) 942-8000 / Fax (401) 942-2360

Taco (Canada) Ltd., 8450 Lawson Road, Unit #3, Milton, Ontario L9T 0J8 / (905) 564-9422 / Fax (905) 564-9436

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Wind Turbine Vestas - V47Dokument6 SeitenWind Turbine Vestas - V47سامح الجاسمNoch keine Bewertungen

- Epsirend FT - Smooth Finish: Epsirend (FT) Render Onto New / Existing Block-WorkDokument1 SeiteEpsirend FT - Smooth Finish: Epsirend (FT) Render Onto New / Existing Block-Workسامح الجاسمNoch keine Bewertungen

- Wind Turbine MaintenanceV47Dokument4 SeitenWind Turbine MaintenanceV47سامح الجاسمNoch keine Bewertungen

- VestasOperatingManual 1Dokument37 SeitenVestasOperatingManual 1سامح الجاسمNoch keine Bewertungen

- Epsitec (SFS, EPS Insulation, Silicone) : Wbs Roughcast Onto New / Existing Block-WorkDokument1 SeiteEpsitec (SFS, EPS Insulation, Silicone) : Wbs Roughcast Onto New / Existing Block-Workسامح الجاسمNoch keine Bewertungen

- Carrier Brochure en 2017Dokument72 SeitenCarrier Brochure en 2017سامح الجاسمNoch keine Bewertungen

- Wbs Brick Effect Render Onto New / Existing BlockworkDokument2 SeitenWbs Brick Effect Render Onto New / Existing Blockworkسامح الجاسمNoch keine Bewertungen

- Industrial Heat Flux SensorDokument27 SeitenIndustrial Heat Flux Sensorسامح الجاسمNoch keine Bewertungen

- Wbs Dry Dash Finish Onto New / Exist-Ing BlockworkDokument1 SeiteWbs Dry Dash Finish Onto New / Exist-Ing Blockworkسامح الجاسمNoch keine Bewertungen

- Rotary Comp PDFDokument44 SeitenRotary Comp PDFسامح الجاسمNoch keine Bewertungen

- Direct Steam Injection HumidifierDokument41 SeitenDirect Steam Injection Humidifierسامح الجاسم100% (1)

- Condensing Dehumidifier ManualDokument44 SeitenCondensing Dehumidifier Manualسامح الجاسمNoch keine Bewertungen

- Humidification and Evaporative Cooling SystemsDokument106 SeitenHumidification and Evaporative Cooling Systemsسامح الجاسمNoch keine Bewertungen

- Steam Humidification Systems ManualDokument52 SeitenSteam Humidification Systems Manualسامح الجاسمNoch keine Bewertungen

- User Manual Hf03-Li19: HuksefluxDokument25 SeitenUser Manual Hf03-Li19: Huksefluxسامح الجاسمNoch keine Bewertungen

- Self-Calibrating Heat Flux SensorDokument39 SeitenSelf-Calibrating Heat Flux Sensorسامح الجاسمNoch keine Bewertungen

- Flare Radiation MonitorDokument27 SeitenFlare Radiation Monitorسامح الجاسمNoch keine Bewertungen

- User Manual: HFP01 & HFP03Dokument43 SeitenUser Manual: HFP01 & HFP03سامح الجاسمNoch keine Bewertungen

- Heat Flux and Temperature SensorDokument23 SeitenHeat Flux and Temperature Sensorسامح الجاسمNoch keine Bewertungen

- Needle Type Heat Flux and Temperature SensorDokument31 SeitenNeedle Type Heat Flux and Temperature Sensorسامح الجاسمNoch keine Bewertungen

- Rock Valve BrochureDokument8 SeitenRock Valve Brochureسامح الجاسمNoch keine Bewertungen

- LoadMatch Temperature Cascade2Dokument3 SeitenLoadMatch Temperature Cascade2سامح الجاسمNoch keine Bewertungen

- Heat Flux SenserDokument35 SeitenHeat Flux Senserسامح الجاسمNoch keine Bewertungen

- User Manual: RHF SeriesDokument21 SeitenUser Manual: RHF Seriesسامح الجاسمNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Draft HandbookDokument122 SeitenDraft HandbookKumar SaurabhNoch keine Bewertungen

- The Hitler EscapeDokument13 SeitenThe Hitler EscapeincroyablNoch keine Bewertungen

- 6sec.600 (Concrete Pavement)Dokument35 Seiten6sec.600 (Concrete Pavement)aalignup arc & const. pvt ltdNoch keine Bewertungen

- S1917301-Application of Colours and Safety ColoursDokument19 SeitenS1917301-Application of Colours and Safety Coloursram27_rajiNoch keine Bewertungen

- ASF Act 1975 (Amd Dec 2012)Dokument10 SeitenASF Act 1975 (Amd Dec 2012)yusha habibNoch keine Bewertungen

- Eurocode 1 Part 1,7 - prEN 1991-1-7-2003Dokument69 SeitenEurocode 1 Part 1,7 - prEN 1991-1-7-2003afqan1100% (1)

- John Deere 210G, 210GLC (PIN. 1FF210GX-E520001-) IT4 - S3B Excavator (TM12333) Shop ManualDokument594 SeitenJohn Deere 210G, 210GLC (PIN. 1FF210GX-E520001-) IT4 - S3B Excavator (TM12333) Shop Manualjessica lima100% (1)

- Executive Summary:: Name of The State Name of The DistrictDokument25 SeitenExecutive Summary:: Name of The State Name of The DistrictAchinta_b11Noch keine Bewertungen

- Tractors FiatDokument523 SeitenTractors Fiatomni_parts100% (2)

- Rail TicketDokument3 SeitenRail TicketRohit SharmaNoch keine Bewertungen

- Motor 08L20 GovernorDokument16 SeitenMotor 08L20 GovernorLucas NevesNoch keine Bewertungen

- Dokumen - Tips - Adeverinta Concediu PT Soferi Tir Tip Arr Engleza 56327abfc6454Dokument1 SeiteDokumen - Tips - Adeverinta Concediu PT Soferi Tir Tip Arr Engleza 56327abfc6454Alex GhimiciNoch keine Bewertungen

- Topic: Circular MotionDokument2 SeitenTopic: Circular MotionDhanBahadurNoch keine Bewertungen

- VTS CommunicationDokument8 SeitenVTS CommunicationRanggaSuryaA.SetyaNoch keine Bewertungen

- University of SarajevoDokument22 SeitenUniversity of Sarajevoamelaa_kNoch keine Bewertungen

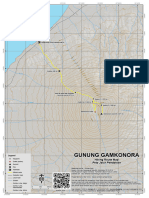

- Peta Jalur Pendakian Gunung GamkonoraDokument1 SeitePeta Jalur Pendakian Gunung GamkonoraMuhammad Radima RahmadNoch keine Bewertungen

- Maintenance Interval Schedule: SMCS Code: 7000Dokument4 SeitenMaintenance Interval Schedule: SMCS Code: 7000wilbert tapia maqueraNoch keine Bewertungen

- Volkswagen TouranDokument13 SeitenVolkswagen Tourantemujin93Noch keine Bewertungen

- China-Pakistan Economic Corridor: Opportunities and Challenges For PakistanDokument17 SeitenChina-Pakistan Economic Corridor: Opportunities and Challenges For Pakistanوقاص صارمNoch keine Bewertungen

- 08 Star Trek Comic Strip US - Its A LivingDokument27 Seiten08 Star Trek Comic Strip US - Its A LivingColin NaturmanNoch keine Bewertungen

- NU Invoice PDFDokument2 SeitenNU Invoice PDFThamizhvanan RaviNoch keine Bewertungen

- Product CatalogueDokument124 SeitenProduct CatalogueRaron1Noch keine Bewertungen

- Service Bulletin M-1107 Strator RelocationDokument2 SeitenService Bulletin M-1107 Strator RelocationDosenwurstNoch keine Bewertungen

- 1mesh TrackDokument92 Seiten1mesh TrackAbdon CastroNoch keine Bewertungen

- PS Order Revised Packing List 16-05-2023Dokument54 SeitenPS Order Revised Packing List 16-05-2023aman.dubey.resNoch keine Bewertungen

- Weekly Movement PLAN (To Be: Filled-Out When Taking An Advance/TO or OB)Dokument3 SeitenWeekly Movement PLAN (To Be: Filled-Out When Taking An Advance/TO or OB)Marlito Joshua AmistosoNoch keine Bewertungen

- ZF PDFDokument38 SeitenZF PDFluiscterrazas100% (6)

- Pallet Truck wp3000 Spec1 GBDokument6 SeitenPallet Truck wp3000 Spec1 GBEjaz EjazNoch keine Bewertungen

- 8F Forklift Parts: Item FLS# Description App. Model Part# Remark UnitDokument20 Seiten8F Forklift Parts: Item FLS# Description App. Model Part# Remark Unitadam leeNoch keine Bewertungen

- Ca 2013 14Dokument36 SeitenCa 2013 14singh1699Noch keine Bewertungen