Beruflich Dokumente

Kultur Dokumente

W501 - Window Schedule

Hochgeladen von

Ar Hanz Gerome SuarezCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

W501 - Window Schedule

Hochgeladen von

Ar Hanz Gerome SuarezCopyright:

Verfügbare Formate

GENERAL:

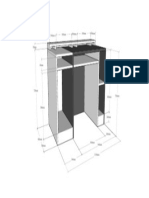

220

900

340

340

250

1200

1200

250

340

600

G1. THE DESIGN ON THIS DRAWING IS COPYRIGHT AND REMAINS THE PROPERTY OF

TONDOLO ARCHITECTS.

G2. THE DRAWING MAY NOT BE COPIED OR REPRODUCED IN WHOLE OR IN PART

WITHOUT THE WRITTEN PERMISSION OF TONDOLO ARCHITECTS.

G3. ANY CONSTRUCTION WORK UNDERTAKEN PRIOR TO MUNICIPAL APPROVAL OF

THE PROJECT SHALL BE UNDERTAKEN AT THE RISK OF THE CLIENT.

G4. ALL WORK TO COMPLY WITH NBR AND BUILDING STANDARDS ACT 103 OF 1977,

SANS 10400 AND SANS 204.

G5. THIS DRAWING IS NOT TO BE SCALED, FIGURED DIMENSIONS PREVAIL.

G6. ALL RELEVANT DETAILS, DIMENSIONS AND LEVELS TO BE CHECKED ON SITE

BEFORE COMMENCEMENT OF ANY WORK. DISCREPANCIES TO BE

IMMEDIATELY REPORTED TO THE ARCHITECT. THE ARCHITECT ACCEPTS NO

RESPONSIBILITY FOR THE MISINTERPRETATION OF DRAWINGS.

G7. SAMPLES OF ALL SPECIFIED PRODUCTS TO BE SUBMITTED FOR APPROVAL TO

THE ARCHITECT BEFORE FITTING ON SITE.

G8. A FULL SET OF THE LATEST DRAWINGS ARE TO BE KEPT AND MAINTAINED ON

SITE FOR REFERENCE.

1500

600

90

1800

DPC

ELEVATION

1200

1500

PC SILL

1200

1200

600

CONSTRUCTION:

C1. REINFORCED CONCRETE, STRUCTURAL STEELWORK INCLUDING CONNECTIONS

OF BALUSTRADES AND LAMINATED BEAMS TO STRUCTURES, LOAD BEARING

MASONRY WALLS AND TIMBER STRUCTURES ALL TO BE IN ACCORDANCE WITH

THE STRUCTURAL ENG'S DESIGN AND SPECS.

C2. ALL MECHANICAL VENTILATION TO BE ACCORDING TO ENG'S DETAILS AND SPECS.

C3. DPC TO ALL WALLS AT FLOOR LEVEL, UNDER WINDOW CILLS, AGAINST

RETAINING WALLS AT CHANGES IN FLOOR LEVELS, BELOW CONCRETE SURFACE

BEDS AND AT JUNCTIONS OF P.C COPINGS.

C4. ALL GLAZING TO BE IN ACCORDANCE WITH SANS 10400 PART N AND SANS 204.

ALL GLAZING, EXCEPT WHERE INDICATED, IS TO BE LAMINATED SAFETY GLASS

PERMANENTLY MARKED WITH GLASS CODE AND READILY VISIBLE.

C5. WINDOW AREA TO BE MINIMUM 10% OF FLOOR AREA. OPENING SECTIONS OF

WINDOWS AND DOORS TO BE MINIMUM 5% OF FLOOR AREA FOR VENTILATION.

250

SECTION

PC SILL

C6. WATERPROOFING OF FLAT ROOFS TO BE UNDERTAKEN ACCORDING TO

MANUFACTURER'S DETAILS AND SPECS.

C7. PITCHED ROOFS WITH STEEL OR TILED COVERING TO BE WATERPROOFED

AGAINST PARAPET WALLS WITH 1.2mm GS FLASHING AND COUNTER FLASHING,

AND ALL JOINTS SEALED ACCORDING TO MANUFACTURER'S DETAILS AND SPECS.

PC SILL

PC SILL

SEWER AND STORM WATER:

DPC

ELEVATION

DPC

ELEVATION

DPC

P1.

ELEVATION

PC SILL

SECTION

SECTION

SECTION

PC SILL

DPC

ELEVATION

P5.

DPC

90

P13. GEYSERS INSTALLED ACCORDING TO MANUFACTURER'S SPECS, WITH A

DRIP TRAY AND TO SABS 0524 REGULATIONS.

P14. MIN. FALL OF 100m LONG DRAINS TO BE 1:60, WITH A MIN. COVER OF 300mm. FALLS

EXCEEDING 1:10 TO BE PROVIDED WITH BACK DROPS.

P15. SOIL DRAINS UNDER GROUND SLABS TO BE FITTED IN PC CHAMBER FILLED WITH

CRUSHED STONE AND PC COVER WITHOUT CHANGES IN DIRECTION. NO SEWER IS

TO BE CAST IN FOUNDATION FOOTING.

340

90

340

250

340

250

630

1230

930

1530

615

PLAN

VENT. PIPES TO EXTEND 2m ABOVE ANY WINDOW OR DOOR OPENING IN THE

BUILDING OR ANY OTHER BUILDING WITHIN A DISTANCE OF 6m.

IE TO ALL BENDS AND JUNCTIONS OF SOIL AND WASTE PIPES.

RE TO HEADS OF DRAINS AND AT A MAX 25m INTERVALS ALONG RUNS OF DRAINS.

RESEAL TRAPS TO ALL WASTE FITTINGS.

CI COVERS AT GROUND LEVEL FITTED IE AND RE MANHOLES

SECTION

340

340

P6.

P7.

P8.

P9.

ELEVATION

250

SECTION

1230

ALL PLUMBING WORK TO BE CARRIED OUT BY LICENSED PLUMBERS AND WORK

TO COMPLY WITH SANS 10400 P.

ALL DRAINAGE RUNS TO BE ACCESSIBLE ALONG THEIR ENTIRE LENGTH.

ALL HOT AND COLD WATER RETICULATION, BULK SEWER AND STORM WATER

COLLECTION TO BE ACCORDING TO ENG'S DETAILS AND SPECS.

P2.

P3.

PLAN

PLAN

PLAN

PLAN

P17. ALL BRANCH DRAINS EXCEEDING 6m IN LENGTH TO BE VENTED.

P18. uPVC SEWER PIPES TO SABS 791 CLASS 34 STANDARDS AND LAID IN

ACCORDANCE WITH THE MANUFACTURER'S DETAILS AND SPEC.

P19. HOT AND COLD WATER PIPES FOR INTERNAL RETICULATION TO BE CLASS 1

COPPER TUBING AND INSULATED ACCORDING TO SANS 204.

PLAN

FIRE PROTECTION:

F1.

F2.

ALL WORK TO COMPLY WITH SABS 0400-1990, OCCUPANCY CLASSIFICATION E2.

INSTALLATION OF FIRE EQUIPMENT TO BE ACCORDING TO SABS 0105 FOR

EXTINGUISHERS, SABS 543 FOR FIRE HOSE REELS AND SABS 1128 PART 1

FOR HYDRANTS.

STRUCTURAL ELEMENTS AND COMPONENTS TO COMPLY WITH REQUIREMENTS

AS SPECIFIED IN THE RATIONAL FIRE REPORT AND SANS 10400-T 4.7,

AND TO HAVE FIRE STABILITY OF MIN. 120 MINUTES.

QUANTITY REQUIRED:

DESCRIPTION:

38mm WIDE ALUMINIUM PROFILE TYPE: FT4000.

38mm WIDE ALUMINIUM PROFILE TYPE: FT4000.

CODE: CUSTOM

38mm WIDE ALUMINIUM PROFILE TYPE: FT4000.

CODE: PTT 612

38mm WIDE ALUMINIUM PROFILE TYPE: FT4000.

CODE: PT 126

38mm WIDE ALUMINIUM PROFILE TYPE: FT4000.

CODE: PTT 612

38mm WIDE ALUMINIUM PROFILE TYPE: FT4000.

CODE: PT 918

THE PRODUCT MUST HAVE PASSED THE MINIMUM

PERFORMANCE REQUIREMENTS AS PUBLISHED BY AAAMSA

HS-B2. CORNERS OF SASH AND FRAME TO BE MITRED AND

CRIMPED WITH ALUMINIUM CORNER CLEATS. SEALANT TO

BE APPLIED TO ALL MATING SURFACES AND TO GLAZING

REBATES. ALL JOINTS TO BE SELF-ALIGNING, RIGID, AND

WATER TIGHT. ALL FASTENING DEVICES TO BE

NON-CORROSIVE MATERIAL COMPATABLE WITH ALUMINIUM.

THE PRODUCT MUST HAVE PASSED THE MINIMUM PERFORMANCE REQUIREMENTS

AS PUBLISHED BY AAAMSA HS-B2. CORNERS OF SASH AND FRAME TO BE MITRED

AND CRIMPED WITH ALUMINIUM CORNER CLEATS. SEALANT TO BE APPLIED TO ALL

MATING SURFACES AND TO GLAZING REBATES. ALL JOINTS TO BE SELF-ALIGNING,

RIGID, AND WATER TIGHT. ALL FASTENING DEVICES TO BE NON-CORROSIVE

MATERIAL COMPATABLE WITH ALUMINIUM.

THE PRODUCT MUST HAVE PASSED THE MINIMUM PERFORMANCE

REQUIREMENTS AS PUBLISHED BY AAAMSA HS-B2.

CORNERS OF SASH AND FRAME TO BE MITRED AND CRIMPED WITH

ALUMINIUM CORNER CLEATS. SEALANT TO BE APPLIED TO ALL

MATING SURFACES AND TO GLAZING REBATES. ALL JOINTS TO BE

SELF-ALIGNING, RIGID, AND WATER TIGHT. ALL FASTENING

DEVICES TO BE NON-CORROSIVE MATERIAL COMPATABLE WITH

ALUMINIUM.

THE PRODUCT MUST HAVE PASSED THE MINIMUM PERFORMANCE

REQUIREMENTS AS PUBLISHED BY AAAMSA HS-B2.

CORNERS OF SASH AND FRAME TO BE MITRED AND CRIMPED WITH

ALUMINIUM CORNER CLEATS. SEALANT TO BE APPLIED TO ALL

MATING SURFACES AND TO GLAZING REBATES. ALL JOINTS TO BE

SELF-ALIGNING, RIGID, AND WATER TIGHT. ALL FASTENING

DEVICES TO BE NON-CORROSIVE MATERIAL COMPATABLE WITH

ALUMINIUM.

THE PRODUCT MUST HAVE PASSED THE MINIMUM PERFORMANCE REQUIREMENTS AS PUBLISHED

BY AAAMSA HS-B2. CORNERS OF SASH AND FRAME TO BE MITRED AND CRIMPED WITH ALUMINIUM

CORNER CLEATS. SEALANT TO BE APPLIED TO ALL MATING SURFACES AND TO GLAZING REBATES.

ALL JOINTS TO BE SELF-ALIGNING, RIGID, AND WATER TIGHT. ALL FASTENING DEVICES TO BE

NON-CORROSIVE MATERIAL COMPATABLE WITH ALUMINIUM.

THE PRODUCT MUST HAVE PASSED THE MINIMUM PERFORMANCE

REQUIREMENTS AS PUBLISHED BY AAAMSA HS-B2.

CORNERS OF SASH AND FRAME TO BE MITRED AND CRIMPED WITH ALUMINIUM

CORNER CLEATS. SEALANT TO BE APPLIED TO ALL MATING SURFACES AND TO

GLAZING REBATES. ALL JOINTS TO BE SELF-ALIGNING, RIGID, AND WATER

TIGHT. ALL FASTENING DEVICES TO BE NON-CORROSIVE MATERIAL

COMPATABLE WITH ALUMINIUM.

FRAME FINISH:

25 MICRONS POWDER COATED BLACK FINISH TO SABS SPEC

25 MICRONS POWDER COATED BLACK FINISH TO SABS SPEC

25 MICRONS POWDER COATED BLACK FINISH TO SABS SPEC

25 MICRONS POWDER COATED BLACK FINISH TO SABS SPEC

25 MICRONS POWDER COATED BLACK FINISH TO SABS SPEC

25 MICRONS POWDER COATED BLACK FINISH TO SABS SPEC

PORTABLE FIRE EXTINGUISHERS TO BE HUNG ON PURPOSE MADE BOARDS AND

FIXED IN SECURE POSITIONS AS INDICATED ON THE PLAN AT A HEIGHT NOT

EXCEEDING 750mm.

F6. FIRE HYDRANTS TO INCLUDE 75mm PILLAR WITH DOUBLE HEADED BOOSTER

CONNECTION, PRESSURE GAUGE AND NON-RETURN VALVE TO ENG. SPECS.

F7. SMOKE CONTROL AND DETECTION INSTALLED ACCORDING TO ENG'S DETAIL

AND SPEC. AND RATIONAL FIRE DESIGN REPORT.

F8. EMERGENCY LIGHTING TO BE INSTALLED ACCORDING TO THE ENG'S SPECS.

F9. SYMBOLIC SAFETY SIGNS TO BE IN ACCORDANCE WITH SABS CODE 1186 AND

POSITIONED AS REQUIRED BY THE FIRE DEPARTMENT.

F10. FIRE DOORS TO BE FITTED WITH EMERGENCY EXIT LOCKSETS.

F11. CLASS B FIRE DOORS TO COMPLY WITH SABS CODE 1253 AND TO BE FITTED

WITH APPROVED SELF-CLOSING OR AUTOMATIC CLOSING DEVICES.

GLAZING:

W1 - 3+3mm LAMINATED OBSCURE GLASS. W4 - 3+3mm LAMINATED

CLEAR FLOAT GLASS. GLAZING TO COMPLY TO NATIONAL

BUILDING REGULATIONS PART N.

W1 - 200x200mm CERAMIC WALL TILES, W4 - 15x150mm FIBRE

CEMENT INTERNAL SILL FIXED WITH LUGS, PRIMED AND 2 COATS

ENAMEL PAINT, COLOR TO ARCH SPEC.

PRECAST CONCRETE EXTERNAL SILL. CODE: DI, TYPE: WATCRETE.

3+3mm LAMINATED CLEAR FLOAT GLASS. GLAZING TO COMPLY TO NATIONAL

BUILDING REGULATIONS PART N.

3+3mm LAMINATED CLEAR FLOAT GLASS. GLAZING TO COMPLY TO

NATIONAL BUILDING REGULATIONS PART N.

3+3mm LAMINATED CLEAR FLOAT GLASS. GLAZING TO COMPLY TO

NATIONAL BUILDING REGULATIONS PART N.

3+3mm LAMINATED CLEAR FLOAT GLASS. GLAZING TO COMPLY TO NATIONAL BUILDING

REGULATIONS PART N.

3+3mm LAMINATED CLEAR FLOAT GLASS. GLAZING TO COMPLY TO NATIONAL

BUILDING REGULATIONS PART N.

E1.

E2.

15x150mm FIBRE CEMENT INTERNAL SILL FIXED WITH LUGS, PRIMED AND 2 COATS

ENAMEL PAINT, COLOR TO ARCH SPEC.

200x200mm CERAMIC WALL TILES, COLOR TO ARCH SPEC.

15x150mm FIBRE CEMENT INTERNAL SILL FIXED WITH LUGS,

PRIMED AND 2 COATS ENAMEL PAINT, COLOR TO ARCH SPEC.

15x150mm FIBRE CEMENT INTERNAL SILL FIXED WITH LUGS, PRIMED AND 2 COATS ENAMEL PAINT,

COLOR TO ARCH SPEC.

15x150mm FIBRE CEMENT INTERNAL SILL FIXED WITH LUGS, PRIMED AND

2 COATS ENAMEL PAINT, COLOR TO ARCH SPEC.

PRECAST CONCRETE EXTERNAL SILL. CODE: DI, TYPE: WATCRETE.

PRECAST CONCRETE EXTERNAL SILL. CODE: DI, TYPE: WATCRETE. PRECAST CONCRETE EXTERNAL SILL. CODE: K, TYPE: WATCRETE.

PRECAST CONCRETE EXTERNAL SILL. CODE: DI, TYPE: WATCRETE.

PRECAST CONCRETE EXTERNAL SILL. CODE: DI, TYPE: WATCRETE.

BURGLAR PROOFING:

NIL

NIL

IRONMONGERY:

FACTORY FITTED WITH ALUMINIUM HANDLES, 400mm S.S (SUS 304) FACTORY FITTED WITH ALUMINIUM HANDLES, 400mm S.S (SUS 304) HEAVY DUTY FLAT

HEAVY DUTY FLAT FRICTION STAYS FOR A TOP HUNG WINDOW.

FRICTION STAYS FOR A SIDE HUNG WINDOW.

CODE: PS 1512

F3.

F5.

MOVEMENT JOINTS

GRILL TO ARCH DETAIL ON THE OUTSIDE OF WINDOW FRAME.

220

250

1500

1200

600

600

600

PC SILL

1500

DPC

ELEVATION

FACTORY FITTED WITH ALUMINIUM HANDLES, 400mm S.S (SUS 304) HEAVY DUTY

FLAT FRICTION STAYS FOR A TOP HUNG WINDOW.

250

600

PC SILL

ELEVATION

NIL

250

220

600

600

NIL

FACTORY FITTED WITH ALUMINIUM HANDLES, 400mm S.S (SUS 304) HEAVY DUTY FLAT FRICTION

STAYS FOR A SIDE HUNG WINDOW.

FOR TENDER ONLY

NIL

FACTORY FITTED WITH ALUMINIUM HANDLES, 400mm S.S (SUS 304) FACTORY FITTED WITH ALUMINIUM HANDLES, 400mm S.S (SUS 304)

HEAVY DUTY FLAT FRICTION STAYS FOR A TOP HUNG WINDOW.

HEAVY DUTY FLAT FRICTION STAYS FOR A TOP HUNG WINDOW.

PC SILL

DPC

ELEVATION

DPC

SECTION

SECTION

TIMBER

W1. TIMBER WALL PLATES TO BE TANALIZED.

W2. STRUCTURAL TIMBER TO BE IN ACCORDANCE WITH SABS 1245 AND MARKED WITH

STRESS GRADE. LAMINATED TIMBER TO COMPLY WITH SABS 1460

W3. THE CONTRACTOR TO PROTECT ALL TIMBER MATERIALS AGAINST WEATHER

W4. TRUSS HOLD-DOWN, CONNECTIONS, HANGERS AND CLEATS TO BE IN

ACCORDANCE WITH ENG'S DETAILS AND SPEC.

W5. THE CONTRACTOR TO CHECK CORRECT FIXING OF ALL SPECIFIED BRACING

W6. ALL TRUSSES AND TIMBER LOAD BEARING STRUCTURES TO BE IN ACCORDANCE

TO ENG'S DETAIL & SPECS. INCLUDING TRUSS HOLD-DOWN, CONNECTIONS,

HANGERS AND CLEATS.

45

EXTERNAL SILL:

600

INTERNAL SILL:

ALL MOVEMENT JOINTS ACCORDING TO ENG'S DETAIL AND SPEC.

NO STRUCTURAL, FLOOR OR WALL FINISH TO BE TAKEN OVER EXPANSION JOINTS.

SECTION

38

REV DATE

DESCRIPTION

PC SILL

THIS DRAWING IS COPYRIGHT OF TONDOLO PARTNERSHIP

TYPICAL 45x38mm ALUMINIUM

WINDOW PROFILE, MINIMUM

THICKNESS 2mm.

DPC

ELEVATION

PC SILL

SECTION

ELEVATION

ALUMNIUM PROFILE DETAIL

DPC

SCALE 1 : 1

1530

600

PLAN

630

630

PLAN

W18, W19, W20, W21, W22, W27, W28, W29,

W23, W24, W36, W37, W38, W39, W40.

W30, W31, W32, W33, W34, W35.

QUANTITY REQUIRED:

14

DESCRIPTION:

38mm WIDE ALUMINIUM PROFILE TYPE: FT4000.

600x600mm ALUMINIUM LOUVER

38mm WIDE ALUMINIUM PROFILE TYPE: FT4000.

CODE: PS 612

38mm WIDE ALUMINIUM PROFILE TYPE: FT4000.

CODE: PT 66

38mm WIDE ALUMINIUM PROFILE TYPE: FT4000.

CODE: PT 66

THE PRODUCT MUST HAVE PASSED THE MINIMUM

PERFORMANCE REQUIREMENTS AS PUBLISHED BY AAAMSA

HS-B2. CORNERS OF SASH AND FRAME TO BE MITRED AND

CRIMPED WITH ALUMINIUM CORNER CLEATS. SEALANT TO BE

APPLIED TO ALL MATING SURFACES AND TO GLAZING REBATES.

ALL JOINTS TO BE SELF-ALIGNING, RIGID, AND WATER TIGHT.

ALL FASTENING DEVICES TO BE NON-CORROSIVE MATERIAL

COMPATABLE WITH ALUMINIUM.

THE PRODUCT MUST HAVE PASSED THE MINIMUM PERFORMANCE

REQUIREMENTS AS PUBLISHED BY AAAMSA HS-B2.

CORNERS OF SASH AND FRAME TO BE MITRED AND CRIMPED WITH

ALUMINIUM CORNER CLEATS. SEALANT TO BE APPLIED TO ALL MATING

SURFACES AND TO GLAZING REBATES. ALL JOINTS TO BE

SELF-ALIGNING, RIGID, AND WATER TIGHT. ALL FASTENING DEVICES TO

BE NON-CORROSIVE MATERIAL COMPATABLE WITH ALUMINIUM.

THE PRODUCT MUST HAVE PASSED THE MINIMUM PERFORMANCE

REQUIREMENTS AS PUBLISHED BY AAAMSA HS-B2.

CORNERS OF SASH AND FRAME TO BE MITRED AND CRIMPED WITH

ALUMINIUM CORNER CLEATS. SEALANT TO BE APPLIED TO ALL MATING

SURFACES AND TO GLAZING REBATES. ALL JOINTS TO BE

SELF-ALIGNING, RIGID, AND WATER TIGHT. ALL FASTENING DEVICES TO

BE NON-CORROSIVE MATERIAL COMPATABLE WITH ALUMINIUM.

THE PRODUCT MUST HAVE PASSED THE MINIMUM PERFORMANCE

REQUIREMENTS AS PUBLISHED BY AAAMSA HS-B2.

CORNERS OF SASH AND FRAME TO BE MITRED AND CRIMPED WITH

ALUMINIUM CORNER CLEATS. SEALANT TO BE APPLIED TO ALL MATING

SURFACES AND TO GLAZING REBATES. ALL JOINTS TO BE

SELF-ALIGNING, RIGID, AND WATER TIGHT. ALL FASTENING DEVICES TO

BE NON-CORROSIVE MATERIAL COMPATABLE WITH ALUMINIUM.

25 MICRONS POWDER COATED BLACK FINISH TO SABS SPEC

CODE: PS 1512

THE PRODUCT MUST HAVE PASSED THE MINIMUM PERFORMANCE REQUIREMENTS AS

PUBLISHED BY AAAMSA HS-B2. CORNERS OF SASH AND FRAME TO BE MITRED AND CRIMPED

WITH ALUMINIUM CORNER CLEATS. SEALANT TO BE APPLIED TO ALL MATING SURFACES

AND TO GLAZING REBATES. ALL JOINTS TO BE SELF-ALIGNING, RIGID, AND WATER TIGHT. ALL

FASTENING DEVICES TO BE NON-CORROSIVE MATERIAL COMPATABLE WITH ALUMINIUM.

FRAME FINISH:

25 MICRONS POWDER COATED BLACK FINISH TO SABS SPEC

25 MICRONS POWDER COATED BLACK FINISH TO SABS SPEC

25 MICRONS POWDER COATED BLACK FINISH TO SABS SPEC

25 MICRONS POWDER COATED BLACK FINISH TO SABS SPEC

GLAZING:

3+3mm LAMINATED CLEAR FLOAT GLASS. GLAZING TO COMPLY TO NATIONAL BUILDING

REGULATIONS PART N.

NIL

3+3mm LAMINATED CLEAR FLOAT GLASS. GLAZING TO COMPLY TO

NATIONAL BUILDING REGULATIONS PART N.

3+3mm LAMINATED OBSCURE GLASS. GLAZING TO COMPLY TO NATIONAL 3+3mm LAMINATED CLEAR FLOAT GLASS. GLAZING TO COMPLY TO

BUILDING REGULATIONS PART N.

NATIONAL BUILDING REGULATIONS PART N.

INTERNAL SILL:

15x150mm FIBRE CEMENT INTERNAL SILL FIXED WITH LUGS, PRIMED AND 2 COATS ENAMEL

PAINT, COLOR TO ARCH SPEC.

15x150mm FIBRE CEMENT INTERNAL SILL FIXED WITH LUGS,

PRIMED AND 2 COATS ENAMEL PAINT, COLOR TO ARCH SPEC.

15x150mm FIBRE CEMENT INTERNAL SILL FIXED WITH LUGS, PRIMED AND 2

COATS ENAMEL PAINT, COLOR TO ARCH SPEC.

200x200mm CERAMIC WALL TILES, COLOR TO ARCH SPEC.

15x150mm FIBRE CEMENT INTERNAL SILL FIXED WITH LUGS, PRIMED AND

2 COATS ENAMEL PAINT, COLOR TO ARCH SPEC.

EXTERNAL SILL:

PRECAST CONCRETE EXTERNAL SILL. CODE: DI, TYPE: WATCRETE.

PRECAST CONCRETE EXTERNAL SILL. TYPE: DI

PRECAST CONCRETE EXTERNAL SILL. CODE: DI, TYPE: WATCRETE.

PRECAST CONCRETE EXTERNAL SILL. CODE: DI, TYPE: WATCRETE.

PRECAST CONCRETE EXTERNAL SILL. CODE: DI, TYPE: WATCRETE.

BURGLAR PROOFING:

NIL

IRONMONGERY:

FACTORY FITTED WITH ALUMINIUM HANDLES, 400mm S.S (SUS 304) HEAVY DUTY FLAT

FRICTION STAYS FOR A SIDE HUNG WINDOW.

NIL

FACTORY FITTED

NIL

FACTORY FITTED WITH ALUMINIUM HANDLES, 400mm S.S (SUS 304) HEAVY

DUTY FLAT FRICTION STAYS FOR A SIDE HUNG WINDOW.

NIL

NORTH WEST PROVINCIAL

GOVERNMENT

630

PLAN

PLAN

PLAN

CLIENT

250

250

220

220

250

SECTION

NIL

FACTORY FITTED WITH ALUMINIUM HANDLES, 400mm S.S (SUS 304) HEAVY FACTORY FITTED WITH ALUMINIUM HANDLES, 400mm S.S (SUS 304) HEAVY

DUTY FLAT FRICTION STAYS FOR A TOP HUNG WINDOW.

DUTY FLAT FRICTION STAYS FOR A TOP HUNG WINDOW.

DEPARTMENT OF HEALTH

NOTE :

INTERNAL WINDOW CILLS TO BE INSET INTO BRICKWORK

BY MIN 15mm ON EACH SIDE.

PROJECT

PROPOSED NEW COMMUNITY HEALTH

CENTRE IN

MATLOSANA

SANS10400 Specification Requirements Aluminium Windows

1 - All panes to be permanently marked by installer with

glass code made clearly visible.

2 - SAFIERA Certificate of Performance rating for each

window type to be submitted.

3 - All windows to comply with SANS 1263-1 for

security and safety specifications, and with SANS

10137 for installation of glazing specifications.

4 - All windows to comply with SANS 613-2009 for air

infiltration, water penetration and structural strength

specifications.

*

*

*

UNIT

MAIN RECEPTION AND

ADMINISTRATION - UNIT 5

WORKING DRAWINGS

WINDOW SCHEDULE

SCALE

DATE

1:20/1

PROJ NO

2011 / 44

2015.03.20

REV

DATE

DRAWN

*

DRAWING NO

W501

Das könnte Ihnen auch gefallen

- Basic Plumbing SymbolsDokument1 SeiteBasic Plumbing SymbolsBrandon Borromeo75% (4)

- Price Index 2015 PDFDokument14 SeitenPrice Index 2015 PDFLowell ValienteNoch keine Bewertungen

- Estimates Table (Construction)Dokument3 SeitenEstimates Table (Construction)Joe A. Cagas86% (114)

- Requirements For Application For Electric Service ConnectionDokument1 SeiteRequirements For Application For Electric Service ConnectionAr Hanz Gerome SuarezNoch keine Bewertungen

- BP - Res U2 Elect Symbols Outlets Note PDFDokument23 SeitenBP - Res U2 Elect Symbols Outlets Note PDFyeng botzNoch keine Bewertungen

- Construction Estimates Tables PDFDokument2 SeitenConstruction Estimates Tables PDFAr Hanz Gerome SuarezNoch keine Bewertungen

- Republic of The Philippines Philippine Statistics Authority Quezon CityDokument1 SeiteRepublic of The Philippines Philippine Statistics Authority Quezon CityAr Hanz Gerome SuarezNoch keine Bewertungen

- E-1 TibiaoDokument1 SeiteE-1 TibiaoleniNoch keine Bewertungen

- 1 PDFDokument1 Seite1 PDFAr Hanz Gerome SuarezNoch keine Bewertungen

- 2018 1206 Fairfield County Auditor Drawings VOL 2 PDFDokument40 Seiten2018 1206 Fairfield County Auditor Drawings VOL 2 PDFAr Hanz Gerome SuarezNoch keine Bewertungen

- AEC Form B 1Dokument1 SeiteAEC Form B 1Ar Hanz Gerome SuarezNoch keine Bewertungen

- 1pc Table PDFDokument1 Seite1pc Table PDFAr Hanz Gerome SuarezNoch keine Bewertungen

- E-1 TibiaoDokument1 SeiteE-1 TibiaoleniNoch keine Bewertungen

- Plumbing and SanitaryDokument13 SeitenPlumbing and SanitaryEllixerxes Channel100% (1)

- Electrical Plan Guidelines 1Dokument4 SeitenElectrical Plan Guidelines 1alexandermiller19100% (1)

- Specification Digest: Building FabricDokument4 SeitenSpecification Digest: Building FabricAr Hanz Gerome SuarezNoch keine Bewertungen

- Z:/dwgs/2011/2011-150 - Dairy Queen 6th Avenue/Arch/A7.1 REFLECTED CEILING PLAN & DETAILS - DWG, 04/04/2012 4:30:40 PM, DWG To PDF - pc3Dokument1 SeiteZ:/dwgs/2011/2011-150 - Dairy Queen 6th Avenue/Arch/A7.1 REFLECTED CEILING PLAN & DETAILS - DWG, 04/04/2012 4:30:40 PM, DWG To PDF - pc3Ar Hanz Gerome SuarezNoch keine Bewertungen

- Methods of Compensation and Schedule of Fees RevisedDokument55 SeitenMethods of Compensation and Schedule of Fees Revisedclifford sabigan100% (2)

- Front Elevation Rear Elevation: 50KVA, 3phase GensetDokument8 SeitenFront Elevation Rear Elevation: 50KVA, 3phase GensetAr Hanz Gerome SuarezNoch keine Bewertungen

- Measuring dimensions of a multi-section layoutDokument1 SeiteMeasuring dimensions of a multi-section layoutAr Hanz Gerome SuarezNoch keine Bewertungen

- 1 PDFDokument1 Seite1 PDFAr Hanz Gerome SuarezNoch keine Bewertungen

- M201 07262017 000091 Biddoc PDFDokument32 SeitenM201 07262017 000091 Biddoc PDFAr Hanz Gerome SuarezNoch keine Bewertungen

- Design Standards 3Dokument24 SeitenDesign Standards 3Edelyn Lindero AmbosNoch keine Bewertungen

- Hosts UmbrellaDokument1 SeiteHosts UmbrellaFabsor SoralNoch keine Bewertungen

- Construction of Multi-Level ParkingDokument13 SeitenConstruction of Multi-Level Parkingdunknown15Noch keine Bewertungen

- List of Construction Supplies and Materials Breakdown:: Pmo/spb-O /STPDokument4 SeitenList of Construction Supplies and Materials Breakdown:: Pmo/spb-O /STPAldrene KyuNoch keine Bewertungen

- Two-Storey Residential SpecsDokument7 SeitenTwo-Storey Residential SpecsJayson Hernandez75% (32)

- Septic Tank Design Computation PDFDokument4 SeitenSeptic Tank Design Computation PDFAr Hanz Gerome SuarezNoch keine Bewertungen

- Specification Digest: Building FabricDokument4 SeitenSpecification Digest: Building FabricAr Hanz Gerome SuarezNoch keine Bewertungen

- Archit. Working DrawingDokument20 SeitenArchit. Working DrawingMarvin Messi100% (1)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- BP 2632 GBDokument24 SeitenBP 2632 GBالمهندسوليدالطويلNoch keine Bewertungen

- Principles of Indigenous Creative CraftsDokument33 SeitenPrinciples of Indigenous Creative CraftsNyak nyakNoch keine Bewertungen

- GUIDANCE ON USING WATERPROOF MEMBRANES FOR BRIDGE DECKSDokument17 SeitenGUIDANCE ON USING WATERPROOF MEMBRANES FOR BRIDGE DECKSDanny LamNoch keine Bewertungen

- Contoh EcaDokument13 SeitenContoh EcaHafizi Abu HasanNoch keine Bewertungen

- Excavation Breaking of Concrete and Re Instatement WorkDokument5 SeitenExcavation Breaking of Concrete and Re Instatement WorksujanNoch keine Bewertungen

- Geopolymer Chemistry and Applications: January 2008Dokument38 SeitenGeopolymer Chemistry and Applications: January 2008Mahendra AdiNoch keine Bewertungen

- Concrete-Encased CFST Structures: Behaviour and Application: June 2018Dokument11 SeitenConcrete-Encased CFST Structures: Behaviour and Application: June 2018Adarsh PNoch keine Bewertungen

- BOQ-CIVIL Sample LucknowDokument25 SeitenBOQ-CIVIL Sample LucknowSantosh Thakur100% (1)

- Eea Unit 1 - Passive DesignDokument270 SeitenEea Unit 1 - Passive DesigntinabhuvanNoch keine Bewertungen

- ADokument3 SeitenAAri MulyaNoch keine Bewertungen

- Qatar Co DB 20090518Dokument110 SeitenQatar Co DB 20090518Jeetesh HarjaniNoch keine Bewertungen

- NovesDokument47 SeitenNovesAbdul GhafoorNoch keine Bewertungen

- MYSORE URBAN DEVELOPMENT AUTHORITY PROJECT ESTIMATEDokument5 SeitenMYSORE URBAN DEVELOPMENT AUTHORITY PROJECT ESTIMATESunilkumar CeNoch keine Bewertungen

- Koya University Building Materials Course BookDokument17 SeitenKoya University Building Materials Course BookMariwan MirNoch keine Bewertungen

- Contents - VitalDokument14 SeitenContents - VitalEpherem DanielNoch keine Bewertungen

- Repair and Maintenance Work BoQ for Nayab Tehsildar Residential QuarterDokument5 SeitenRepair and Maintenance Work BoQ for Nayab Tehsildar Residential QuarterrkmeenaNoch keine Bewertungen

- Acronal 5442 - TDS PDFDokument1 SeiteAcronal 5442 - TDS PDFA N MurthyNoch keine Bewertungen

- PU CRETE APPLICATION GUIDE: TIPS FOR INSTALLING JOTAFLOOR PU CRETE FLOORINGDokument25 SeitenPU CRETE APPLICATION GUIDE: TIPS FOR INSTALLING JOTAFLOOR PU CRETE FLOORINGKenji TanNoch keine Bewertungen

- Thioflex 600Dokument5 SeitenThioflex 600talatzahoorNoch keine Bewertungen

- WCD P3Dokument43 SeitenWCD P3RupaliNoch keine Bewertungen

- Installation Guidelines For Adhered Concrete Masonry VeneerDokument43 SeitenInstallation Guidelines For Adhered Concrete Masonry VeneerscoobyozNoch keine Bewertungen

- QA/QC Professionals Certification CoursesDokument29 SeitenQA/QC Professionals Certification CoursesSafeeruddin KhanNoch keine Bewertungen

- Company Introduction: Asphalt & Concrete Engineering Since 1919 The Perfect Mix of Tradition & TechnologyDokument38 SeitenCompany Introduction: Asphalt & Concrete Engineering Since 1919 The Perfect Mix of Tradition & TechnologyLuis Mogrovejo100% (1)

- Luis Romero CV UpdateDokument6 SeitenLuis Romero CV UpdateLuis Enrique RomeroNoch keine Bewertungen

- STS02465Dokument25 SeitenSTS02465JunaidAhmedNoch keine Bewertungen

- Concreting: 6.1. Knowledge of ActivityDokument9 SeitenConcreting: 6.1. Knowledge of ActivityYogendra PatilNoch keine Bewertungen

- Deep BeamsDokument11 SeitenDeep BeamsArcon Solite BarbanidaNoch keine Bewertungen

- Designofwallsbin00ketcuoft BW PDFDokument612 SeitenDesignofwallsbin00ketcuoft BW PDFmohamnamam100% (2)

- Bill of Quantities: 1 Provisional SumDokument41 SeitenBill of Quantities: 1 Provisional SumAbinash MandalNoch keine Bewertungen

- Spun Pile@UFGS 31 62 13.24Dokument58 SeitenSpun Pile@UFGS 31 62 13.24Sigit BintanNoch keine Bewertungen