Beruflich Dokumente

Kultur Dokumente

IS 10124 Part 9 1988 PVC Fittings 60° Bends Specification

Hochgeladen von

gavallapalliOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

IS 10124 Part 9 1988 PVC Fittings 60° Bends Specification

Hochgeladen von

gavallapalliCopyright:

Verfügbare Formate

IS t 10124( Part 8 ) - 1888

Indian Standard

( Reaffirmed 1998 )

SPECIFICATION FOR

FABRICATED PVC FITTINGS FOR

POTABLE WATER SUPPLIES

PART 9

SPECIFIC

(

REQUIREMENTS

FOR 60 BENDS

First Revision )

_.-

UDC

62164340623

C 67874322 1 : 696117

--\

I

,

,-

.4

r-\

,

,. ..

BUREAU

MANAK

*2

OF

BHAVAN,

Coprrighi 1988

INDIAN

STANDARDS

9 BAHADUR

SHAH

NEW DELHI 110002

ZAFAR

MARG

November

1988

IS : 10124 ( Part 9 ) - 1988

SPECIFICATION FOR

FABRICATED PVC FITTINGS FOR

POTABLE WATER SUPPLIES

PART

SPECIFIC

REQUlREMENTS

FOR

60 BENDS

( First Revision )

0. FOREWORD

0.1

This Indian Standard ( Part 9 ) ( First Revision ) was adopted by the Bureau of Indian

Standards on 20 June 1988, after the draft finalized by the Sanitary

Appliances

and Water

Fittings Sectional Committee had been approved

by the Civil Engineering Division Council.

0.2 The fabricated PVC fittings are to be used

for jointing to PVC pipes covered by IS : 49851988*.

0.3 ?he requirements of fabricated

PVC fittings are covered in the following thirteen parts

of the standard:

Part 1 General requirements

Part 2 Specific requirements for sockets

Part 3 Specific

requirements

for straight

reducers

Part 4 Specific requirements for caps

Part 9 Specific requirements

Part 10 Specific requirements for 45 bends

Part 11 Specific requirements for 30 bends

Part 12 Specific requirements for 22p bends

i,

requirements

Part 8 Specific requirements

part 13 Specific requirements

for 1 I& bends

0.3.1 Part 1 of this series deals with the general

requirements applicable to all fabricated PVC

fittings. Specific requirements of different types

of fittings are covered in separate parts ~of the

standard. This standard (Part 9 ) deals with the

specific requirements for 60 bends. This part

was first published in 1982. The present revision

has been taken up to extend the size of fittings

to 630 mm in line with the sizes of pipes specified

in IS : 4985-1988*.

0.4 For the purpose of deciding whether a particular requirement of this standard is complied

with, the final value, observed or calculated,

expressing the result of a test or analysis, shall be

rounded off in accordance with IS : 2-1960t.

The number of significant places retained in the

rounded off value should be the same as that of

the specified value in this standard.

Part 5 Specific requirements for equal tees

Part 6 Specific requirements for flanged tail

pieces with metallic flanges

Part 7 Specific

adaptors

for 60 bends

for threaded

for 90 bends

*Specificationfor unplasticized PVC pipes for potable

*Specificationfor unplasticized PVC pipes for potable water supplies ( second revision ).

i-Rules for rounding off numerical values ( revised ).

water supplies ( second revision ).

1. SCOPE

criteria for conformity

shall conform

10124 (Part 1 ) - 1988+.

1.1 This. standard

( Part 9 ) lays down the

requirements for manufacture,

dimensions and

marking for fabricated PVC 60 bends for potable water supplies.

to IS :

2.2 Manufacture

2.2.1 A typical

shown in Fig. 1.

illustration

of 60 bend is

2. REQUIREMENTS

2.1 General -

The general requirements

material, sizes, methods of test, sampling

*Specificationfor fabricated PVC fitting for potable

water supplies : Part 1 General requirements ( first

for

and

revision ).

IS:

10124(Part9 I-1988

2.2.2

Dimensions

bends shall

Fig. 1.

The

comply

of 60

1 read with

dimensions

with Table

IS : 10124 ( Part 1 ) - 1988*.

NOTE1 -For 0.25 MPa pressure class, fabricated

bends should not be made from 0.25 MPa pressure class

prpes. For this, bends made from 0.4 MPa pressure

class pipe should be used.

2.2.3 The bends may either be plain at both

ends or socketed either at one end or at both ends

as agreed to between the manufacturer

and the

purchaser. In -the case of socketed bends, the

shall

comply

measurements

with

socket

FIG. 1

*Specificationfor fabricated PVC fittings for potable

water supplies: Part 1 General requirements (first revision ).

60 BEND

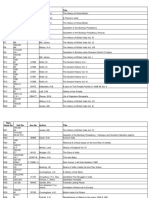

TABLE1

DIMENSIONS OF 60" BENDS

( Clauses 2.2.2,

2.2.3

and Fig. 1 )

All dimensions

Y*

SIZE

in millimetrer.

MINI~AUMWALL THICKNESS

BOR WORKINQ PRESSGRE

Rt

Min

Min

( t )

r-_-____A-__-____~

( Only for

Plain Ends )

0.4 MPa

( Class 2 )

06 MPa

( Class 3 )

1.0 MPa

( Qass 4 )

(1)

(2)

(3)

(4)

(5)

(6)

(7)

63

75

90

110

125

140

160

180

200

225

250

280

315

355

400

450

500

560

630

198

236

283

346

393

440

503

566

629

707

786

880

990

1 115

1256

1 413

1570

1 759

1 979

63

75

90

110

125

140

160

180

200

225

250

280

315

355

400

450

500

560

630

189

225

270

330

375

420

400

540

600

675

750

840

945

1065

1200

1 350

1 500

1 680

1 890

l-4

l-7

19

23

2.7

29

34

3.8

4.2

4-7

5.2

5.8

6.5

7.3

8.2

9.3

103

116

13.0

2-O

2-4

2.8

3.4

39

44

49

5.5

6.2

69

7.7

8.6

9.7

108

12.2

137

153

17.2

192

3.2

3.8

45

5.5

6.3

7-o

8.0

9.0

10.0

112

125

13.9

15.6

17.7

198

224

248

278

31.3

-NOTE -

Minimum

wall thickness

is calculated on the

basis

of 90 percent

of the minimum

the corresponding six and pressure class ( I ) pipe rounded off to the next higher 0.1 mm.

*Y is calculated

from-$:;,,

x 2 R.

fR, radius of the bend, is equal to 3 times the nominal

outside diameter

( D ).

wall thickness

of

IS : 10124( Part 9 ) - 1918

NOTE 2 - The drawing is only intended to define the

terms used in Table 1 and is not intended to illustrate

specificdesign features.

3. MARKING

3.1 Each 60 bend fitting

the following information:

a)

b)

c)

d)

Manufacturers

mark,

shall

name

be marked

or

Coloour

Class 2 ( 04 MPa 1

Class 3 ( 06 MPa )

Class 4 ( 10 MPa )

Blue

Green

Yellow

with

3.1.1 Each 60 bend fitting

marked with the Standard Mark.

indentification

may also be

The use of the Standard Mark is governed

NOTEby the provision of the Bureau of Indian Standards Act

1986 and the Rules and Regulations made thereunder.

The Standard Mark on products covered by an Indian

Standard conveys the assurance that they have been

produced to comply with the requirements of that standard under a well defined system of inspection, testing

and quality control which is devised and supervised by

BIS and operated by the producer. Standard marked

products are also continuously checked by BIS for

conformity to that standard as a further safeguard.

Details of conditions under which a licence for the use

of the Standard Mark may be granted to manufacturres

or producers may be obtained from the Bureau of

Indian Standards.

The size of the bend and the appropriate

class ( working pressure ) of JS : 4985

1988* to which the pressure rating of the

fitting corresponds,

The degree of bend, and

The bend shall be marked

in colour

indicated below for different

classes

fittings:

Class of Fitting

as

of

*Specification for unplasticized PVC pipes for potable

water supplies ( second revision ).

BUREAU OF 4NDldN

STANDARDS

Headquarters:

Manak Bhavan,

Telephones:

9 Bahadur

110002

Shah Zafar Marg, NEW DELHI

Telegrams : Manaksanstha

( Common to all offices )

3310131, 3311375

Regional Offices:

Telephone

Central: Manak Bhavan,

NEW DELHI

9 Bahadur

Shah

3310131,3311375

Zafar Marg,

110002

*Eastern: l/14 C.I.T. Scheme

CALCUTTA

700054

VII M, V.I.P. Road, Maniktola,

Northern:

SC0 445-446, Sector 35-C, CHANDIGAR-H

Southern:

C.I.T.

Campus,

twestern:

Manakalaya,

BOMBAY 400093

MADRAS

E9 MIDC,

362499

160036

21843, 31641

600113

Marol,

412442, 412519, 412916

Andheri

( East ),

6329295

Branch Offices:

Pushpak

Nurmohamed

Peenya Industrial

BANGALORE

Shaikh

Marg, Khanpur,

AHMADABAD

Area, 1st Stage, ~Bangalore-Tumkur

560058

Gangotri Complex, 5th Floor, Bhadbhada

BHOFAL 462003

Plot No. 82/83, Lewis Road,

Marg, C Scheme,

117/418 B Sarvodaya

Patliputra

Industrial

Estate, PATNA

T.C. No. 14/1421, University

Inspection Offices ( With

Pushpanjali,

Square,

Station

JAIPUR

Nagar, KANPUR

384955, 384956

66716

53627

GUWAHATI

781003

Road ),

231083

302005

63471_, 69832

208005

216876, 218292

800013

P.O. Palayam,

62305

TRIVANDRUM

695035

62104, 62117

Sale Point ):

First Floor, 205A West High Court

NAGPUR 440010

fnstitution

of Engineers

PUNE 411005

Road,

751002

53/5 Ward No. 29, R.G. Barua Road, 5th By-lane,

R14 Yudhister

26348, 26349

Road, T.T. Nagar,

BHUBANESHWAR

5-8-56C L. N. Gupta Marg ( Nampally

HY DERABAD

500001

380001

( India ) Building,

Road, Shankar

1332 Shlvajl

*Sales

Office in Calcutta is at 5 Chowrlnghee

tSales

Office in Bombay is at Novelty Chambers,

Approach,

Nagar

25171

52435

Nagar,

P. 0. Prlncep Street,

Grant Road, Bombay

400097

Calcutta 700072

278800

898528

Printed at Said Printers. Delhi. India

Das könnte Ihnen auch gefallen

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsVon EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsBewertung: 4.5 von 5 Sternen4.5/5 (10)

- Design Guidelines for Surface Mount TechnologyVon EverandDesign Guidelines for Surface Mount TechnologyBewertung: 5 von 5 Sternen5/5 (1)

- Oil and Gas Pipelines: Integrity and Safety HandbookVon EverandOil and Gas Pipelines: Integrity and Safety HandbookNoch keine Bewertungen

- 02 ACSR ZEBRA ConductorDokument37 Seiten02 ACSR ZEBRA Conductorsanjeevchhabra100% (2)

- 6T40 45 Diag FixesDokument69 Seiten6T40 45 Diag Fixesjosue100% (12)

- Drilling Fluids Processing HandbookVon EverandDrilling Fluids Processing HandbookBewertung: 4.5 von 5 Sternen4.5/5 (4)

- Rare Books PDFDokument49 SeitenRare Books PDFgavallapalliNoch keine Bewertungen

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionVon EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionBewertung: 4.5 von 5 Sternen4.5/5 (16)

- Basic Metatrader 5 GuideDokument22 SeitenBasic Metatrader 5 GuideDavid Al100% (1)

- Maximum Pressure Rating Schedule 160, Schedule 40 and Schedule 80 - Engineers EdgeDokument5 SeitenMaximum Pressure Rating Schedule 160, Schedule 40 and Schedule 80 - Engineers EdgeDevanshu KrNoch keine Bewertungen

- 2663 Technical SpecificationDokument70 Seiten2663 Technical SpecificationCgpscAspirantNoch keine Bewertungen

- Welding Specification for Carbon and Alloy Steel PipingDokument82 SeitenWelding Specification for Carbon and Alloy Steel PipingsendelkrNoch keine Bewertungen

- Concrete Pipes and Portal Culverts HandbookDokument52 SeitenConcrete Pipes and Portal Culverts HandbookKenya Ayallew Asmare100% (3)

- Autocad ShortcutsDokument13 SeitenAutocad ShortcutsKriscel CaraanNoch keine Bewertungen

- FUJI FRONTIER 340E - PartslistDokument172 SeitenFUJI FRONTIER 340E - Partslistvitprint22Noch keine Bewertungen

- Piping SpecDokument355 SeitenPiping Speclcaron44100% (1)

- Flat Panel Display ManufacturingVon EverandFlat Panel Display ManufacturingJun SoukNoch keine Bewertungen

- API 5l Spec OngcDokument27 SeitenAPI 5l Spec OngcjamilvoraNoch keine Bewertungen

- Enbridge Pipeline Repair Workplan WeldingDokument23 SeitenEnbridge Pipeline Repair Workplan WeldingJesus MaestreNoch keine Bewertungen

- Brass Cable Glands SpecificationdryDokument10 SeitenBrass Cable Glands Specificationdrynirbhay111Noch keine Bewertungen

- De ShawDokument10 SeitenDe ShawNishant GuptaNoch keine Bewertungen

- GRP Pipelien MaterialDokument22 SeitenGRP Pipelien MaterialSyed Ashfaq100% (1)

- P&ID Check ListDokument2 SeitenP&ID Check ListHadi ShahsavanNoch keine Bewertungen

- Asme Q&aDokument57 SeitenAsme Q&amsraja7767% (3)

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeVon EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNoch keine Bewertungen

- E9d0' R""o .: Indian StandardDokument26 SeitenE9d0' R""o .: Indian Standards_samirkumar1008100% (1)

- 01 Samss 035 API LinepipeDokument28 Seiten01 Samss 035 API Linepipemdsazidalam100% (2)

- Pressuremeter Testing: Methods and InterpretationVon EverandPressuremeter Testing: Methods and InterpretationBewertung: 5 von 5 Sternen5/5 (2)

- Hager Protection Devices TechnicalDokument70 SeitenHager Protection Devices TechnicalerreagaaNoch keine Bewertungen

- IONE-VP-02-H-001-075 - Rv11 - C - INSTRUMENT ALARM AND TRIP LIST - R11Dokument3 SeitenIONE-VP-02-H-001-075 - Rv11 - C - INSTRUMENT ALARM AND TRIP LIST - R11dhiaa mohammedNoch keine Bewertungen

- Specificatio-N FOR Fabricatedpvcfittingsfor PotablewatersuppliesDokument3 SeitenSpecificatio-N FOR Fabricatedpvcfittingsfor PotablewatersuppliesgavallapalliNoch keine Bewertungen

- Specification For Fabricated PVC Fittings For Potable Water SuppliesDokument5 SeitenSpecification For Fabricated PVC Fittings For Potable Water SuppliesgavallapalliNoch keine Bewertungen

- Specification For Fabricated PVC Fittings For Potable Water SuppliesDokument5 SeitenSpecification For Fabricated PVC Fittings For Potable Water SuppliesRitesh kumarNoch keine Bewertungen

- Specification For Fabricated PVC Fittings For Potable Water SuppliesDokument5 SeitenSpecification For Fabricated PVC Fittings For Potable Water SuppliesgavallapalliNoch keine Bewertungen

- Specification FOR Fabricated PVC Fittings For Potable Water SuppliesDokument7 SeitenSpecification FOR Fabricated PVC Fittings For Potable Water SuppliesgavallapalliNoch keine Bewertungen

- Specification For Fabricated PVC Fittings For ' Potable Water SuppliesDokument5 SeitenSpecification For Fabricated PVC Fittings For ' Potable Water SuppliesgavallapalliNoch keine Bewertungen

- Specification For Fabricated PVC Fittings For Potable Water SuppliesDokument5 SeitenSpecification For Fabricated PVC Fittings For Potable Water SuppliesRitesh kumarNoch keine Bewertungen

- IS8008 8reducing TeeDokument5 SeitenIS8008 8reducing TeeAshish TanejaNoch keine Bewertungen

- Specification For Fabricated PVC Fittings For Potable Water SuppliesDokument5 SeitenSpecification For Fabricated PVC Fittings For Potable Water SuppliesRitesh kumarNoch keine Bewertungen

- Specification For Fabricated PVC Fittings For Potable Water SuppliesDokument5 SeitenSpecification For Fabricated PVC Fittings For Potable Water SuppliesRitesh kumarNoch keine Bewertungen

- Bureau of Indian Standards: For BIS Use OnlyDokument6 SeitenBureau of Indian Standards: For BIS Use OnlyanmoljassalNoch keine Bewertungen

- Is 1626 Part 2Dokument11 SeitenIs 1626 Part 2Sheetal JindalNoch keine Bewertungen

- Disclosure To Promote The Right To InformationDokument8 SeitenDisclosure To Promote The Right To InformationCst WclNoch keine Bewertungen

- Is Code-447 - 1988Dokument6 SeitenIs Code-447 - 1988Manas NayakNoch keine Bewertungen

- Suction Hose Couplings For Fire Fighting Purposes - SpecificationDokument9 SeitenSuction Hose Couplings For Fire Fighting Purposes - SpecificationDebajani DekabaruahNoch keine Bewertungen

- Is 4885 Specification For Sewer Bricks R1.182104631Dokument5 SeitenIs 4885 Specification For Sewer Bricks R1.182104631Arvind DhimanNoch keine Bewertungen

- MQP 2Dokument10 SeitenMQP 2prithvirajd20Noch keine Bewertungen

- Is 8008 4 2003Dokument13 SeitenIs 8008 4 2003GAURAV BHAVSARNoch keine Bewertungen

- Is 6595 2 1993Dokument10 SeitenIs 6595 2 1993mishraenggNoch keine Bewertungen

- 12231Dokument7 Seiten12231vsajuNoch keine Bewertungen

- Is 3063Dokument11 SeitenIs 3063Sumit ShyamalNoch keine Bewertungen

- Disclosure To Promote The Right To InformationDokument18 SeitenDisclosure To Promote The Right To InformationNayan VyasNoch keine Bewertungen

- Ced50 (7622)Dokument19 SeitenCed50 (7622)anmoljassalNoch keine Bewertungen

- 10646Dokument6 Seiten10646Richa JainNoch keine Bewertungen

- Is-903 Couplings, Branch Pipe, NozzlesDokument13 SeitenIs-903 Couplings, Branch Pipe, NozzlesCharls JamesNoch keine Bewertungen

- Cutback Bitumen From Waxy Crude - Specification (: Indian StandardDokument6 SeitenCutback Bitumen From Waxy Crude - Specification (: Indian Standardamit jainNoch keine Bewertungen

- Projet Topping de Condensat - Skikda SC Instrument Specification For Tank Gauging SystemDokument19 SeitenProjet Topping de Condensat - Skikda SC Instrument Specification For Tank Gauging SystemKARIMNoch keine Bewertungen

- 71-BD-15 DraftDokument15 Seiten71-BD-15 DraftRakesh JainwalNoch keine Bewertungen

- Dimensional Re@@Irements: Indian StandardDokument2 SeitenDimensional Re@@Irements: Indian Standardadambox1986Noch keine Bewertungen

- Draft Item Specific Guidelines For Improved Switch Expansion Joints TDG 0022 Rev-2Dokument9 SeitenDraft Item Specific Guidelines For Improved Switch Expansion Joints TDG 0022 Rev-2Pradeep PanwarNoch keine Bewertungen

- Specification For Sewer Bricks (: Indian StandardDokument5 SeitenSpecification For Sewer Bricks (: Indian StandardAmbrishNoch keine Bewertungen

- ENA - 12 - 24 TS For Ducts - Buried Electric CablesDokument17 SeitenENA - 12 - 24 TS For Ducts - Buried Electric CablessdvijayNoch keine Bewertungen

- 3468 - Pipe Nuts - SpecificationDokument5 Seiten3468 - Pipe Nuts - SpecificationVikash YadavNoch keine Bewertungen

- Is 10238Dokument6 SeitenIs 10238kundank_32Noch keine Bewertungen

- Informe Tuberia 12 InglesDokument18 SeitenInforme Tuberia 12 InglesJonathan MartinezNoch keine Bewertungen

- 217 Specification For Cutback Bitumen PDFDokument7 Seiten217 Specification For Cutback Bitumen PDFAsnan Khan100% (1)

- Is.9523.2000 0 PDFDokument38 SeitenIs.9523.2000 0 PDFVijay Rama RajuNoch keine Bewertungen

- Optimization and Business Improvement Studies in Upstream Oil and Gas IndustryVon EverandOptimization and Business Improvement Studies in Upstream Oil and Gas IndustryNoch keine Bewertungen

- Architecture of HindusDokument203 SeitenArchitecture of HindusgavallapalliNoch keine Bewertungen

- Dictionarymixed00unkngoog PDFDokument170 SeitenDictionarymixed00unkngoog PDFShayan GudipalliNoch keine Bewertungen

- 4332 7 PDFDokument12 Seiten4332 7 PDFgavallapalliNoch keine Bewertungen

- 4332 8 PDFDokument15 Seiten4332 8 PDFgavallapalliNoch keine Bewertungen

- Sangraha Chudamani of GovindaDokument554 SeitenSangraha Chudamani of GovindaPSGNoch keine Bewertungen

- Naradiya Darma SastraDokument174 SeitenNaradiya Darma SastragavallapalliNoch keine Bewertungen

- Reaffirmed 1995Dokument14 SeitenReaffirmed 1995gavallapalliNoch keine Bewertungen

- Flltration Equipment: I'dian StandardDokument10 SeitenFlltration Equipment: I'dian Standardnimm1962Noch keine Bewertungen

- Kondamarajupalem Final LPS NumberingDokument1 SeiteKondamarajupalem Final LPS NumberinggavallapalliNoch keine Bewertungen

- 4332 7 PDFDokument12 Seiten4332 7 PDFgavallapalliNoch keine Bewertungen

- 8419 2Dokument9 Seiten8419 2gavallapalliNoch keine Bewertungen

- 2 IndiaDokument78 Seiten2 IndiagavallapalliNoch keine Bewertungen

- 2720 7 PDFDokument13 Seiten2720 7 PDFjageshwariNoch keine Bewertungen

- Structural Design of Multi-Story Residential BuildingDokument9 SeitenStructural Design of Multi-Story Residential Buildingatac101Noch keine Bewertungen

- Structural Safety and ServicesDokument6 SeitenStructural Safety and ServicesAmit GargNoch keine Bewertungen

- Raft Draw.Dokument31 SeitenRaft Draw.gavallapalliNoch keine Bewertungen

- Code of Practice For Laying of Cast Iron Pipes: Indian StandardDokument15 SeitenCode of Practice For Laying of Cast Iron Pipes: Indian StandardgavallapalliNoch keine Bewertungen

- SS Filters DesignDokument2 SeitenSS Filters DesigngavallapalliNoch keine Bewertungen

- Discusion Forum Nov 2006Dokument2 SeitenDiscusion Forum Nov 2006gavallapalliNoch keine Bewertungen

- Flltration Equipment: I'dian StandardDokument10 SeitenFlltration Equipment: I'dian Standardnimm1962Noch keine Bewertungen

- PNNL (2009) Country Report IndiaDokument24 SeitenPNNL (2009) Country Report Indiabcap-oceanNoch keine Bewertungen

- Sup Court Judgment DT 210509 PDFDokument36 SeitenSup Court Judgment DT 210509 PDFgavallapalliNoch keine Bewertungen

- Discusion Forum Nov 2006Dokument2 SeitenDiscusion Forum Nov 2006gavallapalliNoch keine Bewertungen

- CountryReport IndiaDokument39 SeitenCountryReport IndiagavallapalliNoch keine Bewertungen

- 4985 PDFDokument26 Seiten4985 PDFgavallapalliNoch keine Bewertungen

- PDFDokument13 SeitenPDFgavallapalliNoch keine Bewertungen

- 8419 2 PDFDokument9 Seiten8419 2 PDFgavallapalliNoch keine Bewertungen

- Code of Practice For Sanitation With Leaching Pits For Rural CommunitiesDokument9 SeitenCode of Practice For Sanitation With Leaching Pits For Rural CommunitiesgavallapalliNoch keine Bewertungen

- PMOS RunsheetDokument3 SeitenPMOS Runsheetkrishna_singhalNoch keine Bewertungen

- Inverting Power Supply Using A TPS54202 BuckDokument25 SeitenInverting Power Supply Using A TPS54202 Buckg4okkNoch keine Bewertungen

- Irf 744 PBFDokument8 SeitenIrf 744 PBFPosada Burgueño CarlosNoch keine Bewertungen

- The Existence of An External Redundancy ASM DiskgroupDokument55 SeitenThe Existence of An External Redundancy ASM Diskgroupsidd_aish@yahoo.comNoch keine Bewertungen

- Introduction LetterDokument4 SeitenIntroduction LetterKashifRaza0% (1)

- Indigo GdpiDokument1 SeiteIndigo Gdpimanoj agrawallaNoch keine Bewertungen

- Polymer PhysicsDokument9 SeitenPolymer PhysicslotannaNoch keine Bewertungen

- MC Lab Manual ModifiedDokument64 SeitenMC Lab Manual ModifiedBaswamy CseNoch keine Bewertungen

- Everything you need to know about your new washing machineDokument20 SeitenEverything you need to know about your new washing machinesenhbox4180Noch keine Bewertungen

- Coils TransponderDokument4 SeitenCoils TransponderGuadalajara JaliscoNoch keine Bewertungen

- Connector CatalogDokument60 SeitenConnector CatalogYadira De De Ciam100% (1)

- Nitotile Fix PRO - High performance tile adhesiveDokument2 SeitenNitotile Fix PRO - High performance tile adhesivetalatzahoorNoch keine Bewertungen

- Vend RegDokument49 SeitenVend RegProcaeHexdofNoch keine Bewertungen

- Face Recognization and Detection System For Attendance.Dokument39 SeitenFace Recognization and Detection System For Attendance.Deepanshu Sharma33% (3)

- Debug 1214Dokument15 SeitenDebug 1214manhlong2009Noch keine Bewertungen

- TAICDokument8 SeitenTAICparthNoch keine Bewertungen

- Part - I (MCQ) (Compulsory) : M A A ADokument4 SeitenPart - I (MCQ) (Compulsory) : M A A AAfzaal GhaziNoch keine Bewertungen

- Coke Bottle Tutorial For MayaDokument42 SeitenCoke Bottle Tutorial For MayadumbledoreaaaaNoch keine Bewertungen

- Digital Logic Families GuideDokument82 SeitenDigital Logic Families Guidemoney_kandan2004Noch keine Bewertungen

- Romanian Power Grid Substation Refitting StrategyDokument16 SeitenRomanian Power Grid Substation Refitting StrategyParmeshwar MbNoch keine Bewertungen

- Ce R&D/Dli-22/CHANDI/2010-2011 Ce R&D/Dli - 24/CHANDI/2010-2011Dokument61 SeitenCe R&D/Dli-22/CHANDI/2010-2011 Ce R&D/Dli - 24/CHANDI/2010-2011rajjjjjiNoch keine Bewertungen

- AP238 PS09 ManualDokument28 SeitenAP238 PS09 ManualEuro-Kitchen, Inc.100% (4)