Beruflich Dokumente

Kultur Dokumente

Design Inducer Pump

Hochgeladen von

nicoCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Design Inducer Pump

Hochgeladen von

nicoCopyright:

Verfügbare Formate

Design of an Inducer Pump with High Suction Performance and Backflow Control | ...

home

products

services

applications

about

support

news

Page 1 sur 2

webinars

Home Applications Applications Examples Design of an Inducer Pump with High Suction Performance and

Backflow Control

Subscribe via email

Design of an Inducer Pump with High Suction Performance and Backflow Control

The design of inducers is critical to achieving high suction performance in industrial pumps and rocket engine

Follow us:

turbopumps. However, the conventional design approach, based on blade angles, often causes unstable

pump operation. Instabilities such as strong inlet backflow and rotating cavitation in inducers may cause

applications

mechanical failures in pumps and the entire pumping system.

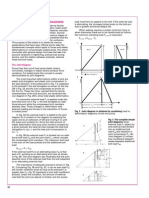

TURBOdesign1 has been successfully applied to the design of inducers and validated by experiments. By

optimizing blade loading, the suction performance can be improved over the operating range. The low

pressure area was reduced as shown in Figures1 and 2.

It was also confirmed that the inlet backflow can be controlled by optimizing the blade loading at the leading

edge.

Design of High Perform

Stage

1/15

publications

Fig.1: Conventional (Helical Type)

Study of Turbopump In

Designed by 3-D Invers

Method

Fig.2: TURBOdesign1

Design Optimisation of

Pump Inducer

TURBOdesign1 was also applied in the design of the main impeller of an inducer

pump, see Figure 3.

Development of Cryoge

Hydrodynamics Using I

Design Method and CF

Experimental validation confirmed that employing aft-loading at the shroud was

effective in achieving high suction performance. In addition, consideration of the

Improvements of Induc

Backflow Characteristic

Inverse Design Method

pre-swirl created by the inducer is important in improving the suction performance

of the main impeller. See Figure 4.

The design of a highly loaded, rocket engine, turbo pump inducer, was carried out

Fig.3

using TURBOdesign1 (Figure 5). The conventional helical type inducer has a

Effects of Blade Loadin

Inducer Performance a

case studies

strong inlet backflow even at the design point, the presence of which is confirmed

Design of a Second Sta

Rocket Turbopump by

TURBOdesign1

by the photograph in Figure 6. This inlet backflow at the design point was

eliminated by optimizing the blade loading distribution using TURBOdesign1, see

Application of TURBOd

Compact Design of Roc

Turbopump - JAXA

Figure 7. The meridional geometry was also re-designed to achieve high loading.

Figures 8 and 10 show the streamlines at design point, the elimination of the inlet

backflow can be clearly seen.

Fig.4

Design of Mixed Flow P

Using TURBOdesign1

Code, Hyosung-Ebara

3D Inverse Method Imp

Design, Carver Pump c

times and increases pro

growth

Development of New V

Shaft Pumps

your account

Login or Register

Fig.5

Fig.6: Conventional

Fig.7: TURBOdesign1

The elimination of inlet backflow is important for assuring mechanical reliability, and avoiding deterioration of

the thermodynamic effects on suppressing cavitation of liquid hydrogen. Figures 9 and 11 show the FFT

analysis results of measured pressure fluctuation at the design point, and a cavitation number of = 0.04. In

the case of the inducer designed by TURBOdesign1, pressure oscillation was maintained at a very low level

and no evidence of rotating cavitation was observed.

Fig.8: Conventional

Fig.9: Conventional

Fig.10: TURBOdesign1

Fig.11: TURBOdesign1

References:

Ashihara, K. and Goto, A., 1999, Improvements of Pump Suction Performance using 3-D Inverse Design

Method, ASME FEDSM99-6846

This site uses cookies. By continuing to browse the site you are agreeing to our use of cookies.

http://www.adtechnology.co.uk/applications/design-inducer-pump-suction-performance 01/07/2013

Design of an Inducer Pump with High Suction Performance and Backflow Control | ...

Page 2 sur 2

Ashihara, K. and Goto, A., 2002, Effects of Blade Loading on Pump Inducer Performance and Flow Fields,

ASME FEDSM 2002

Ashihara, K., Goto, A., Kamijo, K., Yamada, H., Hashimoto, and T., Uchiumi, M., 2001, Study on

Turbopump Inducers Designed by 3-D Inverse Design Method, AFI-2001, Zao, Japan.

Login or Register to read the entire article.

ShareThis:

Advanced Design Technology Dilke House, 1 Malet Street, London WC1E 7JN United Kingdom

tel: +44 (0)20 7299 1170 fax: +44 (0)20 7636 8028 info@adtechnology.co.uk

1998-2013 Advanced Design Technology Ltd - Disclaimer - Privacy Policy - Usage Terms and Conditions

This site uses cookies. By continuing to browse the site you are agreeing to our use of cookies.

http://www.adtechnology.co.uk/applications/design-inducer-pump-suction-performance 01/07/2013

Das könnte Ihnen auch gefallen

- Design and Analysis of Centrifugal CompressorsVon EverandDesign and Analysis of Centrifugal CompressorsNoch keine Bewertungen

- Design Optimization of Fluid Machinery: Applying Computational Fluid Dynamics and Numerical OptimizationVon EverandDesign Optimization of Fluid Machinery: Applying Computational Fluid Dynamics and Numerical OptimizationNoch keine Bewertungen

- Hydraulic Efficiencies of Impeller and PumpDokument9 SeitenHydraulic Efficiencies of Impeller and PumpJohn Archie MendozaNoch keine Bewertungen

- 10 Development of A High Performance Centrifugal Compressor Using A 3D Inverse Design TechniqueDokument11 Seiten10 Development of A High Performance Centrifugal Compressor Using A 3D Inverse Design TechniqueSubhash PadmanabhanNoch keine Bewertungen

- Design and Analysis of TPA Purdue PDFDokument24 SeitenDesign and Analysis of TPA Purdue PDFJohn DoeNoch keine Bewertungen

- These Is On Turbopump.Dokument44 SeitenThese Is On Turbopump.Madhusudan SharmaNoch keine Bewertungen

- InducerDokument54 SeitenInducerYaswanthNoch keine Bewertungen

- Preliminary Design of Turbopumps and Related Machinery - NASA PDFDokument406 SeitenPreliminary Design of Turbopumps and Related Machinery - NASA PDFStacy WilsonNoch keine Bewertungen

- 3 - 2C Ah-2vomDokument1 Seite3 - 2C Ah-2vomMamiherintsoa Issaia RanaivoarimananaNoch keine Bewertungen

- Axial Flow Pump Design PDFDokument10 SeitenAxial Flow Pump Design PDFHalit Baris SertbakanNoch keine Bewertungen

- Agard CFD PDFDokument492 SeitenAgard CFD PDFVinoth NagarajNoch keine Bewertungen

- Finite Element Analysis On Screw CompressorDokument20 SeitenFinite Element Analysis On Screw CompressorJiss George MancherikalamNoch keine Bewertungen

- Centrifugal Pumps - Impeller Reverse Design PDFDokument4 SeitenCentrifugal Pumps - Impeller Reverse Design PDFYinka AkinkunmiNoch keine Bewertungen

- Cavitation and Pump NPSHRDokument39 SeitenCavitation and Pump NPSHRRicardo BarrosNoch keine Bewertungen

- DVMX. Between-Bearings, Multistage, Axially Split Pump. API-610,10th Edition ISO M A R E L L IDokument6 SeitenDVMX. Between-Bearings, Multistage, Axially Split Pump. API-610,10th Edition ISO M A R E L L Imiguel hernandezNoch keine Bewertungen

- EPA EmissionsDokument46 SeitenEPA EmissionsDustin WinnNoch keine Bewertungen

- Simple Turbojet Cycle: Alberto Mag-Aso IIIDokument22 SeitenSimple Turbojet Cycle: Alberto Mag-Aso IIIAlberto Mag-aso IIINoch keine Bewertungen

- Rod Loading of Reciprocating CompressorsDokument18 SeitenRod Loading of Reciprocating Compressors최승원Noch keine Bewertungen

- Parametric Design of Rocket Engine Turbopumps With Genetic AlgorithmsDokument5 SeitenParametric Design of Rocket Engine Turbopumps With Genetic Algorithmsjoojoo987654321Noch keine Bewertungen

- Wal Correction AgardDokument552 SeitenWal Correction AgardSrinivasan SiddhamoorthyNoch keine Bewertungen

- Dynamic Response of Cavitating TurbomachineryDokument208 SeitenDynamic Response of Cavitating TurbomachinerymsreerajvarmaNoch keine Bewertungen

- Solutions For Reduced Life Cycle Costs of Centrifugal Compressors in Oil and Gas IndustryDokument7 SeitenSolutions For Reduced Life Cycle Costs of Centrifugal Compressors in Oil and Gas Industryzeinab_jahani5799Noch keine Bewertungen

- TM 5-2036 (Pump, Centrifugal 1.5 Discharge, 125 G.P.M. 300 PDFDokument127 SeitenTM 5-2036 (Pump, Centrifugal 1.5 Discharge, 125 G.P.M. 300 PDFferdockmNoch keine Bewertungen

- Condition Monitoring of Pump (Vibration)Dokument5 SeitenCondition Monitoring of Pump (Vibration)Zaki Rizqi FadhlurrahmanNoch keine Bewertungen

- Design of Impeller Blade by Varying Blades and Type of Blades Using Analytical PDFDokument11 SeitenDesign of Impeller Blade by Varying Blades and Type of Blades Using Analytical PDFasrikalyanNoch keine Bewertungen

- Centrifugal PumpDokument360 SeitenCentrifugal PumpArnel V. EsllerNoch keine Bewertungen

- How To Read Pump CurveDokument4 SeitenHow To Read Pump CurvenghiemvhNoch keine Bewertungen

- Experimental Investigations of Flow Through ConicalDokument25 SeitenExperimental Investigations of Flow Through Conicalaizatul nurulain binti mohd halilNoch keine Bewertungen

- The Effect of Air Inlet System Features On Automotive Turbocharger Compressor PerformanceDokument19 SeitenThe Effect of Air Inlet System Features On Automotive Turbocharger Compressor Performancestefan.vince536Noch keine Bewertungen

- Multistage Pump RepairDokument5 SeitenMultistage Pump RepairCheyanSathishNoch keine Bewertungen

- Steamturbines ChurchDokument296 SeitenSteamturbines ChurchVictor GonçalvesNoch keine Bewertungen

- 5.7 Centrifugal PumpsDokument8 Seiten5.7 Centrifugal PumpsSaleem Chohan100% (1)

- Study of The Centrifugal Pump Efficiency at Throttling and Speed ControlDokument4 SeitenStudy of The Centrifugal Pump Efficiency at Throttling and Speed ControlHassan SouleymanNoch keine Bewertungen

- Presentation of PumpDokument46 SeitenPresentation of PumpArindam SamantaNoch keine Bewertungen

- Centrifugal Pumps PDFDokument114 SeitenCentrifugal Pumps PDFNovancy100% (2)

- Trim Optimisation - Theory and PracticeDokument6 SeitenTrim Optimisation - Theory and Practicepoker12345Noch keine Bewertungen

- OH2 PumpDokument8 SeitenOH2 PumpMayuresh MahajanNoch keine Bewertungen

- Kaplan DesignDokument2 SeitenKaplan DesignruralworldNoch keine Bewertungen

- Throttling ProcessDokument3 SeitenThrottling ProcessFarhatul Abrar AnandaNoch keine Bewertungen

- Turbomachinery Performance Modeling: David JapikseDokument26 SeitenTurbomachinery Performance Modeling: David JapikseVictor Dominguez GarciaNoch keine Bewertungen

- Increasing Pump CapacityDokument3 SeitenIncreasing Pump Capacitydk4monjureNoch keine Bewertungen

- Review of Parameters Influencing Hydraulic Forces On Centrifugal ImpellersDokument12 SeitenReview of Parameters Influencing Hydraulic Forces On Centrifugal ImpellersHosseinNoch keine Bewertungen

- Turbo-Pump Supply System For Liquid-Propellant Rocket EngineDokument8 SeitenTurbo-Pump Supply System For Liquid-Propellant Rocket EngineĐinh Quốc TríNoch keine Bewertungen

- Axial Fan NotchDokument3 SeitenAxial Fan NotchhahasiriusNoch keine Bewertungen

- 10 Fan DrycoolerDokument36 Seiten10 Fan DrycoolersamersibaniNoch keine Bewertungen

- Bolt Joint-DiagramsDokument6 SeitenBolt Joint-Diagramskulov1592Noch keine Bewertungen

- Cavitation PhotographsDokument6 SeitenCavitation PhotographsgsmilebamNoch keine Bewertungen

- Introduction To TurbomachineryDokument66 SeitenIntroduction To TurbomachineryJeff SimpsonNoch keine Bewertungen

- Turbo MachineryDokument182 SeitenTurbo MachineryAnkit GandhiNoch keine Bewertungen

- Rotor-Bearing Dynamics Technology Design Guide Par PDFDokument370 SeitenRotor-Bearing Dynamics Technology Design Guide Par PDFSeethaNoch keine Bewertungen

- Bombas Sumergibles KSBDokument92 SeitenBombas Sumergibles KSBArturPNoch keine Bewertungen

- Cavitation Instabilities and Rotordynamic Effects in Turbopumps and Hydroturbines Turbopump and InducerDokument288 SeitenCavitation Instabilities and Rotordynamic Effects in Turbopumps and Hydroturbines Turbopump and InducerAlbertoPitaNoch keine Bewertungen

- Application of Composites For Centrifugal PumpsDokument4 SeitenApplication of Composites For Centrifugal Pumpsravide76Noch keine Bewertungen

- Experimental Fluid Mechanics: The Commonwealth and International Library: Thermodynamics and Fluid Mechanics DivisionVon EverandExperimental Fluid Mechanics: The Commonwealth and International Library: Thermodynamics and Fluid Mechanics DivisionBewertung: 4 von 5 Sternen4/5 (2)

- Turbulent Buoyant Jets and Plumes: HMT: The Science & Applications of Heat and Mass Transfer. Reports, Reviews & Computer ProgramsVon EverandTurbulent Buoyant Jets and Plumes: HMT: The Science & Applications of Heat and Mass Transfer. Reports, Reviews & Computer ProgramsNoch keine Bewertungen

- Stabilization and Dynamic of Premixed Swirling Flames: Prevaporized, Stratified, Partially, and Fully Premixed RegimesVon EverandStabilization and Dynamic of Premixed Swirling Flames: Prevaporized, Stratified, Partially, and Fully Premixed RegimesNoch keine Bewertungen

- Cavitation Performance Improvement of An Industrial Cryogenic Centrifugal Pump by Implementing Variable Pitch InducerDokument12 SeitenCavitation Performance Improvement of An Industrial Cryogenic Centrifugal Pump by Implementing Variable Pitch InducerKOWSHIK 4310Noch keine Bewertungen

- Increasing The Profits & Production of Mature Fields Through Optimized Jet Pump Design & Operational ConsiderationsDokument9 SeitenIncreasing The Profits & Production of Mature Fields Through Optimized Jet Pump Design & Operational ConsiderationsIndra BayuNoch keine Bewertungen

- Physical Constants ListingDokument4 SeitenPhysical Constants ListingnicoNoch keine Bewertungen

- Energas - Particularcuba - Cuba NewsDokument2 SeitenEnergas - Particularcuba - Cuba NewsnicoNoch keine Bewertungen

- Catalogue Cryostar MagazineDokument12 SeitenCatalogue Cryostar MagazinenicoNoch keine Bewertungen

- Specific Heat of Liquids and FluidsDokument4 SeitenSpecific Heat of Liquids and FluidsnicoNoch keine Bewertungen

- Hoffmann & Feige: Evaluation of LNG Facilities For AgingDokument32 SeitenHoffmann & Feige: Evaluation of LNG Facilities For AgingnicoNoch keine Bewertungen

- Onshore Brochure - Small Scale and Mini LNG SystemsDokument8 SeitenOnshore Brochure - Small Scale and Mini LNG SystemsnicoNoch keine Bewertungen

- Experimental Observations On The Flow Past A Plano-Convex HydrofoilDokument10 SeitenExperimental Observations On The Flow Past A Plano-Convex Hydrofoilekybagaskara13Noch keine Bewertungen

- Saudi Aramco Gas Flow Measurement PDFDokument130 SeitenSaudi Aramco Gas Flow Measurement PDFFox Alpha Delta100% (1)

- Pipe Flow Lab ReportDokument11 SeitenPipe Flow Lab ReportGuy PatersonNoch keine Bewertungen

- Pump Performance Datasheet: Operating Conditions LiquidDokument2 SeitenPump Performance Datasheet: Operating Conditions LiquidAntonio ChavezNoch keine Bewertungen

- Rheological Properties of Gelled Rocket PropellantsDokument2 SeitenRheological Properties of Gelled Rocket PropellantsAhmed AbdullahNoch keine Bewertungen

- Experiment 1 - Friction Losses in Pipes-ReportDokument41 SeitenExperiment 1 - Friction Losses in Pipes-ReportKhairil Ikram67% (3)

- 1st Puc Physics Chapter8-Gravitation Notes by U N SwamyDokument11 Seiten1st Puc Physics Chapter8-Gravitation Notes by U N Swamyashwinikumari bNoch keine Bewertungen

- Static Pressure and Pressure Head in FluidsDokument8 SeitenStatic Pressure and Pressure Head in Fluidsyarzar17Noch keine Bewertungen

- Hydraulics and Pneumatics Test 2 Max Marks 20 Answer All QuestionsDokument1 SeiteHydraulics and Pneumatics Test 2 Max Marks 20 Answer All QuestionsJayadev ENoch keine Bewertungen

- Single Phase Flow Vjan2020 - MyAbdn PDFDokument53 SeitenSingle Phase Flow Vjan2020 - MyAbdn PDFUsman MuhammadNoch keine Bewertungen

- Factors Affecting GPE and KE FinalDokument1 SeiteFactors Affecting GPE and KE FinalAzanNoch keine Bewertungen

- 05 Free Fall SVDokument6 Seiten05 Free Fall SVSamaher AzNoch keine Bewertungen

- Fluid Mechanics PDFDokument184 SeitenFluid Mechanics PDFctguyoungNoch keine Bewertungen

- Newton's Three Laws of MotionDokument28 SeitenNewton's Three Laws of MotionDan Luigi TipactipacNoch keine Bewertungen

- On The Stability of Pressure Relief ValvesDokument84 SeitenOn The Stability of Pressure Relief ValvesYenshan LiuNoch keine Bewertungen

- H405 Pipe Surge DatasheetDokument5 SeitenH405 Pipe Surge DatasheetAdakole ObekaNoch keine Bewertungen

- SBIInstructionManual17 03 2014Dokument11 SeitenSBIInstructionManual17 03 2014ramon duldulaoNoch keine Bewertungen

- 211 FA05 HE 1A - QuestionsDokument14 Seiten211 FA05 HE 1A - QuestionsGeorge KongNoch keine Bewertungen

- Projectile MotionDokument8 SeitenProjectile Motionapi-336277944Noch keine Bewertungen

- Spike Contour AlgorithmDokument10 SeitenSpike Contour AlgorithmAleksa TrifkovićNoch keine Bewertungen

- CentrifugationDokument15 SeitenCentrifugationSathish KumarNoch keine Bewertungen

- 5350 Mass and Momentum EquationsDokument12 Seiten5350 Mass and Momentum EquationsGlan DevadhasNoch keine Bewertungen

- Isentropic Flow Through Varying Area DuctDokument9 SeitenIsentropic Flow Through Varying Area DuctpgkaeroNoch keine Bewertungen

- MotionDokument1 SeiteMotionGoh Teck AngNoch keine Bewertungen

- Design Calculation Sheet: Booster PumpsDokument2 SeitenDesign Calculation Sheet: Booster PumpsAhmadNoch keine Bewertungen

- Fluid-Structure Interaction Analysis of A Peristaltic PumpDokument4 SeitenFluid-Structure Interaction Analysis of A Peristaltic PumpSheikh ShoaibNoch keine Bewertungen

- Mekanika Benda Langit - Gerak Dalam Orbit & Transfer OrbitDokument30 SeitenMekanika Benda Langit - Gerak Dalam Orbit & Transfer OrbitafaqihudinNoch keine Bewertungen

- Matrikulasi Hidrolika: Joko NugrohoDokument27 SeitenMatrikulasi Hidrolika: Joko Nugrohoمحمد عزيرNoch keine Bewertungen

- Ata 52 53 56Dokument10 SeitenAta 52 53 56anilmathew244Noch keine Bewertungen

- Vortex - Wikipedia, The Free EncyclopediaDokument8 SeitenVortex - Wikipedia, The Free EncyclopediaSheikh Zakir100% (1)