Beruflich Dokumente

Kultur Dokumente

MultiGrip PDF

Hochgeladen von

luning liOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

MultiGrip PDF

Hochgeladen von

luning liCopyright:

Verfügbare Formate

E N GI NE E RED

B UILD ING

PR OD UC TS

MultiGrip

Mu

lt i

Gr

i p

THE ALL PURPOSE TIMBER

FRAMING ANCHOR

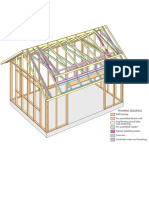

APPLICATION:

The MultiGrip has been developed as an economical

connecting unit to simplify structural jointing in timber

roof, wall, ceiling and floor framing.

ADVANTAGES

SPECIFICATIONS:

MultiGrip can be formed by the

builder on the job as required for

various connections.

Steel Grade

G300

The design incorporates fold

points so that it can be bent on

the job to suit any application.

Thickness

(Total Coated)

1.0mm

MultiGrip reduces the need for

a variety of connectors because

of its suitability for an extremely

wide variety of applications.

Galvanized

Coating

Z275

Nails

By eliminating notches, halved

joints and other difficult and time

consuming carpentry techniques,

it is ideal for both the professional

builder and home handyman.

MiTek 30 x 2.8mm

hot dipped galvanized

reinforced head.

Product Code

This Engineered Building Product complies with the

National Construction Code Series and Australian Standards.

TGM

Mu

lt i

Gr

i p

- Lo

Data

a d

USES

40mm

40mm

MultiGrip is a versatile low cost framing anchor for countless

timber connections.

LOAD DIRECTION

A

B

95mm

LOAD DATA

Limit State Design Capacity (kN)

Load

Direction

A

C/D

Joint Group

Load Case

J2

J3

J4

J5

J6

JD3

JD4

JD5

JD6

DL Only

2.1

1.6

1.1

0.9

0.6

2.1

1.6

1.3

1.0

DL + WL

4.3

3.1

2.3

1.7

1.3

4.3

3.1

2.6

1.9

DL Only

3.1

2.3

1.7

1.3

0.9

3.1

2.3

1.9

1.4

DL + WL

6.3

4.6

3.4

2.6

1.9

6.3

4.6

3.7

2.8

DL Only

2.1

1.6

1.1

0.9

0.6

2.1

1.6

1.3

0.9

DL + WL

3.9

3.0

2.3

1.7

1.3

3.6

2.5

1.9

1.4

DL Only

2.4

1.7

1.3

0.9

0.6

2.4

1.7

1.4

1.0

DL + WL

4.9

3.4

2.3

2.0

1.4

4.9

3.4

2.9

2.1

Values in this table incorporate the Category 1 capacity factor ()

for houses. For other categories, multiply the design capacities by the

following factors. Refer to AS1720.1 for a full definition of each category.

Category

Design capacities have been obtained from laboratory testing and

procedures given in AS1720.1.

Adjustment factor

1.00

0.94

0.88

Mu

lt i

Gr

i p

- In

s ta l l at i o n

INSTALLATION

DESIGN LOADS

1. Fix 10 MiTek 30 x 2.8mm hot dipped galvanized reinforced head

nails in positions shown according to connector orientation.

When fixed as shown the design capacities in different directions

are given in the Table over.

AS1684 COMPLIANCE

MultiGrip complies as a framing anchor and the corresponding

alternative uplift capacities in AS1684 may be used in designs

within the confines of this standard.

Figure 1

4 MiTek nails

Figure 2

4 MiTek nails

2 MiTek nails

4 MiTek nails

Figure 3

4 MiTek nails

2 MiTek nails

5 MiTek nails

5 MiTek nails

TGM 07/15

For more information about MiTeks Engineered Building Products or any other MiTek products or your nearest

licensed MiTek fabricator, please call your local state office or visit: mitek.com.au

HOME OF GANG-NAIL BUILDING SYSTEMS

VIC (03) 8795 8888

NSW (02) 8525 8000

QLD (07) 3861 2100

SA (08) 8234 1326

WA (08) 9412 3534

New Zealand (09) 274 7109

Das könnte Ihnen auch gefallen

- Sanaa PDFDokument68 SeitenSanaa PDFLjiljana Pucelj50% (4)

- Coastalpricelist 2011 09 05Dokument44 SeitenCoastalpricelist 2011 09 05api-181026307Noch keine Bewertungen

- Early Bronco Disc Brake ConversionDokument2 SeitenEarly Bronco Disc Brake ConversionJIMJEO100% (1)

- 2012 Shed TechartDokument15 Seiten2012 Shed TechartMujNoch keine Bewertungen

- Metricon Studio-M House Product CatalogueDokument68 SeitenMetricon Studio-M House Product CatalogueAlvinNoch keine Bewertungen

- Fire Engineering GuideDokument248 SeitenFire Engineering Guideluning li100% (4)

- Plan Bed Heirloom Arts and Crafts PDFDokument13 SeitenPlan Bed Heirloom Arts and Crafts PDFSorin CraciunNoch keine Bewertungen

- 6 Tipuri Pentru MeseDokument19 Seiten6 Tipuri Pentru MesemracneaNoch keine Bewertungen

- Wood Joint Work Part 4Dokument2 SeitenWood Joint Work Part 4Lo M'hNoch keine Bewertungen

- Windsorone Farmhouse Style 2022b WebDokument16 SeitenWindsorone Farmhouse Style 2022b WebStephen Mark Garcellano DalisayNoch keine Bewertungen

- The Super FMT JigDokument2 SeitenThe Super FMT JigflerziNoch keine Bewertungen

- Extreme How To - August 2015Dokument100 SeitenExtreme How To - August 2015gapostoNoch keine Bewertungen

- Arcadia Glasshouse Planning Guide PDFDokument12 SeitenArcadia Glasshouse Planning Guide PDFArya ParamelNoch keine Bewertungen

- Convertible TableDokument18 SeitenConvertible TableFrancisco Huor Melwasul MolinaNoch keine Bewertungen

- EUROmodul Containers 2007Dokument36 SeitenEUROmodul Containers 2007okisoundNoch keine Bewertungen

- The Shabby Craftsman Kitchen Cabinet PricingDokument47 SeitenThe Shabby Craftsman Kitchen Cabinet PricingSamuel Martin McCallNoch keine Bewertungen

- Arched-Stretcher Sofa Table: © 2018 Cruz Bay Publishing, IncDokument11 SeitenArched-Stretcher Sofa Table: © 2018 Cruz Bay Publishing, IncAdam MikitzelNoch keine Bewertungen

- Usa PDFDokument10 SeitenUsa PDFKOOPER FRUITTENoch keine Bewertungen

- Wide Module Pan Skip Joist Spandrel Torsion Concrete Floor Design Detailing PDFDokument92 SeitenWide Module Pan Skip Joist Spandrel Torsion Concrete Floor Design Detailing PDFGonzalo Gomez CastilloNoch keine Bewertungen

- Figure B Framing: Pre-Assembled Dormer Wall Roof Framing (Install After Wall Sheathing) Wall FramingDokument13 SeitenFigure B Framing: Pre-Assembled Dormer Wall Roof Framing (Install After Wall Sheathing) Wall FramingMúsica viajera MX0% (1)

- Nepal Wood 2017Dokument4 SeitenNepal Wood 2017ShouruvhRajouriaNoch keine Bewertungen

- Materials, Supplies, & Cutting Diagram: Traditional Corner Media Cabinet - Upper CabinetDokument2 SeitenMaterials, Supplies, & Cutting Diagram: Traditional Corner Media Cabinet - Upper CabinetDavid TuaineNoch keine Bewertungen

- Loft Conversion (Roof Extension) : Class BDokument0 SeitenLoft Conversion (Roof Extension) : Class BjakescribdNoch keine Bewertungen

- Rear Floor No.6 Crossmember (Assy) : Super Long BodyDokument2 SeitenRear Floor No.6 Crossmember (Assy) : Super Long BodyMilton Poma CabasNoch keine Bewertungen

- Custom Kitchen Cabinets For Your Dream HouseDokument2 SeitenCustom Kitchen Cabinets For Your Dream HouseAlamocabinetsNoch keine Bewertungen

- All Decked Out?: Department of InspectionsDokument2 SeitenAll Decked Out?: Department of InspectionsErMelvinDias100% (1)

- Adirondack Chair PlansDokument9 SeitenAdirondack Chair PlansBEA18Noch keine Bewertungen

- Cut Saw SP720 - EN - Webb2011Dokument16 SeitenCut Saw SP720 - EN - Webb2011MAKRONNoch keine Bewertungen

- TC Owners ManualDokument28 SeitenTC Owners ManualAdrian BernaNoch keine Bewertungen

- U-Bild: Planter BenchDokument2 SeitenU-Bild: Planter BenchEmilian Baluta100% (1)

- Doghouse Project Plan (Casa Caine)Dokument1 SeiteDoghouse Project Plan (Casa Caine)bogd32000Noch keine Bewertungen

- Kitchen DimensionsDokument6 SeitenKitchen DimensionsKirstie Ann Lee - CortesNoch keine Bewertungen

- Hardie Eaves and Soffits Installation ManualDokument28 SeitenHardie Eaves and Soffits Installation ManualpeterpaulwNoch keine Bewertungen

- BUILD116 40 BRANZ Renovation ProjectDokument2 SeitenBUILD116 40 BRANZ Renovation ProjectJpver1000Noch keine Bewertungen

- Architectural Designs:: 57 Danbury Road:: Wilton, CT 06897 USA & Canada 1-800-854-7852 or 1-877-229-2447:: International 262-521-4596Dokument23 SeitenArchitectural Designs:: 57 Danbury Road:: Wilton, CT 06897 USA & Canada 1-800-854-7852 or 1-877-229-2447:: International 262-521-4596farhat4464Noch keine Bewertungen

- Cabinets FrontsDokument41 SeitenCabinets FrontslauraNoch keine Bewertungen

- Family Handyman - June 2023Dokument68 SeitenFamily Handyman - June 2023Ognjen MočevičNoch keine Bewertungen

- An Easy-To-Follow Guide To Achieving A Perfect Result. - Outlines All The Tools You Will Need For The Job. - Includes A Materials ChecklistDokument12 SeitenAn Easy-To-Follow Guide To Achieving A Perfect Result. - Outlines All The Tools You Will Need For The Job. - Includes A Materials ChecklistIrinel DobrisorNoch keine Bewertungen

- 08.24.16 - BOS - Packet Public Works PagesDokument46 Seiten08.24.16 - BOS - Packet Public Works PagesCantonCompassNoch keine Bewertungen

- Ywy8m Extreme Howto Holiday 2013Dokument67 SeitenYwy8m Extreme Howto Holiday 2013José Carlos Alves NogueiraNoch keine Bewertungen

- Smart Kit Kitchens - Company ProfileDokument6 SeitenSmart Kit Kitchens - Company ProfilesmartkitkitchensNoch keine Bewertungen

- Deck Construction GuideDokument13 SeitenDeck Construction Guidefaxtackley100% (2)

- Build A Retaining WallDokument13 SeitenBuild A Retaining WallAnonymous 1TTYYaNoch keine Bewertungen

- 2202 Duo 75 PDFDokument1 Seite2202 Duo 75 PDFWilson Medes AndrinNoch keine Bewertungen

- TE Plywood BrochureDokument6 SeitenTE Plywood BrochureomahasessionsNoch keine Bewertungen

- Tiny Prefab v1Dokument10 SeitenTiny Prefab v1johnykatNoch keine Bewertungen

- Beach ChairDokument48 SeitenBeach ChairEmilian BalutaNoch keine Bewertungen

- LP® Shed Assembly Instructions Hawthorne Place 10'X12' Gable Roof ShedDokument10 SeitenLP® Shed Assembly Instructions Hawthorne Place 10'X12' Gable Roof ShedMinuteman ModelworksNoch keine Bewertungen

- THC ShellKit CASULADokument1 SeiteTHC ShellKit CASULAAdolf John Montero EceNoch keine Bewertungen

- Plan 1Dokument24 SeitenPlan 1ParZiValNoch keine Bewertungen

- Red Wing Steel Works 3x5 Heavy Duty Welding Table Plans PDFDokument7 SeitenRed Wing Steel Works 3x5 Heavy Duty Welding Table Plans PDFDavid BondNoch keine Bewertungen

- The Trend Toward Tiny House Has Become A Social Movement. People Choose ToDokument4 SeitenThe Trend Toward Tiny House Has Become A Social Movement. People Choose Tojhonatan cobosNoch keine Bewertungen

- WWMM Lumber Storage CartDokument9 SeitenWWMM Lumber Storage CartjlpicardNoch keine Bewertungen

- Perfomance Rated I-Joits Roof Framing DetailsDokument10 SeitenPerfomance Rated I-Joits Roof Framing DetailsCeyanezNoch keine Bewertungen

- Retaining WallsDokument4 SeitenRetaining Wallssnorburn1Noch keine Bewertungen

- Horrible Mistakes You're Making With Shoe CabinetDokument2 SeitenHorrible Mistakes You're Making With Shoe CabinetcalvinhmtaNoch keine Bewertungen

- Floor Waste Installation OverviewDokument2 SeitenFloor Waste Installation OverviewstarykltNoch keine Bewertungen

- Under-Sink StorageRDokument5 SeitenUnder-Sink StorageRWalter AcuñaNoch keine Bewertungen

- Enrich Lifestyle Kitchen PresentationDokument60 SeitenEnrich Lifestyle Kitchen PresentationMandar NaniwadekarNoch keine Bewertungen

- Installing a Garage Door and Opener- Special Bundle: Cake Decorating for BeginnersVon EverandInstalling a Garage Door and Opener- Special Bundle: Cake Decorating for BeginnersNoch keine Bewertungen

- Multi GripDokument4 SeitenMulti Gripluning liNoch keine Bewertungen

- Triple L GripDokument4 SeitenTriple L GripjlolhnpNoch keine Bewertungen

- Geo ReportDokument19 SeitenGeo Reportluning liNoch keine Bewertungen

- Self Weight Section Material Ix10 Ex10 KN/MDokument2 SeitenSelf Weight Section Material Ix10 Ex10 KN/Mluning liNoch keine Bewertungen

- Multi GripDokument4 SeitenMulti Gripluning liNoch keine Bewertungen

- Sika Grout 212, 215 - PDSDokument4 SeitenSika Grout 212, 215 - PDSluning liNoch keine Bewertungen

- CURRICULUM VITAE - Internship of Civil Engineering: Career ProfileDokument3 SeitenCURRICULUM VITAE - Internship of Civil Engineering: Career Profileluning liNoch keine Bewertungen

- 07-01-2021Dokument3.032 Seiten07-01-2021kiran raghukiranNoch keine Bewertungen

- Abcd - 05 May 2012Dokument76 SeitenAbcd - 05 May 2012jumanleeNoch keine Bewertungen

- Lift Slab Construction of Pre-CastDokument16 SeitenLift Slab Construction of Pre-CastZahra ZeeNoch keine Bewertungen

- Internship Report On PWDDokument17 SeitenInternship Report On PWDbrhamsterNoch keine Bewertungen

- ITP For Concrete Paving WorkDokument15 SeitenITP For Concrete Paving WorkShewale Pravin100% (1)

- UAUIM School of ArchitectureDokument68 SeitenUAUIM School of ArchitectureValentin PașaNoch keine Bewertungen

- Duct Size CalculationDokument4 SeitenDuct Size CalculationRashel HasanNoch keine Bewertungen

- Case Study and Design ProgramDokument27 SeitenCase Study and Design ProgramĂxmêď Yáżìñ Hlg100% (1)

- Bub GB STn96Qeg3D4CDokument126 SeitenBub GB STn96Qeg3D4Carchsubhankar100% (1)

- The Chettiar Identity Subtitle Script - V3Dokument5 SeitenThe Chettiar Identity Subtitle Script - V3Dr.Srinivasan KannappanNoch keine Bewertungen

- Journal Article Summary: Andre Geovano PongpareDokument2 SeitenJournal Article Summary: Andre Geovano PongpareBerliana Para'pakNoch keine Bewertungen

- Cheat Sheet Right For YouDokument2 SeitenCheat Sheet Right For YouAshish NegiNoch keine Bewertungen

- Comparative History of ArchitectureDokument21 SeitenComparative History of ArchitectureEvaraNoch keine Bewertungen

- Soal Pas KLS 7 Sem 2 TH 2023 KunciDokument6 SeitenSoal Pas KLS 7 Sem 2 TH 2023 Kuncisaniah_daniaNoch keine Bewertungen

- Scott Schedule Example 1 and 2Dokument3 SeitenScott Schedule Example 1 and 2Megan DeeNoch keine Bewertungen

- It Controls The Capacity of Road. It Has Highest Cost Per KM Run. If Bridge Fails, System FailsDokument18 SeitenIt Controls The Capacity of Road. It Has Highest Cost Per KM Run. If Bridge Fails, System Fails19rikenNoch keine Bewertungen

- 456 - Ammendment No. 3 Aug07Dokument3 Seiten456 - Ammendment No. 3 Aug07Ravi Singh0% (1)

- Lect - 3 - Earthquake - Design - Philosophy - Part 1Dokument8 SeitenLect - 3 - Earthquake - Design - Philosophy - Part 1jana ShmaysemNoch keine Bewertungen

- 104 1F CompletedDokument383 Seiten104 1F CompletedAlfredo Landaverde GarcíaNoch keine Bewertungen

- COnstruciton Operation ManualDokument81 SeitenCOnstruciton Operation ManualShankey BafnaNoch keine Bewertungen

- How To Fix Leaks On Clay Tile Roofs PDFDokument4 SeitenHow To Fix Leaks On Clay Tile Roofs PDFNishith ReddyNoch keine Bewertungen

- Sekaran Lyrica Phase 2Dokument12 SeitenSekaran Lyrica Phase 2Kayalvizhi BommanNoch keine Bewertungen

- Product Kemcrete Nov16 PDFDokument2 SeitenProduct Kemcrete Nov16 PDFSeifeldin Ali MarzoukNoch keine Bewertungen

- Reinforced Strip Foundation of A Single-Storey Building As Per BS 8100.Dokument7 SeitenReinforced Strip Foundation of A Single-Storey Building As Per BS 8100.GOUTAM NANDINoch keine Bewertungen

- National Building Code of India 2005Dokument1.178 SeitenNational Building Code of India 2005Sonmoy Chatterjee82% (39)

- Pennar - Decking Profile-REPLYDokument3 SeitenPennar - Decking Profile-REPLYkushaljp8989Noch keine Bewertungen

- Quality Assurance Deliverables Checklist 2014Dokument57 SeitenQuality Assurance Deliverables Checklist 2014Jakechris SicadNoch keine Bewertungen

- Building Construction - Stair DesignDokument16 SeitenBuilding Construction - Stair DesignRobert LaneNoch keine Bewertungen

- Housing, Space and Quality of Life:: Ricardo García-Mira, David L. Uzzell, J. Eulogio Real and José RomayDokument5 SeitenHousing, Space and Quality of Life:: Ricardo García-Mira, David L. Uzzell, J. Eulogio Real and José RomayalonurNoch keine Bewertungen