Beruflich Dokumente

Kultur Dokumente

Download

Hochgeladen von

Afia S HameedCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Download

Hochgeladen von

Afia S HameedCopyright:

Verfügbare Formate

778

Zhu et al. / J Zhejiang Univ-Sci A (Appl Phys & Eng) 2013 14(11):778-788

Journal of Zhejiang University-SCIENCE A (Applied Physics & Engineering)

ISSN 1673-565X (Print); ISSN 1862-1775 (Online)

www.zju.edu.cn/jzus; www.springerlink.com

E-mail: jzus@zju.edu.cn

Mechanical behavior of concrete filled glass fiber

reinforced polymer-steel tube under cyclic loading*

Chun-yang ZHU, Ying-hua ZHAO, Shuang GAO, Xiao-fei LI

(Institute of Road and Bridge Engineering, Dalian Maritime University, Dalian 116026, China)

E-mail: chunyangzhu86224@gmail.com; yhzhao@dlmu.edu.cn

Received June 15, 2013; Revision accepted Sept. 29, 2013; Crosschecked Oct. 12, 2013

Abstract: The mechanical behavior of concrete-filled glass fiber reinforced polymer (GFRP)-steel tube structures under combined seismic loading is investigated in this study. Four same-sized specimens with different GFRP layout modes were tested by a

quasi-static test system. Finite element analysis (FEA) was also undertaken and the results were presented. Results of the numerical simulation compared well with those from experimental tests. Parametric analysis was conducted by using the FE models

to evaluate the effects of GFRP thickness, axial compression rate, and cross sectional steel ratio. The experimental and numerical

results show that the technique of GFRP strengthening is effective in improving the seismic performance of traditional

concrete-filled steel tubes, with variations related to different GFRP layout modes.

Key words: Concrete-filled glass fiber reinforced polymer (GFRP)-steel tube, Seismic, Energy dissipation, Stiffness degradation

doi:10.1631/jzus.A1300206

Document code: A

CLC number: TU398+.9

1 Introduction

Concrete-filled steel tube (CFT) structures have

been widely used in tall buildings and arch bridges

around the world. The steel tube and concrete work

together, to resist applied loads. The external steel

tube provides confinement for the inner concrete

which in turn delays local buckling of the tube and so

increases the stability and strength of the column as a

system. Previous studies have shown that CFT structural members have a number of distinct advantages

over equivalent steel, reinforced concrete, or

steel-reinforced concrete members, especially for

seismic resistance. These advantages include high

stiffness and strength, large energy absorption and

enhanced ductility and stability (Shams and Saadeghvaziri, 1997; Morino, 1998; Uy, 1998; Schneider,

Corresponding author

Project supported by the National Natural Science Foundation of

China (No. 51178068), and the Fundamental Research Funds for the

Central Universities of China (No. 3132013315)

Zhejiang University and Springer-Verlag Berlin Heidelberg 2013

*

1998; Zhang and Shahrooz, 1999; Liang and Uy,

2000; Bradford et al., 2002). However, since the

Poissons ratio of steel is higher than that of concrete,

a separation, caused by differential expansion between the steel tube and the concrete will occur at the

early stages of loading (Roeder et al., 1999), which

will inevitably delay the activation of the confinement

mechanism. Furthermore, exposed steel is doomed to

a limited service life and high maintenance costs,

especially if it is used in harsh marine environments

(Brown and Powers, 1986; Lasa et al., 1998).

Another similar structure is the concrete-filled

fiber reinforced polymer (FRP) tube (CFFT). The

main advantage of this composite construction is the

optimal use of materials based on their mechanical

properties and corrosion resistance (Mirmiran and

Shahawy, 1996). FRP with its extremely high tensile

strength provides a more effective confinement for

concrete and its laminate structure can be controlled

to provide different proportions of strength and

stiffness in the longitudinal and transverse directions.

A FRP jacket withstands a harsh, salty environment

with high internal temperature, direct sunlight,

Zhu et al. / J Zhejiang Univ-Sci A (Appl Phys & Eng) 2013 14(11):778-788

moisture, vapor, and seawater (Chajes et al., 1995;

Steckel et al., 1998) indicating that CFFT overcomes

the defect of low corrosion resistance of CFT and can

be used in some extreme environments. However,

since FRP is a brittle material, if it breaks suddenly

under accidental loads, such as an earthquake or an

impact, the strength of the whole system would drop

dramatically (Fam and Rizkalla, 2001), inevitably

resulting in insufficient ductility compared with the

equivalent CFT structure.

Following extensive studies on CFT and CFFT

columns, a new CFT structure, termed concrete-filled

FRP-steel tube (FRP-CFT), has been introduced

(Wang and Zhao, 2003), which is made by filling a

steel tube with concrete and wrapping the tube with

FRP sheet. FRP wrapping enables the column to develop multi mechanical properties and acts as an

anti-corrosion jacket for the steel tube, and the steel

tube, providing compensation for the brittleness of the

FRP, assures the ductility of the whole system.

Experimental and theoretical research on

concrete-filled carbon fiber reinforced polymer

(CFRP)-steel tube (CFRP-CFT) has been carried out.

(Gu and Zhao, 2007) conducted experiments on concrete-filled hoop CFRP-steel tube under axial compression. Specimens included long and short columns.

The results on short columns showed a significant

improvement in the loading capacity compared with

the equivalent CFT structure; however, with the increase in the slenderness ratio, the strengthening effect of CFRP declined. When the slenderness ratio

reached a certain value, there was no strengthening

effect of CFRP. Gu et al. (2006) deduced formulas for

the loading capacity under axial compression of

concrete-filled CFRP-steel tubes of different slenderness, which showed good agreement with experimental results. Wang et al. (2008) reported on

torsion and bending experiments with concrete-filled

CFRP-steel tube. The results showed that both

circumferential and longitudinal CFRPs can enhance

the ultimate torsion capacity of the specimens. Longitudinal CFRP enhances the ultimate moment and

flexural stiffness of the composite members significantly. Tao and Yu (2006) treated CFRP as a retrofitting technique for repairing CFT structures damaged

by fire. A number of tests for compression and

bending were conducted. The results proved that

779

CFRP strengthening can effectively improve the

mechanical properties of a damaged CFT structure.

2 Aim and scope

Another FRP, GFRP, which is being widely used

for strengthening old or damaged infrastructure, can

also be used in combination with a CFT column.

Compared with CFRP, GFRP has notable advantages

(Nishizaki and Meiarashi, 2002; Bousias et al., 2004;

Huang et al., 2005a; 2005b; Gadve et al., 2009).

1. The ultimate elongation rate of GFRP is

higher than that of CFRP. By using this property,

GFRP combined structures should have more deformable capacity than CFRP ones.

2. GFRP is an electronic isolation material and

so, when combined with steel, it can protect it from

the electrochemical corrosion which readily occurs on

steel or steel reinforced concrete structures in marine

environments.

3. The thermal expansion coefficient of GFRP is

similar to that of steel, which eliminates thermal

stress at the interface with the steel surface.

4. The cost of GFRP is lower and its production

process is well-established.

By using these characteristics of GFRP, a new

FRP-CFT, termed concrete-filled GFRP-steel tube

(GFRP-CFT), is proposed. In this paper, we describe

an investigation of the mechanical properties of a

GFRP-CFT structure member under cyclic loading. A

quasi-static test was developed and the influence of

different GFRP layout modes was analyzed. Finite

element models were applied based on the experimental process and the seismic performance of GFRPCFT was studied at varying GFRP thicknesses, axial

compression ratios, and cross sectional steel ratios.

As a novel combining structure, GFRP-CFT is a

three-phase composite structure. Investigations of

the failure modes and the GFRP strengthening

mechanisms under cyclic loading are essential when

using. A GFRP-steel composite jacket can also be

used as a retrofitting tool for old or damaged concrete structures. It might also be used as an

anti-corrosion jacket for structures in marine environments, and that will be investigated in future

study based on this research.

780

Zhu et al. / J Zhejiang Univ-Sci A (Appl Phys & Eng) 2013 14(11):778-788

3 Experimental

3.1 Specimens and apparatus

Four same-sized CFT or GFRP-CFT specimens

were prepared as listed in Table 1, where K-0 is ordinary CFT as reference. H-1G, L-1G, and B-2G are

circumferential, longitudinal, and bi-directional

GFRP wrapping specimens, respectively. For all

specimens, the lengths are 1700 mm and the outer

diameters and thickness of the steel tubes are 114 mm

and 3.5 mm, respectively.

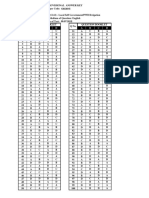

Table 1 Parameters of specimens

Serial

GFRP

GFRP

Axial comnumber layers/thickness wrapping mode pression ratio

K-0

H-1G

1/0.354 mm Circumferential

0.14

L-1G

1/0.354 mm

Longitudinal

B-2G*

2/0.708 mm

Bi-direction

*

Bi-direction wrapping mode is longitudinal wrapping inside

and circumferential wrapping outside

Commercial C40 concrete is used with an average compressive strength of 38.70 MPa for 150 mm

cubic specimens and a compressive initial elastic

modulus of 32 500 MPa. Yield stress of the seamless

steel tube is 245 MPa, and the elastic modulus is

206 000 MPa. The parameters of the glass fiber are

described in Table 2.

Table 2 Mechanical properties of glass fiber

Thickness

(mm)

0.354

Mass per

unit area

(g/m2)

900

Tensile

strength

(MPa)

1500

Tensile Limit elonmodulus

gation

(MPa)

(%)

72 000

2.0

Specimens were constructed as follows. Seamless steel tubes were cut to the designed length, ensuring that the cross-sections of the two ends were

perpendicular to the axis. A steel plate was then

welded onto one end of the tube and the tube was

filled with concrete. After 28 d the redundant concrete

expanded from the tube was cut off and another steel

plate was welded to the free end. Lastly, the surfaces

of the steel tubes were polished before affixing the

GFRP sheets by daubing the surface of the tubes with

resinous glue and wrapping the GFRP sheets around

them, scraping the surface of the sheets to squeeze out

air between them and the steel tubes. To assure that

the GFRP sheets were immersed in resinous glue.

After 48 h, the specimens were ready for testing.

Specimens were installed horizontally and both

ends were pinned, as shown in Figs. 1 and 2. The

multiple loads included cyclic lateral load and axial

compression. Lateral load was provided by two vertical hydraulic jacks and axial compression was provided by a horizontal hydraulic jack, which were both

measured by load cells. The axial compression was

applied to a pre-fixed value and kept the compression

ratio stable at 0.14 during the testing period. For

convenience of comparison, the axial compression

ratio n calculation method for CFT is used for all

specimens, defined as follows:

n

N

,

N u,cr

(1)

where N is the applied axial load, Nu,cr is the ultimate

axial loading capacity, which can be determined by

N u,cr Asc f scy ,

(2)

where =0.000120.228+1.277 is the stability coefficient and is the slenderness ratio. Asc is the

cross-sectional area, Asc=As+Ac, where Ac and As are

the cross sectional areas of the concrete and steel

tubes, respectively. Fscy=(1.14+1.02)fck is the

strength index of concrete, =Asfy/(Acfc), in which fc

and fs are the axial compressive strengths of concrete

and the yield stress of the steel tube, respectively.

Cyclic load is applied in a perpendicular direction. The force-displacement double control law is

used, with force control before yield of the specimen

and displacement control after yield. Loading and

displacing steps are 5 kN and 10 mm, respectively.

The loading law is shown in Fig. 3.

Hydraulic jack

Pressure sensor

Pressure sensor

Gauge

Specimen

Reaction bar

Clamp

Pressure sensor

Hydraulic jack

Hydraulic jack

Fig. 1 Loading schema

Zhu et al. / J Zhejiang Univ-Sci A (Appl Phys & Eng) 2013 14(11):778-788

Top jack

Horizontal jack

Clamp

Bottom jack

Fig. 2 Loading system

30

20

Load (kN)

10

0

-10

-20

-30

0

12

18 24

Load cycle

(a)

30

36

is followed by breaking of the GFRP at the bottom at

the second peak, accompanied with a loud and clear

cracking sound. The GFRP sheet near the ruptures

debonds with the tube surface. After that, fragmentary

cracking sounds can be heard as the deflection increases. The corresponding broken mode is shown in

Fig. 4c. For specimen B-2G, the first fracture occurs

in the 62nd cycle, that is, =50 mm. It is later than

that of specimen L-1G, but is also accompanied with a

loud and clear cracking sound. As shown in Fig. 4d,

because of restriction by the outer circumferential

GFRP the broken GFRP sheet near the crannies does

not de-bond from the steel tube. In testing, local

buckling of the steel tube is hardly observed, indicating that circumferential GFRP provides an effective confinement for the inner steel tube. The development of local buckling of the steel tube, which

would rapidly increase the strain in attached

42

Displacement (mm)

60

40

(a)

20

0

-20

-40

-60

42

48

54

60

Load cycle

(b)

66

72

(b)

Fig. 3 Loading law

(a) Load control; (b) Displacement control

3.2 Test observations

In testing, local buckling of the steel tube can be

observed in mid-span for K-0 when the deflection

reaches a maximum. The failure form is shown in

Fig. 4a. For specimen H-1G, several crannies appear

in the epoxy, accompanied by a cracking sound when

the deflection reaches about 20 mm. These crannies

occur in mid-span and surround the tube, but rupture

of the fiber was not observed in testing. The corresponding broken mode after testing is shown in

Fig. 4b. The first signs of distress in specimens L-1G

and B-2G are fracture of the GFRP at the top and the

bottom. For L-1G, it is at the first peak of the 55th

cycle, that is, =40 mm. Fracture of GFRP at the top

781

(c)

(d)

Fig. 4 Specimens failure forms

(a) K-0; (b) H-1G; (c) L-1G; (d) B-2G

782

Zhu et al. / J Zhejiang Univ-Sci A (Appl Phys & Eng) 2013 14(11):778-788

longitudinal GFRP in the buckling region, is restrained by the circumferential GFRP; as a result, the

longitudinal GFRP of B-2G fractures later than that of

L-1G.

3.3 Hysteresis curves

80

80

60

60

40

40

20

Load (kN)

Load (kN)

Hysteresis curves for all specimens from the

tests are shown in Fig. 5. Fig. 5a is for K-0, which is a

typical hysteresis curve for a general CFT structure.

Note that the hysteresis loops for the different load

cycles partly overlap and each summit point falls on

the next loop. The outline of the entire hysteresis

curve is smooth. There are reasonable similarities in

the form of the hysteresis curves of K-0 and H-1G,

showing that circumferential GFRP wrapping makes

little contribution to seismic performance in this test.

Since GFRP is an anisotropic material, its tensile

strength and elastic modulus in the fiber direction are

much higher than those in other directions, and

circumferential GFRP strengthening provides confinement in the hoop direction and restrains local

buckling of the steel tube, resulting in improved

loading capacity. However, this strengthening effect

becomes weaker as the length of column increases. In

this test, where the slenderness ratio for all specimens

is 14.9, the strengthening effect from circumferential

GFRP is not notable. Therefore, there is no obvious

difference between the hysteresis curves for K-0 and

H-1G.

However, the hysteresis curves change very obviously for L-1G and B-2G compared with those for

K-0 (or H-1G). Their outlines can be described by

combining two different hysteresis loops. Since there

are reasonable similarities in form of these two hysteresis curves, only the hysteresis curve for L-1G is

taken for illustration here (Fig. 6). Before GFRP

failure, the hysteresis curve for L-1G is in the dark

loop and the longitudinal GFRP strengthening effect

is mainly reflected there. Two load summit points A

and B are located outside the equivalent loop of K-0,

showing that the loading capacity for specimen L-1G

is enhanced; the area of the dark loop is much larger

than that of the K-0 counterpart, indicating that

specimen L-1G has a better energy dissipation

0

-20

-40

0

-20

-40

-60

-80

-80

20

-60

-40

-20

20

40

K-0

-60

60

-80

-80

80

H-1G

-60

60

GFRP fracture

40

20

20

Load (kN)

Load (kN)

20

40

60

80

80

40

0

-20

-40

GFRP fracture

0

-20

-40

-60

-80

-80

-20

(b)

80

60

-40

Displacem ent (m m )

Displacement (mm )

(a)

L-1G

-60

-40 -20

0

20 40

Displacem ent (mm )

60

-60

80

-80

-80

B-2G

-60

(c)

-40 -20

0

20 40

Displacement(m m)

(d)

Fig. 5 Experimental hysteresis curves

(a) K-0; (b) H-1G; (c) L-1G; (d) B-2G

60

80

783

Zhu et al. / J Zhejiang Univ-Sci A (Appl Phys & Eng) 2013 14(11):778-788

ability than K-0. However, as deflection develops, the

shape of the hysteresis loop reverts to that of K-0 after

the longitudinal GFRP fractures and the GFRP

strengthening effect fades away at this time.

90

The last hyesteretic loop of L-1G before

GFRP fracture and counterpart of K-0

pmax

60

Load (kN)

slope of the line joining the origin and the loading

summit point of hysteresis loop, which can be defined

as

30

0

-30

K-0

L-1G

-60

-90

-90

-60

The last hyesteretic

loops for K-0 and L-1G

-30

30

60

90

Displacement (mm)

(3)

where Pmax is the loading summit value of each cyclic

loop, and c is the corresponding displacement.

The variation of K is shown in Fig. 8. K decreases

rapidly with increased displacement. Compared with

specimen K-0, GFRP strengthened specimens have

low equivalent rigidity degradation before GFRP

failure, especially for specimens L-1G and B-2G at the

post-elastic stage.

Fig. 6 Hysteresis curves for L-1G and K-0

80

3.4 Loading carrying capacity

3.5 Equivalent rigidity degradation

Damage of the specimens can be assessed by the

degradation of the equivalent rigidity K, which is the

Load (kN)

40

20

Post-elastic stage

Elastic stage

0

-20

K-0

H-1G

L-1G

B-2G

-40

-60

-80

-80 -60 -40 -20 0

20 40

Displacement (mm)

60

80

Fig.7 Skeleton curves for different FRP wrapping modes

3.5

Equivalent stiffness (kN/mm)

Comparison of the skeleton curve of specimen

K-0 with those of specimens H-1G, L-1G, and B-2G

shows the remarkably beneficial effect of GFRP

wrapping on the strength of columns (Fig. 7). It can

be seen that all load-displacement (P-) curves

overlap closely at the elastic stage, showing that

GFRP strengthening cannot improve elastic stiffness

effectively for every structure. When entering the

post-plastic stage, the strengthening effect appears

gradually. Tangential stiffness for GFRP wrapping

specimens improves to different extents compared

with that for K-0. Since GFRP hoop strengthening is

not very effective for these long columns, the loading

improvement for H-1G is the lowest among the three

GFRP wrapping specimens. For L-1G, the longitudinal GFRP can work with the steel tube under bending

and provides effective stress compensation for it in

the tensile zone, eventually improving post-elastic

stiffness and loading capacity effectively for the

whole structure. For B-2G, bi-directional GFRP can

both restrain local buckling and strengthen the steel

tube in the tensile direction. Thus, its ultimate

strength improvements are the highest among all the

specimens. The load summit also occurs later than in

other GFRP wrapping specimens due to the confinement of the steel tube by the hoop GFRP.

60

K-0

H-1G

L-1G

B-2G

3.0

2.5

2.0

1.5

1.0

0.5

-80

-60

-40 -20

0

20 40

Displacement (mm)

60

80

Fig. 8 Stiffness degradation for different GFRP wrapping

specimens

3.6 Energy dissipation capacity

In order to evaluate the energy dissipation capacity of all specimens, a normalized energy dissipative coefficient E is calculated by

E

S ABCD

,

S OBF SODE

(4)

784

Zhu et al. / J Zhejiang Univ-Sci A (Appl Phys & Eng) 2013 14(11):778-788

where SABCD is the area of the hysteresis curve (the

outlines of the whole hysteresis curve used to calculate

E are marked blue in Fig. 9), SOBF and SODG are the

areas of the corresponding triangles (marked red in

Fig. 9) (in the web version). Because GFRP strengthening enlarges the areas of the hysteresis curves, energy dissipation capacity for GFRP wrapping specimens improves to different levels compared with that

of specimen K-0. Results for calculating E are shown

in Table 3.

Table 3 Energy dissipation capacity for GFRP strengthened CFT

Serial number

K-0

H-1G

L-1G

B-2G

80

60

E

2.23

2.29

2.47

2.61

Improvement (%)

2.7

10.8

17.0

Outline of hyesteretic curves

for K-0

with a Youngs modulus of 60 000 MPa. The fracture

of GFRP is emulated by using the Hashin damage

laws. Interface constraints between different materials (GFRP, steel tube and concrete) use binding constraints (tie) which assume no relative sliding between interfaces.

Concrete is modeled with an eight-node linear

reduced integration with an hourglass control solid

element (C3D8R). This element has large deflection

and strain capabilities. The steel tube was modeled

with an eight-node continuum shell with a reduced

integration and hourglass control membrane element

(SC8R). For GFRP, a four-node membrane with reduced integration and an hourglass control element

(M3D4R) is used.

The calculated stress contours of the concrete,

steel tube and GFRP are shown in Figs. 10a, 10b, and

10c, respectively. Obvious protrusions occur on both

sides of the load-acting position on the steel tube

Load (kN)

40

20

0

A

O

-20

-40

-60

-80

Outline of hyesteretic

curves for L-1G

-80 -60 -40 -20 0

20 40

Displacement (mm)

60

(a)

80

Fig. 9 Schematic sketch of E calculation for L-1G

4 Finite element investigation

4.1 Finite element modeling

In order to study the influence of GFRP wrapping on the seismic properties of the structure,

ABAQUS finite element analysis (FEA) software is

used for numerical analyses. Due to the symmetry of

loads and structure geometry, semi-structures of CFT

and GFRP-CFTs with different GFRP layout modes,

are modeled. The experimental program is completely emulated. In the modeling process, a concrete

damage plastic model provided by the ABAQUS

material library is used to realize the damage processes in the concrete and standard elastic-plastic

model, and the von Mises yield criterion is used for

the steel tube. GFRP is treated as an elastic material

(b)

(c)

Fig. 10 Concrete longitudinal stresses distribution (a),

steel tube von Mises stresses distribution (b), and GFRP

longitudinal stresses distribution (c)

785

Zhu et al. / J Zhejiang Univ-Sci A (Appl Phys & Eng) 2013 14(11):778-788

under combined loads of axial and vertical pressures,

indicating that buckle will occur at that region.

Comparisons of hysteresis curves from experiment and numerical simulations are shown in Fig. 11,

in which green and red curves (in the web version) are

the skeleton curves. From these figures, the stiffness

of hysteresis curves at both elastic and post-elastic

stages from ABAQUS simulations is a little higher

than that from experiment, with an average error of

5%. This is mainly because binding constraints between the interfaces of different materials increase the

integral rigidity of the FE models, resulting in FE

models stiffer than the real structures. In reality, relative sliding does exist between the interfaces, but if it

were perfectly simulated, the cost of calculation

would be excessive. However, the entire shapes of the

hysteresis curves from ABAQUS simulation are coincident with those from experiment and the trends of

two corresponding skeleton curves are nearly identical, indicating that the finite element models are reasonably built and can be used for the parameter study.

80

In order to investigate the influences of GFRP

thickness on seismic performance, FE models with

different GFRP thicknesses are built. Simulation results are shown in Fig. 12. Compared with CFT,

loading capacity for the GFRP-CFTs is improved and

the improvement is related to the GFRP wrapping

direction and thickness. Circumferential GFRP

thickness has little effect to the ultimate loading capacity, with less than a 1% improvement for the four

circumferential GFRP layers. However, the ultimate

loading capacity improves significantly with the increase in the longitudinal GFRP thickness. At the

same time, the tangential stiffness of the post-elastic

stage of the skeleton curve improves correspondingly.

The relationship of the thickness of longitudinal

GFRP to equivalent stiffness and ultimate loading

capacity is shown in Fig. 13, indicating that equivalent

stiffness and ultimate loading capacity are almost

linearly related to the increase in longitudinal GFRP

thickness.

80

Experiment, hysteresis curve

FEM, hysteresis curve

60

40

40

20

20

Load (kN)

Load (kN)

60

4.2 Parametric analysis

0

-20

FEM, skeleton curve

Experiment, skeleton curve

-60

80

-20

-60

-40 -20 0

20 40

Displacement (mm)

(a)

60

-60

-80

-80

80

80

Experiment, hysteresis curve

FEM, hysteresis curve

60

40

40

20

20

Load (kN)

Load (kN)

60

-40

-40

-80

-80

0

-20

FEM, skeleton curve

Experiment, skeleton curve

-60

-40 -20 0

20 40

Displacement (mm)

(b)

60

80

Experiment, hysteresis curve

FEM, hysteresis curve

0

-20

-40

-40

-60

Experiment, hysteresis curve

FEM, hysteresis curve

FEM, skeleton curve

Experiment, skeleton curve

-80

-80 -60 -40 -20 0

20 40

Displacement (mm)

(c)

60

80

-60

FEM, skeleton curve

Experiment, skeleton curve

-80

-80 -60 -40 -20 0 20 40

Displacement (mm)

(d)

60

Fig. 11 Comparison of experimental and simulation hysteresis curves of all specimens

(a) K-0; (b) H-1G; (c) L-1G; (d) B-2G

80

786

Zhu et al. / J Zhejiang Univ-Sci A (Appl Phys & Eng) 2013 14(11):778-788

80

60

40

40

20

20

0

1-layer

2-layer

3-layer

4-layer

-20

-40

-60

-80

-80

-60

(b)

60

Load (kN)

Load (kN)

80

(a)

-40 -20 0

20

Displacement (mm)

40

0

-20

1-layer

2-layer

3-layer

-40

-60

-80

60

-60

-40 -20

0

20

40

Displacement (mm)

60

56

(a)

55

(b)

50

Ultimate load (kN)

54

Equivalent stiffness ( 1

0 kN/mm)

Fig. 12 Skeleton curves for specimens with different circumferential/longitudinal GFRP thickness

(a) Circumferential GFRP; (b) Longitudinal GFRP

52

50

48

46

1.062

0.354

0.708

Longitudinal GFRP thickness (mm)

45

40

35

30

0.354

1.062

0.708

Longitudianl GFRP thickness mm)

Fig. 13 GFRP layers-ultimate load (a) and GFRP layers-equivalent stiffness (b) relationships

Note: The longitudinal thicknesses of 0.354, 0.708, and 1.062 mm are for 1-layer, 2-layer, and 3-layer GFRPs,

respectively

60

(a)

Load (kN)

40

20

0

n=0

n=0.07

n=0.14

n=0.21

n=0.28

-20

-40

-60

60

(b)

40

Load (kN)

Skeleton curves under different axial compression ratios n are shown in Fig. 14, in which the hysteresis curves under axial compression ratios of 0 and

0.28 are given. As the axial compression ratio increases, the loading capacity and tangential stiffness

of the skeleton curve in the post-plastic stage degrade

significantly. The shape of the hysteresis curve under

high axial compression also changes. The load summit occurs earlier and the post strength degrades more

with each hysteresis loop as n increases.

Fig. 15 shows the relationship between equivalent

tangential stiffness in the post-plastic stage of the

skeleton curve and axial compression ratios. It indicates that for the longitudinal GFRP layout specimens,

as the axial compression ratio increases, the equivalent

tangential stiffness declines almost linearly, but for the

circumferential GFRP wrapping specimens, the decline is non-linear and the decreasing amplitude is low.

Varying the cross sectional steel rate of L-1G by

changing the thickness of the steel tube (keeping the

inner diameter stable and varying the outer diameter),

20

0

n=0

n=0.07

n=0.14

n=0.21

n=0.28

-20

-40

-60

-60

-40

-20

0

20

40

Displacement (mm)

60

Fig. 14 Skeleton curves of H-1G (a) and L-1G (b) under

different axial compression ratios

Zhu et al. / J Zhejiang Univ-Sci A (Appl Phys & Eng) 2013 14(11):778-788

Equivalent stiffness (kN/mm)

gives the hysteresis and skeleton curves as shown in

Fig. 16. All hysteresis curves get plumper as the cross

sectional steel ratio () increases; elastic and postelastic stiffness and loading capacity also improve.

0.40

H-1G

L-1G

0.35

0.30

0.25

0.20

0.15

0.10

0.00 0.05 0.10 0.15 0.20 0.25 0.30

Axial compression ratio

Fig. 15 Relationship of equivalent tangential stiffness for

elastic-plastic stage of the skeleton curve and axial compression ratios

80

=0.15

(a)

=0.11

=0.07

=0.04

60

Load (kN)

40

20

0

-20

-40

-60

-80

-60 -40 -20 0 20 40 60

Displacement (mm)

80

80 100

(b)

60

Load (kN)

40

20

0

-20

=0.04

=0.07

=0.11

=0.15

-40

-60

-80

-60

-40 -20

0

20

40

Displacement (mm)

60

Fig. 16 Hysteresis (a) and skeleton (b) curves with different steel rates of L-1G

787

steel tube while longitudinal wrapping inhibits bending. GFRP strengthening can also improve the initial

strength of the composite column.

2. Seismic performance for GFRP-CFT improves because of the GFRP strengthening. The

equivalent rigidity degeneration rates for GFRP-CFTs,

especially for longitudinal and bi-directional GFRP

layout ones, are lower than that of CFT. The normalized energy dissipation coefficients for specimens

with circumferential, longitudinal, and bi-direction

GFRPs improve by 2.7%, 10.8% and 17.0%,

respectively.

3. A plastic-damage model for concrete and the

Hashin damage laws for fiber can be used to model

GFRP-CFT which is a three-phase composite structure. The reinforcement effect of GFRP is mainly

reflected at the post-plastic stage. The longitudinal

and bi-directional GFRP layouts are more effective

than the circumferential one for improving the bending strength of a long column. As the GFRP thickness

increases, the ultimate bearing capacity and skeleton

curve tangential stiffness for the post-plastic stage

improve linearly, causing a corresponding increase in

the area of the hysteresis loop representing energy

dissipation capacity.

4. The axial compression ratio and steel rate

have obvious effects on GFRP-CFT seismic behavior:

post-elastic stiffness and post-strength degrade with

the increase of the axial compression ratio. The decline for longitudinal GFRP wrapping specimens is

greater than that for circumferential GFRP wrapping

ones. The higher the steel rate, the more energy dissipation capacity the structure has.

References

Bousias, S.N., Triantafillou, T.C., Fardis, M.N., Spathis, L.,

ORegan, B.A., 2004. Fiber-reinforced polymer retrofitting of rectangular reinforced concrete columns with or

without corrosion. ACI Structural Journal, 101(4):512520.

Bradford, M.A., Loh, H.Y., Uy, B., 2002. Slenderness limits

for filled circular steel tubes. Journal of Constructional

Steel Research, 58(2):243-252. [doi:10.1016/S0143-974X

(01)00043-8]

5 Conclusions

1. The mechanical properties of the GFRP-CFT

are improved compared with CFT and that improvement is also related to the GFRP layout modes.

GFRP hoop wrapping can inhibit local buckling of the

Brown, R.P., Powers, R.G., 1986. Update on the Use of Conductive Materials for Cathodic Protection of Steel in

Concrete, NACE, Houston, USA, p.264.1-264.8.

Chajes, M.J., Thomson, T.A.Jr, Farschman, C.A., 1995. Durability of concrete beams externally reinforced with

composite fabrics. Construction and Building Materials,

9(3):141-148. [doi:10.1016/0950-0618(95)00006-2]

788

Zhu et al. / J Zhejiang Univ-Sci A (Appl Phys & Eng) 2013 14(11):778-788

Fam, A.Z., Rizkalla, S.H., 2001. Confinement model for axially loaded concrete confined by circular fiber-reinforced

polymer tubes. ACI Structural Journal, 98(4):451-461.

Gadve, S., Mukherjee, A., Malhotra, S.N., 2009. Corrosion of

steel reinforcements embedded in FRP wrapped concrete.

Construction and Building Materials, 23(1):153-161.

[doi:10.1016/j.conbuildmat.2008.01.008]

Gu, W., Zhao, Y.H., 2007. Experimental study on concrete

filled CFRP-steel tube columns with axial compression.

China Civil Engineering Journal, 40(11):23-28 (in

Chinese).

Gu, W., Zhao, Y.H., Shang, D.W., 2006. Load carrying capacity of concrete filled CFRP-steel tubes under axial compression. Engineering Mechanics, 23(1):149-153 (in

Chinese).

Huang, Y.L., Hung, C.H., Yen, T., Wu, J.H., Lin, Y., 2005a.

Strengthening reinforced concrete beams using

prestressed glass fiber-reinforced polymer-Part II: Analytical study. Journal of Zhejiang University-SCIENCE A,

6(8):844-852. [doi:10.1631/jzus.2005.A0844]

Huang, Y.L., Wu, J.H., Yen, T., Hung, C.H., Lin, Y., 2005b.

Strengthening reinforced concrete beams using prestressed

glass fiber-reinforced polymer-Part I: Experimental study.

Journal of Zhejiang University-SCIENCE A, 6(3):166-174.

[doi:10.1631/jzus.2005. A0166]

Lasa, I.R., Powers, R.G., Kessler, R.J., 1998. Practical Application of Cathodic Protection Systems for Reinforcing

Steel Substructures in Marin Environment. Proceedings

of the International Seminar on Repair and Rehabilitation

of Reinforced Concrete Structures, p.16-31.

Liang, Q.Q., Uy, B., 2000. Theoretical study on the post-local

buckling of steel plates in concrete-filled box column.

Computers & Structures, 75(5):479-490. [doi:10.1016/

S0045-7949(99)00104-2]

Mirmiran, A., Shahawy, M., 1996. A new concrete-filled hollow FRP composite column. Composites Part B: Engineering, 27(3-4):263-268. [doi:10.1016/1359-8368(95)

00019-4]

Morino, S., 1998. Recent developments in hybrid structures in

Japanresearch, design and construction. Engineering

Structures, 20(4-6):336-346.

[doi:10.1016/S0141-0296

(97)00022-9]

Nishizaki, I., Meiarashi, S., 2002. Long-term deterioration of

GFRP in water and moist environment. Journal of Composites for Construction, 6(1):21-27. [doi:10.1061/(ASCE)

1090-0268(2002)6:1(21)]

Roeder, C.W., Cameron, B., Brown, C.B., 1999. Composite

action in concrete filled tubes. Journal of Structural Engineering, 125(5):477-484. [doi:10.1061/(ASCE)07339445(1999)125:5(477)]

Schneider, S.P., 1998. Axially loaded concrete-filled steel

tubes. Journal of Structural Engineering, 124(10):

1125-1138. [doi:10.1061/(ASCE)0733-9445(1998)124:10

(1125)]

Shams, M., Saadeghvaziri, M.A., 1997. State of the art of

concrete-filled steel tubular columns. ACI Structural

Journal, 94(5):558-571.

Steckel, G.L., Hawkins, G.F., Bauer, J.L., 1998. Environmental

Durability of Composites for Seismic Retrofit of Bridge

Columns. Second International Conference on Composites in Infrastructure, Tucson, USA, 2:460-475.

Tao, Z., Yu, Q., 2006. New Combing Structure. Science Express, Beijing, China, p.366-382 (in Chinese).

Uy, B., 1998. Local and post-local buckling of concrete filled

steel welded box columns. Journal of Constructional

Steel Research, 47(1-2):47-72. [doi:10.1016/S0143-974X

(98)80102-8]

Wang, Q.L., Zhao, Y.H., 2003. A presumption on the concrete

filled CFRP-steel composite tube structures. Journal of

Jilin University (Engineering and Technology Edition),

33(Suppl):352-355 (in Chinese).

Wang, Q.L., Ye, M., Zhou, L., 2008. Study on the flexural

behaviour of concrete filled circular CFRP-steel tubular

members. China Civil Engineering Journal, 41(10):30-38

(in Chinese).

Zhang, W.Z., Shahrooz, B.M., 1999. Comparison between ACI

and AISC for concrete-filled tubular columns. Journal of

Structural Engineering, 125(11):1213-1223. [doi:10.

1061/(ASCE)0733-9445(1999)125:11(1213)]

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Beam Deflection FormulaeDokument2 SeitenBeam Deflection Formulae7575757575100% (6)

- CSE 28363 - Structural Concrete Design: Lecture 10: Shear and ServiceabilityDokument44 SeitenCSE 28363 - Structural Concrete Design: Lecture 10: Shear and ServiceabilityBitch CarrieNoch keine Bewertungen

- Summary of DPWH Standard Specs and Min Test RequirmentDokument35 SeitenSummary of DPWH Standard Specs and Min Test RequirmentWynna Segundo86% (14)

- Concrete BasementsDokument184 SeitenConcrete BasementsAustin Devin100% (13)

- BeamDokument18 SeitenBeamAfia S Hameed100% (1)

- BQLibraryRev Nov29017Dokument288 SeitenBQLibraryRev Nov29017sanglimNoch keine Bewertungen

- Plate GirderDokument45 SeitenPlate GirderAfia S HameedNoch keine Bewertungen

- AnsysDokument46 SeitenAnsysapi-3719538100% (9)

- Plate GirderDokument11 SeitenPlate GirderAfia S HameedNoch keine Bewertungen

- Is 6533 Part-1 Design of Construction ofDokument23 SeitenIs 6533 Part-1 Design of Construction ofJoshue Adele0% (1)

- Fiber Reinforced Polymers - The Technology Applied For Concrete Repair - Martin Alberto Masuelli 2013Dokument240 SeitenFiber Reinforced Polymers - The Technology Applied For Concrete Repair - Martin Alberto Masuelli 2013Jhon Hilario AquinoNoch keine Bewertungen

- Ansys TipsDokument79 SeitenAnsys TipsMuhammad AliNoch keine Bewertungen

- Steelwise PDFDokument3 SeitenSteelwise PDFFourHorsemenNoch keine Bewertungen

- 1 s2.0 S0141029617303577 MainDokument13 Seiten1 s2.0 S0141029617303577 MainAfia S HameedNoch keine Bewertungen

- FE Lab 1Dokument23 SeitenFE Lab 1patrickNX9420Noch keine Bewertungen

- Method of SectionDokument10 SeitenMethod of SectionAfia S HameedNoch keine Bewertungen

- Multiple Choice Type Questions and Answers 201Dokument16 SeitenMultiple Choice Type Questions and Answers 201Afia S HameedNoch keine Bewertungen

- 115 Sample Chapter PDFDokument111 Seiten115 Sample Chapter PDFAmey GudigarNoch keine Bewertungen

- Engineering Structures: Pablo M. Páez, Beradi SensaleDokument10 SeitenEngineering Structures: Pablo M. Páez, Beradi SensaleAfia S HameedNoch keine Bewertungen

- BEng PaperDokument5 SeitenBEng PaperAfia S Hameed100% (1)

- Intro PDFDokument1 SeiteIntro PDFAfia S HameedNoch keine Bewertungen

- Pky 130 15Dokument1 SeitePky 130 15Afia S HameedNoch keine Bewertungen

- Module 28CDokument24 SeitenModule 28CAfia S HameedNoch keine Bewertungen

- Extraordinary Gazette Date:-28.06.2017 Last Date: 02.08.2017 Category No: 218/2017Dokument2 SeitenExtraordinary Gazette Date:-28.06.2017 Last Date: 02.08.2017 Category No: 218/2017Afia S HameedNoch keine Bewertungen

- Use The Xbox App To Record Your Screen in Windows 10Dokument7 SeitenUse The Xbox App To Record Your Screen in Windows 10Afia S HameedNoch keine Bewertungen

- Area Under ParabolaDokument6 SeitenArea Under ParabolaAfia S HameedNoch keine Bewertungen

- Schedule: IS:800-2007 (General Construction in Steel - Code of Practice)Dokument2 SeitenSchedule: IS:800-2007 (General Construction in Steel - Code of Practice)Afia S HameedNoch keine Bewertungen

- Limit StateDokument16 SeitenLimit StateAfia S HameedNoch keine Bewertungen

- GKDokument7 SeitenGKAfia S HameedNoch keine Bewertungen

- Renaissance in Kerala Part - 1 - PSC Rankfile 24 - 7 - More Information, More MarkDokument4 SeitenRenaissance in Kerala Part - 1 - PSC Rankfile 24 - 7 - More Information, More MarkAfia S HameedNoch keine Bewertungen

- Sa 11Dokument1 SeiteSa 11Afia S HameedNoch keine Bewertungen

- The Day of Laziness Will Be Soon For The All The PersondsDokument1 SeiteThe Day of Laziness Will Be Soon For The All The PersondsAfia S HameedNoch keine Bewertungen

- Lec Notes-1Dokument5 SeitenLec Notes-1Mehul JoshieNoch keine Bewertungen

- Current Affairs PDF December 2014 PDFDokument31 SeitenCurrent Affairs PDF December 2014 PDFsureshraj220Noch keine Bewertungen

- 1 IntroductionDokument13 Seiten1 IntroductionAfia S HameedNoch keine Bewertungen

- ContentsDokument4 SeitenContentsAfia S HameedNoch keine Bewertungen

- The Day of Laziness Will Be Soon For The AllDokument1 SeiteThe Day of Laziness Will Be Soon For The AllAfia S HameedNoch keine Bewertungen

- Grinding Technical Questions of Producing Composite CementDokument10 SeitenGrinding Technical Questions of Producing Composite CementAziz MalkiNoch keine Bewertungen

- I. Enabling System Sr. No. Work Description Quantity Unit Rate Amount 1 M.S. Props: 2 ScaffoldingDokument4 SeitenI. Enabling System Sr. No. Work Description Quantity Unit Rate Amount 1 M.S. Props: 2 ScaffoldingPiyushNoch keine Bewertungen

- Nov Dec 2011 Theory ExamDokument118 SeitenNov Dec 2011 Theory ExamHem KantNoch keine Bewertungen

- Concrete Masonry UnitDokument14 SeitenConcrete Masonry UnitNehaNairNoch keine Bewertungen

- Nelson Forensics - AHS Stadium 6-19-14Dokument34 SeitenNelson Forensics - AHS Stadium 6-19-14Anonymous ovJgHANoch keine Bewertungen

- Monthly HSE Activities Report For July - 07Dokument7 SeitenMonthly HSE Activities Report For July - 07MyolwinooNoch keine Bewertungen

- TDS Nyxon Green LDokument2 SeitenTDS Nyxon Green LBejinariu ValentinNoch keine Bewertungen

- Astm D 1002Dokument5 SeitenAstm D 1002Aisya IbrahimNoch keine Bewertungen

- STR Final 02112319473547375Dokument20 SeitenSTR Final 02112319473547375Muhammad AfrasiyabNoch keine Bewertungen

- GATE Architecture Planning Paper 2016Dokument13 SeitenGATE Architecture Planning Paper 2016Ar Gazzala PerweenNoch keine Bewertungen

- Impact Echo: Product Brochure NDT EquipmentDokument2 SeitenImpact Echo: Product Brochure NDT EquipmentDilhara WickramaarachchiNoch keine Bewertungen

- TM Rhenofol EDokument89 SeitenTM Rhenofol EPaul FlorianNoch keine Bewertungen

- BondingTilesOverWetseal WaterproofingDokument3 SeitenBondingTilesOverWetseal WaterproofingAnjali AnjuNoch keine Bewertungen

- Good Thesis PDFDokument444 SeitenGood Thesis PDFZarr AkshNoch keine Bewertungen

- Pune DSR 2016 17Dokument448 SeitenPune DSR 2016 17Er Hemant Patil0% (1)

- Excel Tulangan Slab On Pile 3Dokument2 SeitenExcel Tulangan Slab On Pile 3panduNoch keine Bewertungen

- Sampling and Testing Procedures For Materials & Products For ConstructionDokument49 SeitenSampling and Testing Procedures For Materials & Products For ConstructionN P Srinivasarao100% (1)

- Saudi Arabia and UAE: Nañadiego Nicolas PaningbatanDokument22 SeitenSaudi Arabia and UAE: Nañadiego Nicolas PaningbatangarhgelhNoch keine Bewertungen

- SPC Module 4 Notes PDFDokument11 SeitenSPC Module 4 Notes PDFmonikaNoch keine Bewertungen

- Shotcrete Guides and SpecificationsDokument4 SeitenShotcrete Guides and Specificationskiet eelNoch keine Bewertungen

- Residential Building at CoimbatoreDokument12 SeitenResidential Building at CoimbatoreKarthi Keyan RNoch keine Bewertungen

- T Proc Notices Notices 040 K Notice Doc 37393 619114859Dokument21 SeitenT Proc Notices Notices 040 K Notice Doc 37393 619114859Umar ShahNoch keine Bewertungen