Beruflich Dokumente

Kultur Dokumente

Double-Stage Vacuum Transformer Oil Purifier Series ZYD

Hochgeladen von

130792Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Double-Stage Vacuum Transformer Oil Purifier Series ZYD

Hochgeladen von

130792Copyright:

Verfügbare Formate

ALFAWEST AUSTRALIA PTY LTD

Double-Stage Vacuum Transformer Oil Purifier Series ZYD

ALFAWEST AUSTRALIA PTY,LTD

5 Nutmeg Fairway, The Ponds NSW 2769

Sydney- Australia, Tel:+ 612 96726945

ALFAWEST - Oil Purifier System

www.alfawest.com.au

CONTENT

Company Profile-------------------------------------------3

Application and Features---------------------------------3/4

Working Principle and Flow Chart---------------------4/5

Technical Data and Quality Indexes--------------------6

Machine Technology------------------------------- -------7/8

ALFAWEST - Oil Purifier System

www.alfawest.com.au

Company Profile

ALFAWEST AUSTRALIA PTY, LTD is a professional company with tremendous strength in the fields,

excellent after-sales service as well as a perfect image we earned in the competitive market.

Our main products are: Centrifuges, Decanters, Plate Heat Exchangers and Oil Vacuum purification

System.

Oil Purifiers Systems are widespread in the fields of Electric Power, Petrifaction, Mineral, Shipbuilding,

Steel Construction, Bridge, Automobile and Railway, playing a great role in the way of reducing energy

consumption for the clients and meanwhile the environmental pollution.

The company takes the mission of existing on the basis of quality as well as developing in regard to

technical innovation, introduces foreign advanced technology of vacuum oil purifying, moreover,

continues researching and supplying oil purifying equipments that are available both in the domestic and

international market.

Not Best, Only Better . Alfawest will as always make great effort to provide you the better oil purifying

equipments.

ALFAWEST - Oil Purifier System

www.alfawest.com.au

II Application and Features

Application

The machine can remove the free water, soluble water, gas, acid, free carbon (polarity material) and

other impurities high-efficiently, increasing the pressure force and quality of oil, improving the insulation

oil dielectric value, making sure the electric device running safely. The ZYD mainly purifies the

insulation oil, which includes transformer oil, break oil, capacitor oil, switch oil, mutual oil, cable oil and

so on. Our machine can regenerate those oils effectively. Meanwhile, this machine can inject oil into the

electric device under the vacuum situation. Besides the insulation oil, ZYD also can purify any

non-emulsification oil. It is a good oil purification system for the power station, transformer station, and

other relative line.

Features:

1. ZYD can evacuate the vacuum for the electric equipments separately, such as the transformer. Also it

can be used to dry the electric equipment and input the oil into the electric equipment under the

vacuum state.

2. This machine have two vacuum pumps (one is the vacuum pump, other one is the roots pump), which

can improve the working value highly. Making sure the water-content of the treated oil is less than 3

ppm.

3. The machine adopts the double-infrared liquid automatic controller, pressure automatic-protector

which can make sure the machine works online for150 hours continuously without person. So it is a

reliable and high automatically machine.

4. Besides the common vacuum oil purifiers function of dewatering, degassing, and removing the

impurity, this machine can regenerate the seriously bad oil by separating the electric-polarity

materials, such as deeply oxides and free carbon from the oil effectively. The treated oil can reach

the specifications of the new oil, such as the oil dielectric strength, flash point, acid value and

oxidation resisting etc.

5. There is a interlocked preventive device, which connect vacuum pump, oil pump, roots pump and

heater. It can be power off automatically if theres something wrong with anyone of the three parts.

Avoiding the oil purifier dry, leak oil and be electric.

6. Adopts the thin film technology, which can remove the free water, soluble water, gas, acid

effectively.

ALFAWEST - Oil Purifier System

www.alfawest.com.au

III Working Principle and Structure

1. Working Principle

The working principle and structure (Chart1, Chart2):

When this machine start working, the used oil will be injected into the primary filter under the pressure,

the primary filter will remove the big impurities, then the oil which just contains the particles is heated

by the heater. Then the treated oil enter into the vacuum separator, the vapor is separated from the oil and

refrigerate to water under the process of the lowest-vacuum pressure and the degassing equipments. The

last procedure is that the fine filter removes the particles completely.

1. Detail flow chart

Z Y D D e ta il flo w c h a rt

V a cu u m g a u g e

P rim a ry filte r

C o o le r

V a cu u m se p a ra to r P

S e co n d a ry filte r

B yp a ss va lve

T e m p e ra tu re

co n tro lle r

o il in le t va lve

va cu u m a d ju st

va lve

o il in le t

E le ctro m a g n e tic

va lve

R o o ts p u m p

In fra re co n tro lle r

h e a te r

D isch a rg e va lve

D isch a rg e va lve

D isch a rg e va lve

C ircu la tio n va lve

F in e filte r

D a m p in g fla n g e s

P re ssu re g a u g e

P

P re ssu re C o n tro lle r

V a cu u m p u m p

o il o u tle t

o il o u tle t va lve

sa m p le va lve

O il p u m p

D isch a rg e va lve

O il p u m p

m o to r

V a cu u m p re ssu re

d iffe re n ce

E le ctro m a g n e tic

va lve

ALFAWEST - Oil Purifier System

www.alfawest.com.au

2. Structure Chart

Front side

ALFAWEST - Oil Purifier System

www.alfawest.com.au

Right side

Left side

1. Vacuum Tank 2. Roots pump 3. Control cabinet 4. Vacuum pump motor 5. Vacuum control valve 6. Water

storage device 7. Display Tube 8. Vacuum pump 9. Heater 10. Primary filter 11. Oil inlet 12. Secondary filter 13.

Observation hole 14. External valve 15. Oil outlet 16. Sampling valve 17. Fine filter 18. Pressure Gauge 19.

Contact vacuum gauge 20. Temperature controller 21. Electromagnetic valve 22. Bypass valve 23. Circulation

valve 24. Pressure controller

ALFAWEST - Oil Purifier System

www.alfawest.com.au

IV Technical Data

Table 1 Vacuum Oil Purifier Technology Standard

Parameters

Unit

ZYD-30

ZYD-50

ZYD-100

Flow Rate

Working

vacuum

Working

Pressure

Temperature

Range

Power

Working

Noise

Heating

Power

Total Power

L/H

1800

3000

6000

Inlet/Outlet

Overall

9000

ZYD-200

ZYD-250

12000

15000

18000

MPa

-0.08 -0.099

MPa

0.3

20 80

ZYD-300

Three Phase 60Hz,440V (or as needed)

dB

A

70

70

70

75

75

75

75

kW

28

30

45

60

75

90

120

kW

35.5

37.5

52.5

71.4

86.5

102.5

135

25

32

42

50

50

60

60

600

1050

750

800

1100

800

1050

1200

950

1400

1450

950

1800

1600

1100

2000

1800

1200

2200

1900

1200

1350

1400

1500

1650

1800

1900

1900

L

W

mm

Kg

mm

mm

mm

Weight

ZYD-150

Table2 ZYD Oil Purifier after Treated Guarantee Value

Item

Unit

After treatment

Breakdown Voltage

kV

75

Moisture content

PPM

1

Gas content

%

0.01

Impurity size

micron

0.5 (no free carbon)

ALFAWEST - Oil Purifier System

www.alfawest.com.au

V Machine Technology

Dehydration (Degas) System

The duplex-stereo vacuum evaporation vessel can enlarge evaporation area efficiently. The heater, being

placed on the duplex-stereo vacuum evaporation vessel, becomes an evaporator. Thus the evaporation

area of duplex-stereo vacuum evaporation vessel is three times more than that of the common vacuum

vessel. This innovation can dehydrate and degas effectively and efficiently.

The optimal structure of the dehydration (degas) system enlarges the surface area of oil exposed to the

vacuum system and extends the flowing distance of the oil in the vacuum system. Thus there has

sufficient time to remove the moisture and gas from the oil by vaporization.

Filtering System

The filtering materials with variable apertures are made of specialized glass fiber. The sizes of the

filtering fiber and aperture dwindle gradually in the different filtering stages. The impurities with

different particulate sizes are filtered step by step. The capability of removing particulate matters and

impurities is improved greatly by this method.

The filtering system has stable and perfect filtering fineness. The filtering fineness has several grades,

including 1, 2,3,4,5,6,10 m etc. Oil 1000 after filter.

The filtering system is equipped with reverse rinse and filth device. It improves the effectiveness of

filtering and extends the lifetime of filter awfully.

Electrical Apparatus controlling System

The main components of the electrical apparatus made by Siemens Company ensure the safety of the

controlling system. Having several protection systems which will avoid oil ejection, overload and over

voltage etc.

Oil heating System

The unique heater structure heats the oil uniformly.

Oil Heater System assures less than 1.0 w/cm. During the heating process, the deterioration of the oil

caused by overheating is avoided.

The oil temperature can be adjusted between 0 to 100.The heater is controlled manually or

automatically. The heater will stop automatically when the oil temperature reaches a certain degree.

Being installed with safety protection devices, the heating system is secure and reliable. The heater will

stop operation automatically when the oil volume of inlet is too low to avoid the damages of the heater.

Oil-level Controlling System

The oil-level floating ball and infrared liquid level automatic controller system are installed in the

vacuum vessel to control the oil level so as to avoid the oil leaking in the operation.

The new innovation of eliminating froth can avoid the oil ejecting and gushing during the process.

High quality components

The main component parts of our products such as vacuum pump, oil pump and electric apparatus are

from SIEMENS, ABB, SCHNEIDER and AMICO etc. It ensures our products high quality and

9

ALFAWEST - Oil Purifier System

www.alfawest.com.au

reliability.

Structure and appearance of Oil purifier

Our products adopt ship-shape chassis-mount structure to ensure oil leak proof and protect the

environment from pollution.

The whole equipment is characterized by small size, light weight and convenient to move around.

Various sizes and configurations(alloy shield) available

Available in mobile or stationary options

Automatic vacuum oil purifier or anti-explosion vacuum oil purifier is both available according to

customers needs.

Cooler, Condenser System

The system is composed of cooler, condenser, water receiver etc

The vapor and other gas, which is evaporated from vacuum separator, first drop in temperature and are

rid of moisture in condenser, then are condensed again in cooler which has retarded exchange media. The

reductive condensed water are discharged by water receiver. The dry gas, which are condensed and rid of

moisture twice, are discharged to air by vacuum pump so that it protects vacuum pump.

The plant is characterized by small size, light weight, rich color. And our company can produce trail car

type and whole lock (alloy shield) type according to the customers requirement.

In order to make sure that the stable of oil purifier plant which can work long time and extend the life of

the machine, the electric control parts and electric parts of TOP oil purifier are imported from

ZHENGTAI, DELIXI SIEMENS, LEYBOLD, PALL, ABB etc

10

Das könnte Ihnen auch gefallen

- IEEE STD C57.147-2018Dokument47 SeitenIEEE STD C57.147-2018Mark Onofre100% (1)

- Operational Manual CMM-0.6Dokument31 SeitenOperational Manual CMM-0.6alvimranNoch keine Bewertungen

- Specification For Hyundai Synchronous GeneratorDokument27 SeitenSpecification For Hyundai Synchronous Generatorwin htikeNoch keine Bewertungen

- HFO SET WARTSILA 9R32D 3 SET AVAILABLEDokument18 SeitenHFO SET WARTSILA 9R32D 3 SET AVAILABLEA2 Bhaskar100% (1)

- PIERALISI Decanter Technology1Dokument29 SeitenPIERALISI Decanter Technology1Danilo Jose Saavedra Mayer100% (1)

- WTD Test ReportDokument4 SeitenWTD Test ReportBheem NaveenNoch keine Bewertungen

- Sampling Insulating Liquids For Gas Analysis and Determination of Water ContentDokument4 SeitenSampling Insulating Liquids For Gas Analysis and Determination of Water ContentanitanizamaNoch keine Bewertungen

- Lubricants For The Manufacturing IndustryDokument20 SeitenLubricants For The Manufacturing IndustrynarenjiNoch keine Bewertungen

- ZYD CatalogueDokument13 SeitenZYD CatalogueKevin Wenger MwangiNoch keine Bewertungen

- 50 HZ UMA: Applications Submersible Motors UMA 150D, 200D, 250D and 300DDokument28 Seiten50 HZ UMA: Applications Submersible Motors UMA 150D, 200D, 250D and 300DFuentes MauricioNoch keine Bewertungen

- 50Hz R22 Air-Cooled Modular Chiller Technical Manual20120210Dokument117 Seiten50Hz R22 Air-Cooled Modular Chiller Technical Manual20120210avouzikisNoch keine Bewertungen

- Appendix D - Particle Filter and Back Flush PumpDokument134 SeitenAppendix D - Particle Filter and Back Flush Pumppetro100% (1)

- Data Sheet: Three Phase Induction Motor - Squirrel CageDokument3 SeitenData Sheet: Three Phase Induction Motor - Squirrel CageErick Nilzon Montañez CalachuaNoch keine Bewertungen

- 20170710100925-Lubricating Oil Purifier NAKINDokument8 Seiten20170710100925-Lubricating Oil Purifier NAKINAntonioAriasNoch keine Bewertungen

- Ap B14 02L 01e - Akm - 38750 PDFDokument4 SeitenAp B14 02L 01e - Akm - 38750 PDFsamsungloverNoch keine Bewertungen

- Series ZYD Operation ManualDokument11 SeitenSeries ZYD Operation ManualDaniel SubelzaNoch keine Bewertungen

- IRD1-G: Differential Protection Relay For Generators and MotorsDokument24 SeitenIRD1-G: Differential Protection Relay For Generators and MotorsTaufiqtadNoch keine Bewertungen

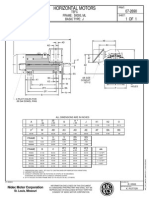

- Motor Us Frame 5800 JceDokument1 SeiteMotor Us Frame 5800 JceingeisaaclgNoch keine Bewertungen

- EkekDokument18 SeitenEkekrestu97Noch keine Bewertungen

- Chongqing TOP Oil Purifier Manufacture Co High Vacuum Insulating Oil Purifier Series ZYDokument10 SeitenChongqing TOP Oil Purifier Manufacture Co High Vacuum Insulating Oil Purifier Series ZYMartha BenavidesNoch keine Bewertungen

- Types of Generator ProtectionDokument14 SeitenTypes of Generator ProtectionRana RavirajsinhNoch keine Bewertungen

- WEG Motorized Brush Lifting System 655 Brochure English PDFDokument4 SeitenWEG Motorized Brush Lifting System 655 Brochure English PDFidontlikeebooksNoch keine Bewertungen

- ANSI Code 87 Type RMC-131D Differential Current RelayDokument2 SeitenANSI Code 87 Type RMC-131D Differential Current RelayshyamamolNoch keine Bewertungen

- Catلlogo COMEMDokument72 SeitenCatلlogo COMEMsoltani100% (1)

- Atuador ADB225 PIB2000 - C - 225 SeriesDokument1 SeiteAtuador ADB225 PIB2000 - C - 225 SeriesnandomataNoch keine Bewertungen

- Osisense Xs Xsav11801Dokument2 SeitenOsisense Xs Xsav11801jcadvNoch keine Bewertungen

- Turbair Blower (Type RC)Dokument2 SeitenTurbair Blower (Type RC)Amir AbbaszadehNoch keine Bewertungen

- NEX 17.5KV InstructionsDokument43 SeitenNEX 17.5KV InstructionsThức VõNoch keine Bewertungen

- RDOL Power and Control Wiring DrawingDokument2 SeitenRDOL Power and Control Wiring DrawingPrachi DongreNoch keine Bewertungen

- Vibration Rack SpecDokument25 SeitenVibration Rack SpecMajid ManouchehriNoch keine Bewertungen

- ADVR-12: Hybrid Universal Analog Digital Voltage Regulator Operation ManualDokument10 SeitenADVR-12: Hybrid Universal Analog Digital Voltage Regulator Operation ManualcarmeniyoNoch keine Bewertungen

- MV DriveDokument92 SeitenMV DriveKrishna Bhanu SinghNoch keine Bewertungen

- 155.16-RP3 11-06 YiaDokument88 Seiten155.16-RP3 11-06 YiaLuis DerasNoch keine Bewertungen

- Ariel compressor instrumentation requirementsDokument8 SeitenAriel compressor instrumentation requirementsFaisal NaeemNoch keine Bewertungen

- Lorentz PS4000Dokument2 SeitenLorentz PS4000SINES FranceNoch keine Bewertungen

- RMC-131D, Installation Instructions 4189340121 UKDokument4 SeitenRMC-131D, Installation Instructions 4189340121 UKUday PowarNoch keine Bewertungen

- Flame Scanner Sensor PDFDokument36 SeitenFlame Scanner Sensor PDFGhuna UcihaNoch keine Bewertungen

- PS451 ManualDokument106 SeitenPS451 ManualUsama Sheikh100% (1)

- Kliger Water Level Gauge PDFDokument48 SeitenKliger Water Level Gauge PDFGarry Bernard NelsonNoch keine Bewertungen

- Sipart DR21 User ManualDokument14 SeitenSipart DR21 User ManualTeddy HariyantoNoch keine Bewertungen

- Lsa 501Dokument8 SeitenLsa 501Lorenzo RossiNoch keine Bewertungen

- Generator Voltage Regulator ManualDokument48 SeitenGenerator Voltage Regulator ManualvjNoch keine Bewertungen

- W8L20 - Engine AttachmentsDokument348 SeitenW8L20 - Engine AttachmentsTuan Linh VoNoch keine Bewertungen

- Actuator Data SheetsDokument4 SeitenActuator Data SheetsCibi SubramaniamNoch keine Bewertungen

- Motor protection relay user manualDokument13 SeitenMotor protection relay user manualrpshvjuNoch keine Bewertungen

- Trench Bushings Cot 24kv To 550kvDokument24 SeitenTrench Bushings Cot 24kv To 550kvdsanmi0% (1)

- Rapid Pressure Rise Relay Response CurvesDokument4 SeitenRapid Pressure Rise Relay Response CurvesTarun Bhateja0% (1)

- Gladiator Microwave ManualDokument49 SeitenGladiator Microwave ManualCardonettiNoch keine Bewertungen

- Fuel Oil Meter ManualDokument89 SeitenFuel Oil Meter ManualbouguerraNoch keine Bewertungen

- QSK60 G6 PDFDokument2 SeitenQSK60 G6 PDFShahzad Ali100% (2)

- 994-0078 - D20 D200 Installation and Operations Guide V200 R7 PDFDokument132 Seiten994-0078 - D20 D200 Installation and Operations Guide V200 R7 PDFrommel76Noch keine Bewertungen

- Unitrol 1020 ManualDokument2 SeitenUnitrol 1020 ManualKarthick Kumaresan50% (2)

- Excel ApodysDokument4 SeitenExcel ApodysjeremiahNoch keine Bewertungen

- Long Travel Retractable Sootblower: SpecificationsDokument2 SeitenLong Travel Retractable Sootblower: SpecificationsvtbkNoch keine Bewertungen

- Axial 'Hunting' Of 2-Pole Motors: Causes And CuresDokument3 SeitenAxial 'Hunting' Of 2-Pole Motors: Causes And Cureskimpatrick19Noch keine Bewertungen

- ABB Distribution: SF - Circuit Breaker ManualDokument28 SeitenABB Distribution: SF - Circuit Breaker ManualwiyatnoNoch keine Bewertungen

- Micro ScannerDokument2 SeitenMicro ScannerArun KumarNoch keine Bewertungen

- LEA Digital Control Systems e PDFDokument12 SeitenLEA Digital Control Systems e PDFJaime CalmetNoch keine Bewertungen

- Lightening Arrester 500kVTest Report EnglishDokument20 SeitenLightening Arrester 500kVTest Report Englishashwani2101Noch keine Bewertungen

- Electric Part-Turn Actuators: SG 03.3 - SG 04.3 Auma NormDokument28 SeitenElectric Part-Turn Actuators: SG 03.3 - SG 04.3 Auma Normابزار دقیق100% (1)

- ZYD-I Transformer Oil Regeneration SystemDokument22 SeitenZYD-I Transformer Oil Regeneration SystemEdgarNoch keine Bewertungen

- Car Dumper-Operating Instruction ManualDokument40 SeitenCar Dumper-Operating Instruction ManualParthiban KarunaNoch keine Bewertungen

- Efficient PA purifier system for fuel and oil purificationDokument4 SeitenEfficient PA purifier system for fuel and oil purificationRizal Falevy100% (1)

- Reactor Spec DEWA ReqDokument1 SeiteReactor Spec DEWA ReqbyjuvcNoch keine Bewertungen

- CIGRÉ 2008 - Corrosive Sulfur in FR3Dokument8 SeitenCIGRÉ 2008 - Corrosive Sulfur in FR3Felipe VargasNoch keine Bewertungen

- Module 19: Transformers and Circuit BreakersDokument67 SeitenModule 19: Transformers and Circuit BreakersDipayan DasNoch keine Bewertungen

- Hypertrans HR Iec 60296 2012 (Latest)Dokument2 SeitenHypertrans HR Iec 60296 2012 (Latest)Sharin Bin Ab GhaniNoch keine Bewertungen

- MEE Micro projectDokument15 SeitenMEE Micro projectSanchit BamaneNoch keine Bewertungen

- General Instruction Manual: ScopeDokument14 SeitenGeneral Instruction Manual: ScopeJithuRajNoch keine Bewertungen

- Weidman - Changes in Diagnostic C57-106 StandardsDokument2 SeitenWeidman - Changes in Diagnostic C57-106 StandardsJeff ProulxNoch keine Bewertungen

- Technical Specification of Transformer OilDokument8 SeitenTechnical Specification of Transformer OilPratik987Noch keine Bewertungen

- Diala AX TdsDokument2 SeitenDiala AX TdsAbdalhakeem Al turkyNoch keine Bewertungen

- Roger RatioDokument5 SeitenRoger RatiovapouroilNoch keine Bewertungen

- Nynas Transformer Oil - Nytro 10GBN: Naphthenics Product Data SheetDokument1 SeiteNynas Transformer Oil - Nytro 10GBN: Naphthenics Product Data SheetAnonymous S29FwnFNoch keine Bewertungen

- Overhauling of pumps, pipes and valves at Ranichak pumping stationDokument40 SeitenOverhauling of pumps, pipes and valves at Ranichak pumping stationTarunPatraNoch keine Bewertungen

- Oil Testing Kit 60KV - Ins ManualDokument5 SeitenOil Testing Kit 60KV - Ins Manualilesh22100% (1)

- Nota TransformerDokument60 SeitenNota TransformerMohd HakimNoch keine Bewertungen

- Fiber Optic Hot Spot Temperature Monitoring - Qualitrol CorpDokument3 SeitenFiber Optic Hot Spot Temperature Monitoring - Qualitrol CorpAV REDDYNoch keine Bewertungen

- En 50216-6 2002Dokument15 SeitenEn 50216-6 2002Mahmoud ShaheenNoch keine Bewertungen

- Laporan Pekerjaan Preventive MaintenanceDokument25 SeitenLaporan Pekerjaan Preventive MaintenanceWay'sjustakid Crhimineal0% (1)

- Revised IEC Standard For Maintenance of In-Service Insulating OilDokument14 SeitenRevised IEC Standard For Maintenance of In-Service Insulating OilMashkoor Hussain80% (5)

- Testing & Commissioning Manual SECDokument125 SeitenTesting & Commissioning Manual SECmissle2007100% (6)

- Transformer Oil TestingDokument29 SeitenTransformer Oil TestingMrunal Salve67% (3)

- 17bee0202 VL2019201007349 Ast09Dokument5 Seiten17bee0202 VL2019201007349 Ast09Ankur PraveerNoch keine Bewertungen

- Transformer Instruction Manual: GMX Ground Mounted TransformersDokument20 SeitenTransformer Instruction Manual: GMX Ground Mounted TransformersnooruddinkhanNoch keine Bewertungen

- Testing Instruments for Condition Based Maintenance of TRD AssetsDokument58 SeitenTesting Instruments for Condition Based Maintenance of TRD Assetsbharath100% (1)

- TESTING LABORATORY SERVICESDokument22 SeitenTESTING LABORATORY SERVICESSandeep YadavNoch keine Bewertungen

- Scope of Work For TR Oil Filteration 10 Sep 2016Dokument2 SeitenScope of Work For TR Oil Filteration 10 Sep 2016chandruNoch keine Bewertungen

- FM Global Property Loss Prevention Data Sheets: List of TablesDokument20 SeitenFM Global Property Loss Prevention Data Sheets: List of TablesDhairyasheel PatilNoch keine Bewertungen

- 2015-Pre-Breakdown Phenomena in New Vegetable Oil - Based Jatropha Curcas Seeds As Substitute of Mineral Oil in High Voltage EquipmentDokument5 Seiten2015-Pre-Breakdown Phenomena in New Vegetable Oil - Based Jatropha Curcas Seeds As Substitute of Mineral Oil in High Voltage EquipmentDAMORA RHAKASYWINoch keine Bewertungen