Beruflich Dokumente

Kultur Dokumente

Sepulveda 2011

Hochgeladen von

Glorie Mae BurerosOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Sepulveda 2011

Hochgeladen von

Glorie Mae BurerosCopyright:

Verfügbare Formate

Quim. Nova, Vol. 34, No.

4, 601-606, 2011

Jorge H. Seplveda*, Carlos R. Vera, Juan C. Yori y Juan M. Badano

Instituto de Investigaciones en Catlisis y Petroqumica, Santiago del Estero 2654, 3000 Santa Fe, Argentina

Daniel Santarosa

Faculdade Qumica, Pontifcia Universidade Catlica de Campinas, Rod. D. Pedro I, km 136, 13020-904 Campinas - SP, Brasil

Dalmo Mandelli

Faculdade Qumica, Pontifcia Universidade Catlica de Campinas, Rod. D. Pedro I, km 136, 13020-904 Campinas SP / Centro

de Cincias Naturais e Humanas, Universidade Federal do ABC, Rua Santa Adlia, 166, 09210-170 Santo Andr - SP, Brasil

Artigo

H3PW12O40 (HPA), AN EFFICIENT AND REUSABLE CATALYST FOR BIODIESEL PRODUCTION RELATED

REACTIONS. ESTERIFICATION OF OLEIC ACID AND ETHERIFICATION OF GLYCEROL

Recebido em 4/5/10; aceito em 17/11/10; publicado na web em 14/3/11

In esterification of oleic acid with methanol at 25 C HPA displayed the highest activity. Moreover the HPA could be reused after

being transformed into its cesium salt. In the reaction of etherification of glycerol HPA and Amberlyst 35W showed similar initial

activity levels. The results of acid properties demonstrate that HPA is a strong protonic acid and that both surface and bulk protons

contribute to the acidity. Because of its strong affinity for polar compounds, HPA is also seemingly dissolved in both oleic acid and

methanol. The reaction in this case proceeds with the catalyst in the homogenous phase.

Keywords: heteropolyacids; esterification; etherification.

INTRODUCTION

Heteropoly compounds are used both as heterogeneous solid

catalysts and as homogeneous catalysts.1 The acidic as well as the

oxidizing properties of heteropoly compounds in the solid state are

very sensitive to the kind of counter cation and to the constituent

elements of the polyanions.2 The acidity of concentrated aqueous and

non aqueous solutions of heteropoly acids (HPA) is higher than that

of HClO4 and H2SO4 by about 0.3 or 1.5 units of the Hammett acidity

function.3 For this reason heteropoly acids are very active in reactions

demanding high acid strength.4-6 They also attract some interest because they can replace hazardous liquid acids, such as sulfuric acid

or corrosive Lewis solid acids (aluminum chloride) currently used

in organic synthesis. In this sense they are regarded as potentially

environmentally friendly solid acid catalysts.7-9

In bulk form heteropolyacids have a low specific surface area (<

10 m2 g-1) but they can alternatively be used in supported form when

the reaction needs to be performed heterogeneously. A heterogeneous

reaction advantageously enables the separation of the catalyst from

the products and unreacted reactants. Several supports of adequate

high specific surface area can be used, such as silica, activated carbon,

alumina, MCM-41 aluminosilicates and zirconia.10-13

One great disadvantage of heteropoly compounds and hence of

HPA, is their relatively high solubility in water and polar solvents.

This makes them prone to leaching from the catalyst surface and

into the reaction medium. Once in solution the heteropoly compound

continues to catalyse the reaction homogeneously until it is removed

from the reaction medium with the reaction products. Exchanging part

of the protons of HPA with different cations results in the formation

of the corresponding salts. Salts of HPA and cations, like Cs+, Ag+ or

NH4+ are insoluble or scarcely soluble in polar solvents and have a

fairly high surface area (> 100 m2 g-1).14 However these salts someti*e-mail: jsepulve@fiq.unl.edu.ar

mes tend to form colloidal suspensions in polar media and may pose

difficulties for catalyst separation. Centrifugation might be required

in order to separate the catalyst for further use.

The use of non-soluble HPA heterogeneous catalysts for many

acid catalyzed reactions is therefore attractive as far as the catalysts

are easily separated from the reaction media and prove to be reusable.

In this sense the heterogeneization of HPA has attracted much interest

and many efforts have been devoted to the preparation of solvent

tolerant HPA formulations.15-17

One possible use of this special HPA catalysts could be in the acidcatalyzed production of biodiesel. Biodiesel comprises a mixture of

fatty acid alkyl esters of natural origin produced by transesterification

of natural oils and fats with short chain alcohols such as methanol or

ethanol. It is totally compatible with petrodiesel and can be used in

Diesel motors almost without any modification. Due to the natural

origin of biodiesel the feedstocks may contain many undesirable

components. Typical impurities are free fatty acids (FFA) and other

minor compounds.18 FFAs are especially problematic in plants using

homogeneous alkali-catalyzed transesterification reactors. They react

with the dissolved alkaline catalyst and form soaps that plug pipelines

and process vessels and that interfere with phase separation in some

units. In order to run the process without plant upsets the FFA content

must be reduced to less than 3% by caustic refining. This is a big

loss for high acidity feedstocks (10-30% FFA) because raw materials

account for about 80% of the cost of the finished fuel.

High FFA feedstocks for biodiesel manufacture can be processed

with no waste if acid catalysts are used. In the past concentrated H2SO4

have been tried but they have proved to supply only a small reaction

rate in comparison to alkaline catalysts. In the usual industrial practice

the unreacted oil fraction is sent to an alkali-catalyzed reactor after

the acid-catalyzed pretreatment, thus adding to the complexity and

cost of the process.

Solid acid catalysts could be advantageously used for biodiesel

manufacture from high FFA feedstocks. Not only they are not affec-

602

Seplveda et al.

ted by the presence of acids but they can also be easily separated

from the reaction products. Tungsten-zirconia,19 sulfated-zirconia,20

polyvinylsulfonic resins21 and heteropolyacids,22,23 have been recently

used for the catalytic synthesis of biodiesel.

The performance of esterification catalysts for biodiesel production can be tested with real feedstocks or alternatively with model

compounds. In this sense oleic acid and oleic triglycerides are useful

model compounds because oleyl chains are the most common components of many natural oils. Esterification of the acid is especially

difficult because water is formed as a by-product and tends to deactivate the catalyst acid centers.

Another problem in the biodiesel industry is that of the glycerol

by-product. In the last years the market price of glycerol has plummeted due to the availability of great glycerol surpluses from the

biodiesel industry.24 This has motivated the interest in the valorization

of glycerol by transformation into another product of low cost of

manufacture. One such products is GTBE (Glycerol tertiary butyl

ether). GTBE is an additive produced by etherification of glycerol with

t-butanol or isobutylene that is used as Diesel fuel smoke, pour and

cloud point depressant.25 GTBE synthesis is a typical acid catalyzed

reaction.26 The reaction has been mainly studied using resins,27 and

supported acids.28 No applications of heteropolyacid compounds as

etherification catalysts have been yet reported.

This paper studies the acid-catalyzed esterification of oleic acid

with methanol over H3PW12O40 both in the homogeneous and heterogeneous phase. This reaction is used as a model reaction test for the

production of biodiesel from high FFA feedstocks. The reutilization

of the HPA by separation and precipitation into Cs2.5H0.5PW12O40 was

specially studied. The results obtained with these HPA catalysts were

compared with those achieved with a commercial Amberlyst 35W

resin catalyst. The catalysts were further characterized by using them

in the acid-catalyzed, liquid-phase etherification of glycerol with

tert-butanol to form GTBE.

EXPERIMENTAL

Materials

H3PW12O40 (HPA) was supplied by Merck. The Amberlyst 35W

resin was supplied by Rohm and Haas. Cs2.5H0.5PW12O40, the cesium

salt of H3PW12O40 was prepared by precipitation from an aqueous HPA

solution with a suitable amount of a Cs2CO3 solution as described

elsewhere.29 The latter salt was supplied by Sigma-Aldrich.

Catalysts characterization

The textural properties of the solid catalyst were measured in a

Quantachrome Nova-1000 equipment by physisorption of N2 at the

temperature of -196.5 C. The crystalline structure of the catalysts was

determined by X-ray diffraction using a Shimadzu XD-3A diffractometer and CuK radiation filtered with Ni. Spectra were recorded

with a step size of 0.02 and a counting time of 1 s.

UV-Vis spectroscopy was used to determine the content of HPA

in solution. Spectra were measured in a UV-1800 double beam Shimadzu spectrophotometer. The samples were measured with 10 mm

optical path cells and the HPA content was determined with the aid

of calibration curves.

Esterification of oleic acid

A two-necked round-bottom glass flask was used as reactor. It

had a reflux condenser and a magnetic stirrer. In a typical run, 2.82

g (10 mmol) of oleic acid, 5 mL of methanol and 1.3 g (10 mmol)

Quim. Nova

of di-n-butyl ether (internal standard) were added before starting the

reaction. Three different values of catalyst mass were used, 0.03, 0.05

and 0.1 g, in order to see the influence of the catalyst-to-reactant ratio.

Then the temperature was rapidly raised to the desired value and the

catalysts were put into the solution. The products of the reaction

were analyzed with an HP6890 gas chromatograph equipped with a

poly-methyl-phenyl-siloxane capillary column (30 m, 0.53 mm ID,

1.5 mm film thickness). The analysis was performed with an injector

temperature of 250 C and an oven temperature program with an initial

value of 60 C (hold 5 min), a heating rate of 10 C min-1 and a final

temperature of 220 C. The amount of each product was obtained

with the aid of calibration curves. These curves were constructed by

the analysis of standard solutions of methyl oleate and oleic acid of

varying concentration.

Etherification of glycerol

The reaction was performed in the liquid phase in an autoclave

stirred reactor. The vessel and all connections were made of stainless

steel. In a typical run 19.9 g of glycerol (Gly) and 32.0 g of tertbutanol (tB) (molar ratio, tB/Gly:2) were charged to the reactor. The

mixture was purged with nitrogen and then heated to 70 C under

vigorous stirring (1000 rpm were used in order to avoid interphase

mass transfer restrictions related to the low solubility of tert-butanol in

glycerol). The reaction was carried at the autogenous pressure of the

closed system. In all cases a fixed amount of 0.5 g of catalyst ground

to 35-80 meshes was used. The reaction was carried out at the specified temperature for a given time. Then the stirring and heating were

stopped and the reaction was quenched by cooling the reactor in an

ice bath. The unreacted tB concentration in the reaction products was

determined by gas chromatography. The technique requires the use of

an internal standard, isopropylic alcohol (IPA, Ciccarelli, >99%). The

analysis were performed in a Varian Star 3400 CX chromatograph

with a flame ionization detector. A 30 m long, 0.53 mm ID, 1 mm film

thickness, fused silica Zebron ZB-5 (Phenomenex) capillary column,

was used for the chromatographic analysis. An injector temperature

of 250 C, an initial column temperature of 60 C (hold 5 min), a

heating rate of 10 C min-1 and a final temperature of 250 C, were

used in all the analysis.

Dehydration of 1,4 butanediol

Dehydration of 1-4-butanediol in the liquid phase was used for

assessing the acidity of the catalysts.30 The reaction was carried out

in a Parr autoclave. In each run 1.8 g of 1-4-butanediol, 12 mL of 1-4

dioxane (solvent) and 0.12 g of catalysts were charged to the reactor.

Then the mixture was heated to 100 C under vigorous stirring to

start the reaction. The products of the reaction were analyzed by gas

chromatography, using calibration curves and di-n-butyl ether (10

mmol) as an internal standard. The chromatograph was a Varian 3400

CX equipped with a flame ionization detector and an HP-Innowax

capillary column (30 m, 0.32 mm ID, 0.50 mm film thickness). The

temperature of the injector was 270 C, the column oven initial temperature was 120 C (hold 5 min), the heating rate was 10 C min-1

and the final temperature was 250 C (hold 10 min).

Reuse of the catalyst

HPA dissolved in solution is recovered after the reaction and

separated from other products by means of precipitation with a cesium salt (CO3Cs2). The salt reacts with HPA forming an insoluble

solid of formula C2.5H0.5PW12O40 that can be separated by filtration

once the reaction is completed. The salt is then dried in a stove at

H3PW12O40 (HPA), an efficient and reusable catalyst for biodiesel production related reactions

Vol. 34, No. 4

110 C overnight and calcined in a muffle at 300 C in still air for

3 h. The Cs salt can then be used in the reactions of etherification

and esterification by using the same procedure employed for HPA.

RESULTS AND DISCUSSION

Catalyst characterization

Table 1 shows some measured properties of the catalysts such as

specific surface area as measured by nitrogen adsorption and acidity as

measured by NH3 temperature programmed desorption and conversion

of 1-4-butanediol at 100 C after 4 h of reaction.31 The value of the

specific surface area of the cesium salt was similar to other results

reported elsewhere.32 The acidity of each catalyst can be a priori

indirectly estimated from the data of dehydration of 1,4-butanediol.

These acidity values can then be compared with those obtained by

ammonia desorption. However there is no good correlation between the acid amount per unit mass and the data of dehydration of

1,4-butanediol. There is a relatively good correspondence between

the values for the HPA and its Cs salt but the data for the Amberlyst

resin look like an outlier.

603

spite of this the conversion of 1,4-butanediol is higher on HPA. This

is attributed a priori to HPA having a higher proportion of strong acid

sites needed to catalyze the reaction. Another possible explanation is

the higher affinity displayed by HPA for butanediol and other polar

compounds in the homogeneous phase. Though being performed in

batch mode, in one set of experiments, sampling was done continuously. These results are shown in Figure 1. The pattern of conversion

of butanediol to tetrahydrofuran as a function of time of reaction is

identical for both the HPA and the Amberlyst 35W catalysts. The high

activity of HPA despite its low amount or density of acid sites in the

solid state might be related to its solubility in alcoholic media. This

solubilization would dramatically increase the amount of available

acid sites. The solution of HPA appears completely crystalline when

inspected visually. When analyzed by UV, Keggin structures in a true

solution state can be detected both in aqueous and alcoholic media.34

Table 1. Catalyst properties

Catalyst

HPA

BET area, Acidity,

Acid density, Conversiona of

m2 g-1 mmol NH3 g-1 mmol NH3 m-2 1,4-butanediol,

%

6

0.316

0.0523

55

Cs2.5H0.5PW12O40

135

0.065

0.00045

16

Amberlyst 35W

45

4.8 b

0.106 b

44

Conversion (mol %) to tetrahydrofuran after 4 h of reaction at 100 C. b Not

measured. Data supplied by the supplier (Rohm and Haas products division

of Dow Chemical Co.).

a

Both HPA and the resin Amberlyst 35W are strong acids and they

have been termed superacids because they have a surface acidity

greater than 100% H2SO4 in the Hammet acidity scale. In this sense

both have strong enough acid sites to perform the dehydration of

1,4-butanediol at relatively mild temperatures. The surface acidity

of the resin is one order of magnitude higher than that of HPA and

its cesium salt. The observed differences in the rate of butanediol

dehydration can be possibly attributed to the pseudoliquid behavior

of HPA compounds. In this state of the HPA related compounds all

protons in the bulk of the solid contribute to the reaction.

If we compare the dehydration activity of HPA and its Cs salt we

can see that the activity of HPA is higher. This is most likely related

to the higher amount of acid sites per unit mass present in the HPA

catalysts. Accessibility of the butanol to the surface seemed to have

no impact on the activity results. The HPA catalyst for example had

only 5 m2 g-1 and its activity was the highest. The results seem to indicate that the global activity is proportional to the amount of strong

acid sites per unit mass.

Some authors have postulated that the Cs2.5H0.5PW12O40 and

HPA catalysts display superacidity. The Cs salt had an Ho value of

ca. -13.6 Hammet units. This acid strength should be enough for

dehydrating 1,4-butanediol to a great extent.33 The results indicate

that the conversion of the HPA catalyst was four times higher than

the conversion of the Cs-salt. These results correlate with the lower

amount of acid sites per unit mass of the Cs-salt.

The Amberlyst 35W resin and the HPA catalysts displayed a

similar density of acid sites (0.5-1.0 mmolNH3 m-2) and both had

protonic acid sites. The absolute amount of acid sites was however

much higher for the resin (4.8 mmolNH3 m-2 compared to 0.3). In

Figure 1. Conversion (mol %) of 1,4-butanediol to tetrahydrofuran at 100 C

as a function of reaction time. () Amberlyst 35W resin. () HPA

The high activity of HPA is best explained by the affinity of polar

molecules for HPA when this is present in the medium as a soluble

or partly soluble species. Misono and coworkers35 have coined the

term pseudo-liquid to refer to the particular state of heteropolyacids

in some media that enables them to have all their polyanions and

protons, even those of the solid bulk, available for acting as active

catalytic sites. This property gives HPA very high activity and unique

selectivity features. The hiper active pseudo-liquid behavior has

been found both in liquid-solid and gas-solid systems.

Catalytic esterification of oleic acid

In Figure 2 are shown the results of conversion oleic acid as

a function of reaction time during its esterification with methanol

as catalyzed by HPA at 25C. It can be seen that for an oleic acid/

HPA ratio of 94 g/g (0.03 g HPA) 40% conversion of the oleic acid

into methyl oleate is achieved at 10 h reaction time. HPA is very

efficient; when 0.1 g are used near 80% conversion is obtained at

10 h reaction time. Other results not shown in this figure stress the

efficiency of HPA. For example when 0.2 g of HPA at 50 C are

used (oleic/HPA=14 g/g) 50% conversion is achieved in 2 h. In

contrast when 0.1 or 0.2 g of the resin 35W and Cs2.5H0.5PW12O40

are used at 25C no conversion of the oleic acid can be detected

after 10 h reaction time.

604

Seplveda et al.

Quim. Nova

likely catalyzed by the large number of surface acid sites of the HPA

cesium salt or by surface acid-base pairs.

In some liquid phase reactions HPA and Cs2.5H0.5PW12O40 have

shown very different reactivities.39 In these reactions different substrates and solvents of different polarity were employed. Therefore

the different reactivity can be explained by their different solubility,

surface acidity and acid strength. For the esterification the catalytic

activity does not show a correlation with the acidity (Table 1). In the

case of the esterification of oleic acid with methanol the higher solubility of HPA in methanol is one main reason of its higher activity in

comparison to that of the corresponding Cs salt; this reaction mostly

took place in the homogeneous solutions.

Catalytic etherification of glycerol

Figure 2. Esterification of oleic acid (10 mmol) with methanol (24.6 mmol).

Conversion as a function of reaction time. H3PW12O40 catalyst, 25 C

The results of the esterification reaction using the cesium salt of

HPA and the Amberlyst 35W resin are included in Figure 3. At low

temperatures these catalysts cannot convert oleic acid into methyl

oleate. A minimum temperature of 90-110 C seems necessary to

achieve a high value of conversion. The resin and the Cs salt show

similar activity patterns at these reaction conditions when using the

same catalyst/reactant ratio.

The results for the HPA and Amberlyst 35W catalyst can be seen

in Figure 4. At the beginning of the reaction, before the 2 h reaction

time, the conversion increases with time of reaction more rapidly in

the case of the resin catalyst. The resin yields 40% conversion at 1 h

time of reaction while the same value is achieved by the HPA catalyst

at 2 h reaction time. In the case of the resin an equilibrium value of

about 55% is obtained after 3-4 h of reaction time. Conversely in

the case of the HPA there seems to be no saturation value and the

conversion increases steadily with reaction time and values of 80-90%

conversion are obtained at the end of the reaction.

Figure 4. Etherification of glycerol with tert-butanol at 90C. Conversion

as a function of time

Figure 3. Esterification of oleic acid (10 mmol) with methanol (24.6 mmol) at

110 C. Conversion as a function of reaction time. () 0.2 g Cs2,5 H0,5PW12O40.

() 0.1 g Cs2,5 H0,5PW12O40. () 0.1 g 35W resin

HPA and Cs 2.5H0.5PW12O40 show remarkable differences in

catalytic activity for the esterification of oleic acid with methanol.

Both seem to have superacidity though HPA has a higher amount of

Brnsted acid sites (Table 1). HPA cesium salts exhibit a a reportedly

high catalytic activity in many reactions, like the hydrolysis of ethyl

acetate,36 the isomerization of n-butane,37 or the alkylation of m-xylene

and 1,3,5 trimethylbenzene with cyclohexane.38 These reactions are

The reaction main products were mono-, di- and tri- glyceryl

tert-buthyl ethers. The relative abundance of these products in the

final solution was 3:1:1 (mass ratio) for both the HPA and the resin

catalysts. Other products related to glycerol and tert-butanol were

found in minor quantities but were not fully identified.

These results cannot be simply explained by resorting to the

simple concept of reaction catalyzed over non-deactivating acid

sites. The Amberlyst 35W has a higher protonic density than HPA

but it does not yield a higher conversion value at high values of

time of reaction. The plateau effect in the case of the resin can be

due to the inhibiting effect of water. Etherification with the alcohol

produces water as a by-product and this water becomes irreversibly adsorbed on the stronger acid sites. Hydration decreases the

acid strength and hence the activity for etherification. Water acts

Vol. 34, No. 4

H3PW12O40 (HPA), an efficient and reusable catalyst for biodiesel production related reactions

605

as a weak base and indeed the hydrated Brnsted acid site has a

lower acidity than the free one. Moreover the attachment of water

molecules to protonic sites brings about some steric hindrance if

the site is not easily accesible.

The inhibiting effect would be much stronger in the case of the

resin and much milder in the case of the HPA catalyst.

HPA reuse

The reaction products of the HPA-catalyzed esterification of

oleic acid with methanol were washed several times with water.

Then the oil and aqueous phases were separately analyzed by gas

chromatography. Oleic acid, methanol (0.021% w/w) and methyl

oleate were present in the oil phase. Methanol, di-n-butyl ether and

oleic acid (0.024% w/w) were present in the aqueous phase. UV-vis

spectra were recorded and analyzed in order to detect the Keggin

structure of HPA in these phases. No signals due to HPA were present in the spectrum of the oil phase. HPA was noticeably present

in the aqueous phase (Figure 5). The position of the maximum of

the UV-vis spectrum of HPA dissolved in water (curve A) is 260

nm. When dissolved in methanol (curve B) the maximum occurs

at 265 nm. In the case of the spectrum of the HPA present in the

aqueous phase of the reaction products the maximum appears at

264 nm (curve C). This shift is due to the influence of the pH of

the solution that governs the relative equilibrium concentration of

the different species in solution.34,40,41

Figure 5. UV-Vis absorbance spectra. (A) 10 mg of HPA dissolved in 100 mL

of water. (B) 10 mg of HPA dissolved in 100 mL of methanol. (C) 2 mg of the

reaction products dissolved in 10 mL of water

The aqueous phase at the end of the esterification reaction was

further used to test the reuse of the catalyst. For this purpose the Cs

salt of HPA was prepared by adding a salt of Cs with a weak base

in order to perform an acid-base reaction in which the carbonate

anion is replaced by the heterepolyanion. Then the Cs salt can be

used in a second esterification reaction. Despite the fact that the

catalyst is not the original HPA solid, the activity of the Cs salt is

similar to that of the resin and the reaction can proceed with good

conversion.

The solution of Cs2CO3 was added dropwise and a white precipitate of Cs2.5H0.5PW12O40 was formed. When precipitation was

completed, the precipitate was filtered, dried at 100 C in a stove

and finally calcined at 300 C in a muffle. The XRD spectrum of this

powder, after it was used in the esterification reaction, is shown in

Figure 6. The XRD spectrum of the Cs salt is similar to the spectrum

of the free acid, thus confirming that the Keggin structure of the free

acid is retained in the Cs salt.42

Figure 6. XRD spectrum of the Cs2.5H 0.5PW12O40 salt

CONCLUSIONS

The heteropolyacid H3PW12O40 catalyst shows a higher activity

than the Amberlyst 35W resin and its homologous Cs salt, in the reaction of oleic acid esterification with methanol. In the acid-catalyzed

dehydration of 1,4-butanediol the activity of HPA is similar to that

of the resin.

HPA shows a high efficiency for the esterification of oleic acid

with methanol at 25 C and it is possible to reuse it in the form of

Cs2.5H0.5PW12O40, though this partially exchanged cesium salt is not

as active as HPA itself. Cs2.5H0.5PW12O40 needs a reaction temperature

of 90 C to have a meaningful activity level.

HPA and Amberlyst 35W have a similar acid strength. However

the resin is not active at 25 C for the esterification of oleic acid with

methanol and has an activity-temperature pattern similar to that of

the cesium salt. HPA is active at room temperature and displays the

highest esterification activity.

This result indicates that HPA is a strong protonic acid and that

both surface and bulk protons contribute to the acidity. HPA is seemingly dissolved in polar oleic acid and methanol and the reaction

proceeds homogenously. The Amberlyst 35W resin and the cesium

salt are hardly soluble and in this case the catalytic action is constrained to the surface active sites.

In the case of the reaction of etherification of glycerol with

tert-butanol both the Amberlyst 35W and HPA catalyst had similar

initial activity levels. However at long reaction times the activity of

the resin is limited likely because of the chemisorption of water on

acid sities. Conversely HPA has a pattern of increasing conversion

with reaction time.

The Cs salt of HPA proved to be a potential reusable catalyst

for the trans/esterification of fatty materials and the etherification

of glycerol, thus comprising a versatile material for the biodiesel

production industry.

REFERENCES

1. Xiu-Kai, L.; Jink, Z.; Wei-Jie, J.; Zhi-Bing, Z.; Yi, C.; Chak-Tong, A.;

Scott, H.; Hartmut, H.; J. Catal. 2006, 237, 58.

2. Rafiee, E.; Paknezhad, F.; Shahebrahimi, Sh.; Joshaghani, M.; Eavani,

S.; Rashidzadeh, S.; J. Mol. Catal. A: Chem. 2008, 282, 92.

3. Misono, M.; Catal. Rev.-Sci. Eng. 1987, 29, 269.

606

Seplveda et al.

4. Justus, J.; Vinu, A.; Devassy, B.; Balasubramanian, V.; Bohringer, W.;

Fletcher, J.; Halligudu, S.; Catal. Commun. 2008, 9, 1671.

5. Dias, J.; Rangel, M. C.; Dias, S.; Caliman, E.; Garcia, F.; Appl. Catal.,

A 2007, 328, 189.

6. Okumura, K.; Yamashita, K.; Yamada, K.; Niwa, M.; J. Catal. 2007,

245, 75.

7. Blasco, T.; Corma, A.; Martnez-Escolano, P.; J. Catal. 1998, 177, 306.

8. Benaissa, H.; Davey, P.; Khimyak, Y.; Kozhevnikov, K.; J. Catal. 2008,

253, 244.

9. Devassy, B.; Halligudi, S.; J. Catal. 2005, 236, 323.

10. Rajasekar, K.; Pandurangan, A.; Catal. Commun. 2007, 8, 635.

11. Das, D.; Parida, K.; Appl. Catal., A 2006, 305, 32.

12. Rafiee, E.; Paknezhad, F.; Shahebrahimi, Sh.; Joshaghani, M.; Eavani,

S.; Rashidzadeh, S.; J. Mol. Catal. A: Chem. 2008, 282, 92.

13. Jermy, R.; Pandurangan, A.; Catal. Commun. 2008, 9, 577.

14. Rao, P. M.; Wolfson, A.; Kababya, S.; Vega, S.; Landau, M.; J. Catal.

2005, 232, 210.

15. Okumura, K.; Yamashita, K.; Hirano, M.; Niwa, M.; J. Catal. 2005, 234,

300.

16. Yuan, C.; Zhang, F.; Wang, J.; Ren, X.; Catal. Commun. 2005, 6, 721.

17. Amini, M.; Seyyedhamzeh, M.; Bazgir, A.; Mozhdeh, A.; Appl. Catal.,

A 2007, 323, 242.

18. Ma, F.; Hanna, M.; Bioresour. Technol. 1999, 70, 1.

19. Furuta, S.; Matsuhashi, H.; Arata, K.; Biomass Bioenergy 2006, 30, 870.

20. Martn, D.; Lpez, M.; Mariscal, R.; Yori, J. C.; Vera, C. R.; Grau, J. M.;

Proceedings XV CAC, IV MercoCAT, La Plata, Argentina, November

12-16, 2007, ID-191.

21. zbaya, N.; Oktar, N.; Tapana, N.A.; Fuel 2008, 87, 1789.

22. Caetano, C.; Fonseca, I.; Ramos, A.; Vital, J.; Castanheiro, J.; Catal.

Commun. 2008, 9, 1996.

23. Sunita, G.; Devassy, B.; Vinu, A.; Sawant, D.; Balasubramanian, V.;

Halligudi, S.; Catal. Commun. 2008, 9, 696.

Quim. Nova

24. Pagliaro, M.; Ciriminna, R.; Kimura, H.; Rossi, M.; Della Pina, C.;

Angew. Chem., Int. Ed. 2007, 46, 4434.

25. Noureddini, H.; US Patent 6,174,501 2001.

26. Dewattines, C.; Hinnekens, H.; Zeolites 1996, 16, 318.

27. Klepov, K.; Mravec, D.; Bajus, M.; Appl. Catal., A 2005, 294, 141.

28. Melero, J. A.; Vicente, G.; Morales, G.; Paniagua, M.; Moreno, J. M.;

Roldn, R.; Ezquerro, A.; Prez, C.; Appl. Catal., A 2008, 346, 44.

29. Yanyong, L.; Gaku, K.; Kyutae, N.; Misono, M.; Appl. Catal., A 1998,

166, L263.

30. Seplveda, J.; Texeira, S.; Schuchardt, U.; Appl. Catal., A 2007, 323,

242.

31. Balbinot, L.; Schuchardt, U.; Vera, C.; Seplveda, J.; Catal. Commun.

2008, 9, 1878.

32. Koyano, G.; Ueno, K.; Misono, M.; J. Mol. Catal. A: Chem 1994, 86,

319.

33. Liu, Y.; Koyano, G.; Misono, M.; Top. Catal. 2000, 11/12, 239.

34. Seplveda, J.; Yori, J. C.; Vera, C. R.; Appl. Catal., A 2005, 288, 18.

35. Kengaku, T.; Matsumoto, Y.; Na, K.; Misono, M.; J. Mol. Catal. A:

Chem. 1998, 134, 237.

36. Nakato, T.; Kimura, M.; Nakata, S.; Okuhara, T.; Langmuir 1998, 14,

319.

37. Na, K.; Okuhara, T.; Misono, M.; J. Chem. Soc. Faraday Trans. 1995,

91, 367.

38. Mizuno, N.; Misono, M.; J. Mol. Catal. A: Chem. 1994, 86, 319.

39. Koyano, G.; Ueno, K.; Misono, M.; Appl. Catal., A 1999, 181, 267.

40. Pizzio, L.; Caceres, C.; Blanco, M.; Appl. Catal., A 1998, 167, 283.

41. Kimura, H.; Nakato, T.; Okuhara, T.; Appl. Catal., A 1997, 165, 227.

42. Soled, S.; Miseo, S.; McVicker, G.; Gates, W. E.; Gutierrez, A.; Paes, J.;

J. Chem. Eng. 1996, 64, 247.

Das könnte Ihnen auch gefallen

- Differences of Classical and Modern Views On GravityDokument4 SeitenDifferences of Classical and Modern Views On GravityJose Miguel Lopez83% (6)

- Skyrim Potions GuideDokument26 SeitenSkyrim Potions GuideMarkinhos RuviaroNoch keine Bewertungen

- Major Practice in Swine ProductionDokument29 SeitenMajor Practice in Swine ProductionMark GarciaNoch keine Bewertungen

- Bagi Exercise Listening and StructureDokument16 SeitenBagi Exercise Listening and StructureDwiva Muna100% (1)

- NRTL ParametersDokument3 SeitenNRTL ParameterskaramniaNoch keine Bewertungen

- History of CFD Work in IndiaDokument10 SeitenHistory of CFD Work in IndiajoemonjacobNoch keine Bewertungen

- Timber Deck CargoesDokument12 SeitenTimber Deck CargoeschristieSINoch keine Bewertungen

- CW2b05f03a61a2aad3 ACS-10.1021 Acs - Iecr.6b03581 PDFDokument10 SeitenCW2b05f03a61a2aad3 ACS-10.1021 Acs - Iecr.6b03581 PDFVinny RossaNoch keine Bewertungen

- Assignment On Uber: Going Global From Day One: Course Name: International Business Course Code: BUS 606 Section: ADokument5 SeitenAssignment On Uber: Going Global From Day One: Course Name: International Business Course Code: BUS 606 Section: AIqbal JoyNoch keine Bewertungen

- Article: Cr/Al Oxide As Solid Acid Catalyst To Afford Babassu BiodiselDokument11 SeitenArticle: Cr/Al Oxide As Solid Acid Catalyst To Afford Babassu BiodiselLiz PonceNoch keine Bewertungen

- ChinaPetProcessPei ZrOCl2 38H2ODokument6 SeitenChinaPetProcessPei ZrOCl2 38H2OJuan Daniel Hernandez ValenzuelaNoch keine Bewertungen

- Agirre2011 PDFDokument7 SeitenAgirre2011 PDFAlan ConnorNoch keine Bewertungen

- Silica-Supported Tin Oxides As Heterogeneous Acid Catalysts For Transesterification of Soybean Oil With MethanolDokument7 SeitenSilica-Supported Tin Oxides As Heterogeneous Acid Catalysts For Transesterification of Soybean Oil With MethanolSichem GuerreroNoch keine Bewertungen

- Biolubricant synthesis from waste cooking oilDokument6 SeitenBiolubricant synthesis from waste cooking oilLeonardo IndraNoch keine Bewertungen

- Cordeiro Et Al. - 2012 - LDHs Instability in Esterification Reactions and Their Conversion To Catalytically Active Layered Carboxylates-AnnotatedDokument8 SeitenCordeiro Et Al. - 2012 - LDHs Instability in Esterification Reactions and Their Conversion To Catalytically Active Layered Carboxylates-AnnotatedJin WangNoch keine Bewertungen

- Methanolic HCLDokument2 SeitenMethanolic HCLKalim IqbalNoch keine Bewertungen

- 3 PDFDokument10 Seiten3 PDFKunalTelgoteNoch keine Bewertungen

- Full Length Article: Contents Lists Available atDokument11 SeitenFull Length Article: Contents Lists Available atAlexis MiguelNoch keine Bewertungen

- Yang 2016Dokument36 SeitenYang 2016Febrian Dimas Adi NugrahaNoch keine Bewertungen

- Biomass and Bioenergy: Aleksander Hykkerud, Jorge M. MarchettiDokument4 SeitenBiomass and Bioenergy: Aleksander Hykkerud, Jorge M. MarchettiIris Bustamante PájaroNoch keine Bewertungen

- Catalizatori Eterogeni Pentru Productia de BiodieselDokument4 SeitenCatalizatori Eterogeni Pentru Productia de BiodieselElly GloriaNoch keine Bewertungen

- Ultrasound-Assisted Synthesis of Biodiesel From Palm Fatty Acid DistillateDokument5 SeitenUltrasound-Assisted Synthesis of Biodiesel From Palm Fatty Acid Distillatedstar13Noch keine Bewertungen

- Energy Conversion and Management: Hu Pan, Hu Li, Heng Zhang, Anping Wang, Duo Jin, Song YangDokument11 SeitenEnergy Conversion and Management: Hu Pan, Hu Li, Heng Zhang, Anping Wang, Duo Jin, Song YangjohnkirubaNoch keine Bewertungen

- Catalytic Application of Al-MCM-41 in The Esterification of Acetic Acid With Various AlcoholsDokument9 SeitenCatalytic Application of Al-MCM-41 in The Esterification of Acetic Acid With Various AlcoholsJenny CórdobaNoch keine Bewertungen

- Metathesis of Unsaturated Fatty Acids: Synthesis of Long-Chain Unsaturated-αDokument6 SeitenMetathesis of Unsaturated Fatty Acids: Synthesis of Long-Chain Unsaturated-αannisak fitriyanaNoch keine Bewertungen

- Silica Sulfuric Acid An Efficient and Reusable Catalyst For The One-Pot Synthesis of 3,4-Dihydropyrimidin-2 (1H) - OnesDokument3 SeitenSilica Sulfuric Acid An Efficient and Reusable Catalyst For The One-Pot Synthesis of 3,4-Dihydropyrimidin-2 (1H) - OnesDuy Phuc LeNoch keine Bewertungen

- Journal Pre-Proof: Applied Catalysis B: EnvironmentalDokument43 SeitenJournal Pre-Proof: Applied Catalysis B: EnvironmentalMichael RosoNoch keine Bewertungen

- Sintesis de CineolDokument4 SeitenSintesis de CineolNatalia RuizNoch keine Bewertungen

- Tetrahedron Letters 52 (2011) 3339-3341Dokument3 SeitenTetrahedron Letters 52 (2011) 3339-3341Arthur Girardi CarpanezNoch keine Bewertungen

- Research ArticleDokument13 SeitenResearch Articlekishore dasmunshiNoch keine Bewertungen

- Aranda 2007Dokument6 SeitenAranda 2007ALAADDIN SAEEDNoch keine Bewertungen

- Junying Fu, Liangguang Chen, Pengmei LV, Lingmei Yang, Zhenhong YuanDokument8 SeitenJunying Fu, Liangguang Chen, Pengmei LV, Lingmei Yang, Zhenhong Yuanjulius vincentNoch keine Bewertungen

- Synthesis of Waste Cooking Oil-Based Biodiesel Via Effectual RecyclableDokument8 SeitenSynthesis of Waste Cooking Oil-Based Biodiesel Via Effectual RecyclableDiko FernandoNoch keine Bewertungen

- Rattana Phra 2012Dokument9 SeitenRattana Phra 2012Shurooq TaibNoch keine Bewertungen

- Acid-Catalyzed Alcoholysis of Soybean OilDokument6 SeitenAcid-Catalyzed Alcoholysis of Soybean OilChristopherNoch keine Bewertungen

- A Single Step Non-Catalytic Esterification of Palm Fatty Acid Distillate (PFAD) ForDokument8 SeitenA Single Step Non-Catalytic Esterification of Palm Fatty Acid Distillate (PFAD) ForNestor Armando Marin SolanoNoch keine Bewertungen

- Catalysis Communications: Suresh D. Salim, Krishnacharya G. AkamanchiDokument4 SeitenCatalysis Communications: Suresh D. Salim, Krishnacharya G. AkamanchinileshsalunkheNoch keine Bewertungen

- Efficient solid acid catalyst for esterification of myristic acidDokument9 SeitenEfficient solid acid catalyst for esterification of myristic acidChau MaiNoch keine Bewertungen

- Yan 2009Dokument6 SeitenYan 2009theressa julietaNoch keine Bewertungen

- Jurnal EkstraksiDokument5 SeitenJurnal EkstraksiLukman VyatrawanNoch keine Bewertungen

- Metathesis of Unsaturated Fatty Acids: Synthesis of Long-Chain Unsaturated-??,??-Dicarboxylic AcidsDokument7 SeitenMetathesis of Unsaturated Fatty Acids: Synthesis of Long-Chain Unsaturated-??,??-Dicarboxylic AcidsByounghak KimNoch keine Bewertungen

- Cholin BaseDokument5 SeitenCholin Basex_aav3Noch keine Bewertungen

- Performance of Bubble Column ReactorDokument6 SeitenPerformance of Bubble Column ReactorArtha WijayaNoch keine Bewertungen

- Catalytic Esterification of Bio-Oil by Ion Exchange Resins (WANG Jin-Jiang, CHANG Jie, FAN Juan)Dokument5 SeitenCatalytic Esterification of Bio-Oil by Ion Exchange Resins (WANG Jin-Jiang, CHANG Jie, FAN Juan)HappyNoch keine Bewertungen

- Mendaros 2020Dokument11 SeitenMendaros 2020JohnNoch keine Bewertungen

- Reference For R-101Dokument9 SeitenReference For R-101aibbycatalanNoch keine Bewertungen

- Biodiesel From Batch and Continuous Oleic Acid Esterification Using Zeolite CatalystsDokument7 SeitenBiodiesel From Batch and Continuous Oleic Acid Esterification Using Zeolite CatalystsArif HidayatNoch keine Bewertungen

- Fast Pyrolysis of Cassava Rhizome in The Presence of CatalystsDokument8 SeitenFast Pyrolysis of Cassava Rhizome in The Presence of CatalystsyemresimsekNoch keine Bewertungen

- Hexadecane CrackingDokument15 SeitenHexadecane CrackingcligcodiNoch keine Bewertungen

- Macromolecular Symposia - 2016 - Muniz Wypych - Poly Alkyl Acrylates As Pour Point Improvers For BiofuelsDokument9 SeitenMacromolecular Symposia - 2016 - Muniz Wypych - Poly Alkyl Acrylates As Pour Point Improvers For BiofuelsAustin SmithNoch keine Bewertungen

- Biodiesel Production From Waste Oil Feedstocks by Solid Acid CatalysisDokument7 SeitenBiodiesel Production From Waste Oil Feedstocks by Solid Acid CatalysisThói ĐờiNoch keine Bewertungen

- Esterification of Acetic Acid Via Semi-Batch Reactive Distillation For Pyrolysis Oil Upgrading: Experimental ApproachDokument8 SeitenEsterification of Acetic Acid Via Semi-Batch Reactive Distillation For Pyrolysis Oil Upgrading: Experimental ApproachYanin CyrusNoch keine Bewertungen

- Synthesis of Biodiesel From Soybean Oil Using Heterogeneous Kf/Zno CatalystDokument7 SeitenSynthesis of Biodiesel From Soybean Oil Using Heterogeneous Kf/Zno CatalystitzelselNoch keine Bewertungen

- One-Pot Synthesis of Alkyl Levulinates From Biomass Derivative Carbohydrates in Tin (II) Exchanged Silicotungstates-Catalyzed ReactionsDokument17 SeitenOne-Pot Synthesis of Alkyl Levulinates From Biomass Derivative Carbohydrates in Tin (II) Exchanged Silicotungstates-Catalyzed Reactionsbruno barrosNoch keine Bewertungen

- Chemical Engineering Journal: Chenju Liang, Ming-Chi Wei, Hui-Hsin Tseng, En-Chin ShuDokument10 SeitenChemical Engineering Journal: Chenju Liang, Ming-Chi Wei, Hui-Hsin Tseng, En-Chin ShuPuguh Arif Nur HidayatNoch keine Bewertungen

- Peigao Duan, Xiujun Bai, Yuping Xu, Aiyun Zhang, Feng Wang, Lei Zhang, Juan MiaoDokument9 SeitenPeigao Duan, Xiujun Bai, Yuping Xu, Aiyun Zhang, Feng Wang, Lei Zhang, Juan MiaoyemresimsekNoch keine Bewertungen

- Screening Acidic Zeolites For Catalytic Fast Pyrolysis of Biomass and Its ComponentsDokument15 SeitenScreening Acidic Zeolites For Catalytic Fast Pyrolysis of Biomass and Its ComponentsMikael SalamancaNoch keine Bewertungen

- Hydroprocessed Rapeseed Oil FuelsDokument5 SeitenHydroprocessed Rapeseed Oil Fuelsscorpion2001glaNoch keine Bewertungen

- Vinicius Rossa, Production of Solketal Using Acid Zeolites As CatalystsDokument18 SeitenVinicius Rossa, Production of Solketal Using Acid Zeolites As Catalystsnysa arientikaNoch keine Bewertungen

- Nbnfi Fe2019090626964Dokument22 SeitenNbnfi Fe2019090626964fajarNoch keine Bewertungen

- Biolubricant synthesis from waste cooking oilDokument6 SeitenBiolubricant synthesis from waste cooking oilTomy Wijaya PutraNoch keine Bewertungen

- Candida Antarctica As A Novel Catalyst: Full Length ArticleDokument8 SeitenCandida Antarctica As A Novel Catalyst: Full Length ArticleFikka RuhaiyaNoch keine Bewertungen

- Catalytic Conversion of Glycerol To Acrolein Over Modified Molecular SievesDokument10 SeitenCatalytic Conversion of Glycerol To Acrolein Over Modified Molecular SievesAnonymous Wcj4C3jNoch keine Bewertungen

- Sub/Supercritical Carbon Dioxide Induced Phase Switching For The Reaction and Separation in Ils/MethanolDokument5 SeitenSub/Supercritical Carbon Dioxide Induced Phase Switching For The Reaction and Separation in Ils/MethanolDoni RopawandiNoch keine Bewertungen

- Preparation of Carbon-Based Solid Acid Catalysts UDokument19 SeitenPreparation of Carbon-Based Solid Acid Catalysts UJustin Marc EstiponaNoch keine Bewertungen

- Bioresources.: Upgrading of Bio-Oil in Supercritical Ethanol: Using Furfural and Acetic Acid As Model CompoundsDokument19 SeitenBioresources.: Upgrading of Bio-Oil in Supercritical Ethanol: Using Furfural and Acetic Acid As Model CompoundsJohn ShipNoch keine Bewertungen

- Catalytic Synthesis of Aspirin Using a Green and Recyclable Solid Acid CatalystDokument4 SeitenCatalytic Synthesis of Aspirin Using a Green and Recyclable Solid Acid CatalystPaula Málaga EspichánNoch keine Bewertungen

- Transition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesVon EverandTransition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesNoch keine Bewertungen

- Physical and Chemical Characteristics and Sensory Evaluation of PomegranateDokument12 SeitenPhysical and Chemical Characteristics and Sensory Evaluation of PomegranateJefferson ThiamNoch keine Bewertungen

- Energy and Greenhouse Gas Emissions Effects of Fuel EthanolDokument12 SeitenEnergy and Greenhouse Gas Emissions Effects of Fuel EthanolGlorie Mae BurerosNoch keine Bewertungen

- Yoshizawa 15Dokument4 SeitenYoshizawa 15Glorie Mae BurerosNoch keine Bewertungen

- Visayas RSM 3 LA CuevasDokument45 SeitenVisayas RSM 3 LA CuevasGlorie Mae BurerosNoch keine Bewertungen

- 2 Out of 3 or 4Dokument6 Seiten2 Out of 3 or 4Glorie Mae BurerosNoch keine Bewertungen

- 58 60 Pmrapr89Dokument3 Seiten58 60 Pmrapr89Glorie Mae BurerosNoch keine Bewertungen

- 5 Paper 2 Biodiesel Plant Design For Rural ApplicationDokument8 Seiten5 Paper 2 Biodiesel Plant Design For Rural ApplicationGlorie Mae BurerosNoch keine Bewertungen

- China's 1984 Law on Prevention and Control of Water PollutionDokument8 SeitenChina's 1984 Law on Prevention and Control of Water PollutionGlorie Mae BurerosNoch keine Bewertungen

- Homework 11. ProcessDokument6 SeitenHomework 11. ProcessNur Amira Mardiana ZulkifliNoch keine Bewertungen

- Tabla de DatosDokument40 SeitenTabla de DatosGlorie Mae BurerosNoch keine Bewertungen

- Request For Profiles - 03.10.08Dokument2 SeitenRequest For Profiles - 03.10.08Glorie Mae BurerosNoch keine Bewertungen

- Modeling alcohol dehydrogenase kinetics in microreactorsDokument8 SeitenModeling alcohol dehydrogenase kinetics in microreactorsGlorie Mae BurerosNoch keine Bewertungen

- Assignment 4Dokument3 SeitenAssignment 4Jessica SaballeroNoch keine Bewertungen

- Tesser 2005Dokument5 SeitenTesser 2005Glorie Mae BurerosNoch keine Bewertungen

- Engineering Economy QuestionsDokument10 SeitenEngineering Economy QuestionsGlorie Mae BurerosNoch keine Bewertungen

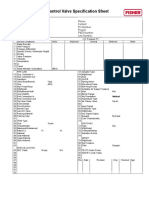

- Control Valve Specification SheetDokument1 SeiteControl Valve Specification SheetGlorie Mae BurerosNoch keine Bewertungen

- Visayas RSM 3 LA CuevasDokument45 SeitenVisayas RSM 3 LA CuevasGlorie Mae BurerosNoch keine Bewertungen

- Esterification of Higher Fatty Acids by A Novel Strong Solid AcidDokument5 SeitenEsterification of Higher Fatty Acids by A Novel Strong Solid AcidGlorie Mae BurerosNoch keine Bewertungen

- CrystalstructureDokument71 SeitenCrystalstructureGlorie Mae BurerosNoch keine Bewertungen

- Tabla de DatosDokument40 SeitenTabla de DatosGlorie Mae BurerosNoch keine Bewertungen

- Preparation of CSAC MethodsDokument3 SeitenPreparation of CSAC MethodsGlorie Mae BurerosNoch keine Bewertungen

- BookmarksDokument4 SeitenBookmarksGlorie Mae BurerosNoch keine Bewertungen

- Engineers justify large projects with time value of money questionsDokument13 SeitenEngineers justify large projects with time value of money questionsGlorie Mae BurerosNoch keine Bewertungen

- Homework 11. ProcessDokument6 SeitenHomework 11. ProcessNur Amira Mardiana ZulkifliNoch keine Bewertungen

- Agua de Gloria Id-1Dokument1 SeiteAgua de Gloria Id-1Glorie Mae BurerosNoch keine Bewertungen

- Critique On PD 856 Industrial HygieneDokument2 SeitenCritique On PD 856 Industrial HygieneGlorie Mae BurerosNoch keine Bewertungen

- Mind Map of The Principles of Professional ConductDokument1 SeiteMind Map of The Principles of Professional ConductGlorie Mae BurerosNoch keine Bewertungen

- Esterification of Higher Fatty Acids by A Novel Strong Solid AcidDokument5 SeitenEsterification of Higher Fatty Acids by A Novel Strong Solid AcidGlorie Mae BurerosNoch keine Bewertungen

- Analysis of Caffeine Content in Kola Acuminate and Kola NitidaDokument50 SeitenAnalysis of Caffeine Content in Kola Acuminate and Kola Nitidaebuka100% (1)

- Chapter 14: Understanding Clutches and Their Operating PrinciplesDokument39 SeitenChapter 14: Understanding Clutches and Their Operating PrinciplespapipapiiNoch keine Bewertungen

- People Vs VelardeDokument4 SeitenPeople Vs VelardeFred SperryNoch keine Bewertungen

- Parts Catalogue: Nova L5-L6Dokument69 SeitenParts Catalogue: Nova L5-L6juanjoserodriguezalzNoch keine Bewertungen

- Director Contract Management in Florida North Carolina Resume Thomas CzajaDokument3 SeitenDirector Contract Management in Florida North Carolina Resume Thomas CzajaThomas CzajaNoch keine Bewertungen

- English 4 Q2 Weeks 1-4Dokument36 SeitenEnglish 4 Q2 Weeks 1-4Em AdrianoNoch keine Bewertungen

- Hydrolysis of Lactose in Whey Permeate For Subsequent Fermentation To EthanolDokument13 SeitenHydrolysis of Lactose in Whey Permeate For Subsequent Fermentation To EthanolkaltoumNoch keine Bewertungen

- Modeling Relationships in Scatter PlotsDokument45 SeitenModeling Relationships in Scatter PlotsSiddarth Kalyan100% (1)

- Corrosion Management and Cathodic Protection GuideDokument52 SeitenCorrosion Management and Cathodic Protection GuideErol DAĞNoch keine Bewertungen

- AR213 PostWar AjKanokwan HandoutDokument28 SeitenAR213 PostWar AjKanokwan Handoutpranutchaya.bamNoch keine Bewertungen

- Managing Demand Uncertainty in Supply Chain PlanningDokument6 SeitenManaging Demand Uncertainty in Supply Chain PlanningSuraj NamdeoNoch keine Bewertungen

- 10TH Gseb PaperDokument10 Seiten10TH Gseb Paperkhushboo guptaNoch keine Bewertungen

- PID and Feedback Compensation Design for Control SystemsDokument32 SeitenPID and Feedback Compensation Design for Control SystemsNikhil PanikkarNoch keine Bewertungen

- Ecotek DesignManual v2015 02Dokument44 SeitenEcotek DesignManual v2015 02benNoch keine Bewertungen

- Shortcuts and Quick Tips To Solve CAT MBA Quantitative Questions CAT, Entrance Exams, MBA - iHelpStudyDokument21 SeitenShortcuts and Quick Tips To Solve CAT MBA Quantitative Questions CAT, Entrance Exams, MBA - iHelpStudySofi DinendranNoch keine Bewertungen

- Mitsubishi: Technical Service BulletinDokument11 SeitenMitsubishi: Technical Service BulletinKonstantinNoch keine Bewertungen

- The Journey of HIV 1 Non-Nucleoside Reverse TranscriptaseDokument33 SeitenThe Journey of HIV 1 Non-Nucleoside Reverse TranscriptaseAnkit Kumar SinghNoch keine Bewertungen

- Tots FaqDokument12 SeitenTots FaqkbsnNoch keine Bewertungen

- ALL-Q (Coenzyme Q10) Plus - PDSDokument3 SeitenALL-Q (Coenzyme Q10) Plus - PDSMarlon2370Noch keine Bewertungen

- Modelacion UreaDokument20 SeitenModelacion UreaJesus Enrique Alfonzo RiveroNoch keine Bewertungen

- Chapter 4Dokument9 SeitenChapter 4Aung KhantNoch keine Bewertungen

- 200 300 Series Installation Guide USDokument48 Seiten200 300 Series Installation Guide USLhexter Mhervin CoNoch keine Bewertungen

- Tactile Internet MSC V2Dokument28 SeitenTactile Internet MSC V2hendNoch keine Bewertungen