Beruflich Dokumente

Kultur Dokumente

1.0 Beam Design

Hochgeladen von

klynchelleOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

1.0 Beam Design

Hochgeladen von

klynchelleCopyright:

Verfügbare Formate

DOCUMENT No

SHEET

0006 - MN00166 - MNC - 00

SUBJECT

SHEAR DESIGN

SUBJECT

PERCI

CALCULATIONS

OUTPUT

PERCI

ACI 318M-05

SHEAR DESIGN

BEAM:

LEVEL:

LOCATION:

Av = total number of legs * Area of 1 link

11.3.1.1

11.5.6

11.5.5.3

Vc = 0.17 (fc')0.5 bw d

s=

Av f

750 mm

yt d

h = 750 mm

V u V c

s2=

Av min f

yt

s3=

0. 062 fc ' bw

0.75

(shear)

11.5.2

420

fyt (MPa)

11.1.2

40

600

fc' (Mpa)

bw beam width (mm)

750

h total depth (mm)

20

bar dia - main reinf (mm)

# of bar layer/s

40

clear cover (mm)

661.5

320.1

B

Av min f

yt

bw = 600 mm

0 .35 b w

effective depth, d (mm)

Vc (KN)

BEAM OR ONE-WAY SLAB?

FOR EDGE

.

.

1500

Vu (KN)

# of legs

16

link dia (mm)

s = 142

11.5.4

spacing = smallest of

(mm)

FOR MIDSPAN

1500

Vu (KN)

# of legs

16

link dia (mm)

s = 142

d/4 = 165

d/4 = 165

300 = 300

s2 = 1436

s3 = 1608

300 = 300

s2 = 1436

s3 = 1608

REQD spacing = 125 mm

USE spacing = 125 mm

USE: 4L - T16 - 125

REQD spacing = 125 mm

USE spacing = 125 mm

USE: 4L - T16 - 125

DOCUMENT No

SHEET

0006 - MN00166 - MNC - 00

SUBJECT

CRACK WIDTH ANALYSIS

SUBJECT

PERCI

CALCULATIONS

OUTPUT

PERCI

ACI224R-90

ACI 318M-05

CRACK WIDTH ANALYSIS

BEAM:

LEVEL:

LOCATION:

PARAMETERS:

beam width

total depth

EQ (4.2)

SI

1200 mm

1330 mm

b

h

bottom clear cover

cover reduction

link diameter

bar diameter

# of bars (tension)

cover

50

0

12

32

16

mm

mm

mm

mm

bars

conc cylinder strength

steel

elas mod conc

elas mod steel

n = Es / Ec

effective depth

cover to centroid of bars

cover + d link + d b / 2

fc'

fy

Ec

Es

n

d

y

dc

35

460

27806

200000

7.2

1220.00

110.00

78

12868

0.0088

MPa

MPa

MPa

MPa

Steel Area

p = As / bd

As

p

Service Moment

crack width limit

Ms

w allow

CALCULATIONS

k

j

Steel Stress:

A

z

{sqrt[(pn)^2 + 2pn] - pn}

1-k/3

h2 / h1

fs=Ms/[As*jd]

A=(2y*b)/n

fs*(dc*A)^1/3

d link

db

IMPERIAL

47.24 in

52.36 in

1.97

0.00

0.47

1.26

66.72 ksi

mm

mm

mm

mm^2

2000 kN-m

0.2 mm

in

in

in

in

48.03

4.33

3.07

19.95

in

in

in

in^2

17701.50 Kip-in

0.01 in

0.30

0.90

1.09

20.51 ksi

25.58 in^2

87.85 kips/in

=0.076*(*z)/1000

crack width, w

w

0.186 mm

0.007 in

kd

d

h2

h1

y

y

b

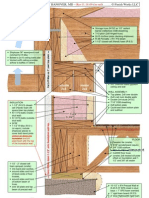

NOTE: for illustration purposes

only

dc

crack width

0.186<=0.2

OK

DOCUMENT No

SHEET

0006 - MN00166 - MNC - 00

SUBJECT

TORSION DESIGN

SUBJECT

PERCI

CALCULATIONS

OUTPUT

PERCI

ACI 318M-05

TORSION DESIGN

BEAM:

LEVEL:

LOCATION:

11.5.2

11.6.3.4

700

950

865.5

40

420

420

0.75

mm

mm

mm

MPa

MPa

MPa

40

40

40

mm

mm

mm

665000

3300

515816

2916

438444

45

mm2

mm

mm2

mm

mm2

deg

Tu FOR DESIGN

E

1500

400

400

KN

KNm

KNm

Tcr

210

KNm

web width, b

overall thickness or height of member, h

effective depth, d

specified compressive strength of concrete, fc'

specified yield strength of reinforcement, fy

specified yield strength fy of transverse reinforcement, fyv / fyt

strength reduction factor,

clear cover, top

clear cover, bottom

clear cover, sides

area enclosed by outside perimeter of concrete cross section, Acp

outside perimeter of concrete cross section, pcp

area enclosed by CL of the outermost closed transverse torsional reinf, Aoh

perimeter of centerline of outermost closed transverse torsional reinf, ph

0.85 Aoh = Ao

11.6.3.6

1. Equilibrium or Compatibility Torsion?

Vu

Tu

2. Check if torsion may be neglected

11.6.2.2

Tcr / 4

52

KNm

Tu > Tcr / 4 - Design for Torsion

3. Check if Section Dimensions are OK

11.3.1.1

nominal shear strength provided by conc, Vc

651

11.6.3.1

shear stress at the section

3.57

limiting shear stress

KN

3.94

SECTION OK

DOCUMENT No

SHEET

0006 - MN00166 - MNC - 00

SUBJECT

TORSION DESIGN

SUBJECT

PERCI

CALCULATIONS

OUTPUT

4. Required Area of Stirrups for Torsion

11.6.3.6

required At / s

1.448

mm2 / mm / leg

d link torsion

spacing

provided At / s

At / s provided - At / s reqd = unused At / s

2At / s = unused Av / s

16

100

2.011

0.562

1.125

mm

mm

mm2 / mm / leg

mm2 / mm / leg

mm2 / mm

3.710

2.585

4

16

300

2.681

mm2 / mm

mm2 / mm

Required Shear Links (from Shear Design)

( Vu - Vc ) / ( fy d ) = required Av / s

required Av / s - unused Av / s = remaining required Av / s

# of legs

d link shear

spacing

provided Av / s

OK

mm

mm

OK

Minimum Area of Transverse Closed Stirrups

11.6.5.2

(Av + 2At) / s min

0.654

(Av + 2At) / s

4.021

5. Required Area of Longitudinal Torsion Reinforcement

11.6.3.7

Al

11.6.5.3

Al min

4223

mm2

-17

mm2

4223

875

875

1237

1237

mm2

mm2

mm2

mm2

mm2

>=

Al

Al TOP

Al BOT

Al LEFT

Al RIGHT

NOTE:

Spacing of longitudinal bars or side bars <= 300 & ph/8 = 364.5

There should be atleast one longitudinal bar in each corner of stirrup

Longitudinal reinf must have a dia > (1/24 of stirrup spacing or 10mm )

and should be inside the stirrup to avoid buckling

DOCUMENT No

SHEET

0006 - MN00166 - MNC - 00

SUBJECT

SUBJECT

TORSION DESIGN

CALCULATIONS

PERCI

OUTPUT

DOCUMENT No

SHEET

0002 - MN00155 - MNC - 01

SUBJECT

DESIGN TO FLEXURE

SUBJECT

ACI 318M-05

CALCULATIONS

DESIGN TO FLEXURE

70

460

0.9

f'c (MPa)

fy (MPa)

flexure

0.65

0.0357

0.0045

max

min

Y-STRIP

Strip

Name

YSF1

CSY1,19

Mu

kN-m

-2778

300

Reinf

Provided

T32-100

T32-100

Width

mm

1000

1000

Height

mm

2000

2000

Clear

Cover

72

107

Diameter

mm

32

32

Spacing

mm

100

100

As

mm2

8042

8042

d eff

mm

1912

1877

0.0042

0.0043

0.0276

0.0282

M capacity

kN-m

6262

6146

YSF2

20,21

-3106

4970

T32-100

T32-100

1000

1000

2000

2000

72

107

32

32

100

100

8042

8042

1912

1877

0.0042

0.0043

0.0276

0.0282

6262

6146

YSF3

22,23

-3054

5545

T32-100

T32-100

1000

1000

2000

2000

72

107

32

32

100

100

8042

8042

1912

1877

0.0042

0.0043

0.0276

0.0282

6262

6146

YSF4

24,25

-4372

5468

T32-100

T32-100

1000

1000

2000

2000

72

107

32

32

100

100

8042

8042

1912

1877

0.0042

0.0043

0.0276

0.0282

6262

6146

SUMMARY - Y STRIP

TOP

T32-100-T1

BOTTOM

T32-100-B1 (crack width)

T32-100-B2

REFERENCE SAFE MODEL:

RES TOWER P2.FDB

SHEET

OUTPUT

PERCI

Remarks

OK

OK

OK

OK

OK

OK

OK

OK

DOCUMENT No

SHEET

0006 - MN00166 - MNC - 00

SUBJECT

DESIGN TO FLEXURE - SRB

SUBJECT

PERCI

CALCULATIONS

OUTPUT

PERCI

ACI 318M-05

DESIGN TO FLEXURE - SINGLY REINFORCED BEAM

BEAM:

LEVEL:

LOCATION:

h = 1200 mm

bw = 800 mm

specified compressive strength of concrete

specified yield strength of reinforcement

70

460

MPa

MPa

800

1200

107

0

0.9

1077.00

mm

mm

mm

mm

mm

As

32

6

0

0

4825

As / b d

maximum reinforcement ratio

minimum reinforcement ratio

max

min

0.0056

0.0357

0.0045

depth of equivalent rectangular stress block

flexural capacity

1

a

Mn

0.65

46.63

2105

web width

overall thickness or height of member

clear cover of reinforcement (bottom)

link diameter

strength reduction factor - flexure

effective depth

main reinf diameter

no. of bars in outermost layer

no. of bars in 2nd layer

no. of bars in 3rd layer

10.5.1

10.2.7.3

fc'

fy

bw

h

cc

d link

d

db

mm

mm2

OK

OK

mm

kNm

DOCUMENT No

SHEET

0006 - MN00166 - MNC - 00

SUBJECT

SHEAR DESIGN

SUBJECT

PERCI

CALCULATIONS

OUTPUT

PERCI

ACI 318M-05

SHEAR DESIGN

BEAM:

LEVEL:

LOCATION:

Av = total number of legs * Area of 1 link

11.3.1.1

11.5.6

11.5.5.3

Vc = 0.17 (fc')0.5 bw d

950 mm

Av f yt d

Vu Vc

s2

h = 950 mm

Av min f yt

0.062

s3

fc 'bw

0.75

(shear)

11.5.2

420

fyt (MPa)

11.1.2

40

700

fc' (Mpa)

bw beam width (mm)

950

h total depth (mm)

20

bar dia - main reinf (mm)

# of bar layer/s

40

clear cover (mm)

861.5

486.3

B

Av min f yt

bw = 700 mm

0.35 b w

effective depth, d (mm)

Vc (KN)

BEAM OR ONE-WAY SLAB?

FOR EDGE

.

.

1500

Vu (KN)

# of legs

16

link dia (mm)

s = 215

11.5.4

spacing = smallest of

(mm)

FOR MIDSPAN

1500

Vu (KN)

# of legs

16

link dia (mm)

s = 215

d/4 = 215

d/4 = 215

300 = 300

s2 = 1231

s3 = 1379

300 = 300

s2 = 1231

s3 = 1379

REQD spacing = 200 mm

USE spacing = 200 mm

USE: 4L - T16 - 200

REQD spacing = 200 mm

USE spacing = 200 mm

USE: 4L - T16 - 200

DOCUMENT No

SHEET

0006 - MN00166 - MNC - 00

SUBJECT

CRACK WIDTH ANALYSIS

SUBJECT

PERCI

CALCULATIONS

OUTPUT

PERCI

ACI224R-90

ACI 318M-05

CRACK WIDTH ANALYSIS

BEAM:

LEVEL:

LOCATION:

PARAMETERS:

beam width

total depth

EQ (4.2)

SI

1200 mm

1350 mm

b

h

bottom clear cover

cover reduction

link diameter

bar diameter

# of bars (tension)

cover

conc cylinder strength

steel

elas mod conc

elas mod steel

n = Es / Ec

effective depth

cover to centroid of bars

cover + d link + d b / 2

fc'

fy

Ec

Es

n

d

y

dc

Steel Area

p = As / bd

As

p

Service Moment

crack width limit

Ms

w allow

CALCULATIONS

k

j

Steel Stress:

A

z

{sqrt[(pn)^2 + 2pn] - pn}

1-k/3

h2 / h1

fs=Ms/[As*jd]

A=(2y*b)/n

fs*(dc*A)^1/3

IMPERIAL

47.24 in

53.15 in

40 mm

mm

12 mm

32 mm

16 bars

d link

db

35

460

27806

200000

7.2

1250.00

100.00

68

12868

0.0086

1.57

0.00

0.47

1.26

MPa

MPa

MPa

MPa

66.72 ksi

mm

mm

mm

mm^2

2000 kN-m

0.2 mm

in

in

in

in

49.21

3.94

2.68

19.95

in

in

in

in^2

17701.50 Kip-in

0.01 in

0.29

0.90

1.08

20.00 ksi

23.25 in^2

79.26 kips/in

=0.076*(*z)/1000

crack width, w

w

0.165 mm

0.006 in

kd

d

h2

h1

y

y

b

NOTE: for illustration purposes

only

dc

crack width

0.165<=0.2

OK

Das könnte Ihnen auch gefallen

- 2.0 Design of SlabDokument25 Seiten2.0 Design of Slabklynchelle100% (4)

- No Passive & WaterDokument13 SeitenNo Passive & WaterArnel Dodong100% (1)

- BEAM DesignDokument45 SeitenBEAM DesignJoseph Cloyd L. LamberteNoch keine Bewertungen

- Connection DesignDokument87 SeitenConnection DesignJigarNoch keine Bewertungen

- Beam Design TorsionDokument20 SeitenBeam Design Torsionmailmaverick8167100% (1)

- 10.0design of Baseplate and Anchor BoltsDokument7 Seiten10.0design of Baseplate and Anchor BoltsklynchelleNoch keine Bewertungen

- Slab Design SpreadsheetDokument16 SeitenSlab Design SpreadsheetmuraliNoch keine Bewertungen

- Design of PileDokument2 SeitenDesign of PileklynchelleNoch keine Bewertungen

- Reinforced Concrete Design of Beams, Columns, One-Way Slab, and Two-Way Slab With EstimateDokument74 SeitenReinforced Concrete Design of Beams, Columns, One-Way Slab, and Two-Way Slab With EstimateEmmanuel LazoNoch keine Bewertungen

- Therefore Use, Therefore UseDokument4 SeitenTherefore Use, Therefore UseJason Teves DomasigNoch keine Bewertungen

- Hindustan Construction Co. Ltd. Mumbai. Subject: Design of RC Column Standard Excel Design DetailsDokument28 SeitenHindustan Construction Co. Ltd. Mumbai. Subject: Design of RC Column Standard Excel Design DetailsImranSohailNoch keine Bewertungen

- Doubly Reinforced BeamDokument10 SeitenDoubly Reinforced Beamkalpanaadhi50% (2)

- Design of Combined FootingDokument6 SeitenDesign of Combined FootingEric John PedrosoNoch keine Bewertungen

- Design of Beam (Internal) at Midspan: Solution (Using NSCP 7th Edition)Dokument9 SeitenDesign of Beam (Internal) at Midspan: Solution (Using NSCP 7th Edition)Nico Paulo RuzNoch keine Bewertungen

- Beam-Design-R CDokument123 SeitenBeam-Design-R CMarkNoch keine Bewertungen

- Column DesignDokument6 SeitenColumn DesignKenneth CajefeNoch keine Bewertungen

- Squre Footing Design (WSD)Dokument3 SeitenSqure Footing Design (WSD)api-19753598Noch keine Bewertungen

- RCC Beam Design Task-01Dokument29 SeitenRCC Beam Design Task-01Mohamed SaheelNoch keine Bewertungen

- 11.0design of Corbel-FINALDokument8 Seiten11.0design of Corbel-FINALklynchelleNoch keine Bewertungen

- Two Way Slab DesignDokument1 SeiteTwo Way Slab DesignMuhammad FaisalNoch keine Bewertungen

- Design of Footing and Anchor BoltsDokument9 SeitenDesign of Footing and Anchor BoltsMUTHUKKUMARAM100% (1)

- Chap6 Stair Design MDMDokument33 SeitenChap6 Stair Design MDMJordan Allen BarriosNoch keine Bewertungen

- Design of Cold-Formed Purlins: Section AdequateDokument1 SeiteDesign of Cold-Formed Purlins: Section AdequateAndro RebuyasNoch keine Bewertungen

- Design of Combined-Footing: Input DataDokument7 SeitenDesign of Combined-Footing: Input DataUzziel Abib GabiolaNoch keine Bewertungen

- RC Beam Onewayslab DesignDokument10 SeitenRC Beam Onewayslab Designmegget100% (1)

- Slab Design-ExcelDokument2 SeitenSlab Design-ExceltechnopreneurvizagNoch keine Bewertungen

- My - Spreadsheet - SlabDokument26 SeitenMy - Spreadsheet - SlabBilal Ahmed Barbhuiya50% (2)

- Beam of Span37.75Dokument203 SeitenBeam of Span37.75Ferdie TolosaNoch keine Bewertungen

- Two Way Slab DesignDokument2 SeitenTwo Way Slab DesignRoda CadizNoch keine Bewertungen

- Raft Footing DesignDokument7 SeitenRaft Footing DesignPrakash ShresthaNoch keine Bewertungen

- Design of STRIP FoundationDokument21 SeitenDesign of STRIP FoundationPremasiri Karunarathna100% (5)

- Design of Rectangular Short Column: (Column Behaves As Long Column)Dokument3 SeitenDesign of Rectangular Short Column: (Column Behaves As Long Column)Umer Aleem50% (2)

- Slab DesignDokument6 SeitenSlab DesignJonasIrvinGallegoNoch keine Bewertungen

- Design of Two Way Slab S3: MM C/C, MM C/C (Extra) MM C/CDokument6 SeitenDesign of Two Way Slab S3: MM C/C, MM C/C (Extra) MM C/CMuhammad Azeem KhanNoch keine Bewertungen

- Project Flat SlabDokument4 SeitenProject Flat SlabRahul Harsha ThatiNoch keine Bewertungen

- Made Date Sheet AR 17-Jul-11 1 Check Date Rev. MKI 17-Jul-11 0 PROJECT TITLE: Minhal Crowne Plaza Location: RiyadhDokument6 SeitenMade Date Sheet AR 17-Jul-11 1 Check Date Rev. MKI 17-Jul-11 0 PROJECT TITLE: Minhal Crowne Plaza Location: Riyadhsidiq7Noch keine Bewertungen

- Isolated Footing DesignDokument14 SeitenIsolated Footing DesignDhandapany ArunNoch keine Bewertungen

- Design of Eccentric Footing - F5Dokument3 SeitenDesign of Eccentric Footing - F5Nikita MeshramNoch keine Bewertungen

- One Way Slab ProgramDokument140 SeitenOne Way Slab ProgramRachelle CapulNoch keine Bewertungen

- RCC Doubly Reinforced Beam by Is 456: 2000 (LSM)Dokument26 SeitenRCC Doubly Reinforced Beam by Is 456: 2000 (LSM)mafiapumba67% (3)

- All Type of Footing DesignDokument23 SeitenAll Type of Footing DesignAyazAkram100% (6)

- Eccentric FootingDokument16 SeitenEccentric Footingersivaraj50% (2)

- Column Design Subjected To Axial and BendingDokument4 SeitenColumn Design Subjected To Axial and BendingArnel Dodong0% (1)

- Column Design 300x300Dokument7 SeitenColumn Design 300x3001234 1234Noch keine Bewertungen

- Strap Footing DesignDokument19 SeitenStrap Footing DesignMainali Ishu100% (1)

- Beam Design For Moment, Shear & TorsionDokument6 SeitenBeam Design For Moment, Shear & TorsionRajendra BadjatyaNoch keine Bewertungen

- Design of Beams Columns Base PlateDokument67 SeitenDesign of Beams Columns Base PlateRommel Dave TejanoNoch keine Bewertungen

- Design of Slab (Two Way)Dokument9 SeitenDesign of Slab (Two Way)shivshankar kushwahaNoch keine Bewertungen

- One Way Slab DesignDokument4 SeitenOne Way Slab DesignMario FeghaliNoch keine Bewertungen

- Two-Way Slab Design Based On ACI 318-19 Using Finite Element Method Input Data & Design SummaryDokument4 SeitenTwo-Way Slab Design Based On ACI 318-19 Using Finite Element Method Input Data & Design SummaryChrispin BarnigoNoch keine Bewertungen

- Design of Beams & Slab (ACI 318-14)Dokument354 SeitenDesign of Beams & Slab (ACI 318-14)emonwre100% (1)

- 7 Slab Design 1503Dokument32 Seiten7 Slab Design 1503Er Mohd NoshadNoch keine Bewertungen

- Design of Rectangular Footing Col at Edge - 3Dokument27 SeitenDesign of Rectangular Footing Col at Edge - 3Glenn SarneNoch keine Bewertungen

- One Way Slab - ACIDokument1 SeiteOne Way Slab - ACIsharanekkmNoch keine Bewertungen

- 1.0 Beam DesignDokument8 Seiten1.0 Beam Designklynchelle100% (1)

- Deep Beam TypicalDokument6 SeitenDeep Beam TypicalArpit SinghNoch keine Bewertungen

- Beam Ledge DesignDokument2 SeitenBeam Ledge Designauatipu100% (1)

- MOMENT EndplateDokument8 SeitenMOMENT Endplatemoseslugtu6324Noch keine Bewertungen

- Composite Steel GirderDokument10 SeitenComposite Steel GirdersorowareNoch keine Bewertungen

- RC BeamDokument77 SeitenRC BeamJvv GudboyNoch keine Bewertungen

- 14.0 Slab ExtractorDokument13 Seiten14.0 Slab ExtractorklynchelleNoch keine Bewertungen

- Bridge Design Section OrganizationDokument10 SeitenBridge Design Section OrganizationniloshaNoch keine Bewertungen

- Beam Forces ExtractorDokument344 SeitenBeam Forces ExtractorklynchelleNoch keine Bewertungen

- 17.0 Wall TensionDokument39 Seiten17.0 Wall TensionklynchelleNoch keine Bewertungen

- Bolt Group and Bolt Stress Analysis Per AISC 9th Edition (ASD)Dokument18 SeitenBolt Group and Bolt Stress Analysis Per AISC 9th Edition (ASD)cengizNoch keine Bewertungen

- Beam Mark Span Beam Section (MM) Top Width (B) Depth (H) M3i M3m M3jDokument11 SeitenBeam Mark Span Beam Section (MM) Top Width (B) Depth (H) M3i M3m M3jFranklyn P. GenoveNoch keine Bewertungen

- 25m Single Lane Bridge Design Calculations LatestDokument30 Seiten25m Single Lane Bridge Design Calculations LatestklynchelleNoch keine Bewertungen

- 1.0 Early Thermal CheckDokument7 Seiten1.0 Early Thermal CheckklynchelleNoch keine Bewertungen

- 3.1a - Reliability & RedundancyDokument6 Seiten3.1a - Reliability & RedundancyklynchelleNoch keine Bewertungen

- Concrete Pour Record - 030: Al Shahad Tower February 17, 2016 C40/20 Retaining Wall at Basement 5Dokument3 SeitenConcrete Pour Record - 030: Al Shahad Tower February 17, 2016 C40/20 Retaining Wall at Basement 5klynchelleNoch keine Bewertungen

- Project MonitoringDokument9 SeitenProject MonitoringklynchelleNoch keine Bewertungen

- Wall Extractor Final v00Dokument3.719 SeitenWall Extractor Final v00klynchelleNoch keine Bewertungen

- Concrete Compressive StrengthDokument4 SeitenConcrete Compressive StrengthklynchelleNoch keine Bewertungen

- Concrete Pour Record - 030: Al Shahad Tower February 17, 2016 C40/20 Retaining Wall at Basement 5Dokument3 SeitenConcrete Pour Record - 030: Al Shahad Tower February 17, 2016 C40/20 Retaining Wall at Basement 5klynchelleNoch keine Bewertungen

- Capping BeamDokument2 SeitenCapping BeamFranklyn P. Genove100% (1)

- Shear Links Design - ColDokument17 SeitenShear Links Design - ColklynchelleNoch keine Bewertungen

- 2.0 CriticalSteelRatio ISO2394 C40 50Dokument4 Seiten2.0 CriticalSteelRatio ISO2394 C40 50klynchelle100% (1)

- 1.0 LTD Check CalcsDokument9 Seiten1.0 LTD Check CalcsklynchelleNoch keine Bewertungen

- 1.0 Purlins DesignDokument10 Seiten1.0 Purlins Designklynchelle100% (1)

- 11.0design of Corbel-FINALDokument8 Seiten11.0design of Corbel-FINALklynchelleNoch keine Bewertungen

- 1.0 LTD Check CalcsDokument9 Seiten1.0 LTD Check CalcsklynchelleNoch keine Bewertungen

- 1.0 Early Thermal CheckDokument7 Seiten1.0 Early Thermal CheckklynchelleNoch keine Bewertungen

- 2.0 CriticalSteelRatio ISO2394 C40 50Dokument4 Seiten2.0 CriticalSteelRatio ISO2394 C40 50klynchelle100% (1)

- Shear Links Design - ColDokument17 SeitenShear Links Design - ColklynchelleNoch keine Bewertungen

- 10.0design of Baseplate and Anchor BoltsDokument7 Seiten10.0design of Baseplate and Anchor BoltsklynchelleNoch keine Bewertungen

- Long Term Deflection DesignDokument1 SeiteLong Term Deflection DesignklynchelleNoch keine Bewertungen

- My Spreadsheet Combined FootingDokument20 SeitenMy Spreadsheet Combined Footingklynchelle100% (4)

- 9.0punching Shear Check (Aci) VerifiedDokument19 Seiten9.0punching Shear Check (Aci) Verifiedklynchelle100% (1)

- Feng, Tiequn - 2019 - 3C - 01Dokument15 SeitenFeng, Tiequn - 2019 - 3C - 01jeferson menacho casoNoch keine Bewertungen

- Red Presentation // Black Explanation Plumbing and Sanitary SystemsDokument58 SeitenRed Presentation // Black Explanation Plumbing and Sanitary SystemsdaisyNoch keine Bewertungen

- Numerical Analysis of Inclined Uplift Ca PDFDokument11 SeitenNumerical Analysis of Inclined Uplift Ca PDFRayodcNoch keine Bewertungen

- BS 8000 Part 10Dokument24 SeitenBS 8000 Part 10TZeLOon100% (2)

- CE-1 Civil Engineering OrientationDokument18 SeitenCE-1 Civil Engineering OrientationLeandro DichosoNoch keine Bewertungen

- Bridge Design GuideDokument44 SeitenBridge Design GuideMohanraj Venu100% (3)

- TRH14 (1985) Guidelines For Road Construction MaterialsDokument69 SeitenTRH14 (1985) Guidelines For Road Construction MaterialsTensarAfrica60% (5)

- 2 15P09 PDFDokument88 Seiten2 15P09 PDFMike2322Noch keine Bewertungen

- Subsalt Challenge SLBDokument14 SeitenSubsalt Challenge SLBMOHAMED ALi IBRAHIM HASSANNoch keine Bewertungen

- Alpha Terminal Pvt. LTD.: Geotechnical Investigation Report (GTI)Dokument38 SeitenAlpha Terminal Pvt. LTD.: Geotechnical Investigation Report (GTI)Avinash MaratheNoch keine Bewertungen

- Lecture 4 - Strain Transformation and Mohr Circle For StrainDokument21 SeitenLecture 4 - Strain Transformation and Mohr Circle For StrainFaran AssifNoch keine Bewertungen

- Self Closing Flood BarrierDokument2 SeitenSelf Closing Flood BarrierMugiwara SparrowNoch keine Bewertungen

- Placenta PitDokument1 SeitePlacenta PitcimpstazNoch keine Bewertungen

- GREEN BUILDING: Framing & Insulation Design DetailDokument4 SeitenGREEN BUILDING: Framing & Insulation Design DetailHarris WoodwardNoch keine Bewertungen

- Upvc PipesDokument36 SeitenUpvc PipesMuneer mahammadNoch keine Bewertungen

- Wellhead and Its ComponentsDokument3 SeitenWellhead and Its ComponentsKodali Naveen KumarNoch keine Bewertungen

- Assignment - Tension MembersDokument3 SeitenAssignment - Tension MembersUlasi IfeanyiNoch keine Bewertungen

- Air Cycle System "Pascalair" For Ultra Low Temperature Cold StorageDokument1 SeiteAir Cycle System "Pascalair" For Ultra Low Temperature Cold StorageMaximoNoch keine Bewertungen

- Design of Return WallDokument3 SeitenDesign of Return WallAshish GNoch keine Bewertungen

- Piezometers in Fully Grouted BoreholesDokument10 SeitenPiezometers in Fully Grouted BoreholesJohan Van StaverenNoch keine Bewertungen

- 12,000sqm of Reinforced Earth Concrete Retaining Walls Supplied To Inner City Bypass Project - BrisbaneDokument15 Seiten12,000sqm of Reinforced Earth Concrete Retaining Walls Supplied To Inner City Bypass Project - Brisbanemehdi_hoseineeNoch keine Bewertungen

- Geotechnical FormulasDokument15 SeitenGeotechnical FormulasDavid King100% (1)

- Investigation For Liquefaction SusceptibilityDokument41 SeitenInvestigation For Liquefaction SusceptibilityMark Armand SegundinoNoch keine Bewertungen

- ESP For SSF-O-R-01Dokument11 SeitenESP For SSF-O-R-01Abdulvasea SaaitNoch keine Bewertungen

- Post Tension Flat SlabsDokument14 SeitenPost Tension Flat Slabsrahulgehlot2008Noch keine Bewertungen

- Analysis and Design of Cantilever Slab Analysis and Design of Cantilever SlabDokument3 SeitenAnalysis and Design of Cantilever Slab Analysis and Design of Cantilever SlabMesfinNoch keine Bewertungen

- Mix Desgn. M-10, M-15 (VRL-TLL RD (Digvijay) )Dokument1 SeiteMix Desgn. M-10, M-15 (VRL-TLL RD (Digvijay) )Mihir GhadiaNoch keine Bewertungen

- Thrust Block CalculationsDokument5 SeitenThrust Block Calculationslouis etienneNoch keine Bewertungen

- Beach Protector HotelsDokument15 SeitenBeach Protector Hotelsgabriela de albaNoch keine Bewertungen

- Shearing Stress of Beams: For Hinged-Ended ColumnsDokument4 SeitenShearing Stress of Beams: For Hinged-Ended ColumnsAbegail A Maga100% (2)