Beruflich Dokumente

Kultur Dokumente

2A-Fatigue of FLNG Hulls-LR

Hochgeladen von

Geoff HunterCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

2A-Fatigue of FLNG Hulls-LR

Hochgeladen von

Geoff HunterCopyright:

Verfügbare Formate

FLNG Hull Structures

Farshid Fardi

Principal Naval Architect

Working together

for a safer world

LLOYDS REGISTER Who are we?

Worlds first Class Society established in 1760

186 countries covered with almost 250 offices

and over 9000 employees

We provide independent assurance to companies

operating high-risk, capital-intensive assets in the

energy and transportation sectors

Four business streams: Marine, Energy,

Management Systems & Transportation

The Edward Lloyds coffee house

Our mission is to protect life and property

and advance transportation and engineering education and research

FLNG Hull Structures

LLOYDS REGISTER Who are we?

FLNG Hull Structures

Assigned class to the worlds first FPSO: Shell Castellon

Assigned class to the worlds largest FLNG: Shell Prelude

LR is financially and technically independent of any government or

commercial interests and has been so since the foundation

Overseen by a general committee of industry representatives

INTRODUCTION

FLNG Hull Structures

Typical structural arrangement of a ship-shaped unit

Plated steel stiffened panels

Stiffener spacing of 800 900 mm

Transverse frames every 4 - 5 m

Transverse bulkheads every 30 - 40 m

Full length longitudinal bulkheads

FLNG Hull Structures

FLNG HULL STRUCTURE COMPARED TO TANKER

FLNG Hull Structures

FLNG hull structure compared to tanker

The majority of FLNGs are ship shaped units:

Design of ship type FLNGs therefore should follow these rules?

Typical tanker

FLNG Hull Structures

FLNG hull structure compared to tanker

Most visible differences

The need to accommodate structures and equipment on deck imposes significant static and dynamic

loads not present in a trading tanker.

Typical topside structures:

Process equipment;

Cranes;

Flares;

Helicopter decks;

Accommodation spaces;

Etc.

FLNG Hull Structures

FLNG hull structure compared to tanker

Less visible differences

Permanent mooring system

Riser connections to sea-bed

Designed to site specific environment

Requirement to stay on location

More complex legislation

Etc.

FLNG Hull Structures

FLNG hull structure compared to tanker

Site-specific environment

Trading tanker rules (CSR) are based on North Atlantic values.

FLNGs need to be designed for site specific environment (wind, waves, current, air temperature).

FLNG Hull Structures

FLNG hull structure compared to tanker

Site-specific environment

Steel weight

Over designed

(expensive)

FLNG - Efficient design

Tanker design (CSR)

Under designed

(risk of structural failure)

Benign

Moderate

Harsh

Environmental loads

FLNG Hull Structures

FLNG hull structure compared to tanker

Other relevant differentiating features

The statistics and nature of the loads on the

unit:

different load return periods considered;

different heading statistics.

The requirement to stay on location in all

the weather conditions:

driven by economics / gas production;

consideration needs to be given to in water

surveys and on site repairs.

FLNG Hull Structures

FLNG hull structure compared to tanker

Typical environmental criteria

Location

Hs (metres)

Nigeria

4.0

Australia (non-cyclonic) 6.0 - 7.0

Australia (cyclonic)

10.0 -14.0

Brazil

7.0

U.K. Central

13.0

Gulf of Mexico

14.5

Nova Scotia

16.0

West of Shetland

17.0

Data relates to the 100 year storm

Gulf of Mexico includes hurricane waves.

FLNG Hull Structures

FLNG hull structure compared to tanker

Mooring arrangement

FLNG Hull Structures

FLNG hull structure compared to tanker

Heading probability

CSR considers an Omni-directional wave environment

Each wave heading relative to the ship has an equal probability

of occurrence.

FLNGs do not operate in an Omni-directional wave

environment:

Weathervaning units predominately see waves

between head sea and beam seas.

Spread-moored units predominately see waves from

one or two quadrants.

FLNG Hull Structures

FLNG hull structure compared to tanker

Site-specific heading analysis

The MetOcean reports provide the input environmental data for the heading

analysis;

The mean vessel heading is determined for each sea state;

The long-term heading probability distribution is used to determine extreme loads.

FLNG Hull Structures

FLNG hull structure compared to tanker

Vessel Heading Analysis Results

Rel. Heading (deg.)

Vessel Relative Heading to Wind Sea

180

150

120

90

60

30

0

-30

-60

-90

-120

-150

-180

0

Wind Sea Hs (m)

FLNG Hull Structures

10

11

12

13

14

FPSO hull structure compared to tanker

Vessel Heading Analysis Results

Relative Heading (deg.)

Vessel Relative Heading to Swell

180

150

120

90

60

30

0

-30

-60

-90

-120

-150

-180

4

Swell Hs (m)

FLNG Hull Structures

FLNG hull structure compared to tanker

FLNG Extreme Response Analysis

Metocean data

Hydrodynamic database (RAOs)

Relative Vessel Heading to swell

Short Term

Motion Responses per sea-state

Relative Vessel

Heading to wind sea

Long Term Response

FLNG Hull Structures

FLNG hull structure compared to tanker

Change of Fatigue Damage due to WeatherVaning:

FLNG Hull Structures

FLNG hull structure compared to tanker

Some factors affecting the hull structural arrangement:

cargo type: oil or LNG;

production/offloading rate and required storage capacity;

single or double bottom;

stability aspects;

collision loads;

Internal fluid motions (sloshing)

loads from on-deck structure / equipment (topsides);

access for inspection maintenance;

mooring arrangement:

Internal or external turret

Spread mooring

etc.

FLNG Hull Structures

FPSO hull structure compared to tanker

Lloyds Register Rules

Based on IACS CSR (delivering the full benefit of the latest tanker

technology) the ROU Rules address the differences between FPSO/

FLNGs and Tankers:

Transparent methods based on sound engineering principles;

Flexible to suit field development requirements (owner defined

corrosion margins, load cases, etc.);

ROU Rules address all types of offshore structures (Semisubmersibles, TLP, Barges, Buoys, etc.).

Not only structural issues also Moorings / Electrical / Machinery /

Safety systems.

FLNG Hull Structures

FPSO hull structure compared to tanker

Lloyds Register Rules Structural arrangements

OIL FPSO Hulls

LNG FPSO Hulls

FLNG Hull Structures

EXAMPLES OF FLNGs

FLNG Hull Structures

Examples of different FPSOs

Shell FLNG (LNG FPSO)

Western Australia (Cyclonic)

New build hull

Largest floating unit ever built

Lbp = 488 m, B = 74 m, > 600,000 tons

Turret moored

LNG stored at -163 C

FLNG Hull Structures

GLOBAL HULL LOADING

FLNG Hull Structures

Global hull loading

When vessel loading goes wrong

FLNG Hull Structures

Global hull loading

Global shear

Global bending

Loads comprise: still water loads + wave loads;

Must be evaluated at every point along vessel;

Must remain below capacity of hull structure;

Operation On-site, Maintenance, Transit/Disconnected and Flooded conditions to be

considered.

FLNG Hull Structures

Global hull loading

Still water global loads

Still water global loads comprise:

Cargo loads;

Empty hull weight;

Buoyancy loads.

Still water loads of FLNG to consider:

Maintenance conditions;

All cargo arrangements;

Inspection conditions;

Weight of turret / mooring / risers etc.

FLNG Hull Structures

Global hull loading

Global wave loads on FLNG hull

Wave loads are:

site specific (require detailed knowledge of wave environment);

complex to evaluate (compared to loads on ships).

FLNG Hull Structures

Global hull loading

Global hull design

Global bending loads determine (mostly)

longitudinal material in deck and bottom;

Global shear loads determine (mostly)

material in vertical longitudinal bulkheads;

Vertical longitudinal bulkheads ideally to be

continuous through vessel length to avoid

problems with shear loads.

FLNG Hull Structures

OTHER LOADS AND MODEL TESTS

FLNG Hull Structures

Other loads and model tests

External wave pressure

FLNG Hull Structures

Other loads and model tests

Inertia loads

Harsh location typical values of acceleration

transverse: 0.5g

vertical: 0.5g

longitudinal: 0.2g

FLNG Hull Structures

Other loads and model tests

Why model tests?

Highlight unusual or unpredictable phenomena;

Prediction of green sea, slamming loads and other

loads not readily calculated from analyses;

Verification of mooring system analysis;

Verification of roll damping values;

Wind tunnel testing for wind/current coefficients;

Sloshing model testing (particularly LNG membrane

tanks).

It is strongly recommended that the testing is

considered following and in conjunction with the

analyses.

FLNG Hull Structures

Response to waves: 1

FLNG Hull Structures

Wave impact event

Response to waves: 2

FLNG Hull Structures

Response to waves: 3

FLNG Hull Structures

Response to waves: 4

FLNG Hull Structures

Green water event

Wave impact loads both on-site and in transit

FLNG Hull Structures

Other loads and model tests

Sloshing

Sloshing is the dynamic magnification of pressures within cargo/ballast tanks.

Partial fillings the norm for FLNGs (NOT so for trading LNG tankers)

Influencing Factors:

Tank size

Hull form

Environment / Weathervaning

Natural periods of both vessel and fluid

Tank fill levels

FLNG Hull Structures

Other loads and model tests

Ice Loading

Additional weight on deck and significant loads at waterline;

Terra Nova FPSO designed for 1.5 m thick sea ice and 2000 tonnes weight on deck.

FLNG Hull Structures

Other loads and model tests

Other loads and accidental loads

Collision due to supply vessel / shuttle tanker /

iceberg;

Dropped object;

Explosion / blast;

Largest wave in 10,000 years;

Emergency helicopter landings;

Etc.

FLNG Hull Structures

HULL STRENGTH ASSESSMENT

FLNG Hull Structures

FATIGUE ASSESSMENT

FLNG Hull Structures

Fatigue assessment - Introduction

Due to cyclical loads (not a strength issue)

Influenced by:

size, shape and design of the component/connection;

condition of the surface or operating environment;

The output of a fatigue analysis is life (in years).

FLNG Hull Structures

Fatigue assessment - Issues

No obvious warning:

a crack forms without appreciable deformation of

structure making it difficult to detect the presence of

growing cracks.

Fractures usually start from weld connections due to a

localised concentration of stress (SCF).

Attention must be given to:

Structural detailing;

Fabrication and construction tolerances;

Corrosion protection and coatings;

Inspection regime and inspectability.

FLNG Hull Structures

Fatigue assessment - Typical fatigue prone locations within hull

FLNG Hull Structures

Fatigue assessment - other fatigue prone locations

Mooring integration structure;

Topsides support and integration structure:

Flare tower support structure;

Crane pedestals and support structure;

Helideck structure.

Any other key structure which experiences high

dynamic loads

FLNG Hull Structures

Fatigue assessment

Fatigue life assessment:

Identification of critical areas;

Detailed finite element analysis of critical areas;

Site specific analysis (+ previous service).

FLNG Hull Structures

Fatigue assessment - typical safety factors

Inspectable /

Repairable

Consequence of Failure

Non substantial*

Substantial*

Yes, dry

Yes, wet

No

10

*Substantial consequences of failure are defined as loss of life, uncontrolled outflow of hazardous

products, collision or sinking and should include for progressive failure scenarios.

FLNG Hull Structures

CORROSION

FLNG Hull Structures

Last but not least: corrosion

FLNG Hull Structures

General advice for FLNG structural design

FLNG Hull Structures

Farshid Fardi Principal Naval Architect

Contact for more Info: Farshid.Fardi@lr.org

Working together

for a safer world

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- 10 Essential Books For Active TradersDokument6 Seiten10 Essential Books For Active TradersChrisTheodorou100% (2)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Vocations The New Midheaven Extension ProcessDokument266 SeitenVocations The New Midheaven Extension ProcessMiss M.100% (24)

- Project Manager PMP PMO in Houston TX Resume Nicolaas JanssenDokument4 SeitenProject Manager PMP PMO in Houston TX Resume Nicolaas JanssenNicolaasJanssenNoch keine Bewertungen

- Brunei MCHE Replacement 2005 IPTC-10676-MS-P PDFDokument3 SeitenBrunei MCHE Replacement 2005 IPTC-10676-MS-P PDFGeoff HunterNoch keine Bewertungen

- Internet Bill FormatDokument1 SeiteInternet Bill FormatGopal Singh100% (1)

- Christena Nippert-Eng - Watching Closely - A Guide To Ethnographic Observation-Oxford University Press (2015)Dokument293 SeitenChristena Nippert-Eng - Watching Closely - A Guide To Ethnographic Observation-Oxford University Press (2015)Emiliano CalabazaNoch keine Bewertungen

- Adime 2Dokument10 SeitenAdime 2api-307103979Noch keine Bewertungen

- Villamaria JR Vs CADokument2 SeitenVillamaria JR Vs CAClarissa SawaliNoch keine Bewertungen

- DLNG Ops Environmental MGMT PlanDokument105 SeitenDLNG Ops Environmental MGMT PlanGeoff Hunter100% (1)

- Indonesia CNG Ship Gresik To Lombok Bima Putrajaya PT Pelayaran 1015Dokument35 SeitenIndonesia CNG Ship Gresik To Lombok Bima Putrajaya PT Pelayaran 1015Geoff HunterNoch keine Bewertungen

- Pricing of A Revolutionary ProductDokument22 SeitenPricing of A Revolutionary ProductiluvparixitNoch keine Bewertungen

- A1188 - R0962 - PER - Volume 1Dokument193 SeitenA1188 - R0962 - PER - Volume 1Geoff HunterNoch keine Bewertungen

- Communidad GNLM Small Scale LNG: 11 November 2015Dokument30 SeitenCommunidad GNLM Small Scale LNG: 11 November 2015Geoff HunterNoch keine Bewertungen

- Osprey Fortress 052 The Fortifications of Gibraltar PDFDokument68 SeitenOsprey Fortress 052 The Fortifications of Gibraltar PDFGeoff Hunter100% (3)

- 74 1009 1.0 Fire Gas Detection For LNG White PaperDokument6 Seiten74 1009 1.0 Fire Gas Detection For LNG White PaperGeoff HunterNoch keine Bewertungen

- Mode of Action of Vancomycin: L D D D D DDokument8 SeitenMode of Action of Vancomycin: L D D D D DNolanNoch keine Bewertungen

- Power Control 3G CDMADokument18 SeitenPower Control 3G CDMAmanproxNoch keine Bewertungen

- Course Projects PDFDokument1 SeiteCourse Projects PDFsanjog kshetriNoch keine Bewertungen

- Applied Physics (PHY-102) Course OutlineDokument3 SeitenApplied Physics (PHY-102) Course OutlineMuhammad RafayNoch keine Bewertungen

- Linear Dynamic Analysis of Free-Piston Stirling Engines OnDokument21 SeitenLinear Dynamic Analysis of Free-Piston Stirling Engines OnCh Sameer AhmedNoch keine Bewertungen

- Engine Controls (Powertrain Management) - ALLDATA RepairDokument3 SeitenEngine Controls (Powertrain Management) - ALLDATA RepairRonald FerminNoch keine Bewertungen

- Avid Final ProjectDokument2 SeitenAvid Final Projectapi-286463817Noch keine Bewertungen

- Le Chatelier's Principle Virtual LabDokument8 SeitenLe Chatelier's Principle Virtual Lab2018dgscmtNoch keine Bewertungen

- Packet Unit 3 - Atomic Structure-Answers ChemistryDokument11 SeitenPacket Unit 3 - Atomic Structure-Answers ChemistryMario J. KafatiNoch keine Bewertungen

- Mitsubishi FanDokument2 SeitenMitsubishi FanKyaw ZawNoch keine Bewertungen

- Lect.1-Investments Background & IssuesDokument44 SeitenLect.1-Investments Background & IssuesAbu BakarNoch keine Bewertungen

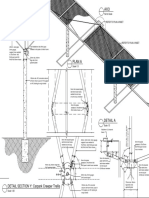

- ARC-232, Material Construction 2Dokument4 SeitenARC-232, Material Construction 2danishali1090Noch keine Bewertungen

- LS01 ServiceDokument53 SeitenLS01 ServicehutandreiNoch keine Bewertungen

- Estate TaxDokument10 SeitenEstate TaxCharrie Grace PabloNoch keine Bewertungen

- Cad Data Exchange StandardsDokument16 SeitenCad Data Exchange StandardskannanvikneshNoch keine Bewertungen

- Internal Analysis: Pertemuan KeDokument15 SeitenInternal Analysis: Pertemuan Kekintan utamiNoch keine Bewertungen

- A SURVEY OF ENVIRONMENTAL REQUIREMENTS FOR THE MIDGE (Diptera: Tendipedidae)Dokument15 SeitenA SURVEY OF ENVIRONMENTAL REQUIREMENTS FOR THE MIDGE (Diptera: Tendipedidae)Batuhan ElçinNoch keine Bewertungen

- TrellisDokument1 SeiteTrellisCayenne LightenNoch keine Bewertungen

- Standard nfx15-211Dokument2 SeitenStandard nfx15-211Luis Enrique Cóndor PorrasNoch keine Bewertungen

- III.A.1. University of Hawaii at Manoa Cancer Center Report and Business PlanDokument35 SeitenIII.A.1. University of Hawaii at Manoa Cancer Center Report and Business Planurindo mars29Noch keine Bewertungen

- Research Paper On Air QualityDokument4 SeitenResearch Paper On Air Qualityluwahudujos3100% (1)

- Adverbs of Manner and DegreeDokument1 SeiteAdverbs of Manner and Degreeslavica_volkan100% (1)