Beruflich Dokumente

Kultur Dokumente

999 Engine Fault

Hochgeladen von

Mohamed RashedCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

999 Engine Fault

Hochgeladen von

Mohamed RashedCopyright:

Verfügbare Formate

999 OPERATORS MANUAL

OPERATING CONTROLS AND PROCEDURES

alert will come on and CONFIRM MODE will appear on

display if operation is attempted).

CAUTION

4.

Mast Assist Damage!

Prevent damage to mast assist arms and cylinders during

cold weather:

Do not attempt to lower mast with boom hoist until

temperature of hydraulic oil is 60F (16C).

Once oil is at specified temperature, fully extend and

retract mast assist cylinders twice to fill cylinders with

warm oil.

5.

Cylinders and arms will bend under weight of mast if this

precaution is not taken.

Machinery Damage!

Continuous operation with hydraulic oil temperature

above 180F (82C) can result in damage to hydraulic

components. Troubleshoot hydraulic system if oil

temperature exceeds 180F (82C).

Offboard Diagnostics requires special hardware/

software from engine manufacturer.

Onboard Diagnostics has warning lights to alert the

operator to engine problems during operation (engine

running) and fault codes to identify specific engine

problems.

STOP engine.

2.

Move engine ignition switch to RUN position.

3.

On cranes with Cummins engine:

Move hand throttle from low speed to high speed

and back to low speed three times within five

seconds.

If no active faults exist, the engine yellow and red

diagnostic lights come on but dont flash.

If there is an active fault the yellow diagnostic light

flashes to indicate that a fault code is about to be

flashed.

After a two second pause the red diagnostic light

flashes the fault code (Figure 3-13).

The engine yellow and red diagnostic lights come

on for five seconds and turn off.

If there is an active fault, the diagnostic lights come

on again and flash the fault codes (Figure 3-13).

The diagnostic lights turn off for five seconds and

come on again to repeat all active fault codes until

the problem is repaired.

See laminated fault codes in operators cab or refer to

engine manufacturers manual.

319

FIGURE 3-13

Boom Hoist Operation

CAUTION

Rigging Damage!

Avoid damage to boom rigging. Check that boom hoist

wire is reeved through all sheaves and spooled properly

onto boom hoist drum before raising boom from ground.

See Boom Rigging Drawing in Section 4 for wire rope

and reeving specifications.

See Wire Rope Installation in Section 4 for

instructions on attaching wire rope to boom hoist

drum.

To identify active faults, proceed as follows:

1.

Fault Code =

The Cummins QSM11 Engine is standard and the Caterpillar

3176C engine is optional. Both engines have two diagnostic

modes:

On cranes with Caterpillar engine:

3 Flashes PAUSE 1 Flash PAUSE 9 Flashes

CAUTION

Engine Diagnostics

After a two second pause the same fault code

flashes a second time before advancing to next fault

code.

1.

Select and confirm desired mode (STANDARD, CLAM,

DRAG).

2.

Turn off boom hoist park.

CAUTION

Boom or Luffing Damage!

Do not turn on boom hoist park while raising or lowering

boom; brake will bring boom to an abrupt stop. This action

could cause shock load damage to boom and luffing jib.

Bring boom to a smooth stop with boom hoist handle and

then turn on boom hoist park.

3.

Increase engine speed to desired rpm with hand throttle.

Depress foot throttle to momentarily increase engine

speed when more power is required.

3-25

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- DRIVE ELECTRONIC (45157812 - ) : Catalogue ID: 82562Dokument2 SeitenDRIVE ELECTRONIC (45157812 - ) : Catalogue ID: 82562Mohamed RashedNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- New Text Document1Dokument1 SeiteNew Text Document1Mohamed RashedNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Diagnosing LEDs and functions on MOKI cranesDokument6 SeitenDiagnosing LEDs and functions on MOKI cranesMohamed Rashed100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- ELECTRIC ABS (18900012 B) : Catalogue ID: 82562Dokument2 SeitenELECTRIC ABS (18900012 B) : Catalogue ID: 82562Mohamed RashedNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Alle V-Infos EnglischDokument43 SeitenAlle V-Infos EnglischMohamed Rashed50% (2)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Contents (Part 4) Foreword (Part 4) Notes For The Operator 1 Notes On SafetyDokument4 SeitenContents (Part 4) Foreword (Part 4) Notes For The Operator 1 Notes On SafetyMohamed Rashed100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Lincoln Auto Lube ManualDokument24 SeitenLincoln Auto Lube ManualAbraham Huaman CondeNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- CYLINDER (21811312 A) : Catalogue ID: 82562Dokument2 SeitenCYLINDER (21811312 A) : Catalogue ID: 82562Mohamed RashedNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Lidos Lwe Webservice: LTM 1160-2-111 Z68148 Z68148 571894208Dokument1 SeiteLidos Lwe Webservice: LTM 1160-2-111 Z68148 Z68148 571894208Mohamed RashedNoch keine Bewertungen

- Fpi 0000Dokument1 SeiteFpi 0000Mohamed RashedNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- 6 HLWH 3 DJHDokument2 Seiten6 HLWH 3 DJHMohamed RashedNoch keine Bewertungen

- PM Charts and Maintenance SchedulesDokument2 SeitenPM Charts and Maintenance SchedulesMohamed RashedNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Fpi 0013Dokument1 SeiteFpi 0013Mohamed RashedNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Safety notes for crane chassis workDokument1 SeiteSafety notes for crane chassis workMohamed RashedNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- 1Dokument1 Seite1Mohamed RashedNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- ET PetrojetDokument88 SeitenET PetrojetMohamed RashedNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- 2Dokument56 Seiten2Mohamed RashedNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- Emcp 4.1 & 4.2 1-16-14 PDFDokument280 SeitenEmcp 4.1 & 4.2 1-16-14 PDFAurelio Serrano93% (14)

- Service Manual: Cargo RangeDokument120 SeitenService Manual: Cargo RangeBubu BubuNoch keine Bewertungen

- 245 Esp Tr477927 - Traxx RF Service Manual Rev 10-14 WebDokument211 Seiten245 Esp Tr477927 - Traxx RF Service Manual Rev 10-14 WebMohamed RashedNoch keine Bewertungen

- IFLEX2 ISCOUT Grove RT TM Service Manual English 1Dokument64 SeitenIFLEX2 ISCOUT Grove RT TM Service Manual English 1Mohamed Rashed100% (1)

- Übergabeprotokoll English1Dokument1 SeiteÜbergabeprotokoll English1Mohamed RashedNoch keine Bewertungen

- Winrar Password by Nasser DZDokument1 SeiteWinrar Password by Nasser DZMohamed RashedNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Service Manual: Cargo RangeDokument120 SeitenService Manual: Cargo RangeBubu BubuNoch keine Bewertungen

- Propvalve e PDFDokument38 SeitenPropvalve e PDFMohamed Rashed100% (1)

- Service Manual: Overload Prevention DeviceDokument276 SeitenService Manual: Overload Prevention DeviceMohamed Rashed100% (8)

- Propvalve eDokument38 SeitenPropvalve eMohamed Rashed100% (1)

- TC Ac55 GB S-65440-45Dokument116 SeitenTC Ac55 GB S-65440-45Mohamed Rashed100% (1)

- SCC500D Hydraulic Crawler Crane PDFDokument86 SeitenSCC500D Hydraulic Crawler Crane PDFMohamed Rashed100% (2)

- Welcome To The World of TEREX Cranes: All Terrain Cranes Rough Terrain Cranes Telescopic Truck CranesDokument1 SeiteWelcome To The World of TEREX Cranes: All Terrain Cranes Rough Terrain Cranes Telescopic Truck CranesMohamed RashedNoch keine Bewertungen

- Parts List 09 636 02 02: AC Brake Motors BMG05-BMG1 Additional List: BrakeDokument2 SeitenParts List 09 636 02 02: AC Brake Motors BMG05-BMG1 Additional List: Brakeali morisyNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- VDP08 Technical CatalogueDokument47 SeitenVDP08 Technical CatalogueAdal VeraNoch keine Bewertungen

- Method StatementDokument2 SeitenMethod StatementKumar Jbs100% (1)

- Consolidation: By. Rajesh S.GujarDokument33 SeitenConsolidation: By. Rajesh S.Gujardarshan_dave17Noch keine Bewertungen

- Velp ZX3 Vortex PDFDokument5 SeitenVelp ZX3 Vortex PDFarodassanchez0% (1)

- 2014 Solder Joint ReliabilityDokument18 Seiten2014 Solder Joint ReliabilitychoprahariNoch keine Bewertungen

- LDX2101 Spec SheetDokument2 SeitenLDX2101 Spec SheetGaurav NarulaNoch keine Bewertungen

- 06 HVAC Plumbing PDFDokument727 Seiten06 HVAC Plumbing PDFTamNoch keine Bewertungen

- Dimensions of Physical Quantities DensityDokument100 SeitenDimensions of Physical Quantities DensityGerman Rincon UrregoNoch keine Bewertungen

- Determining The Redundancy FactorDokument6 SeitenDetermining The Redundancy FactorEdris Salehi GolsefidiNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Causes and Prevention of Crowd DisastersDokument10 SeitenThe Causes and Prevention of Crowd DisastersVarun SwaminathanNoch keine Bewertungen

- For Steel Cage Lapping by Using U-ClipDokument4 SeitenFor Steel Cage Lapping by Using U-Cliptin aungtunNoch keine Bewertungen

- Support Orca3D HelpDokument281 SeitenSupport Orca3D Helplavrik100% (1)

- Micron Ezeprox Access Control KeypadDokument4 SeitenMicron Ezeprox Access Control KeypadThuy VuNoch keine Bewertungen

- IEC CsODESDokument2 SeitenIEC CsODESArun KumarNoch keine Bewertungen

- Cyber Security Research Proposal - SandboxingDokument23 SeitenCyber Security Research Proposal - SandboxingAnonymous Sa6jc83D100% (4)

- Gps VulnerabilityDokument28 SeitenGps VulnerabilityaxyyNoch keine Bewertungen

- Kepb003404 PDFDokument472 SeitenKepb003404 PDFELIAS100% (1)

- Resume of MD Saiful HyderDokument4 SeitenResume of MD Saiful Hyderimtheboss*Noch keine Bewertungen

- False Ceiling Construction Details PDFDokument2 SeitenFalse Ceiling Construction Details PDFAlexis17% (6)

- 1855OME - Instruction Manual - Kinney Oil Mist EliminatorsDokument15 Seiten1855OME - Instruction Manual - Kinney Oil Mist EliminatorsahmedNoch keine Bewertungen

- ETN2A ElectromechanicsDokument64 SeitenETN2A ElectromechanicsEinstein's VanderbijlparkNoch keine Bewertungen

- Foxpro For O LevelDokument3 SeitenFoxpro For O LevelShiv PathakNoch keine Bewertungen

- Sodium Citrate AUDokument3 SeitenSodium Citrate AUKrishna OgotNoch keine Bewertungen

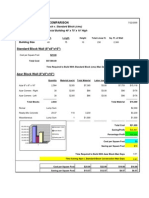

- AZAR Block CostcomparisonDokument8 SeitenAZAR Block CostcomparisontckittuNoch keine Bewertungen

- GaN technology powers bright LEDsDokument13 SeitenGaN technology powers bright LEDsluciowwNoch keine Bewertungen

- Sap MM LSMWDokument18 SeitenSap MM LSMWMani balan100% (1)

- Manual Servicio SubaruDokument5.963 SeitenManual Servicio SubaruCristian Mauricio Alarcon RojasNoch keine Bewertungen

- ApaveMare Training 2013Dokument41 SeitenApaveMare Training 2013fbarakaNoch keine Bewertungen

- Crochet Impkins: Over a million possible combinations! Yes, really!Von EverandCrochet Impkins: Over a million possible combinations! Yes, really!Bewertung: 4.5 von 5 Sternen4.5/5 (9)

- Sri Yantra with Golden Ratio Triangle and InscriptionsVon EverandSri Yantra with Golden Ratio Triangle and InscriptionsBewertung: 5 von 5 Sternen5/5 (1)

- The Martha Manual: How to Do (Almost) EverythingVon EverandThe Martha Manual: How to Do (Almost) EverythingBewertung: 4 von 5 Sternen4/5 (11)

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiVon Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiBewertung: 5 von 5 Sternen5/5 (2)

- Sew Bags: The Practical Guide to Making Purses, Totes, Clutches & More; 13 Skill-Building ProjectsVon EverandSew Bags: The Practical Guide to Making Purses, Totes, Clutches & More; 13 Skill-Building ProjectsBewertung: 5 von 5 Sternen5/5 (3)

- Knitting for Anarchists: The What, Why and How of KnittingVon EverandKnitting for Anarchists: The What, Why and How of KnittingBewertung: 4 von 5 Sternen4/5 (51)

- 100 Crochet Tiles: Charts and patterns for crochet motifs inspired by decorative tilesVon Everand100 Crochet Tiles: Charts and patterns for crochet motifs inspired by decorative tilesNoch keine Bewertungen

- A Life in Stitches: Knitting My Way Through Love, Loss, and Laughter - Tenth Anniversary EditionVon EverandA Life in Stitches: Knitting My Way Through Love, Loss, and Laughter - Tenth Anniversary EditionBewertung: 4.5 von 5 Sternen4.5/5 (23)

- Martha Stewart's Very Good Things: Clever Tips & Genius Ideas for an Easier, More Enjoyable LifeVon EverandMartha Stewart's Very Good Things: Clever Tips & Genius Ideas for an Easier, More Enjoyable LifeNoch keine Bewertungen