Beruflich Dokumente

Kultur Dokumente

Project Planning: Rolta Academy: EDA Technology Mumbai

Hochgeladen von

Rajesh BarkurOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Project Planning: Rolta Academy: EDA Technology Mumbai

Hochgeladen von

Rajesh BarkurCopyright:

Verfügbare Formate

Rolta Academy: EDA Technology Mumbai

CHAPTER 10

PROJECT PLANNING

10.1 Introduction

A project is something, which has start date and finish date with some task to

be performed with allotted resources and with financial implications.

Guidelines and suggestions are given here which outline the organization and

execution of an engineering project as it relates to instrumentation, ft lists

documents which are necessary for communication between owner and builder,

communication within the contractor organization during the engineering phase

and the necessary information for construction. Coordination requirements with

other groups are discussed, planning hints are given, and a checklist for project

control is suggested to ensure the successful completion of the project. The

principles outlined apply to projects whose capital investments range from a few

hundred thousand dollars to the largest of projects.

The viewpoint presented is most applicable to the person responsible for the

application, selection, purchasing and installation of instruments arid control

systems. The documentation necessary for a complete record of a project is

outlined. Even though the viewpoint is slanted toward the responsible project

instrument engineer, other owner and contractor personnel project managers,

process people and leaders of other disciplineswill profit by an understanding

of how the job is organized, developed and executed.

Many jobs appear complex until they are organized and broken down into

components or units easily understood and accomplished. This is certainly true

of instrument work.

Specific documents are required for the workfor installation and later for

maintenance Scheduling, purchasing, installation and calibration must be done.

The following paragraphs discuss what these functions are and how they are

carried out.

10.2 Documents To Be Produced

Most projects require the following engineering documents for a complete job.

When the job is small, some of the functions may be combined in the interest of

space, time and economy. On large jobs, additional documents may be needed.

Generally, however, requirements adhere quite closely to those mentioned below.

10.2.1 Process Flow Sheets

Piping

Rolta Academy: EDA Technology Mumbai

Process flow sheets consist of a pictorial representation of the major pieces of

equipment required with major lines of flow to and from each piece. Material

balances generally are shown. Additional information often given includes

operating conditions at various stages of the process (flows, pressures,

temperatures, viscosities, etc.), equipment size and configuration and, in some

cases, utility requirements. Instrumentation on process flow sheets may or may

not be essentially complete. In some instances, practically all of the

instrumentation is included; in others, only the major control systems are shown.

In most processes the primary control variables have been determined and

verified through laboratory and/or pilot-plant operations if the process is new. On

old processes, previous commercial operations have verified proper or improper

control techniques -The responsible instrument people may be consulted or may

offer suggestions to improve control. The extent of involvement depends primarily

on the experience backgrounds of the process and instrument people assigned

to the job

10.2.2 Mechanical Flow Sheets

Mechanical flow sheets or P&I (Process and Instrument) diagrams provide

much detailed, mechanical information not shown on process flow sheets, while

omitting much of the process information shown on the process flow sheets.

They repeat all the major equipment and piping lines as well as show:

All other equipment items with design temperatures and pressures

All interconnecting piping with size, material and fabrication specifications

indicated

Utility requirements including pipe sizes, materials and fabrication methods

All major instrument devices

In many situations, mechanical flow sheets show schematically every process

and utility line that appears on detailed drawings. They provide a valuable

reference for proper project installation. The instrument engineer uses it as a

source for many documents, which must be prepared.

Complete process and mechanical flow sheets are needed prior to the bulk of

the engineering effort on a job. Changes are often made as jobs progress,

however, particularly on mechanical flow sheets.

Piping

Rolta Academy: EDA Technology Mumbai

10.2.3 Instrument Index Sheets

The instrument index sheets provide a summary of all instruments required

for the job, listing each number-identified item of each loop . The list should be

made near the start of a job and used to check progress in specification writing,

purchasing, expediting, delivery and installation. As items are added, the list

increases; deletions should be lined out (not erased), thus serving as a record of

changes. Even though information is not complete, the list should be issued early

in the job so that project engineers and others concerned with the job may use it

to gauge the job requirements.

Instrument index sheets may serve strictly as an index of items required and

provide minimum information, or they may be expanded to provide a summary of

information about the loop itself, including service conditions of the line or vessel

with which it is associated.

10.2.4 Instrument Specification Sheets

To facilitate and speed up the specification and purchase of instrument items,

forms have been developed which list the main features available and desirable

in various categories of instruments. The Instrument Society of America has been

instrumental in this effort and has developed standard forms for 27 categories of

instrument items. A blank form is included in these standards which can be used

to hand-write specifications not already covered on the other 26 forms.

The ISA forms were revised in 1975 and republished in 1976 {reference

"Standard ISA-S20, Standards and Practices for Instrumentation, 5th Edition,

Instrument Society of America, 400 Stanwix Street, Pittsburgh, PA 15222). This

upgrading of content and format eliminated many of the deficiencies of earlier

forms, although the forms in their present state must still be modified to include

information such as electrical area classification and flow sheet numbers. Use of

the forms is encouraged by the ISA, and copies are available at nominal cost

through their headquarters. The forms may be modified (company headings, new

columns, etc.) and reproduced for internal use (not for commercial sale), so long

as permission is obtained from the ISA.

Specification sheets serve a fourfold purpose.

1. They contain information relating to the process and/or other instruments

which is necessary for complete systems engineering.

2. They provide the purchasing department and other interested people

information necessary for fulfilling their jobs efficientlya communications

channel.

3. They serve as permanent records for plant usefor installation, production

and maintenance groups.

Piping

Rolta Academy: EDA Technology Mumbai

4. They provide specifications to bidders, using a format familiar to both parties.

10.2.5 Loop Wiring Diagrams

Electronic loop wiring diagrams are electrical schematic drawings, which are

prepared for individual (or typical) electronic loops. The simplest loop is one that

contains only a transmitter and a receiver. Other loops may contain many items

transmitter, recorder, controller, alarm units, control valve, transducer,

integrator and perhaps other items.

The amount of documentation on the schematic varies. Some are relatively

simple, showing only the locations of the instruments, their identification numbers

and termination of the interconnecting wiring. Cable routing, wire size,

intermediate terminal points and other pertinent information are necessarily

shown on other drawings.

Other loop wiring diagrams are more comprehensive providing not only the

information previously described but also showing intermediate junction box

terminals properly identified, wire and cable information, complete terminal layout

of individual instruments and other useful information. Included may be the

transmitter range and calibration and pneumatic hookup information on the

transducer and the control valve.

Some loop diagrams are much more complex, especially if the loop contains

several components. Complete documentation, however, makes prestartup

checkout and maintenance much easier Since the loop information is well

documented, additional drawings are seldom needed for maintenance of the

instruments.

10.2.6 Panel Drawings and Specifications

Panel arrangement and layout philosophy are already determined and work

execution only is needed. Panel specifications and instrument specifications for

all panel instruments must be prepared.

Early in the job a decision should be made concerning the extent of

engineering to be done by the panel fabricator. This decision is based on four

primary factors.

1 Cost

2. Time

3. Available manpower

4. Capability

Piping

Rolta Academy: EDA Technology Mumbai

The factors are so interrelated that they need not be listed in a definite order

of importance. Fabrication cost is always important, but other factors such as

installation schedule, startup time, etc., can minimize initial fabrication cost.

Timing and cost, then, must be considered together.

If the timing or schedule is critical, panel fabrication may be started before

engineering is complete with a gain of several weeks in panel delivery. The

added cost of such an action may be small compared to the advantage of earlier

on-stream commitments or other factors.

Capability and availability of manpower are also closely related. In most

cases the buyer knows the panel fabricator well enough to judge his engineering

capabilities. The buyer also knows his own department's workload and

capabilities. From these factors, he then must determine the amount of

engineering to be done by each. In some cases the panel fabricator will do little

or none of it; in other cases, he may do all of it.

Having decided which route to take, the engineer must schedule the work

accordingly. If the detailed engineering is left to the panel fabricator, the contract

must be let at an earlier date to allow time for engineering by the fabricator. The

quality of the written panel specifications must be better for this option than for

one on which detailed engineering is complete, because the written

specifications must convey in word description what detailed drawings normal.

Show pictorially.

10.2.7 Plot Plans

Instrument location plans (plot plans) include all instrument items that

interconnect with other instruments. They usually do not show single items (such

as level or pressure gauges and in-line rotameters) that connect only to process

lines or vessels because those items normally appear on piping and/or

equipment drawings and on mechanical flow sheets.

Many instrument items are shown on two sets of plan drawings because their

installation involves two different craftspipe fitters and electricians. Electrical

plot plan normally show all items that have electrical connection Instrument plot

plans show items that have both electrical and piping connections. The drawing

scale normally used is or 3/8 inch per foot. An advantage of the 3/8-inch scale

that it duplicates the scale normally used by the piping department. Background

layouts may then be traced. Duplicated with little effort and cost. The location of

instrument items also is easy since many of them are shown in piping drawings.

Location of all instrument junction boxes should show on the instrument plans.

Instrument cable and tubing trays, if not shown on electrical drawings, may also

show on the instrument plans.

Piping

Rolta Academy: EDA Technology Mumbai

Underground cable and tubing runs must be carefully routed. Preliminary

locations and routing should be reviewed by piping, electrical and civil

engineering design disciplines to avoid conflicts during construction with new

design and also existing pipes, conduits, electrical grounding systems,

foundations, drains, and sewers.

10.2.8 Installation Details

Installation details or sketches are needed to show mounding and piping

methods and preferences. They show the size, pressure rating and type of

materials required for installation. Sufficient information is given to allow correct

installation even if the craftsman is not familiar with the instrument.

Typical connection details are also made for instrument electrical

connections. Normally these show the proper entry to the instrument, the size

and number of wires needed, the size and type of conduit used and the electrical

fittings required.

These sketches, properly drawn, save many hours of installation labor and

ensure proper installation and operation even when installed by inexperienced

craftsmen They also provide a good basis for material take-off and purchase and

material inventory control during the building phase.

10.3 Bid Documents

These documents are involved only on design and construction projects

on which bids have been made and accepted. They are important to both the

owner and the contractor. The responsible instrument engineers for both parties

should be familiar with the basis on which the work is proposed to be done.

In some instances specifications and standards may be clear enough that

no clarifications or exceptions have been necessary and where no alternatives

have been offered. In such cases the specifications and standards along with the

flow sheets and other drawings are the bid basis. These, however, are often

subject to interpretation. They must be studied and understood by the

contractor's engineer; presumably they are well understood by the owner's

representative.

If exceptions (to the specifications) or clarifications (where specifications

are not clear or may be misinterpreted) have been made or if alternatives have

been offered, both parties should be aware of them to make certain that they do

not affect the total instrument budget or the engineering man-hour estimate.

Piping

Rolta Academy: EDA Technology Mumbai

Prior to beginning work, whether from the owner or contractor viewpoint,

the involved instrument engineers should be familiar with the bid documents and

with the final contract which reflects the bid proposal. Apparent discrepancies in

the two documents should be brought to the attention of the project managers

involved.

10.4 Project Procedures

The lack of communication between individuals and groups is a major

obstacle in most endeavors. Engineering projects are not exceptions. Project

procedures are set up to assure good communication among all involved parties.

They

form:

should

include

the

following

information

in

some

Project organization chart

The function of key personnel assigned to the project, their responsibilities

and duties

Accounting proceduresa code of accounts for proper allocation of material

and labor costs

Distribution of all types of communication forms, including periodic progress

reports, special reports, job schedules, drawings, purchase requisitions and

orders and day-to-day memoranda (these are examples, not a complete list)

Approval procedures for the release of engineering drawings, specifications,

requisitions, purchase orders and other documents

The extent, frequency and complexity of planning, expediting and scheduling

activities

Equipment and material procurement methods and procedures

Engineering drawing sizes and numbering system

Identification systems for equipment and instrument items

This list is not intended to be complete, but it indicates the necessity for job

organization to assure quick and efficient flow of information. It assures orderly

progress and prevents costly mistakes due to lack of information. Primarily, it

saves the valuable time of many people. It includes the flow lines of

communication among the contractor, owner, vendors and subcontractors, as

well as within the contracting organization.

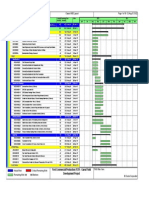

10.4.1 Project Schedule

Piping

Rolta Academy: EDA Technology Mumbai

At the beginning of a project, the responsible instrument engineer determines

from the project schedule the date's for purchasing equipment, for starting field

installation and for completion of various phases of the project. These factors are

interrelated, of course. The various facets of instrumentation (purchase, delivery,

installation, calibration and checkout) are seldom critical in the completion of a

Job, except the last phasecalibration and checkout. By its very nature,

instrument checkout is one of the last work items required prior to plant startup.

Other facets (such as delivery) may be critical if instrument design is delayed

or if special equipment is needed. On small "crash" projects, standard instrument

items may have longer delivery times than other equipment needed for the job. In

any case, the instrument engineer should determine the amount of work to be

done and correlate it with the project schedule.

Instrument items that need to be specified and purchased early are those

which are mounted in-line and whose dimensions need to be known by other

disciplines. For example, the piping people need the dimensions of control

valves, meter runs and other in-line devices to complete their work.

Some other examples of scheduling problems include

Purchase of panel instruments early enough to meet panel fabricator's

requirements.

Purchase of relief valves to meet piping erection schedules.

The requirement of starting up one or more phases of a project ahead of

others. All items required for that phase must be purchased early.

One good approach in scheduling a job is to work from the completion date

backwards to determine logical dates for the completion of various stages of the

job. Allow plenty of time for custom fabricated items, delivery of equipment after

shipment and communication delays that normally affect a job.

After the instrument schedule is temporarily worked out, review the items

again, checking with equipment vendors to verify their probable delivery

commitments.

10.4.2 Equipment Information

Equipment size, nozzle size and orientation (on vessels and other

equipment), materials of construction and pressure ratings of equipment and

flanges must be known prior to the purchase of instrument items related to that

equipment. Most of this information is usually available prior to equipment

purchase, and it must be assembled for reference when purchasing related

instrument items.

Piping

Rolta Academy: EDA Technology Mumbai

Even after equipment specification and purchase is complete, a final check of

vendor's drawings of the purchased items should be made to verify compliance

with purchase specifications. A final check of this nature often avoids costly field

changes.

10.4.3 Vendor Drawings

Vendor drawings of purchased instruments must be checked thoroughly to

determine that they comply with purchase orders and their specifications and

drawings. The assumption should not be that no mistakes will be made by the

many people who handle purchase orders from their origination to the delivery of

the finished items. It can be assumed that some will be made. A thorough check

of vendor drawings will likely catch some errors in time to prevent costly delays

and exchanges.

10.4.4 Work Coordination

Coordination among those responsible for the various phases of engineering

is necessary for an efficient, well run job. The project instrument engineer must

cooperate and work with the following people or groups. He must be aware of

their duties and functions in order to coordinate the work effectively.

10.4.5 Project Manager

Among the many functions of the project manager, those listed below have

the greatest effect on the work in the instrument department.

1. Project procedures

2. Schedules

3. Manpower allocation

4. Job progress

5. Cost control

10.4.6 Manpower Allocation

Manpower requirements to meet job schedules are usually discussed among

the project manager, the instrument project leader and other interested people.

Job requirements and personnel capabilities arc usually known well enough that

assignments can be made to satisfy completion schedules with a fair degree of

accuracy. When additional manpower is needed to meet a commitment or if too

much. Manpower is being used, the project instrument leader should advise the

project manager and other management people who are responsible for

reallocating manpower.

Piping

Rolta Academy: EDA Technology Mumbai

10.4.7 Progress Reports

Periodic progress reports, usually on a monthly basis, are made to the project

manager. it is the most reliable source that he or other interested parties have for

gauging the project status. Proper communication through this channel of

information highlights difficulties, achievements and schedule changes Reports

from each discipline are completed and issued to designated personnel. The

report is used to avoid misunderstandings between owner and builder and within

the contractor organization by keeping everyone posted on the job completion

picture. The owner needs this information for meshing new plant activities with

those existing to reduce overall operating expenses.

The positive psychological effects of just having a monthly status report are

enormous. It stands to reason that the absence of such an indicator will only

cause doubts in the minds of the project manager and the customer. Conversely,

the mere presence of a status report leads interested companies to the

conclusion that the report writer understands the project situation An overall

confidence develops in the managerial skills of the engineer, a confidence which

builds first in the engineer, and which often noticed by the person who can

recommend a salary increment for that engineer.

10.4.8 Cost Control

Factors that cause significant changes in the cost of instrumentation for a

project must be brought to the attention of the project manager Many different

situations arise, alter the original estimate Escalation of material and lab prices,

greater-than-anticipated complexity of COP systems oversight of alloy material

requirements, premium payments to meet schedules for fabricated items, loss of

manpower, misinterpretation of quotationsany these things may occur to

increase the cost. Seldom is -confronted with cost decreases.

Since the project manager is the one ultimately responsible for project cost,

the final decision usually rests with him. The project instrument leader should

make his views know and should advise to the best of his knowledge the proper

action.

10.4.9 Process Engineer

During the course of a project, many questions arise relative to process

conditions that require close cooperation between process and instrument people

For example, the range of flow for a flow meter may be higher than that

attainable by a single orifice meter. A discussion of the problem with responsible

process people will determine whether to use one or two meters or an entirely

different type flow device.

Piping

10

Rolta Academy: EDA Technology Mumbai

There are many instances in which range requirements material

requirements, etc, have been given but which cannot be considered inflexible

They need to be discussed with the proper people before changes are made,

however, the process engineer is the logical person to consult for such problems.

10.4.10 Equipment Engineer

Major pieces of equipment ordinarily are purchased during the initial phase

of the job because delivery times r usually long this is particularly true of large or

complex items, ones requiring a large amount of engineering, those made of

exotic materials or nonstandard items. Most of the; type equipment will have

instrument related itemslevel gauges, thermo wells, pressure connections

that must attach to it The instrument project leader must work with the equipment

engineers to assure proper connection sizes and locations for the instruments,

When complete packages (or systems) are purchase, such as compressors,

extruders, furnaces and refrigeration systems, along with their associated

auxiliary units, the responsible instrument leader should check equipment

specifications, purchase orders and vendor prints to assure the use of proper

instruments and to document information necessary to tie them into the rest of

the plant instrument system,

10.4.11 Piping Design Supervisor

The preparation of piping drawings starts as soon as equipment layouts and

orientation are determined and other pertinent information is available. Costly

revisions (o piping drawings can be avoided if meter run sizes and lengths and

control and relief valve sizes are known and dimensions are given to the piping

section early in the piping design stage. Piping details for level gauges and level

controllers are often shown on piping drawings, and their dimensions are

needed, Connection sizes are needed for pressure and temperature devices.

Forms that contain the needed information are prepared and given to the piping

section. They contain all the size and dimension information needed for relief

valves, level transmitters and controllers, control valves, level gauges and orifice

meter runs.

They can be dated and revised when and if changes occur. The preparation

and issue of such forms provides an efficient and clear means of communication

between departments.

Before piping plans, elevations and isometrics are issued they should receive

a squad" check by the instrument department to make certain that all process

connections are shown and that instrument location drawings (plot plans) and

piping drawings are in agreement.

Piping

11

Rolta Academy: EDA Technology Mumbai

Piping

12

Das könnte Ihnen auch gefallen

- Scope of Work For 3D-Model ProcedureDokument31 SeitenScope of Work For 3D-Model ProcedureMehdi Sadeghi100% (4)

- S-000-5138-302 - B Design Change Procedure PDFDokument6 SeitenS-000-5138-302 - B Design Change Procedure PDFMahadevan MahalingamNoch keine Bewertungen

- Engineering Design QA: Holistic Workflow PhilosophyDokument11 SeitenEngineering Design QA: Holistic Workflow PhilosophyMuhammad SaadullahNoch keine Bewertungen

- Feed Deliverable ListDokument8 SeitenFeed Deliverable Listajuu100% (4)

- Developing Standard Logic For A Detailed Engineering Project Schedule in The Process IndustryDokument40 SeitenDeveloping Standard Logic For A Detailed Engineering Project Schedule in The Process Industrysubir2160% (1)

- Developing The Project PlanDokument8 SeitenDeveloping The Project PlanStephanie BucogNoch keine Bewertungen

- Empowerment Series Social Work With Groups Comprehensive Practice and Self Care 10Th Edition Charles Zastrow Full ChapterDokument67 SeitenEmpowerment Series Social Work With Groups Comprehensive Practice and Self Care 10Th Edition Charles Zastrow Full Chapterruby.levi441100% (5)

- Instrumentation DocumentsDokument81 SeitenInstrumentation DocumentsTurkish Medical CareNoch keine Bewertungen

- PROJECT STANDARDS and SPECIFICATIONS Instrumentation Project Engineering Rev01Dokument20 SeitenPROJECT STANDARDS and SPECIFICATIONS Instrumentation Project Engineering Rev01Laurence Malanum50% (2)

- Career Change From Real Estate to Oil and Gas ProjectsVon EverandCareer Change From Real Estate to Oil and Gas ProjectsBewertung: 5 von 5 Sternen5/5 (1)

- General Requirements For A FEED Study and PTE PreparationDokument3 SeitenGeneral Requirements For A FEED Study and PTE PreparationklmNoch keine Bewertungen

- Controls Instrumentation Detail EngineeringDokument24 SeitenControls Instrumentation Detail EngineeringTimotius Ichan HariadiNoch keine Bewertungen

- Pistep Act ModDokument13 SeitenPistep Act ModkamlNoch keine Bewertungen

- Project Management For EngineersDokument2 SeitenProject Management For EngineersAl VinNoch keine Bewertungen

- FEED Deliverable List (Sample) - The Project DefinitionDokument8 SeitenFEED Deliverable List (Sample) - The Project DefinitionKerleauNoch keine Bewertungen

- 100 A Request For Proposal Lessons LearnedDokument1 Seite100 A Request For Proposal Lessons LearnedEmmanuel Cervantes VelázquezNoch keine Bewertungen

- Detailed Process of Project Execution & Progress Measurement and TrackingDokument22 SeitenDetailed Process of Project Execution & Progress Measurement and Trackingzhangj5100% (1)

- Inst Design GuideDokument35 SeitenInst Design GuidewasimNoch keine Bewertungen

- Control Accounts, Work Packages, Planning PackagesDokument11 SeitenControl Accounts, Work Packages, Planning PackageskbaltimoreNoch keine Bewertungen

- Catalogue Engineering ENG-exDokument16 SeitenCatalogue Engineering ENG-exMus ChrifiNoch keine Bewertungen

- Sibp Gep Design PlanningDokument8 SeitenSibp Gep Design PlanningEnrique PomalesNoch keine Bewertungen

- Transition From Construction To CommissioningDokument30 SeitenTransition From Construction To Commissioningian84Noch keine Bewertungen

- Piping Training - Typical Project TypesDokument12 SeitenPiping Training - Typical Project TypesDinesh Hande100% (2)

- Tender Bulletin 05 Attachment #1 Project Deliverables & Requirements...Dokument26 SeitenTender Bulletin 05 Attachment #1 Project Deliverables & Requirements...Hamza ShujaNoch keine Bewertungen

- Manual de Vaporizadores AmbientalesDokument9 SeitenManual de Vaporizadores AmbientalesJose Luis Tadeo SabinoNoch keine Bewertungen

- RFP For Detailed Engineering of Wellhead DevelopmentDokument10 SeitenRFP For Detailed Engineering of Wellhead DevelopmentHafiz AkhtarNoch keine Bewertungen

- Planning Interview Questions and AnswersDokument2 SeitenPlanning Interview Questions and AnswersWilly K. Ng'etich0% (1)

- Life Cycle Integrity Management: Pre-Feed & FeedDokument1 SeiteLife Cycle Integrity Management: Pre-Feed & FeedDana GuerreroNoch keine Bewertungen

- SRD Tollgate BasedProjectManagementDokument9 SeitenSRD Tollgate BasedProjectManagementKulanthaivelu RamasamyNoch keine Bewertungen

- Construction Managementmajed NouraddinDokument228 SeitenConstruction Managementmajed NouraddinRam L RaoNoch keine Bewertungen

- Piping Progress Measurement (In Dia and in Meter)Dokument6 SeitenPiping Progress Measurement (In Dia and in Meter)bumkj100% (1)

- Schedule Cracker Manual 1.2Dokument45 SeitenSchedule Cracker Manual 1.2greatfargoNoch keine Bewertungen

- Bases FEED EPC Parte 3viDokument229 SeitenBases FEED EPC Parte 3viAbdelhamid LaroussiNoch keine Bewertungen

- Chemical Engineering Plant Design (Che-441) : Dr. Imran HassanDokument24 SeitenChemical Engineering Plant Design (Che-441) : Dr. Imran HassanHassan KhalidNoch keine Bewertungen

- Engineering Deliverable For Chemical OilGas ProjectsDokument6 SeitenEngineering Deliverable For Chemical OilGas Projectskamala 123100% (1)

- How To Get Costing of Labor?: Preparing Detailed EstimateDokument21 SeitenHow To Get Costing of Labor?: Preparing Detailed Estimatecass0608Noch keine Bewertungen

- Man Hours HistogramDokument1 SeiteMan Hours HistogramMostafa Elkadi0% (1)

- Epc Project InterdepencyDokument101 SeitenEpc Project InterdepencyKhaled Slevin100% (6)

- Primavera P6 Reference Table For EPC andDokument1 SeitePrimavera P6 Reference Table For EPC andhichemokokNoch keine Bewertungen

- S ProjectDefinitionOnOffshore PetrofacDokument4 SeitenS ProjectDefinitionOnOffshore PetrofacDiego1980bNoch keine Bewertungen

- Hand Over ProcedureDokument16 SeitenHand Over Procedureangeltandingan100% (1)

- Schedule Updating DOP3000 PRC 011-0-03Dokument8 SeitenSchedule Updating DOP3000 PRC 011-0-03gfgNoch keine Bewertungen

- Costing of Pipelines - 2 - PIPING GUIDE PDFDokument6 SeitenCosting of Pipelines - 2 - PIPING GUIDE PDFvenancio-20100% (1)

- ICARUS ReferenceDokument66 SeitenICARUS Referencerylar999Noch keine Bewertungen

- EPC - EPC Contract - EPC Companies - EPC Engineering - Ador Welding LTDDokument4 SeitenEPC - EPC Contract - EPC Companies - EPC Engineering - Ador Welding LTDchinmayNoch keine Bewertungen

- Front End LoadingDokument2 SeitenFront End LoadingRyan SykesNoch keine Bewertungen

- 07 - Progress Reporting ProceduresDokument60 Seiten07 - Progress Reporting ProceduresGemechuNoch keine Bewertungen

- Garraf FCP DD ScheduleDokument19 SeitenGarraf FCP DD ScheduleSalman HussainNoch keine Bewertungen

- 131 - 100-Yer-Pm-Ppm-0031 - Interface Management Coordination ProcedureDokument14 Seiten131 - 100-Yer-Pm-Ppm-0031 - Interface Management Coordination ProcedureIonut LefterNoch keine Bewertungen

- Schedule LevelsDokument4 SeitenSchedule LevelsNalini TiwariNoch keine Bewertungen

- Costing of Pipelines - 1 - PIPING GUIDEDokument7 SeitenCosting of Pipelines - 1 - PIPING GUIDEfdsaeh67Noch keine Bewertungen

- Deliverables List - EngineeringchecksDokument3 SeitenDeliverables List - EngineeringchecksKarthik NagendraNoch keine Bewertungen

- Project Report ON "Tetra": in Partial Fulfillment For The Award of The Degree ofDokument64 SeitenProject Report ON "Tetra": in Partial Fulfillment For The Award of The Degree ofKanika Khurana100% (2)

- Change Management ProcedureDokument5 SeitenChange Management Procedureautocad abdelmjidNoch keine Bewertungen

- Road Map Update for Carbon Capture, Utilization, and Storage Demonstration and Deployment in the People’s Republic of ChinaVon EverandRoad Map Update for Carbon Capture, Utilization, and Storage Demonstration and Deployment in the People’s Republic of ChinaNoch keine Bewertungen

- A Project Manager's Book of Forms: A Companion to the PMBOK GuideVon EverandA Project Manager's Book of Forms: A Companion to the PMBOK GuideNoch keine Bewertungen

- ABSL Business Cycle Fund - PresentationDokument37 SeitenABSL Business Cycle Fund - PresentationRajesh BarkurNoch keine Bewertungen

- STN ESL SymbolsDokument71 SeitenSTN ESL SymbolsRajesh BarkurNoch keine Bewertungen

- Healthify Diet Plan PDFDokument4 SeitenHealthify Diet Plan PDFRajesh BarkurNoch keine Bewertungen

- Instrumentation - Control Design BasisDokument40 SeitenInstrumentation - Control Design BasisRajesh Barkur100% (2)

- NJ India Safety and Quality: Teemu TeittoDokument8 SeitenNJ India Safety and Quality: Teemu TeittoRajesh BarkurNoch keine Bewertungen

- BKDD00-ME-4M-87-001 Rev.d - Code 2 Data Sheet For Control ValvesDokument25 SeitenBKDD00-ME-4M-87-001 Rev.d - Code 2 Data Sheet For Control ValvesnileshanaNoch keine Bewertungen

- Differential Pressure Transmitters: Date Revision Sheet Inquiry Area CodeDokument4 SeitenDifferential Pressure Transmitters: Date Revision Sheet Inquiry Area CodeRajesh BarkurNoch keine Bewertungen

- LLA-47 Block - Llanos Basin - Colombia, South AmericaDokument4 SeitenLLA-47 Block - Llanos Basin - Colombia, South AmericaRajesh BarkurNoch keine Bewertungen

- Quifa Block - Prospects I and E - Rubiales Field - Colombia, South AmericaDokument4 SeitenQuifa Block - Prospects I and E - Rubiales Field - Colombia, South AmericaRajesh BarkurNoch keine Bewertungen

- Design BasisDokument34 SeitenDesign BasisRajesh BarkurNoch keine Bewertungen

- DotcomDokument325 SeitenDotcomDerence VooNoch keine Bewertungen

- CPO-5 Block - Llanos Basin - Colombia, South AmericaDokument4 SeitenCPO-5 Block - Llanos Basin - Colombia, South AmericaRajesh BarkurNoch keine Bewertungen

- MEB EngDokument69 SeitenMEB EngRajesh BarkurNoch keine Bewertungen

- Blue Creek Project - Blue Creek & West Gallon Jug Blocks - Belize, South AmericaDokument4 SeitenBlue Creek Project - Blue Creek & West Gallon Jug Blocks - Belize, South AmericaRajesh BarkurNoch keine Bewertungen

- Coiron Amargo Block - Argentina, South AmericaDokument4 SeitenCoiron Amargo Block - Argentina, South AmericaRajesh BarkurNoch keine Bewertungen

- Dolphin Gas Field - Qatar, Middle-EastDokument4 SeitenDolphin Gas Field - Qatar, Middle-EastRajesh BarkurNoch keine Bewertungen

- Block 31 - Suriname - Suriname, South AmericaDokument4 SeitenBlock 31 - Suriname - Suriname, South AmericaRajesh BarkurNoch keine Bewertungen

- Block BM-C-36 - Tartaruga Verde (Previously Aruana Prospect) - Brazil, South AmericaDokument7 SeitenBlock BM-C-36 - Tartaruga Verde (Previously Aruana Prospect) - Brazil, South AmericaRajesh BarkurNoch keine Bewertungen

- Block FZA-M-320 - Brazil, South AmericaDokument4 SeitenBlock FZA-M-320 - Brazil, South AmericaRajesh BarkurNoch keine Bewertungen

- Aguas Blancas Oil Field - Colombia, South AmericaDokument4 SeitenAguas Blancas Oil Field - Colombia, South AmericaRajesh BarkurNoch keine Bewertungen

- Process, Power and Marine Division: Neeraj SaxenaDokument33 SeitenProcess, Power and Marine Division: Neeraj SaxenaRajesh BarkurNoch keine Bewertungen

- IES OBJ Civil Engineering 2000 Paper IDokument17 SeitenIES OBJ Civil Engineering 2000 Paper Itom stuartNoch keine Bewertungen

- Caroline G Babin: Undergraduate Degree at Louisiana State University in Baton Rouge, Louisiana - Currently EnrolledDokument2 SeitenCaroline G Babin: Undergraduate Degree at Louisiana State University in Baton Rouge, Louisiana - Currently EnrolledCaroline BabinNoch keine Bewertungen

- Concept of Lokmitra Kendra in Himachal PradeshDokument2 SeitenConcept of Lokmitra Kendra in Himachal PradeshSureshSharmaNoch keine Bewertungen

- Flow Through A Converging-Diverging Tube and Its Implications in Occlusive Vascular Disease-IDokument9 SeitenFlow Through A Converging-Diverging Tube and Its Implications in Occlusive Vascular Disease-IRukhsarAhmedNoch keine Bewertungen

- UntitledDokument5 SeitenUntitledapril montejoNoch keine Bewertungen

- Analysis Chart - Julie Taymor-ArticleDokument3 SeitenAnalysis Chart - Julie Taymor-ArticlePATRICIO PALENCIANoch keine Bewertungen

- Corrosion Protection PT Tosanda Dwi SapurwaDokument18 SeitenCorrosion Protection PT Tosanda Dwi SapurwaYoga FirmansyahNoch keine Bewertungen

- Use The Analysis ToolPak To Perform Complex Data Analysis - Excel - OfficeDokument5 SeitenUse The Analysis ToolPak To Perform Complex Data Analysis - Excel - OfficedakingNoch keine Bewertungen

- (Word 365-2019) Mos Word MocktestDokument4 Seiten(Word 365-2019) Mos Word MocktestQuỳnh Anh Nguyễn TháiNoch keine Bewertungen

- Mediator Analysis of Job Embeddedness - Relationship Between Work-Life Balance Practices and Turnover IntentionsDokument15 SeitenMediator Analysis of Job Embeddedness - Relationship Between Work-Life Balance Practices and Turnover IntentionsWitty MindsNoch keine Bewertungen

- Per Dev Dlp-1-2 - 3 SelfDokument6 SeitenPer Dev Dlp-1-2 - 3 SelfMonisa SocorinNoch keine Bewertungen

- Pamphlet 89 Chlorine Scrubbing SystemsDokument36 SeitenPamphlet 89 Chlorine Scrubbing Systemshfguavita100% (4)

- Slup 230Dokument24 SeitenSlup 230Jelena TodorovicNoch keine Bewertungen

- Code of Federal RegulationsDokument14 SeitenCode of Federal RegulationsdiwolfieNoch keine Bewertungen

- Namagunga Primary Boarding School: Primary Six Holiday Work 2021 EnglishDokument10 SeitenNamagunga Primary Boarding School: Primary Six Holiday Work 2021 EnglishMonydit santinoNoch keine Bewertungen

- Electro TechniquesDokument2 SeitenElectro TechniquesPinkk DaisyfieldNoch keine Bewertungen

- (Ug, PG & PHD) Fellowship: Tih-Iot Chanakya GroupDokument3 Seiten(Ug, PG & PHD) Fellowship: Tih-Iot Chanakya GroupVijay M.MNoch keine Bewertungen

- Most Dangerous City - Mainstreet/Postmedia PollDokument35 SeitenMost Dangerous City - Mainstreet/Postmedia PollTessa VanderhartNoch keine Bewertungen

- EEE301 Digital Electronics Lecture 1 Part 3: Dr. A.S.M. MohsinDokument6 SeitenEEE301 Digital Electronics Lecture 1 Part 3: Dr. A.S.M. MohsinAaa AaaNoch keine Bewertungen

- Manish Kumar: Desire To Work and Grow in The Field of MechanicalDokument4 SeitenManish Kumar: Desire To Work and Grow in The Field of MechanicalMANISHNoch keine Bewertungen

- Aristotle Metaphysics Lambda Accessed 201111 Classicalk LibraryDokument19 SeitenAristotle Metaphysics Lambda Accessed 201111 Classicalk Librarygijsbo2000Noch keine Bewertungen

- Engineering Geology: Wei-Min Ye, Yong-Gui Chen, Bao Chen, Qiong Wang, Ju WangDokument9 SeitenEngineering Geology: Wei-Min Ye, Yong-Gui Chen, Bao Chen, Qiong Wang, Ju WangmazharNoch keine Bewertungen

- DAY 3 STRESS Ielts NguyenhuyenDokument1 SeiteDAY 3 STRESS Ielts NguyenhuyenTĩnh HạNoch keine Bewertungen

- Teachers Guide Lower Secondary Science PDFDokument141 SeitenTeachers Guide Lower Secondary Science PDFNuzhat IbrahimNoch keine Bewertungen

- Lab 3 Report Fins RedoDokument3 SeitenLab 3 Report Fins RedoWestley GomezNoch keine Bewertungen

- Diltoids Numberletter Puzzles Activities Promoting Classroom Dynamics Group Form - 38486Dokument5 SeitenDiltoids Numberletter Puzzles Activities Promoting Classroom Dynamics Group Form - 38486sinirsistemiNoch keine Bewertungen

- Hexoloy SP Sic TdsDokument4 SeitenHexoloy SP Sic TdsAnonymous r3MoX2ZMTNoch keine Bewertungen

- Ad For Guru Ned'S Enlightenment Masterclass 1 of 33Dokument33 SeitenAd For Guru Ned'S Enlightenment Masterclass 1 of 33ElliuggNoch keine Bewertungen