Beruflich Dokumente

Kultur Dokumente

54 C 838287 B 847

Hochgeladen von

8612106535Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

54 C 838287 B 847

Hochgeladen von

8612106535Copyright:

Verfügbare Formate

Technical Information

TI/T

June 2011

= Registered trademark of

BASF SE

Page 1 of 5

Setamol Disperse ws

Universal, anionic dispersing agent for dyes, and protective colloid

TI/T June 2011

Page 2 of 5

Setamol Disperse WS

Nature

Polycondensation product of an aromatic sulfonic acid, anionic

Physical form

Low-dusting, brownish microgranules

Shelf life

Setamol Disperse WS can be kept in the original sealed containers at

temperatures between 0 and 40 C for at least 24 months. Partly used

containers should be kept tightly closed in a cool place and used up as

soon as possible.

Please note the information on handling, ecology and disposal in the

current Safety Data Sheet.

Properties

pH1

Approx. 6.8 (10 % aqueous solution)

Tolerances for the above test characteristic are given in the product

specification.

Solubility (20 C)

Approx. 550 g/l in water; soluble in polar solvents

A 10 % solution in water is brown and clear.

Ionicity

Anionic

Stability

Even under HT conditions, Setamol Disperse WS is stable to acids,

alkalis, hard-water salts and electrolytes.

Compatibility

As an anionic product, Setamol DisperseWS is compatible with all

anionic and nonionic auxiliaries.

In alkaline baths, it can also be used together with the cationic product

TM

TM

Uniperol Level P. Precipitates with Uniperol Level P are only likely

in acid or neutral liquors.

The product property data merely provide an indication of how the

product is to be used. They do not constitute the agreed quality of the

product, nor are they the object of regular quality control tests.

Action

As an effective dispersing agent and protective colloid, Setamol

Disperse WS stabilizes dye dispersions and therefore helps increase

the standard of fastness and the levelness of the dyeings. The product

does not have any wetting or detergent effect.

In acid liquors, Setamol Disperse WS has an affinity to animal fibers

such as wool and silk, and to polyamide fibers.

Application

Preparation of stock solutions

Setamol DisperseWS can be dissolved either by scattering it into 10 to

20 times the quantity of boiling hot water or by pouring the same

quantity of hot water over it and stirring.

10 % stock solutions can be prepared that are clear and very stable at

room temperature.

The product is virtually universally applicable.

1 In accordance with DIN 19268

TI/T June 2011

Page 3 of 5

Setamol Disperse WS

Stabilization of dye liquors and prevention of dye agglomeration

Vat dyes

Stock vat

The stability of stock vats can be considerably improved by adding

approx. 5 10 g/l Setamol DisperseWS. The product must be added to

the dye dispersion before it is vatted.

Jig dyeing

Approx. 2 g/l Setamol Disperse WS is added to improve the stability of

the dye liquor. The product prevents vat acid stains, for example during

dyeing with Vat Blue types.

Package dyeing machine or winch beck Approx. 1 g/l Setamol

Disperse WS is added to prevent precipitation and filtration of the dyes.

This addition is particularly recommended when the pigmentation or

semi-pigmentation process is used.

Pad-steam process Approx. 2 g/l Setamol Disperse WS in the

chemical padder prevents agglomeration of detached dye particles in

the liquor. After steaming, Setamol Disperse WS facilitates removal of

the unfixed dye. The presence of Setamol DisperseWS is especially

important during the oxidation of vat dyes. It prevents agglomeration

and filtration of the newly formed insoluble pigments in the oxidation

bath.

Indigo

Stock vat

Adding approx. 1 g/l Setamol Disperse WS to the stock vat formulation

increases the process reliability.

Disperse dyes

Application rate: approx. 0.5 2 g/l Setamol Disperse WS

The amount of Setamol Disperse WS required depends on the type of

dye preparation. Adding Setamol Disperse WS is particularly important

with liquid dyes that do not contain much dispersing agent, in order to

ensure a stable dye dispersion throughout the dyeing process. A higher

application rate is required with short liquor ratios (jig dyeing) because

of the greater risk of agglomeration.

Setamol Disperse WS both stabilizes the dye dispersion during the

dyeing process and prevents agglomeration of dye particles remaining

in the dyebath as it cools down.

Naphthol dyes

Approx. 1 3 g/l Setamol Disperse WS is added to stabilize naphthol

dye impregnating baths.

Washing off prints

Disperse dyes

Setamol Disperse WS is particularly recommended for washing off

prints with disperse dyes on blends of acetate or triacetate with

polyamide. It stops the dye from going on to the polyamide component

during washing off.

Application rate: approx. 1 1.5 g/l

Basic dyes

On account of its anionic nature, Setamol Disperse WS has affinity to

cationic dyes and is often added to the wash baths.

Application rate: approx. 0.5 1 g/l

TI/T June 2011

Page 4 of 5

Setamol Disperse WS

Safety

When using this product, the information and advice given in our Safety

Data Sheet should be observed. Due attention should also be given to

the precautions necessary for handling chemicals.

Note

The data contained in this publication are based on our current

knowledge and experience. In view of the many factors that may affect

processing and application of our product, these data do not relieve

processors from carrying out their own investigations and tests; neither

do these data imply any guarantee of certain properties, nor the

suitability of the product for a specific purpose. Any descriptions,

drawings, photographs, data, pro-portions, weights etc. given herein

may change without prior information and do not constitute the agreed

contractual quality of the product. It is the responsibility of the recipient

of our products to ensure that any proprietary rights and existing laws

and legislation are observed. Responsibility for compliance with the

requirements of the downstream textile market rests with the textile

processor.

TI/T June 2011

Page 5 of 5

Setamol Disperse WS

Das könnte Ihnen auch gefallen

- Stabaxol LDokument3 SeitenStabaxol LnazarienNoch keine Bewertungen

- Zs Dyeset RFTDokument2 SeitenZs Dyeset RFTRezoanul HaqueNoch keine Bewertungen

- Primal TT 615 Rheology ModifierDokument3 SeitenPrimal TT 615 Rheology ModifierNelson LozanoNoch keine Bewertungen

- Albatex: AR Reduction InhibitorDokument4 SeitenAlbatex: AR Reduction InhibitorsaskoNoch keine Bewertungen

- Tanede RFH-B: Environmentally Friendly Reduction Clearing AgentDokument3 SeitenTanede RFH-B: Environmentally Friendly Reduction Clearing Agentangee paolaNoch keine Bewertungen

- Fixapret F-ECO TIDokument5 SeitenFixapret F-ECO TISajida HafeezNoch keine Bewertungen

- Vitexol KDokument4 SeitenVitexol KRezoanul HaqueNoch keine Bewertungen

- BasotolDokument6 SeitenBasotolFathi Mustafa100% (1)

- E 135Dokument2 SeitenE 135Parashuram ChauhanNoch keine Bewertungen

- Dresinate TX - TDS (En)Dokument2 SeitenDresinate TX - TDS (En)frankNoch keine Bewertungen

- Chemicals Zetag DATA Burst 1002 - 0410Dokument2 SeitenChemicals Zetag DATA Burst 1002 - 0410PromagEnviro.comNoch keine Bewertungen

- Uniperol Level PDokument3 SeitenUniperol Level PMuhammad Aasim HassanNoch keine Bewertungen

- Brochure Raw Materials For Textile AuxiliariesDokument14 SeitenBrochure Raw Materials For Textile Auxiliariesrazamehdi3100% (1)

- Zonyl FSO PDFDokument2 SeitenZonyl FSO PDFarguijNoch keine Bewertungen

- Impression MaterialsDokument41 SeitenImpression MaterialsMohamed NagibNoch keine Bewertungen

- MesamollDokument3 SeitenMesamollKiên PhùngNoch keine Bewertungen

- Poligen WE1: Technical InformationDokument4 SeitenPoligen WE1: Technical InformationCarlotta C.Noch keine Bewertungen

- 3200258e - TDS - ALBATEX OADokument4 Seiten3200258e - TDS - ALBATEX OAeric tanudjajaNoch keine Bewertungen

- Diazo: Sensitizer For Screen Printing EmulsionsDokument3 SeitenDiazo: Sensitizer For Screen Printing EmulsionsBassam Ishak RizkallahNoch keine Bewertungen

- Tablet Ingredients: Pharmaceutical Technology I PHARM 2322 byDokument42 SeitenTablet Ingredients: Pharmaceutical Technology I PHARM 2322 bySuzie JayNoch keine Bewertungen

- ELASTENE 1500 DCM-APR TDS en Final - 1501Dokument2 SeitenELASTENE 1500 DCM-APR TDS en Final - 1501rogerkid17Noch keine Bewertungen

- Acronal 7095Dokument3 SeitenAcronal 7095kishanptlNoch keine Bewertungen

- Matexil Da DLP Ads00 14Dokument2 SeitenMatexil Da DLP Ads00 14psivakumar menakamills100% (1)

- Solusoft SE1 Liq - e TIDokument3 SeitenSolusoft SE1 Liq - e TIekoyonatanNoch keine Bewertungen

- Bentone 38 - TDS - eDokument2 SeitenBentone 38 - TDS - eDũng ĐỗNoch keine Bewertungen

- Silegen Softener SIS enDokument5 SeitenSilegen Softener SIS enarkcgem100% (1)

- Ficha Tecnica Preventol D6Dokument5 SeitenFicha Tecnica Preventol D6Wilmer SarmientoNoch keine Bewertungen

- Acrysol Adt-100Dokument3 SeitenAcrysol Adt-100wtwilightwNoch keine Bewertungen

- Setavin Rco Asugal RSL!Dokument2 SeitenSetavin Rco Asugal RSL!aniakonik0% (1)

- Dispol_A40_tdsDokument1 SeiteDispol_A40_tdsckarantoniNoch keine Bewertungen

- Chemicals Zetag DATA Organic Coagulants Agefloc WT 40-P SPS - 0410Dokument2 SeitenChemicals Zetag DATA Organic Coagulants Agefloc WT 40-P SPS - 0410PromagEnviro.comNoch keine Bewertungen

- Chemicals Zetag DATA Magnasol 5000 G - 0410Dokument2 SeitenChemicals Zetag DATA Magnasol 5000 G - 0410PromagEnviro.comNoch keine Bewertungen

- Datasheet JotunDokument12 SeitenDatasheet JotunbayuNoch keine Bewertungen

- MagnaflocDokument2 SeitenMagnaflocIgnacioNoch keine Bewertungen

- Chemicals Zetag DATA Beads Zetag 8590 - 1110Dokument2 SeitenChemicals Zetag DATA Beads Zetag 8590 - 1110PromagEnviro.comNoch keine Bewertungen

- Stepan Formulation 1201Dokument2 SeitenStepan Formulation 1201Mohamed AdelNoch keine Bewertungen

- Steelmaster 120sb 120 MinDokument4 SeitenSteelmaster 120sb 120 MinAZadjotunNoch keine Bewertungen

- Surf Act Ant ToolkitDokument9 SeitenSurf Act Ant ToolkitDuggirala Srinivas MurtyNoch keine Bewertungen

- litdoc71717700AL 2011083021560Dokument28 Seitenlitdoc71717700AL 2011083021560LilyNoch keine Bewertungen

- Tween 80Dokument2 SeitenTween 80Christian SFNoch keine Bewertungen

- Rheolate 150Dokument2 SeitenRheolate 150buninaNoch keine Bewertungen

- Sokalan RO 100 - TIDokument2 SeitenSokalan RO 100 - TIEugene MakNoch keine Bewertungen

- Kathon Lxe (Pengawet in Can)Dokument2 SeitenKathon Lxe (Pengawet in Can)DeddyNoch keine Bewertungen

- Size CO Liquid: Technical InformationDokument0 SeitenSize CO Liquid: Technical InformationMuhammad Aasim HassanNoch keine Bewertungen

- RisilMat ProductOverview NA PDFDokument2 SeitenRisilMat ProductOverview NA PDFaromalara12Noch keine Bewertungen

- (Excipient) Memantine SR - SureleaseDokument2 Seiten(Excipient) Memantine SR - SureleaseByunghoon LeeNoch keine Bewertungen

- Pickling Paste Gel Removes Welding OxidesDokument2 SeitenPickling Paste Gel Removes Welding Oxidesmekag94Noch keine Bewertungen

- Avolan IsDokument3 SeitenAvolan IsIván Cuevas100% (1)

- Orotan - 1124 Msds PDFDokument3 SeitenOrotan - 1124 Msds PDFRenato Diaz FrigerioNoch keine Bewertungen

- Jotashield PrimerDokument3 SeitenJotashield PrimerNonie NNoch keine Bewertungen

- Jotun Paint Bathroom FenomasticDokument3 SeitenJotun Paint Bathroom FenomasticDipin Nediya ParambathNoch keine Bewertungen

- Preventol A6Dokument7 SeitenPreventol A6KHANG PHANNoch keine Bewertungen

- Ester Gum EastmanDokument2 SeitenEster Gum EastmanshishirchemNoch keine Bewertungen

- Chemicals Zetag DATA Magnasol 5605 G - 0410Dokument2 SeitenChemicals Zetag DATA Magnasol 5605 G - 0410PromagEnviro.comNoch keine Bewertungen

- Devthane 379H: Aliphatic Urethane Gloss EnamelDokument2 SeitenDevthane 379H: Aliphatic Urethane Gloss EnamelBikeBook EnsenadaNoch keine Bewertungen

- LauGAL TEDokument1 SeiteLauGAL TEHossam EzzatNoch keine Bewertungen

- Creative Resin: Easy techniques for contemporary resin artVon EverandCreative Resin: Easy techniques for contemporary resin artNoch keine Bewertungen

- Ultrapac 290: Ultrapac 290 Technical Data SheetDokument2 SeitenUltrapac 290: Ultrapac 290 Technical Data Sheet8612106535Noch keine Bewertungen

- Sulfonation and Characterization of Poly(styrene-isobutylene-styrene) Triblock CopolymersDokument14 SeitenSulfonation and Characterization of Poly(styrene-isobutylene-styrene) Triblock Copolymers8612106535Noch keine Bewertungen

- Preparation of Acrylyl Chloride Using Phosphorus OxychlorideDokument2 SeitenPreparation of Acrylyl Chloride Using Phosphorus Oxychloride8612106535Noch keine Bewertungen

- Phenolic Resins Specification: Condition ConditionDokument1 SeitePhenolic Resins Specification: Condition Condition8612106535Noch keine Bewertungen

- Self-Adhesive Materials For Plastic Surfaces: Technical Info #7Dokument2 SeitenSelf-Adhesive Materials For Plastic Surfaces: Technical Info #78612106535Noch keine Bewertungen

- Vand Release AgentDokument2 SeitenVand Release Agent8612106535Noch keine Bewertungen

- 60 7170R PDFDokument2 Seiten60 7170R PDF8612106535Noch keine Bewertungen

- Thermal Transitions of Homo PolymersDokument2 SeitenThermal Transitions of Homo PolymersGrace KwanNoch keine Bewertungen

- Mechanical Properties of Unsaturated Polyester ResinDokument5 SeitenMechanical Properties of Unsaturated Polyester ResinNGokce100% (1)

- 1699101Dokument4 Seiten16991018612106535Noch keine Bewertungen

- Greenlink EF507Dokument3 SeitenGreenlink EF5078612106535Noch keine Bewertungen

- BASF R3-12 Data Sheet PDFDokument1 SeiteBASF R3-12 Data Sheet PDF8612106535Noch keine Bewertungen

- European Patent Specification: Printed by Jouve, 75001 PARIS (FR)Dokument9 SeitenEuropean Patent Specification: Printed by Jouve, 75001 PARIS (FR)8612106535Noch keine Bewertungen

- Surfactants Emulsion PolymersDokument2 SeitenSurfactants Emulsion Polymers8612106535100% (2)

- WANNATE 8221 Isocyanate Technical Data SheetDokument2 SeitenWANNATE 8221 Isocyanate Technical Data Sheet8612106535Noch keine Bewertungen

- 15885Dokument1 Seite158858612106535Noch keine Bewertungen

- DAOTAN VTW 1265/36WA: Technical Datasheet Liquid Coating Resins and AdditivesDokument2 SeitenDAOTAN VTW 1265/36WA: Technical Datasheet Liquid Coating Resins and Additives8612106535Noch keine Bewertungen

- Edta Zinc Disodium (Edta-Znna2)Dokument2 SeitenEdta Zinc Disodium (Edta-Znna2)8612106535Noch keine Bewertungen

- 1K Blocked Series BULLETIN PDFDokument1 Seite1K Blocked Series BULLETIN PDF8612106535Noch keine Bewertungen

- Carbo Hydra Zi deDokument2 SeitenCarbo Hydra Zi de8612106535Noch keine Bewertungen

- Edta Cupric Salt (Edta-Cuna2)Dokument2 SeitenEdta Cupric Salt (Edta-Cuna2)8612106535Noch keine Bewertungen

- Ethylene Diamine Tetraacetic Acid Tetrasodium (EDTADokument2 SeitenEthylene Diamine Tetraacetic Acid Tetrasodium (EDTA8612106535Noch keine Bewertungen

- Morpholine 1 Oxa 4 Azacyclohexane Tetrahydro 2H 1,4 Oxazine Diethylene OximideDokument2 SeitenMorpholine 1 Oxa 4 Azacyclohexane Tetrahydro 2H 1,4 Oxazine Diethylene Oximide8612106535Noch keine Bewertungen

- 400 GlossDokument1 Seite400 Gloss8612106535Noch keine Bewertungen

- Ethylene Diamine Tetraacetic Acid DiSodium (EDTADokument2 SeitenEthylene Diamine Tetraacetic Acid DiSodium (EDTA8612106535Noch keine Bewertungen

- Morpholine PDFDokument2 SeitenMorpholine PDF8612106535Noch keine Bewertungen

- EDTA Manganese Sodium (EDTA-MnNa2)Dokument2 SeitenEDTA Manganese Sodium (EDTA-MnNa2)8612106535Noch keine Bewertungen

- EDTA Magnesium Sodium (EDTA-MgNa2)Dokument2 SeitenEDTA Magnesium Sodium (EDTA-MgNa2)8612106535Noch keine Bewertungen

- Morpholine PDFDokument2 SeitenMorpholine PDF8612106535Noch keine Bewertungen

- EDTA-FeNa2 EDTA-Fe EDTA Ferrum Salt EDTA Fe - Made in ChinaDokument2 SeitenEDTA-FeNa2 EDTA-Fe EDTA Ferrum Salt EDTA Fe - Made in China8612106535Noch keine Bewertungen

- Class Timetable Summary for Periods 1-5Dokument14 SeitenClass Timetable Summary for Periods 1-5عبدالرحمن فهمي الشريفNoch keine Bewertungen

- Salman Sweets Case StudyDokument7 SeitenSalman Sweets Case StudySadaqat MajeedNoch keine Bewertungen

- Brinda Raghuveer Resume Jan2010Dokument2 SeitenBrinda Raghuveer Resume Jan2010Shawn SolisNoch keine Bewertungen

- Remembering Zulu, our beloved pet dog who taught unconditional loveDokument3 SeitenRemembering Zulu, our beloved pet dog who taught unconditional loveAnandan Menon100% (1)

- HSE Procedure Manual: Safety FormatsDokument20 SeitenHSE Procedure Manual: Safety FormatsPavan KumarNoch keine Bewertungen

- Suplemento de Aero Controlex GroupDokument266 SeitenSuplemento de Aero Controlex GroupGerardo CordovaNoch keine Bewertungen

- Base Station Antenna: 1.4m 8port 4H Antenna With Integrated RCUDokument2 SeitenBase Station Antenna: 1.4m 8port 4H Antenna With Integrated RCUДмитрий100% (1)

- 08 Property Risk Survey Risk AssessmentDokument20 Seiten08 Property Risk Survey Risk AssessmentRezza SiburianNoch keine Bewertungen

- A Novel Op-Amp Based LC Oscillator For Wireless CommunicationsDokument6 SeitenA Novel Op-Amp Based LC Oscillator For Wireless CommunicationsblackyNoch keine Bewertungen

- Niskama KarmaDokument4 SeitenNiskama Karmachitta84Noch keine Bewertungen

- HoneywellControLinksS7999ConfigurationDisplay 732Dokument32 SeitenHoneywellControLinksS7999ConfigurationDisplay 732Cristobal GuzmanNoch keine Bewertungen

- Cambridge Paper 1 The Red FoxDokument7 SeitenCambridge Paper 1 The Red FoxLee MaiaNoch keine Bewertungen

- MSC Lecture06Dokument28 SeitenMSC Lecture06Arpan GayenNoch keine Bewertungen

- How To Configure A 3COM SwitchDokument5 SeitenHow To Configure A 3COM Switchama1738Noch keine Bewertungen

- Technical Guide Pigment&Coating Colour PreparationDokument18 SeitenTechnical Guide Pigment&Coating Colour PreparationHuy NguyenNoch keine Bewertungen

- Basic Science ParasitDokument33 SeitenBasic Science ParasitNaifahLuthfiyahPutriNoch keine Bewertungen

- BS en 13479-17Dokument48 SeitenBS en 13479-17jeffer rojasNoch keine Bewertungen

- Psychotropic Drug Study in Psychiatry As A Nursing SpecialtyDokument4 SeitenPsychotropic Drug Study in Psychiatry As A Nursing SpecialtyRoland YusteNoch keine Bewertungen

- BUET Chemical Engineering Project on Biodiesel ProductionDokument30 SeitenBUET Chemical Engineering Project on Biodiesel ProductionTamzidul AlamNoch keine Bewertungen

- ExChEL Group Study Session 13 - Day 1 ExaminationDokument15 SeitenExChEL Group Study Session 13 - Day 1 ExaminationRochelle Louise SampagaNoch keine Bewertungen

- Sls Lux Brickell Units ComparisonDokument19 SeitenSls Lux Brickell Units ComparisonHakanNoch keine Bewertungen

- AC Circuit Analysis TechniquesDokument7 SeitenAC Circuit Analysis TechniquesEduardo ReyesNoch keine Bewertungen

- Introduction To Experimental PsychologyDokument27 SeitenIntroduction To Experimental PsychologyJhonel NautanNoch keine Bewertungen

- Final Drone PresentationDokument15 SeitenFinal Drone PresentationAtharva ZagadeNoch keine Bewertungen

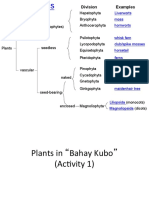

- Bahay KuboDokument21 SeitenBahay KuboEulalio NinaNoch keine Bewertungen

- COVID-19 and Impact On Export Sector in Sri Lanka: Janaka WijayasiriDokument14 SeitenCOVID-19 and Impact On Export Sector in Sri Lanka: Janaka WijayasiriShehan AnuradaNoch keine Bewertungen

- Pasteurization and SterilizationDokument8 SeitenPasteurization and Sterilization611000497Noch keine Bewertungen

- Allyza Diane SauzaDokument60 SeitenAllyza Diane SauzaAllyza Diane SauzaNoch keine Bewertungen

- Organic Chemistry 9th Edition Carey Test BankDokument35 SeitenOrganic Chemistry 9th Edition Carey Test Bankwool.vegetousbbvz100% (23)

- Micronutrients in Hair LossDokument9 SeitenMicronutrients in Hair LossIkbal Adi SaputraNoch keine Bewertungen