Beruflich Dokumente

Kultur Dokumente

Supplier Selection at Casturn Systems

Hochgeladen von

Prashant Pratap Singh100%(2)100% fanden dieses Dokument nützlich (2 Abstimmungen)

1K Ansichten4 SeitenSupplier Selection at Casturn Systems

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenSupplier Selection at Casturn Systems

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

100%(2)100% fanden dieses Dokument nützlich (2 Abstimmungen)

1K Ansichten4 SeitenSupplier Selection at Casturn Systems

Hochgeladen von

Prashant Pratap SinghSupplier Selection at Casturn Systems

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 4

2017

GROUP ASSIGNMENT - 3

Supplier Selection at Casturn Systems ( A ) & ( B )

SUBMITTED BY : Group I-9

Vinayak Sharma

Kartikeya Khare

Keshav Singla

Prashant Pratap Singh

61710959

61710113

61710576

61710779

Case: Supplier Selection at Casturn Systems ( A ) & ( B )

Questions Casturn Systems A:

1. What are the drivers for successful usage of e-RAs?

Following are the various drivers of successful usage of e-RAs:

a. Type of Product Generic/Commodity

b. Product/Service Specification General Industry Standard

c. Supplier Base Large supplier base

d. Supplier Relationship Transactional

e. Switching Cost / Risk Low

f. Supplier Internet knowhow Decent

g. Communication Clear communication of the specifications to the suppliers is required

2. Can e-RAs be used for sourcing highly engineered parts?

It will be difficult to use e-RAs for sourcing highly engineered parts for the following reasons:

a. Supplier Base: It will be difficult to have many suppliers for a highly engineered product. Thus with no or

minimum competition it will be difficult to get the lower price.

b. Communication: It will be difficult to communicate all the aspect of the complex product and any error in

the understanding of the specification may lead to wrong quotes and failure of e-RA exercise.

c. Supplier Relationship: e-RAs induce an abusive and opportunistic behavior among buyers which can strain

the long term buyer-suppler relationships.

3. What are the benefits and disadvantages of the re-sourcing process in Figure 1? Are there any improvements that

should be made to the current practices within Global Supply Management?

BENEFITS:

a. Reverse auction & further negotiation allows Casturn to gain a deeper understanding of the suppler cost

structure and get a cost concession.

b. During technical evaluation, Casturn are able to weed out incapable suppliers who might later create

problems for the company and incur significant cost of lost demand, time and supplier resourcing.

c. The collaborative approach of the teams from engineering, commodity management, launch management

and end user plant in PPAP and business case approval ensures the suppler is of required quality standards.

DISADVANTAGE:

a. Having technical evaluation after the price bid evaluation, the process could lead to choosing an incapable

supplier or someone who misinterpreted the specification of the product just because of the low quoted

price. These errors would slow down the process of sourcing and would demotivate potential suppliers

from participating.

b. The whole process of e-RA takes on an average 18 months and Casturn, which has highly engineered

products, which are changing rapidly with the technology, might miss the chance to capitalize on the

reduced sourcing price for their products.

c. Since the whole process is based on selection of supplier with least quote, the factor of small cycle time

has been neglected in it.

IMPROVEMENTS:

a. The process could be altered with Technical evaluation being the step prior to commercial bid evaluation.

This way the errors could be minimized and cycle time could be improved.

b. Rather than taking the quote on per piece basis, total landing cost to be used for commercial evaluation.

Questions Casturn Systems B:

4. Which parts (if any) should be taken to electronic reverse auction?

In general parts which have simpler specifications, have high supplier base, high competition among the suppliers and

transactional relationship with the suppliers could be procured using e-RA. In reference of the case (Refer Exhibit 2) out

of the three products, Pin and Sleeve could be procured using e-RA.

Pin From M/S Browne, North America

Sleeve From HNC, East Asia

5. What is the optimal setup for electronic reverse auctions?

As discussed in previous questions the optimal setup for the e-RA is as follows:

Note: Technical evaluation could also include non-price factors such as cycle time, reputation etc.

6. Specifically, answer the following questions that Haro and Blake wanted to determine:

a) What should be the duration of the auction event?

The optimum duration of the event should not be so low that it leads to suppliers making errors and should not be

so high that it doesnt seem important. In general, people bidding check the status by using time ending earliest

button. It should also factor in the time difference for bidding parties from different parts of the world. Thus,

duration anywhere between 1 hr to 1 day is good enough for bidding.

b) Should the bid be on piece price or total cost?

The bid should be on per piece basis as it gives a better understanding of the cost structure of the supplier and

gives buyer a better chance for negotiating a better price.

c) Should the auction have a reserve price? Should that price be visible to suppliers?

Yes, auction should have a reserve price and should be visible to the suppliers as it would save the time for both

suppliers, who would not take part if their cost is higher than the reserve price, and buyer, who would not have to

evaluate unfruitful applications.

d) Should it be a dynamic bidding event, or a single-shot (best-and-final) tender?

For parts which are not strategic in nature and low price is the major factor of evaluation, dynamic bidding should

be used. Similarly, for strategic, highly engineered products, the due importance is to be given to other aspects of

the tender such as cycle time, technical evaluation and single-shot tender is best choice here.

EXHIBIT 1: Process flow of resourcing at Casturn

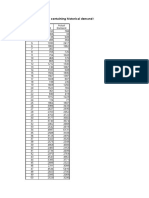

EXHIBIT 2: Net savings calculation with Re-Sourcing

Das könnte Ihnen auch gefallen

- Ducati Harvard Case Study AnalysisDokument4 SeitenDucati Harvard Case Study AnalysisPrashant Pratap Singh100% (5)

- 21 CFR Part 11 Complete Guide To International Computer Validation Compliance For Pharmaceutical IndustryDokument287 Seiten21 CFR Part 11 Complete Guide To International Computer Validation Compliance For Pharmaceutical IndustryFabio Green100% (1)

- PKCLDokument11 SeitenPKCLonkar joshi100% (1)

- Ecsg Assignment - Judo Economics: Submitted byDokument4 SeitenEcsg Assignment - Judo Economics: Submitted byPrashant Pratap Singh100% (2)

- Mygola.com plans to simplify travel planning with new itinerary toolDokument5 SeitenMygola.com plans to simplify travel planning with new itinerary tooldhinuramNoch keine Bewertungen

- Tableau Tutorial PDFDokument10 SeitenTableau Tutorial PDFJaneth bautistaNoch keine Bewertungen

- DMOP Homework: 1. LP and Production PlanningDokument6 SeitenDMOP Homework: 1. LP and Production PlanningShyam Bal0% (2)

- Genentech Case SubmissionDokument2 SeitenGenentech Case SubmissionArijit MajiNoch keine Bewertungen

- 1team - 3 - HP Kittyhawk - Mamak - Adhiraj - 0976Dokument23 Seiten1team - 3 - HP Kittyhawk - Mamak - Adhiraj - 0976rockmanx1820% (1)

- CSTR Notes 1-5 (Gaurav Pansari)Dokument9 SeitenCSTR Notes 1-5 (Gaurav Pansari)Jai KamdarNoch keine Bewertungen

- Operations Management - Group 7 - Sec B - Manzana InsuranceDokument9 SeitenOperations Management - Group 7 - Sec B - Manzana InsuranceVivekMandalNoch keine Bewertungen

- Heidi Roizen - Case Study: MBA ZG515 - Consulting & People SkillsDokument7 SeitenHeidi Roizen - Case Study: MBA ZG515 - Consulting & People Skillsnihal agrawalNoch keine Bewertungen

- Understanding Your Family LegacyDokument81 SeitenUnderstanding Your Family LegacyKimberly Verendia100% (2)

- Gems Group5Dokument4 SeitenGems Group5saurav1202Noch keine Bewertungen

- Group1 - GE and The Industrial InternetDokument2 SeitenGroup1 - GE and The Industrial InternetNishiGogia100% (2)

- Polaroid Case Study SolutionDokument1 SeitePolaroid Case Study SolutionArijit MajiNoch keine Bewertungen

- ABCDEmail Prashant 61710779 13 March 2017Dokument8 SeitenABCDEmail Prashant 61710779 13 March 2017Prashant Pratap Singh100% (1)

- Group 8-Asignment-1 Supplier Selection at Casturn SystemsDokument6 SeitenGroup 8-Asignment-1 Supplier Selection at Casturn SystemsShubham ChauhanNoch keine Bewertungen

- Harvard Business Project Management SimulationDokument5 SeitenHarvard Business Project Management SimulationNihar MandalNoch keine Bewertungen

- VF Corporation'S Global Supply Chain StrategyDokument1 SeiteVF Corporation'S Global Supply Chain Strategypradeep0% (1)

- Owens and Minor TemplateDokument22 SeitenOwens and Minor TemplatePrashant Pratap Singh0% (1)

- MOS GameDokument2 SeitenMOS GameMohan Ram100% (1)

- Group1 - Madras Refineries LimitedDokument5 SeitenGroup1 - Madras Refineries LimitedDHRUV SONAGARANoch keine Bewertungen

- Cashflow Lifetime Options NucleonDokument2 SeitenCashflow Lifetime Options NucleonRitik MaheshwariNoch keine Bewertungen

- Hyrule Cinemas optimal pricing and locationDokument5 SeitenHyrule Cinemas optimal pricing and locationAkash VettavallamNoch keine Bewertungen

- Healthymagination at Ge Healthcare SystemsDokument5 SeitenHealthymagination at Ge Healthcare SystemsPrashant Pratap Singh100% (1)

- Exam 2 Study GuideDokument11 SeitenExam 2 Study GuideAnonymous ewJy7jyvNNoch keine Bewertungen

- Eli Lilly & CoDokument14 SeitenEli Lilly & Corohitmahnot1989100% (3)

- Group 9 - Stermon Mills IncorporatedDokument9 SeitenGroup 9 - Stermon Mills IncorporatedDiptatanu Ganguly100% (3)

- Bergerac Systems: The Challenge of Backward IntegrationDokument3 SeitenBergerac Systems: The Challenge of Backward IntegrationPulkit Aggarwal100% (1)

- Group 3 - Manage Blood at VHS Blood BankDokument8 SeitenGroup 3 - Manage Blood at VHS Blood BankRohan Lunawat100% (1)

- WacDokument8 SeitenWacAnuragBajpaiNoch keine Bewertungen

- ProblemDokument5 SeitenProblemJay PatelNoch keine Bewertungen

- KSA Retail OverviewDokument21 SeitenKSA Retail OverviewPrashant Pratap SinghNoch keine Bewertungen

- Minolta Camera Co. LTD: SEPTEMBER 25, 2016Dokument4 SeitenMinolta Camera Co. LTD: SEPTEMBER 25, 2016Prashant Pratap SinghNoch keine Bewertungen

- M11406 RootBeerGameV2 PDFDokument4 SeitenM11406 RootBeerGameV2 PDFaeromeropNoch keine Bewertungen

- VF Brands Case StudyDokument6 SeitenVF Brands Case StudyJulius ChegeNoch keine Bewertungen

- Scientific Glass Inc - Inventory ManagementDokument11 SeitenScientific Glass Inc - Inventory ManagementdathanNoch keine Bewertungen

- Auction at Casturn SystemsDokument3 SeitenAuction at Casturn Systemsashwini patilNoch keine Bewertungen

- Sample LSCM Exam With SolutionsDokument4 SeitenSample LSCM Exam With SolutionsDushyant ChaturvediNoch keine Bewertungen

- Case-Sports ObermeyerDokument56 SeitenCase-Sports ObermeyerSiddharth MehtaNoch keine Bewertungen

- How Does The Internal Market For Innovation at Nypro FunctionDokument2 SeitenHow Does The Internal Market For Innovation at Nypro Functionprerna004Noch keine Bewertungen

- Davey MukullDokument6 SeitenDavey MukullMukul Kumar SinghNoch keine Bewertungen

- Assignment 1: Terracog Global Positioning Systems: Conflict and Communication On Project AerialDokument5 SeitenAssignment 1: Terracog Global Positioning Systems: Conflict and Communication On Project Aerialharsh singhNoch keine Bewertungen

- Docslide Us Jet Blue Airways Managing Growth Case SolutionDokument12 SeitenDocslide Us Jet Blue Airways Managing Growth Case SolutionprateekNoch keine Bewertungen

- EC2101 Practice Problems 8 SolutionDokument3 SeitenEC2101 Practice Problems 8 Solutiongravity_coreNoch keine Bewertungen

- Barilla Spa (Hbs 9-694-046) - Case Study Submission: Executive SummaryDokument3 SeitenBarilla Spa (Hbs 9-694-046) - Case Study Submission: Executive SummaryRichaNoch keine Bewertungen

- Scotts Miracle-Gro Spreader Sourcing DecisionDokument10 SeitenScotts Miracle-Gro Spreader Sourcing DecisionmsarojiniNoch keine Bewertungen

- Sample Exam QuestionsDokument4 SeitenSample Exam QuestionsVandna Vijay SharmaNoch keine Bewertungen

- Corp Gov Group1 - Sealed AirDokument5 SeitenCorp Gov Group1 - Sealed Airdmathur1234Noch keine Bewertungen

- Mgmt489 Kraft ADokument6 SeitenMgmt489 Kraft Arooba24Noch keine Bewertungen

- Donner Company Process Flow ChartDokument1 SeiteDonner Company Process Flow ChartzindalonerNoch keine Bewertungen

- B - Team3 - KECDokument10 SeitenB - Team3 - KECRakesh Santhapur100% (1)

- DMOP Make-Up Exam 2016Dokument12 SeitenDMOP Make-Up Exam 2016Saurabh Kumar GautamNoch keine Bewertungen

- Precise Software Solutions Case StudyDokument3 SeitenPrecise Software Solutions Case StudyKrishnaprasad ChenniyangirinathanNoch keine Bewertungen

- Assignment 1 Report on Commercializing Technotronics' X-27 MagnetDokument8 SeitenAssignment 1 Report on Commercializing Technotronics' X-27 MagnetVinayNoch keine Bewertungen

- Emergent Technologies perceptual map insightsDokument3 SeitenEmergent Technologies perceptual map insightsAnyone SomeoneNoch keine Bewertungen

- Group 2 - Sattve E TechDokument12 SeitenGroup 2 - Sattve E TechMohanapriya JayakumarNoch keine Bewertungen

- Leitax 19110207Dokument2 SeitenLeitax 19110207Ghulam Mehr Ali ShahNoch keine Bewertungen

- OM - National Cranberry - TemplateDokument3 SeitenOM - National Cranberry - Templatebeta alpha gammaNoch keine Bewertungen

- MOS GAME MAXIMIZE PROFITS THROUGH PRODUCTION PLANNINGDokument2 SeitenMOS GAME MAXIMIZE PROFITS THROUGH PRODUCTION PLANNINGSiddharth BathlaNoch keine Bewertungen

- Intel Pentium Chip Flaw AccountingDokument1 SeiteIntel Pentium Chip Flaw AccountingShaheen MalikNoch keine Bewertungen

- WAC-P16052 Dhruvkumar-West Lake Case AnalysisDokument7 SeitenWAC-P16052 Dhruvkumar-West Lake Case AnalysisDHRUV SONAGARANoch keine Bewertungen

- Karnataka Engineering CaseDokument5 SeitenKarnataka Engineering CaseJSNoch keine Bewertungen

- Rupesh Kumar Gupta-1421229 (Conglomerate Inc Case Study)Dokument8 SeitenRupesh Kumar Gupta-1421229 (Conglomerate Inc Case Study)RupeshGupta50% (2)

- Case Bidding For Antamina: This Study Resource Was Shared ViaDokument6 SeitenCase Bidding For Antamina: This Study Resource Was Shared ViaRishavLakraNoch keine Bewertungen

- Barilla's JITD Strategy vs Toyota's JIT StrategyDokument18 SeitenBarilla's JITD Strategy vs Toyota's JIT Strategychocobearsweets100% (1)

- Barco Case AnalysisDokument2 SeitenBarco Case Analysisaparna jethaniNoch keine Bewertungen

- PVT Case Analysis PDFDokument3 SeitenPVT Case Analysis PDFshivrinderNoch keine Bewertungen

- Quiz 2Dokument7 SeitenQuiz 2clindo2Noch keine Bewertungen

- Poster - LGBT in India - Legalize or Not ?Dokument1 SeitePoster - LGBT in India - Legalize or Not ?Prashant Pratap SinghNoch keine Bewertungen

- SDEC ASsignment 1Dokument2 SeitenSDEC ASsignment 1Prashant Pratap SinghNoch keine Bewertungen

- Casturn Systems ExhibitsDokument16 SeitenCasturn Systems ExhibitsPrashant Pratap Singh0% (1)

- Memo - GSBCDokument3 SeitenMemo - GSBCPrashant Pratap SinghNoch keine Bewertungen

- Note CW SavingsDokument8 SeitenNote CW SavingsSushrut JoshiNoch keine Bewertungen

- Case TypesDokument9 SeitenCase TypesPrashant Pratap SinghNoch keine Bewertungen

- Operation Assignment 2Dokument20 SeitenOperation Assignment 2Prashant Pratap SinghNoch keine Bewertungen

- Huron Absorption Costing Problem and TemplateDokument6 SeitenHuron Absorption Costing Problem and TemplatePrashant Pratap SinghNoch keine Bewertungen

- Solar Power Plants - FAqsDokument5 SeitenSolar Power Plants - FAqsar.ryanortigasNoch keine Bewertungen

- Llbean Inclass2014Dokument32 SeitenLlbean Inclass2014Prashant Pratap SinghNoch keine Bewertungen

- Formula Sheet For Mid-Term ExamDokument4 SeitenFormula Sheet For Mid-Term ExamPrashant Pratap SinghNoch keine Bewertungen

- 3b Extensive-Form GamesDokument17 Seiten3b Extensive-Form GamesMuhammad Ramzan100% (1)

- Formula Sheet For Mid-Term ExamDokument4 SeitenFormula Sheet For Mid-Term ExamPrashant Pratap SinghNoch keine Bewertungen

- Para JumblesDokument2 SeitenPara JumblesPrashant Pratap SinghNoch keine Bewertungen

- OPMG Group Case 1 - L11Dokument11 SeitenOPMG Group Case 1 - L11Prashant Pratap SinghNoch keine Bewertungen

- Emotiv Systems IncDokument2 SeitenEmotiv Systems IncPrashant Pratap Singh100% (1)

- IMD ClassDokument12 SeitenIMD ClassrlyunqueNoch keine Bewertungen

- A Deeper Look at Uber's Dynamic Pricing Model - AbovethecrowdDokument11 SeitenA Deeper Look at Uber's Dynamic Pricing Model - AbovethecrowdPrashant Pratap SinghNoch keine Bewertungen

- Amazon InvoiceDokument1 SeiteAmazon InvoiceChandra BhushanNoch keine Bewertungen

- Recruitment On The InternetDokument8 SeitenRecruitment On The InternetbgbhattacharyaNoch keine Bewertungen

- Vak Sept. 16Dokument28 SeitenVak Sept. 16Muralidharan100% (1)

- Lec 2Dokument10 SeitenLec 2amitava deyNoch keine Bewertungen

- Wagner Group Rebellion - CaseStudyDokument41 SeitenWagner Group Rebellion - CaseStudyTp RayNoch keine Bewertungen

- Definition, Nature, Scope, Subject MatterDokument7 SeitenDefinition, Nature, Scope, Subject MatterNikon SonuNoch keine Bewertungen

- Late Birth Registration Form for KenyaDokument2 SeitenLate Birth Registration Form for KenyaSarati80% (5)

- PW Show Daily at Frankfurt Day 1Dokument68 SeitenPW Show Daily at Frankfurt Day 1Publishers WeeklyNoch keine Bewertungen

- Hitachi Energy BESS PQpluSDokument9 SeitenHitachi Energy BESS PQpluSelpancaseroNoch keine Bewertungen

- Ensuring Ethical Supply ChainsDokument19 SeitenEnsuring Ethical Supply ChainsAbhishekNoch keine Bewertungen

- Resume for College Professor PositionDokument3 SeitenResume for College Professor PositionYours PharmacyNoch keine Bewertungen

- Heaven and Hell in The ScripturesDokument3 SeitenHeaven and Hell in The ScripturesOvidiu PopescuNoch keine Bewertungen

- Barangay SindalanDokument1 SeiteBarangay SindalanAna GNoch keine Bewertungen

- Romanian Society For Lifelong Learning Would Like To Inform You AboutDokument2 SeitenRomanian Society For Lifelong Learning Would Like To Inform You AboutCatalin MihailescuNoch keine Bewertungen

- Tiket Kemahasiswaan Makasar1Dokument4 SeitenTiket Kemahasiswaan Makasar1BLU UnramNoch keine Bewertungen

- ASAP Current Approved Therapists MDokument10 SeitenASAP Current Approved Therapists MdelygomNoch keine Bewertungen

- Social Teachings of The ChurchDokument85 SeitenSocial Teachings of The ChurchJesza IgnacioNoch keine Bewertungen

- Pak Steel Product Price ListDokument6 SeitenPak Steel Product Price ListHamid NaveedNoch keine Bewertungen

- MPRC - OGSE100 FY2020 Report - 0Dokument48 SeitenMPRC - OGSE100 FY2020 Report - 0adamNoch keine Bewertungen

- Hanna Fenichel Pitkin - Fortune Is A Woman - Gender and Politics in The Thought of Nicollo Machiavelli - With A New Afterword (1999)Dokument388 SeitenHanna Fenichel Pitkin - Fortune Is A Woman - Gender and Politics in The Thought of Nicollo Machiavelli - With A New Afterword (1999)Medbh HughesNoch keine Bewertungen

- Group 1 ResearchDokument28 SeitenGroup 1 ResearchKrysler EguiaNoch keine Bewertungen

- Literature ReviewDokument6 SeitenLiterature Reviewapi-549249112Noch keine Bewertungen

- International Business Opportunities and Challenges Vol 2 1St Edition Carpenter Test Bank Full Chapter PDFDokument40 SeitenInternational Business Opportunities and Challenges Vol 2 1St Edition Carpenter Test Bank Full Chapter PDFKathrynBurkexziq100% (7)

- TheoriesDokument87 SeitenTheoriesCzari MuñozNoch keine Bewertungen

- Classical Dances of India Everything You Need To Know AboutDokument18 SeitenClassical Dances of India Everything You Need To Know AboutmohammadjakeerpashaNoch keine Bewertungen

- Chap 1 ScriptDokument9 SeitenChap 1 ScriptDeliza PosadasNoch keine Bewertungen

- Clearlake City Council PacketDokument57 SeitenClearlake City Council PacketLakeCoNewsNoch keine Bewertungen

- Blades of Illusion - Crown Service, Book 2 First Five ChaptersDokument44 SeitenBlades of Illusion - Crown Service, Book 2 First Five ChaptersTerah Edun50% (2)