Beruflich Dokumente

Kultur Dokumente

201611191476157

Hochgeladen von

Nebojša JoksimovićCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

201611191476157

Hochgeladen von

Nebojša JoksimovićCopyright:

Verfügbare Formate

Operation manual for BLHeli_S

SiLabs Rev16.x

BLHeli_S firmware is the next generation code, following the

base BLHeli code.

BLHeli_S is designed for superior performance in multirotors,

and uses hardware generated motor pwm for smooth throttle

response and silent operation.

All codes use damped light mode.

Damped light does regenerative braking, causing very fast

motor retardation, and inherently also does active

freewheeling.

The code supports features to prevent sync loss. There are

tuneable parameters that can make the code run well even in

the most demanding situations, although default settings will

work excellently in normal operating environments.

The code supports regular 1-2ms pulse width input, as well as

Oneshot125 (125-250us), Oneshot42 (41.7-83.3us) and

Multshot (5-25us).

The input signal is automatically detected by the ESC upon

power up.

The code also supports a beacon functionality, where the ESC

will start beeping after a given time of zero throttle. This can

be very useful for finding lost crafts.

Document rev 16.x

Code naming convention:

The BLHeli_S codes are named with a letter, another letter and two numbers, in

addition to the revision. For example "A_L_10_REV16_0.HEX".

The first letter denotes the pinout of the MCU.

The second letter is either L or H. L is for 24MHz MCUs, and H is for 48MHz

MCUs.

The two numbers denote the FET switching deadtime. The unit is 20.4ns.

Some FET drivers have adaptive FET deadtime control, and for these 00 is used

to denote FET switching deadtime.

Document rev 16.x

Programming parameters:

Startup power:

Startup power can be set to relative values from 0.031 to 1.5. This is the maximum power that

is allowed during startup. Actual applied power depends on throttle input, and can be lower,

but the minimum level is a quarter of the maximum level.

Startup power also affects bidirectional operation, as the parameter is used to limit the power

applied during direction reversal.

Commutation timing:

Commutation timing can be set to low/mediumlow/medium/mediumhigh/high, that

correspond to 00/7.50/150/22.50/300 timing advance.

Typically a medium setting will work fine, but if the motor stutters it can be beneficial to

change timing. Some motors with high inductance can have a very long commutation

demagnetization time. This can result in motor stop or stutter upon quick throttle increase,

particularly when running at a low rpm. Setting timing to high will allow more time for

demagnetization, and often helps.

Demag compensation:

Demag compensation is a feature to protect from motor stalls caused by long winding

demagnetization time after commutation. The typical symptom is motor stop or stutter upon

quick throttle increase, particularly when running at a low rpm. As mentioned above, setting

high commutation timing normally helps, but at the cost of efficiency.

Demag compensation is an alternative way of combating the issue. First of all, it detects when

a demag situation occurs.

- In this situation, there is no info on motor timing, and commutation proceeds blindly

with a predicted timing.

- In addition to this, motor power is cut off some time before the next commutation.

A metric is calculated that indicates how severe the demag situation is. The more severe the

situation, the more power is cut off.

When demag compensation is set to off, power is never cut.

When setting it to low or high, power is cut. For a high setting, power is cut more

aggressively.

Generally, a higher value of the compensation parameter gives better protection.

If demag compensation is set too high, maximum power can be somewhat reduced.

Direction:

Rotation direction can be set to fwd/rev/bidirectional fwd/bidirectional rev.

In bidirectional mode, center throttle is zero and above is fwd rotation and below is reverse

rotation. When bidirectional operation is selected, programming by TX is disabled.

Document rev 16.x

Beep strength:

Sets the strength of beeps under normal operation.

Beacon strength:

Sets the strength of beeps when beeping beacon beeps. The ESC will start beeping beacon

beeps if the throttle signal has been zero for a given time. Note that setting a high beacon

strength can cause hot motors or ESCs!

Beacon delay:

Beacon delay sets the delay before beacon beeping starts.

Programming by TX:

If disabled, throttle calibration is disabled.

Min throttle, max throttle and center throttle:

These settings set the throttle range of the ESC. Center throttle is only used for bidirectional

operation. The values given for these settings are for a normal 1000us to 2000us input signal,

and for the other input signals, the values must be scaled.

Thermal protection:

Thermal protection can be enabled or disabled.

Low RPM power protect:

Power limiting for low RPMs can be enabled or disabled. Disabling it can be necessary in

order to achieve full power on some low kV motors running on a low supply voltage.

However, disabling it increases the risk of sync loss, with the possibility of toasting motor or

ESC.

Brake on stop:

Brake on stop can be enabled or disabled. When enabled, brake will be applied when throttle

is zero. For nonzero throttle, this setting has no effect.

LED control:

LEDs can be controlled on ESCs that support it. Up to 4 LEDs can be turned on or off.

Document rev 16.x

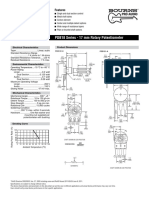

Arming sequence:

The figure below shows an example of throttle value versus time.

100%

Max throttle

during arm

Arm start Arm end

Power on 1 low beep

3 beeps 1 high beep Run

0% Time

At power on, the ESC beeps 3 beeps.

When throttle signal is detected, it beeps one low tone beep. This signals the start of the arming

sequence.

Then, when or if throttle is zero, it beeps one high tone beep. This signals the end of the arming

sequence.

Also, if 100% throttle is detected during the arming sequence, the ESC starts throttle calibration.

If the esc is armed and sees zero throttle for a given time, it beeps beacon beeps, which are about a

beep per three seconds.

Input signal:

Available throttle calibration range is from 1000us to 2000us, and the difference between minimum

and maximum throttle must be more than 140us (70us in bidirectional mode). If a calibration is

done where the difference is less than 140us (70us), the maximum will be shifted so that the

difference is 140us (70us).

Oneshot125 mode works just the same as regular 1-2ms mode, the only difference is that all timing

is divided by 8. And the same for Oneshot42, where all timing is further divided by 3. Multishot

also works similarly, except the input signal range is 5-25us.

The input signal is always sampled with the MCU clock, at 24MHz or 48MHz.

Thermal protection:

The ESC measures temperature within the MCU and limits motor power if the temperature is too

high. Motor power is limited in four steps:

- If the temperature is above 1400C, motor power is limited to 75%.

- If the temperature is above 1450C, motor power is limited to 50%.

- If the temperature is above 1500C, motor power is limited to 25%.

- If the temperature is above 1550C, motor power is limited to 0%.

Document rev 16.x

Stall protection:

If the motor has attempted to start but not succeeded for a few seconds, it will stop attempting and

wait for throttle to be zeroed before attempting again.

Regenerative braking / active freewheeling:

Damped light mode is implemented by doing regenerative braking, and inherently active

freewheeling is also implemented.

Then losses due to braking are counteracted by the reduced losses of active freewheeling.

Motor PWM:

The motor PWM frequency is always 24kHz. The resolution is 2048 steps for MCUs running at

48MHz on ESCs that have automatic deadtime control. On ESCs that have fixed deadtime, the

PWM resolution is 1024 steps. For MCUs running at 24MHz, the PWM resolutions are half.

Maximum speeds:

For ESCs with a 24MHz MCU, maximum speed is limited to 350k eRPM, at which point power to

the motor is limited. For ESCs with an MCU running at 48MHz, this number is 500k eRPM.

Document rev 16.x

Beeps - Normal operation:

Power up:

Once

Throttle signal detected (arming sequence start):

Once

Zero throttle detected (arming sequence end):

Once

After this, the motor will run.

Document rev 16.x

Beeps - Throttle calibration:

Power up:

Once

Throttle signal detected (arming sequence start):

Once

When throttle is above midstick (measuring max throttle):

While measuring

If throttle is above midstick for 3 seconds:

Once

This beep sequence indicates that max throttle has been stored

When throttle is below midstick (measuring min throttle):

While measuring

If throttle is below midstick for 3 seconds:

Once

This beep sequence indicates that min throttle has been stored

At this point throttle calibration values are stored. You may remove power from the ESC, or just

continue running your ESC.

Document rev 16.x

Revision history:

- Rev16.0 Started. Built upon rev 14.5 of base code

Using hardware pwm for very smooth throttle response, silent running and support of

very high rpms

Implemented reverse bidirectional mode

Implemented separate throttle gains fwd and rev in bidirectional mode

Implemented support for Oneshot42 and Multishot

Document rev 16.x

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- BYO - Wine Maker - Beginner's Guide To Win - 2004 PDFDokument46 SeitenBYO - Wine Maker - Beginner's Guide To Win - 2004 PDFNebojša JoksimovićNoch keine Bewertungen

- Design of SpindleDokument36 SeitenDesign of SpindleAMIT SOLANKI0% (1)

- 5 Minute Practice PDFDokument1 Seite5 Minute Practice PDFNebojša JoksimovićNoch keine Bewertungen

- Straw-Bale Building - Home Power, IncDokument6 SeitenStraw-Bale Building - Home Power, IncNebojša JoksimovićNoch keine Bewertungen

- Handling of Turbine During EmergencyDokument17 SeitenHandling of Turbine During EmergencyManohar TatwawadiNoch keine Bewertungen

- The Cerebral Code Thinking and Thought in The Mosaics of The Mind 1998Dokument248 SeitenThe Cerebral Code Thinking and Thought in The Mosaics of The Mind 1998Roberto Arregui100% (2)

- Bergen Evans - The Natural History of NonsenseDokument147 SeitenBergen Evans - The Natural History of NonsenseJex SomosotNoch keine Bewertungen

- RENK MAAG Turbo GearboxesDokument12 SeitenRENK MAAG Turbo Gearboxeshumayun121100% (1)

- 8.16 METO 500L Steam Brewery Equipment Con - 999bao Cang WangDokument22 Seiten8.16 METO 500L Steam Brewery Equipment Con - 999bao Cang WangNebojša JoksimovićNoch keine Bewertungen

- Lee Asher Card Magic Like The Asher Twist, PDFDokument1 SeiteLee Asher Card Magic Like The Asher Twist, PDFNebojša JoksimovićNoch keine Bewertungen

- Bose Response in The Living and Non Living PDFDokument228 SeitenBose Response in The Living and Non Living PDFNebojša JoksimovićNoch keine Bewertungen

- 5 Minute Practice PDFDokument1 Seite5 Minute Practice PDFNebojša JoksimovićNoch keine Bewertungen

- 4-way switch wiring diagram for a 2 pickup guitarDokument1 Seite4-way switch wiring diagram for a 2 pickup guitarNebojša JoksimovićNoch keine Bewertungen

- Standard Telecaster Wiring: Location For Ground (Earth) ConnectionsDokument1 SeiteStandard Telecaster Wiring: Location For Ground (Earth) ConnectionsNebojša JoksimovićNoch keine Bewertungen

- Tele Standard PDFDokument1 SeiteTele Standard PDFNebojša JoksimovićNoch keine Bewertungen

- Mustang With 2 Single Coil Sized Humbuckers: Red & White Wires Get Soldered Together and Taped OffDokument1 SeiteMustang With 2 Single Coil Sized Humbuckers: Red & White Wires Get Soldered Together and Taped OffNebojša JoksimovićNoch keine Bewertungen

- AlphaZero en PDFDokument14 SeitenAlphaZero en PDFLeandro RodríguezNoch keine Bewertungen

- Hipshot Guitar Saddle DimensionsDokument1 SeiteHipshot Guitar Saddle DimensionsNebojša JoksimovićNoch keine Bewertungen

- 400GSV PDFDokument1 Seite400GSV PDFNebojša JoksimovićNoch keine Bewertungen

- Magnet WarmanDokument1 SeiteMagnet WarmanNebojša JoksimovićNoch keine Bewertungen

- AlphaZero en PDFDokument14 SeitenAlphaZero en PDFLeandro RodríguezNoch keine Bewertungen

- 5 Minute Practice TipsDokument1 Seite5 Minute Practice TipsNebojša JoksimovićNoch keine Bewertungen

- 5 Minute Practice PDFDokument1 Seite5 Minute Practice PDFNebojša JoksimovićNoch keine Bewertungen

- 79 Patch Cables Compared and TestedDokument9 Seiten79 Patch Cables Compared and TestedMiguel DiasNoch keine Bewertungen

- 2 Singles 1 Volume - 1 Tone 4 Way Blade: Location For Ground (Earth) ConnectionsDokument1 Seite2 Singles 1 Volume - 1 Tone 4 Way Blade: Location For Ground (Earth) ConnectionsNebojša JoksimovićNoch keine Bewertungen

- Sava VukoBournssavljeGradnja Tamburev - Vojvodjanska TamburaDokument5 SeitenSava VukoBournssavljeGradnja Tamburev - Vojvodjanska TamburaNebojša JoksimovićNoch keine Bewertungen

- 5 Min Practice 2Dokument2 Seiten5 Min Practice 2Nebojša JoksimovićNoch keine Bewertungen

- Whipper Clipper: Bill of Materials Resistors CapacitorsDokument5 SeitenWhipper Clipper: Bill of Materials Resistors CapacitorsNebojša JoksimovićNoch keine Bewertungen

- Tele 2S 4B 1V 1TDokument1 SeiteTele 2S 4B 1V 1TNebojša JoksimovićNoch keine Bewertungen

- Whipped Llama: Design by Erik VincentDokument6 SeitenWhipped Llama: Design by Erik VincentNebojša JoksimovićNoch keine Bewertungen

- Advanced Bottle ConditioningDokument3 SeitenAdvanced Bottle ConditioningRade StevanovicNoch keine Bewertungen

- Manual Canon Powershot - A510Dokument163 SeitenManual Canon Powershot - A510Jonas BarrosNoch keine Bewertungen

- All in One MC 50 (2023)Dokument98 SeitenAll in One MC 50 (2023)YashuNoch keine Bewertungen

- Ag machineryDokument4 SeitenAg machineryvinzyyNoch keine Bewertungen

- Running Procedure: Voestalpine Tubulars GMBH & Co KG Voestalpine Tubulars GMBH & Co KGDokument16 SeitenRunning Procedure: Voestalpine Tubulars GMBH & Co KG Voestalpine Tubulars GMBH & Co KGSumesh DethanNoch keine Bewertungen

- Working Principle of Electric GeneratorDokument3 SeitenWorking Principle of Electric Generatorsajjad ali0% (1)

- MECE680 2013 FallDokument2 SeitenMECE680 2013 FallAmr BalbolaNoch keine Bewertungen

- Limit Switches: FeaturesDokument2 SeitenLimit Switches: FeaturesNoUserNameNoch keine Bewertungen

- Darshan BLDC Market Anaylsysic PDFDokument48 SeitenDarshan BLDC Market Anaylsysic PDFPatidar Darshan PatelNoch keine Bewertungen

- ACS Unit 001Dokument9 SeitenACS Unit 001sarifnNoch keine Bewertungen

- Thermo Heat PumpDokument15 SeitenThermo Heat PumpAkshay BhadangeNoch keine Bewertungen

- Cts Driver Cum Mech (LMV) - Cts - nsqf-3Dokument37 SeitenCts Driver Cum Mech (LMV) - Cts - nsqf-3Rohit RumadeNoch keine Bewertungen

- Gate Flight Mechanics by VayushastraDokument36 SeitenGate Flight Mechanics by Vayushastraudaykumar100% (4)

- Speed of Sound Increases With TemperatureDokument12 SeitenSpeed of Sound Increases With TemperatureAdjazent BuildersNoch keine Bewertungen

- 5 - Structural Mechanics PDFDokument102 Seiten5 - Structural Mechanics PDFeye4aneye1989Noch keine Bewertungen

- FSNF ActuatorsDokument4 SeitenFSNF Actuatorssbalan6949Noch keine Bewertungen

- Grade Markings For Steel Bolts and ScrewsDokument3 SeitenGrade Markings For Steel Bolts and Screwsrexie2canos8964Noch keine Bewertungen

- General Ventilation RequirementsDokument19 SeitenGeneral Ventilation RequirementsNelson VargasNoch keine Bewertungen

- Kershaw 12-12BridgeCraneDokument3 SeitenKershaw 12-12BridgeCranecamelia_pirjan5776Noch keine Bewertungen

- BrochureDokument131 SeitenBrochurestarmusic1013Noch keine Bewertungen

- Cover Handbook Mechanical 1718Dokument180 SeitenCover Handbook Mechanical 1718t0kbilalNoch keine Bewertungen

- Arctic Cat 2008 DVX 50 Utility Service ManualDokument10 SeitenArctic Cat 2008 DVX 50 Utility Service Manualsergio100% (45)

- PUNCHING STRESS CHECK COMPARISON OF ECP203 AND ACI318Dokument10 SeitenPUNCHING STRESS CHECK COMPARISON OF ECP203 AND ACI318Abdelhamid MaymonNoch keine Bewertungen

- Finals TVL-12 2019-2020Dokument3 SeitenFinals TVL-12 2019-2020Mark Emerson MarinNoch keine Bewertungen

- Robotics With: ROS WorkshopDokument30 SeitenRobotics With: ROS WorkshopViba R UdupaNoch keine Bewertungen

- Fiitjee: Answers, Hints & SolutionsDokument10 SeitenFiitjee: Answers, Hints & SolutionsZayanmalikNoch keine Bewertungen

- Ec Axial Fan - Axiblade: Nominal DataDokument1 SeiteEc Axial Fan - Axiblade: Nominal DataAykut BacakNoch keine Bewertungen

- 00 en Drilling 05-2022 No Mark Ups 01Dokument4 Seiten00 en Drilling 05-2022 No Mark Ups 01ihydraulicsNoch keine Bewertungen

- Ej Vol Control Pelu oDokument8 SeitenEj Vol Control Pelu oPablo Martínez CavieresNoch keine Bewertungen