Beruflich Dokumente

Kultur Dokumente

Crane Insp Work Sheet

Hochgeladen von

Pao Barillas100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

148 Ansichten3 SeitenAccording safety manual OSHA

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenAccording safety manual OSHA

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

148 Ansichten3 SeitenCrane Insp Work Sheet

Hochgeladen von

Pao BarillasAccording safety manual OSHA

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 3

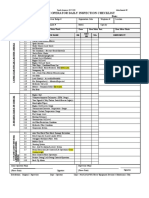

SAFETY INSPECTION FOR CRANES AND HOISTING EQUIPMENT

USACE, Galveston District

Safety and Health Requirements Manual (EM 385-1-1 15/sep/2008)

Contract No. Date of Inspection:

Prime contractor Name:

Inspector Name/signature:

Make: Name of competent person:

Model: Signature of CP/QP:

Serial no.

CRANE INSPECTION CHECKLIST yesno

no n/a

1 Inspector Qualification and Certification - 16.D.02

2 Operator manual available in the cab - 16.A.03

3 Documents of certified mechanic inspection -16.A.02

4 Does equipment have and in working condition: 16.A.08

A- Fuel gage

B- Auditable warning devise (horn)

C- Adequate rearview mirrors

D- Non-slip surface on steps

E- Power operator starting device

F- A seat for the operator

G- At minimum two head lights and two taillights

H- Windshield, windows and door

I- A fire extinguisher

J- A Back or motion alarm

K- Rollover protective structures-(ROPS)

5 Operator manual for hydraulic equipment and attachment- 16.A.10

6 Are all guarding and safety devices in place- 16.A.11

7 Operator qualification and certificated available- 16.B.01

8 Is wire rope in good condition in accordance with- 16.D.12

9 Are all documents available in the cab- 16.G.01

10 Is load test in accordance with- 16.F.03.b

11 Is a wind-indicating device available at the cab- 16.I.01

Attachments:

AHA for crane set-up and set down

Communications system

Electrical clearance plan

Critical lift plan

SWG form 1192-J Previous Edition Obsolete 19/Aug/2010

Report of Crane Test:

Government Owned:

Contractor Owned/Rented: If Rented who Owned:

Length of boom:

Manufacture Rate Capacity:

Max Work Load Anticipated: Tons : Radius Ft:

Position # 1 Load: Radius:

Position # 2 Load: Radius:

Position # 3 Load: Radius:

Position # 4 Load: Radius:

Results of Performance Test:

Note: Performance load test shall be conducted in accordance with the manufacturer's

recommendations. Loads test shall not exceed 100% of the manufacturer's load rating capacity

chart at the configuration of the test.

The test shall consist of lifting, lowering, swinging and braking the test load through all

positions and operations normally performed to demonstrated the equipment's ability to safety

maneuver the load.

Written reports of the rated load test, showing test procedures and confirming the adequacy

of repairs or alterations, shall be maintains with the crane, derrick or at the on-site project office.

Condition of following: S= serviceable U= unserviceable N/A= non-applicable S U N/A

Load Chart

Boom hoist kick out

Interior clean and oil free

Hearing protection available

Operable warning device

Anti-two blocking

load indicating device

Bulkhead lifting device

Boom angle indicator

Drum rotation sensor

Engine throttle and controls

Swing controls, clutches and brakes

Swing lock

Boom hoist controls, clutches and brakes

Main drum controls, clutches and brakes

Aux. drum controls, clutches and brakes

Travel controls, clutches and brakes

Master clutch

Hoist lines- main, aux. and boom

Hooks, blocks

Drums

Rope anchor on drum

Shavers, rollers, equalizers

Crawler chain, tracks, sprockets, rollers

Rotating parts guarded

Mast jib and live mast

SWG form 1192-J Previous Edition Obsolete 19/Aug/2010

Condition of following: (Continuing)

Boom and jib:

Cords, lacings, pins and cotter

Welds, foot and hinge pins

Ware pads and blackstrap

Boom stop

Remarks:

All dents, scratches or damage that do not interfere with the safe operation of the equipment

1- ___________________________________________________________________________________

2- ___________________________________________________________________________________

3- ___________________________________________________________________________________

4- ___________________________________________________________________________________

5- ___________________________________________________________________________________

Corrections of Deficiencies and date corrected:

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

Note: Crane shall not be utilized until all deficiencies have been corrected. If at anytime the crane

or derrick is removed from and subsequently returned to the project it shall be re-inspected

and re-certified prior to use.

Name and Signatures:

Prime Contractor Superintendent: ____________________ ____________________________

Prime Contractor Quality Control Rep: ___________________ __________________________

Subcontractor Forman: ___________________ _____________________________

Crane Operator: _____________________ ______________________________

QA/PE : _______________________ _________________________________

SWG form 1192-J Previous Edition Obsolete 19/Aug/2010

Das könnte Ihnen auch gefallen

- Mobile CranesDokument7 SeitenMobile CranesEr Faiyaz Ahmed100% (1)

- Guidance Inspection Crane RuiDokument34 SeitenGuidance Inspection Crane RuiRonniNoch keine Bewertungen

- Crane Inspection PDFDokument2 SeitenCrane Inspection PDFAniekanNoch keine Bewertungen

- 45 AS-F-HSE 045 - Inspection Report TrucksDokument2 Seiten45 AS-F-HSE 045 - Inspection Report TrucksJHUPEL ABARIAL100% (1)

- Inspection Checklist Overhead Crane PDFDokument2 SeitenInspection Checklist Overhead Crane PDFMOST PASONNoch keine Bewertungen

- 2009 Crane Start Up Inspection FormDokument3 Seiten2009 Crane Start Up Inspection Formsaeed ghafooriNoch keine Bewertungen

- BP 42 Guidance On The Safe Use of Container Lifting LugsDokument7 SeitenBP 42 Guidance On The Safe Use of Container Lifting LugsGaniyuNoch keine Bewertungen

- CCU Cargo ChecklistDokument1 SeiteCCU Cargo ChecklistCostin100% (1)

- Crane Daily Inspection Checklist-Sa 9466Dokument1 SeiteCrane Daily Inspection Checklist-Sa 9466Ricardo DalisayNoch keine Bewertungen

- DailyCranePre OpChecklist PDFDokument1 SeiteDailyCranePre OpChecklist PDFPablo Hidalgo ValenzuelaNoch keine Bewertungen

- Crane Checklist InspectionDokument1 SeiteCrane Checklist InspectionlinkencielNoch keine Bewertungen

- Unlocked - F031 - Tower Crane Inspection Report - Rev 0Dokument2 SeitenUnlocked - F031 - Tower Crane Inspection Report - Rev 0Minami ChiengNoch keine Bewertungen

- Liebherr Crane Inspection SheetDokument10 SeitenLiebherr Crane Inspection SheetDon StorttsNoch keine Bewertungen

- 3 Mobile Crane ChecklistDokument5 Seiten3 Mobile Crane ChecklistEriq100% (1)

- Crane Checklist PDFDokument2 SeitenCrane Checklist PDFWaqar IftikharNoch keine Bewertungen

- 006 Mobile Crane Pre-Use Checklist - NO NEED FOR UPDATEDokument1 Seite006 Mobile Crane Pre-Use Checklist - NO NEED FOR UPDATELijo JohnNoch keine Bewertungen

- Inspection Checklist Overhead CraneDokument2 SeitenInspection Checklist Overhead CraneEzzaddeen albraikiNoch keine Bewertungen

- Form-067-Weekly Crane Inspection ChecklistDokument2 SeitenForm-067-Weekly Crane Inspection Checklistshamroz khanNoch keine Bewertungen

- Mewps Operator Practical Only Assessment Sheets 2021 MercuryDokument4 SeitenMewps Operator Practical Only Assessment Sheets 2021 MercuryWILLIAM KEAGUE100% (1)

- Crane Pre Mobilization Check ListDokument2 SeitenCrane Pre Mobilization Check ListvadivvelkavinNoch keine Bewertungen

- Inspection Checklist Overhead CraneDokument2 SeitenInspection Checklist Overhead CraneMohammad Safdar SadatNoch keine Bewertungen

- Crane Monthly Inspection FormDokument5 SeitenCrane Monthly Inspection FormMohammad Zaenal ArifinNoch keine Bewertungen

- Mobile Crane Inspection ChecklistDokument1 SeiteMobile Crane Inspection ChecklistSaumya Siddhantha Choudhury100% (1)

- Borang Pemeriksaan Air KompressorDokument1 SeiteBorang Pemeriksaan Air KompressorAndara Asifa YudianaNoch keine Bewertungen

- Products - Monthly Checklist MCDokument2 SeitenProducts - Monthly Checklist MCDiegoCaicedo1982Noch keine Bewertungen

- Check List For Mobile Air CompressorDokument1 SeiteCheck List For Mobile Air CompressorSaravanan JambunathanNoch keine Bewertungen

- Crane Inspection Check ListDokument2 SeitenCrane Inspection Check ListKhuda BukshNoch keine Bewertungen

- Cert - Mobile Crane 30T - LOLER - Model Rok300Dokument2 SeitenCert - Mobile Crane 30T - LOLER - Model Rok300Rafael Lecu100% (1)

- 007 Mobile Crane ChecklistDokument2 Seiten007 Mobile Crane ChecklistJoshua ThomasNoch keine Bewertungen

- February 2012 Wire Rope ExchangeDokument80 SeitenFebruary 2012 Wire Rope ExchangeWire Rope ExchangeNoch keine Bewertungen

- Operator Daily ChecklistDokument5 SeitenOperator Daily ChecklistkrissregionNoch keine Bewertungen

- Truck Load-Out ChecklistDokument3 SeitenTruck Load-Out ChecklistIsaac Anthony100% (2)

- 4818 DB1 OpsMan R0Dokument661 Seiten4818 DB1 OpsMan R0sep650cengrNoch keine Bewertungen

- Mobile CraneDokument2 SeitenMobile CraneSHARAFUDHEEN TKNoch keine Bewertungen

- Mobile Elevating Work Platform (MEWP) Pre-Use Inspection: Power Off Checks Power On ChecksDokument1 SeiteMobile Elevating Work Platform (MEWP) Pre-Use Inspection: Power Off Checks Power On Checksfaisal nadeemNoch keine Bewertungen

- Check List of Mobil CraneDokument3 SeitenCheck List of Mobil CraneZulhaidy Salim100% (1)

- Liebherr Crane Inspection SheetDokument9 SeitenLiebherr Crane Inspection SheetDon Stortts0% (1)

- Tower Cranes CommisioningDokument15 SeitenTower Cranes Commisioningpammu18Noch keine Bewertungen

- Crane Inspection ChecklistDokument1 SeiteCrane Inspection ChecklistsudhakarNoch keine Bewertungen

- Tank Container Inspection Handbook TankDokument90 SeitenTank Container Inspection Handbook TankSergiy Kovernik100% (2)

- Cranes & ComponentsDokument13 SeitenCranes & ComponentsdenyNoch keine Bewertungen

- EHSDP0120.9 Crane Operation Pre-Lift ChecklistDokument1 SeiteEHSDP0120.9 Crane Operation Pre-Lift Checklistshravani mangalpalliNoch keine Bewertungen

- Lifting Plan Counter WeightDokument1 SeiteLifting Plan Counter WeightAzhar RimaNoch keine Bewertungen

- HoistingRiggingPlan PDFDokument5 SeitenHoistingRiggingPlan PDFHadiwinata DjakariaNoch keine Bewertungen

- Crane Hoist and Rigging SafetyDokument36 SeitenCrane Hoist and Rigging SafetySalim Mohd RazNoch keine Bewertungen

- Rigging Up Checklist: Rig ModelDokument2 SeitenRigging Up Checklist: Rig Model89simbuNoch keine Bewertungen

- Monthly Crane Inspection ChecklistDokument2 SeitenMonthly Crane Inspection Checklistslamet4riadiNoch keine Bewertungen

- B Lifting Plan Using LorryDokument1 SeiteB Lifting Plan Using LorrySyed Fawad ShahNoch keine Bewertungen

- Mobile Crane Test Procedure.Dokument4 SeitenMobile Crane Test Procedure.Deepak GehlotNoch keine Bewertungen

- Lifting Checklist - 28 Nov 2013 (Final)Dokument1 SeiteLifting Checklist - 28 Nov 2013 (Final)Beste Ardıç ArslanNoch keine Bewertungen

- Service/ PPM Report - Generator: PTW NoDokument2 SeitenService/ PPM Report - Generator: PTW NoYasir MehmoodNoch keine Bewertungen

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDokument3 SeitenAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNoch keine Bewertungen

- Mobile Cranes Approval Checklist FinalDokument1 SeiteMobile Cranes Approval Checklist Finalzelda1022Noch keine Bewertungen

- 5855-Mooring Rope ChecklistDokument4 Seiten5855-Mooring Rope ChecklistSaptarshi Basu0% (1)

- Mobile Crane Operator Candidate Handbook - 120122aDokument33 SeitenMobile Crane Operator Candidate Handbook - 120122a전우영Noch keine Bewertungen

- Hydrojetting SafetyDokument5 SeitenHydrojetting SafetyHeryNoch keine Bewertungen

- Critical Lift PlanDokument2 SeitenCritical Lift PlanjeffotNoch keine Bewertungen

- 2AB Daily Check A319Dokument8 Seiten2AB Daily Check A319Umer JavedNoch keine Bewertungen

- C822444-COR-HS-FRM-0007 Lifting Equipment Inspection FormDokument2 SeitenC822444-COR-HS-FRM-0007 Lifting Equipment Inspection FormAndrianto BakriNoch keine Bewertungen

- tm1 1550 1689 CLDokument196 Seitentm1 1550 1689 CLJessica R LattimoreNoch keine Bewertungen

- Rigging and Pre Lift ChecklistDokument11 SeitenRigging and Pre Lift ChecklistPao Barillas100% (1)

- Osha 2254Dokument270 SeitenOsha 2254Allen Savage100% (4)

- Ufgs 09 96 00Dokument15 SeitenUfgs 09 96 00Pao BarillasNoch keine Bewertungen

- Whittemore Company Material Safety Data SheetDokument4 SeitenWhittemore Company Material Safety Data SheetPao BarillasNoch keine Bewertungen

- 4296-2c Initial Phase ChecklistDokument1 Seite4296-2c Initial Phase ChecklistPao BarillasNoch keine Bewertungen

- Grove RT522Dokument8 SeitenGrove RT522Pao BarillasNoch keine Bewertungen

- 4296-2c Initial Phase ChecklistDokument1 Seite4296-2c Initial Phase ChecklistPao BarillasNoch keine Bewertungen

- UFGS 01 74 19 Waste Management PlanDokument11 SeitenUFGS 01 74 19 Waste Management PlanPao BarillasNoch keine Bewertungen

- Technical Data 1Dokument3 SeitenTechnical Data 1Pao BarillasNoch keine Bewertungen

- Initial Phase ChecklistDokument1 SeiteInitial Phase ChecklistPao BarillasNoch keine Bewertungen

- Scaffolding: Self Inspection ChecklistDokument6 SeitenScaffolding: Self Inspection Checklistmyke_0101Noch keine Bewertungen

- ASTM D-2122 ASTM D-1599 ASTM D-2241 Sec. 8.6 ASTM D-2152 ASTM D1784 ASTM D2672Dokument2 SeitenASTM D-2122 ASTM D-1599 ASTM D-2241 Sec. 8.6 ASTM D-2152 ASTM D1784 ASTM D2672Pao BarillasNoch keine Bewertungen

- Translate - SRD 35Dokument1 SeiteTranslate - SRD 35Pao BarillasNoch keine Bewertungen

- Rigging and Pre Lift ChecklistDokument11 SeitenRigging and Pre Lift ChecklistPao Barillas100% (1)

- Terminos de Desarrollo AcusticoDokument5 SeitenTerminos de Desarrollo AcusticoPao BarillasNoch keine Bewertungen

- Hotels in GuatemalaDokument31 SeitenHotels in GuatemalaLuis Guti RodasNoch keine Bewertungen

- CBSE 10th ResultsDokument1 SeiteCBSE 10th ResultsAkshit SinghNoch keine Bewertungen

- Written Report SampleDokument16 SeitenWritten Report Sampleallanposo3Noch keine Bewertungen

- Fce Use of English 1 Teacher S Book PDFDokument2 SeitenFce Use of English 1 Teacher S Book PDFOrestis GkaloNoch keine Bewertungen

- Ethical Hacking IdDokument24 SeitenEthical Hacking IdSilvester Dian Handy PermanaNoch keine Bewertungen

- French Cuisine RecipeDokument6 SeitenFrench Cuisine RecipeJimmy AchasNoch keine Bewertungen

- A. Computed Only For A 2x2 Table B. 0 Cells (,0%) Have Expected Count Less Than 5. The Minimum Expected Count Is 3,40Dokument1 SeiteA. Computed Only For A 2x2 Table B. 0 Cells (,0%) Have Expected Count Less Than 5. The Minimum Expected Count Is 3,40harvey777Noch keine Bewertungen

- Visi RuleDokument6 SeitenVisi RuleBruce HerreraNoch keine Bewertungen

- Chapter 13 Current Liabilities Test Bank Versi 2Dokument72 SeitenChapter 13 Current Liabilities Test Bank Versi 2Slamet Tri PrastyoNoch keine Bewertungen

- Pyromet Examples Self StudyDokument2 SeitenPyromet Examples Self StudyTessa BeeNoch keine Bewertungen

- LP Week 8Dokument4 SeitenLP Week 8WIBER ChapterLampungNoch keine Bewertungen

- Method Statement FINALDokument61 SeitenMethod Statement FINALshareyhou67% (3)

- Worked Solution Paper5 A LevelDokument8 SeitenWorked Solution Paper5 A LevelBhoosan AncharazNoch keine Bewertungen

- 2015 NSPC Proposed Changes Book PDFDokument268 Seiten2015 NSPC Proposed Changes Book PDFMichelle Pinohermoso JabatNoch keine Bewertungen

- Clinical Skills TrainingDokument12 SeitenClinical Skills TrainingSri Wahyuni SahirNoch keine Bewertungen

- Land CrabDokument8 SeitenLand CrabGisela Tuk'uchNoch keine Bewertungen

- JMC MSDS Puraspec 1173 (GB)Dokument10 SeitenJMC MSDS Puraspec 1173 (GB)Benny Samsul B.Noch keine Bewertungen

- Dist - Propor.danfoss PVG32Dokument136 SeitenDist - Propor.danfoss PVG32Michal BujaraNoch keine Bewertungen

- Canon I-SENSYS MF411dw Parts CatalogDokument79 SeitenCanon I-SENSYS MF411dw Parts Catalogmarian100% (1)

- Docket - CDB Batu GajahDokument1 SeiteDocket - CDB Batu Gajahfatin rabiatul adawiyahNoch keine Bewertungen

- Aircraft Wiring Degradation StudyDokument275 SeitenAircraft Wiring Degradation Study320338Noch keine Bewertungen

- Chapter 4: Thermal ComfortDokument16 SeitenChapter 4: Thermal ComfortWengelNoch keine Bewertungen

- Collecting, Analyzing, & Feeding Back DiagnosticDokument12 SeitenCollecting, Analyzing, & Feeding Back DiagnosticCaroline Mariae TuquibNoch keine Bewertungen

- Zero Tolerance 2010Dokument16 SeitenZero Tolerance 2010Adrian KozelNoch keine Bewertungen

- SL Generator Ultrasunete RincoDokument2 SeitenSL Generator Ultrasunete RincoDariaNoch keine Bewertungen

- Libya AIP Part1Dokument145 SeitenLibya AIP Part1Hitham Ghwiel100% (1)

- Eje Delantero Fxl14 (1) .6Dokument2 SeitenEje Delantero Fxl14 (1) .6Lenny VirgoNoch keine Bewertungen

- Guidelines For Doing Business in Grenada & OECSDokument14 SeitenGuidelines For Doing Business in Grenada & OECSCharcoals Caribbean GrillNoch keine Bewertungen

- Traffic Survey, Analysis, and ForecastDokument91 SeitenTraffic Survey, Analysis, and Forecastsanthosh rajNoch keine Bewertungen

- Rdramirez Aota 2018 Poster For PortfolioDokument1 SeiteRdramirez Aota 2018 Poster For Portfolioapi-437843157Noch keine Bewertungen

- Pantone PDFDokument53 SeitenPantone PDF2dlmediaNoch keine Bewertungen