Beruflich Dokumente

Kultur Dokumente

Design of Beam Ledge

Hochgeladen von

Anonymous 0JQGC2Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Design of Beam Ledge

Hochgeladen von

Anonymous 0JQGC2Copyright:

Verfügbare Formate

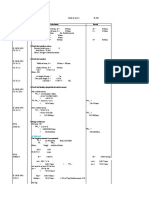

DESIGN OF BEAM LEDGE

1) DESIGN FOR SHEAR FRICTION

Effective Width=bw (Min. of Above)=

Effective Depth (de)=

Vn1=0.9*0.2*fc'*bw*de=

Vn2=0.9*5.5*bw*de=

Required Friction Reinforcement=Avf=Vu/(*fy*)=

2) CHECK FOR PUNCHING SHEAR

at interior/exterior pads where c>S/2

Vn=0.9*0.328*fc'(W+2L+2de)de=

at exterior pads where c<S/2 & (c-0.5W)<de

Vn=0.9*0.328*fc'(W+L+de)de=

at exterior pads where c<S/2 & (c-0.5W)>de

Vn=0.9*0.328*fc'(0.5W+L+de+C)de=

3) CHECK FOR BEARING STRESS

Width of One Ledge=

Stem/Block Width=

B (Min of Above Four)=

Modification Factor (m)=

Pn=0.7*0.85*fc'*A1*m=

4) DESIGN FOR FLEXURE

Mu=(Vu*af)+Nu(h-de)=

Af=Mu/(*fy*jd)=

5) DESIGN FOR DIRECT TENSION

Nu Minimum=0.2*Vu=

Nu Governing=

An=Nu/(*fy)=

6) TOTAL PRIMARY REINFORCEMENT

Area of Primary Reinforcement (As) Shall be Larger of Following Three

As1=2/3Avf+An=

As3=0.04(fc'/fy)*bw*d=

As Governing=

As Governing=

Bar Dia to be Used=

Required Spacing=

Modified Spacing=

7) DESIGN OF HANGER REINFORCEMENT

Reaction at Service Limit State=Vs=

Assumed Bar Spacing=

Ahr (at Strength)=(Vu*s)/(*fy*S)=

Ahr (at Service)=(Vs*s)/((0.5**fy)(W+3*av))=

Bar Dia to be Used=

Vu= 1293 kN

Nu= 258.6 kN

h= 1050 mm

av= 425 mm

af= 500 mm

S= 2625 mm

c= 487 mm

W= 600 mm

L= 500 mm

= 1 (for simultaneously placed Conc.)

fc'= 27.5 MPa

fy= 410 MPa

W+4av= 2300 mm

2c= 974 mm

dth=bw (Min. of Above)= 974 mm

Effective Depth (de)= 975 mm

av/de= 0.435897436 <1 OK

Nu < Vu OK

Nominal Shear Resistance Shall be Lesser of Following Two

Vn1=0.9*0.2*fc'*bw*de= 4700.7675 kN

Vn2=0.9*5.5*bw*de= 4700.7675 kN

Vn= 4700.7675 kN

Vu < Vn OK

ment=Avf=Vu/(*fy*)= 4.317123253 mm2/mm

terior pads where c>S/2 This Section is Not Applicable

28*fc'(W+2L+2de)de= 5358.159888 kN

Vn > Vu OK

D/C= 0.241314188

re c<S/2 & (c-0.5W)<de This Section is Applicable

0.328*fc'(W+L+de)de= 3131.882188 kN

Vn > Vu OK

D/C= 0.412850779

re c<S/2 & (c-0.5W)>de This Section is Not Applicable

fc'(0.5W+L+de+C)de= 3414.12892

Vn > Vu OK

D/C= 0.378720321

Width of One Ledge= 850 mm

Stem/Block Width= 1600 mm

A1= 300000 mm2

B1= 175 mm

B2= 975 mm

B3= 2100 mm

B4= 1012.5 mm

B (Min of Above Four)= 175 mm

W2= 950 mm

L2= 850 mm

A2= 807500 mm2

Modification Factor (m)= 1.64062996 <2 OK

Pn=0.7*0.85*fc'*A1*m= 8053.442318 kN

Pn > Pu OK

D/C= 0.160552463

Mu=(Vu*af)+Nu(h-de)= 665.895 kN-m

Af=Mu/(*fy*jd)= 2.375340252 mm2/mm

Nu Applied= 258.6 kN

Nu Minimum=0.2*Vu= 258.6 kN

Nu Governing= 258.6 kN

An=Nu/(*fy)= 0.719520542 mm2/mm

arger of Following Three

As1=2/3Avf+An= 3.597602711 mm2/mm

As2=Af+An= 3.094860794 mm2/mm

As3=0.04(fc'/fy)*bw*d= 2.615853659 mm2/mm

As Governing= 3.597602711 mm2/mm

As Governing= 3597.602711 mm2/m

Bar Dia to be Used= 25 mm

Required Spacing= 136.3755365 mm

Modified Spacing= 100 mm

Result= Provide d25@100mm

Service Limit State=Vs= 1293 kN

Assumed Bar Spacing= 100 mm

ength)=(Vu*s)/(*fy*S)= 133.488192 mm2

)/((0.5**fy)(W+3*av))= 373.7669377 mm2

Bar Dia to be Used= 25 mm

Result= Provide 2L-d25@100mm

10 78.5

12 113.04

16 200.96

20 314

25 490.625

28 615.44

32 803.84

36 1017.36

Das könnte Ihnen auch gefallen

- Effe. Section HeightDokument132 SeitenEffe. Section HeightNaresh SharmaNoch keine Bewertungen

- ACI 318M-11 RC Beam Ledge Design - v0.04 - 2020-07-23Dokument5 SeitenACI 318M-11 RC Beam Ledge Design - v0.04 - 2020-07-23Vietanh PhungNoch keine Bewertungen

- Lecture 06-A Tied ColumnsDokument5 SeitenLecture 06-A Tied ColumnsArnel G. PetalioNoch keine Bewertungen

- Design of Vertical Bracing Connections For High Seismic DriftDokument12 SeitenDesign of Vertical Bracing Connections For High Seismic DriftvNoch keine Bewertungen

- M M MM MM N/MM N/MM MM MM MM MM MM 2Dokument1 SeiteM M MM MM N/MM N/MM MM MM MM MM MM 2D SRINIVASNoch keine Bewertungen

- Crack Width Calculation (Bs 8110) : InputDokument1 SeiteCrack Width Calculation (Bs 8110) : Inputjacs127Noch keine Bewertungen

- Column-Footing Size 3Dokument8 SeitenColumn-Footing Size 3Anonymous HJ7hmihhNoch keine Bewertungen

- Lecture 11-1 Bases by H.J. MtyanaDokument29 SeitenLecture 11-1 Bases by H.J. MtyanaHarold Jackson Mtyana100% (1)

- Shear EnhancedDokument8 SeitenShear Enhancedunitedfc9612Noch keine Bewertungen

- CE4070 Structural Modelling Yield Line Analysis of Slab IETDokument18 SeitenCE4070 Structural Modelling Yield Line Analysis of Slab IETkartheepan100% (1)

- Slab-On-Grade Reinforcing DesignDokument9 SeitenSlab-On-Grade Reinforcing DesignAdam GreenlawNoch keine Bewertungen

- Steel - 07-Prof. Zahid Siddiqi PDFDokument75 SeitenSteel - 07-Prof. Zahid Siddiqi PDFMuhammad AhmedNoch keine Bewertungen

- Optimal Deign of Pile FoundationDokument13 SeitenOptimal Deign of Pile FoundationJustin Johnson100% (1)

- Staad Foundation Pile Calc SheetDokument6 SeitenStaad Foundation Pile Calc SheetDeepmalaJayeshNoch keine Bewertungen

- Square Reinforced Concrete Column Interaction Diagram Biaxial PDFDokument29 SeitenSquare Reinforced Concrete Column Interaction Diagram Biaxial PDFEng-bashir Said AbshirNoch keine Bewertungen

- Design of Column BasesDokument9 SeitenDesign of Column Basesdarshanakp100% (1)

- Lec (3) Part 2 Combined FootingDokument44 SeitenLec (3) Part 2 Combined FootingDemse ZelelewNoch keine Bewertungen

- Crack Width Check BS5400 4Dokument5 SeitenCrack Width Check BS5400 4saravanan4286100% (1)

- Raw Water Tank-DataDokument1 SeiteRaw Water Tank-DataSivaArabiNoch keine Bewertungen

- Circular ColumnDokument17 SeitenCircular Columnkarthikmr85Noch keine Bewertungen

- End Block Design-1Dokument14 SeitenEnd Block Design-1potpotvolksNoch keine Bewertungen

- Finite Element Analysis of Soil Bearing Capacity Using PlaxisDokument5 SeitenFinite Element Analysis of Soil Bearing Capacity Using PlaxisRehan HakroNoch keine Bewertungen

- Prestress LN5 Black and WhiteDokument19 SeitenPrestress LN5 Black and WhiteEyad SherifNoch keine Bewertungen

- Step5 Lateral CapacityDokument8 SeitenStep5 Lateral CapacityJajat SudrajatNoch keine Bewertungen

- H-Pile Design 1518Dokument22 SeitenH-Pile Design 1518Danny LamNoch keine Bewertungen

- Strength Behavior of Cement Treated Dredged SoilDokument20 SeitenStrength Behavior of Cement Treated Dredged SoilTarhata KalimNoch keine Bewertungen

- Chapter 8-Earth Retaining Structures-13Dokument23 SeitenChapter 8-Earth Retaining Structures-13Alexander AlexanderNoch keine Bewertungen

- 3pile PilecapDokument4 Seiten3pile Pilecapsivaraju1100% (1)

- Spreadsheets To BS 8110: Made by DateDokument1 SeiteSpreadsheets To BS 8110: Made by Datemefaisal75Noch keine Bewertungen

- Inverted-T Capacity Calculation@Phase1v2Dokument11 SeitenInverted-T Capacity Calculation@Phase1v2satyaNoch keine Bewertungen

- SPREW Part 3 of 3 PDFDokument122 SeitenSPREW Part 3 of 3 PDFhz135874Noch keine Bewertungen

- 6 Reinforced ColumnsDokument41 Seiten6 Reinforced ColumnsAnggaWarsitoNoch keine Bewertungen

- Chapter 1 - Introduction To RCDokument34 SeitenChapter 1 - Introduction To RCMARVINNoch keine Bewertungen

- (Etic Far East) : TEST Post-Tensioning LTDDokument39 Seiten(Etic Far East) : TEST Post-Tensioning LTDKunto Dwi WicaksonoNoch keine Bewertungen

- CEC5-4 Seismic Design Lecture by Prof DR Zahid SiddiqiDokument67 SeitenCEC5-4 Seismic Design Lecture by Prof DR Zahid Siddiqimys85Noch keine Bewertungen

- Contech Bridge BrochureDokument12 SeitenContech Bridge BrochureCONTECHCPINoch keine Bewertungen

- GLT Engineers Private, Singapore: Foundation DesignDokument2 SeitenGLT Engineers Private, Singapore: Foundation DesignRio HandokoNoch keine Bewertungen

- Pile FoundationDokument17 SeitenPile Foundationritam1991Noch keine Bewertungen

- SAP2000 Section PropertiesDokument3 SeitenSAP2000 Section PropertiesCon Can100% (1)

- Pile Cap Design 4 PilesDokument1 SeitePile Cap Design 4 PilesdantevariasNoch keine Bewertungen

- 3.13.3-Cofferdam Seal Coat DesignDokument13 Seiten3.13.3-Cofferdam Seal Coat DesignMehdi Alaoui ChrifiNoch keine Bewertungen

- Bearing Capacity of Driven Pile 20201110Dokument5 SeitenBearing Capacity of Driven Pile 20201110Tuan LeNoch keine Bewertungen

- Corbel Design To ACI 381-05Dokument2 SeitenCorbel Design To ACI 381-05Kira YamatoNoch keine Bewertungen

- Comparison of Seismic Response of Multi-Storied Structures With and Without Soil Structure InteractionDokument4 SeitenComparison of Seismic Response of Multi-Storied Structures With and Without Soil Structure InteractionAkhil LamdadeNoch keine Bewertungen

- 9.shear Capacity of Steel Frame Member Rev 0.2Dokument22 Seiten9.shear Capacity of Steel Frame Member Rev 0.2WahidAgungNoch keine Bewertungen

- Number and Spacing of Piles in A GroupDokument7 SeitenNumber and Spacing of Piles in A GroupmadaraNoch keine Bewertungen

- Prestressed Concrete Girder Continuity ConnectionDokument6 SeitenPrestressed Concrete Girder Continuity ConnectionagnayelNoch keine Bewertungen

- Beam Cracked Moment of InertiaDokument1 SeiteBeam Cracked Moment of InertiaAnantPawarNoch keine Bewertungen

- Calculation Sheet Mat - FDNDokument14 SeitenCalculation Sheet Mat - FDNDavid Sinambela0% (1)

- Optimize Positioning of Relief Shelf in Cantilever Retaining WallDokument3 SeitenOptimize Positioning of Relief Shelf in Cantilever Retaining WallGRD Journals100% (1)

- M. Tech. (Structural Engineering) SCHEME OF EXAMINATIONDokument26 SeitenM. Tech. (Structural Engineering) SCHEME OF EXAMINATIONAjay AjaiNoch keine Bewertungen

- Behavior of Piles With Raft Foundation Using Safe Software: Reshma T.V, Bhavya B S, Rashmi Mishra, Sankalpasri S SDokument5 SeitenBehavior of Piles With Raft Foundation Using Safe Software: Reshma T.V, Bhavya B S, Rashmi Mishra, Sankalpasri S Sfrog15Noch keine Bewertungen

- Finite Element Modeling of Concrete Beams Prestressed With External TendonsDokument8 SeitenFinite Element Modeling of Concrete Beams Prestressed With External TendonsviniciusltNoch keine Bewertungen

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionVon EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNoch keine Bewertungen

- RC Corbel Design CON BSDokument3 SeitenRC Corbel Design CON BSMohd ShahrulmiziNoch keine Bewertungen

- Counterfort Retaining WallDokument7 SeitenCounterfort Retaining WallAadarsha timilsinaNoch keine Bewertungen

- Combined Footing DesignDokument1 SeiteCombined Footing DesignOSCARTAWNNoch keine Bewertungen

- Design of Beam:528 Grade of Concrete: at Right EndDokument7 SeitenDesign of Beam:528 Grade of Concrete: at Right EndSudip ShresthaNoch keine Bewertungen

- Masonry Wall Footing DesignDokument18 SeitenMasonry Wall Footing DesignAnonymous 0JQGC2Noch keine Bewertungen

- Bridge Length M COG Height From Transom Top M: Summary of Reactions at Abutment For Tank (Tons)Dokument19 SeitenBridge Length M COG Height From Transom Top M: Summary of Reactions at Abutment For Tank (Tons)Anonymous 0JQGC2Noch keine Bewertungen

- Transom Output ForcesDokument6 SeitenTransom Output ForcesAnonymous 0JQGC2Noch keine Bewertungen

- Analysis of Statically Indeterminate Structures by The Force MethodDokument57 SeitenAnalysis of Statically Indeterminate Structures by The Force MethodArvin ArviniNoch keine Bewertungen