Beruflich Dokumente

Kultur Dokumente

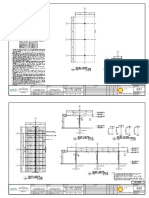

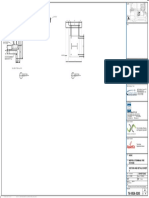

S001 76-10526-Detail Design: Adac Midfield Terminal Fire Station Structural General Notes & Details Sheet 1

Hochgeladen von

Mazen IsmailOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

S001 76-10526-Detail Design: Adac Midfield Terminal Fire Station Structural General Notes & Details Sheet 1

Hochgeladen von

Mazen IsmailCopyright:

Verfügbare Formate

GENERAL NOTES

Key Plan

G1 ALL STRUCTURAL DRAWINGS SHALL BE READ IN CONJUNCTION WITH ALL OTHER DRAWINGS,

DOCUMENTS, SPECIFICATIONS ETC. AS MAY BE ISSUED DURING THE COURSE OF THE CONTRACT.

S11 PROVIDE MINIMUM LENGTH BEARING OF 200mm FOR ALL STEEL BEAMS BEARING ON MASONRY C15 THE CONTRACTOR IS RESPONSIBLE FOR PROVISION OF, AND SCHEDULING OF CHAIRS, SPACERS

ETC. FOR THE SUPPORT OF REINFORCEMENT.

STANDARD NOTATION LEGEND

AND CONCRETE AND A MINIMUM OF 100mm ON STRUCTURAL STEEL, UNLESS OTHERWISE NOTED

ALL DISCREPANCIES SHALL BE REFERRED TO THE ENGINEER FOR DECISION BEFORE OR SHOWN. C16 SURFACE FINISHES:

PROCEEDING. S12 CENTRE BEARING PLATES UNDER BEAMS UNLESS OTHERWISE NOTED OR SHOWN. CONCRETE SURFACES TO - TAMPED SURFACE FINISH T12-250

G2 DIMENSIONS SHALL NOT BE OBTAINED BY SCALING DRAWINGS S13 BEARING PLATE DIMENSION GIVEN FIRST INDICATES SIDE PARALLEL TO BEAM WEB. RECEIVE FUTURE SCREED SPACING (mm)

N

G3 LEVELS SHOWN ARE IN METERS ABOVE NEW ABU DHABI DATUM LEVEL (NADD) S14 NO STRUCTURAL STEEL SHALL BE CUT IN THE FIELD UNLESS REVIEWED AND AGREED BY THE BLINDING CONCRETE - TROWEL FINISH BAR SIZE (mm)

ENGINEER. PLANT ROOMS - POWER FLOATED FINISH TYPE OF REINFORCEMENT

G4 THE CONTRACTOR SHALL SUBMIT RECORD DRAWINGS OF ALL "AS BUILT" WORKS FOR THE

ENGINEER REVIEW & AGREEMENT. S15 WHERE COLUMNS ARE STABILIZED BY WALLS PROVIDE COLUMN ANCHORS AT ABUTTING WALLS. WET AREAS, AMENITIES BLOCKS, KITCHENS - TROWEL FINISH 6T12

A

PROVIDE TEMPORARY BRACING UNTIL WALLS ARE BUILT TIGHTLY TO COLUMNS. TO RECEIVE WATER PROOF MEMBRANE

BL

G5 SETTING OUT DIMENSIONS AND LEVELS SHOWN ON THE DRAWINGS SHALL BE VERIFIED BY BAR SIZE (mm)

QI

S16 ALL WELDS EXPOSED TO VIEW SHALL BE GROUND SMOOTH. ROOF AREAS AND CARPARK ROOF AREAS - POWER FLOATED FINISH

THE CONTRACTOR. THE ENGINEER SHALL BE NOTIFIED OF ANY DISCREPANCIES PRIOR TO TYPE OF REINFORCEMENT

CONSTRUCTION S17 WHERE MOMENT CONNECTIONS ARE CALLED FOR BUT FORCES ARE NOT INDICATED, DESIGN TO RECEIVE SLIP MEMBRANE Notes

CONNECTIONS FOR FULL MOMENT CAPACITY OF THE SMALLER MEMBER JOINED. NUMBER OF BARS

LOADING DOCK AREAS - POWER FLOATED FINISH

1. ALL DIMENSIONS ARE IN MILLIMETER U.N.O.

G6 ALL WORKMANSHIP AND MATERIALS SHALL BE IN ACCORDANCE WITH THE CURRENT BRITISH

STANDARDS UNLESS NOTED OTHERWISE (U.N.O) AND THE REQUIREMENTS OF MUNICIPALITY

S18 SPLICES SHALL BE DESIGNED TO DEVELOP THE FULL CAPACITY OF THE MEMBER AT THE POINT

OF THE SPLICE. MEMBERS SHALL NOT BE SPLICED AT POINTS OF MAXIMUM STRESS. NO SPLICES

C17 FORMED FINISHES:

EXTERNAL BURIED - FORMED FINISH

REINFORCEMENT 2. ALL THE LEVELS ARE IN METER.

3. REFER TO THE ARCHITECTURAL DRAWINGS FOR THE RELATION BETWEEN

SHALL BE MADE UNLESS SHOWN ON THE DRAWINGS OR REVIEWED AND AGREED BY THE ENGINEER

G7 ALL DIMENSIONS ARE IN MILLIMETRES AND ALL LEVELS ARE IN METERS UNLESS NOTED INTERNAL FACE OF BURIED STRUCTURES - NORMAL FAIR FACED FINISH THE BUILDING LEVELS AND THE PROJECT DATUM.

S19 PROVIDE WELDED STIFFENER PLATES ON BOTH SIDES OF THE WEB OF BEAMS AT POINTS OF 4. GENERAL NOTES, STANDARD DETAILS, WATERPROOFING AND MATERIAL

OTHERWISE CONCENTRATED LOAD INCLUDING BEAMS SUPPORTING COLUMNS OR RUNNING OVER TOPS OF SOFFITS/COLUMN /WALLS, UNO - NORMAL FAIR FACE FINISH PROPERTIES REFER TO DRAWINGS. " S001 - S005"

G8 DETAIL R.C. SHOP DRAWINGS AND BAR BENDING SCHEDULES SHALL BE PREPARED BY THE COLUMNS CIRCULAR COLUMNS - NORMAL FAIR FACE FINISH 5. THIS DRAWING SHOULD BE READ IN CONJUNCTION WITH THE RELATIVE

CONTRACTOR AND SUBMITTED TO THE ENGINEER FOR REVIEW. WORK SHALL NOT COMMENCE EXISTING BUILDING

S20 CONNECT ALL COLUMNS TO THE BASE PLATES FOR THE LARGER OF THE FOLLOWING FORCES IN C18 REFER ALSO TO THE SPECIFICATION AND ARCHITECTURAL DRAWINGS FOR TYPE OF CONCRETE ARCHITECTURAL, MEP AND CIVIL DRAWINGS. COORDINATE ALL

UNTIL REVIEWED AND ACCEPTED. REVIEW OF THESE DRAWINGS DOES NOT ALLEVIATE THE PENETRATIONS CONDUTES AND EQUIPMENT REQUIREMENTS.

ADDITION TO OTHER FORCES SHOWN: SURFACE FINISH REQUIRED

CONTRACTOR'S RESPONSIBILITIES.

A) AT BRACING FOR THE HORIZONTAL COMPONENTS FROM THE BRACING. COLUMN OR WALL UNDER

G9 FOR GROUND WATER TABLE REFER TO THE SOIL INVESTIGATION REPORT.

B) FOR 3% OF THE FACTORED VERTICAL COLUMN LOAD APPLIED HORIZONTALLY. C19 NON STRUCTURAL CONCRETE USED TO MAKE UP LEVELS & INFILL VOIDS AS SHOWN ON THE (INCLUDING HEADER BEAMS)

G10 WHERE DEWATERING IS TO BE CARRIED OUT THE SYSTEM IS TO BE SUBMITTED OF TO THE S21 SHAPE AND SIZE OF GUSSET PLATES TO CLEAR ARCHITECTURAL FINISHES AND MECHANICAL DRAWINGS SHALL BE A LIGHTWEIGHT CONCRETE WITH A MAXIMUM DENSITY OF 15kN/m AND

ENGINEER FOR REVIEW PRIOR TO INSTALLATION DUCTS, PIPES AND ELEVATOR SHAFTS. COMPRESSIVE STRENGTH 15N/mm , AS AGREED WITH THE ENGINEER.

S22 PROVIDE ALL ANCHOR BOLTS, CAST IN PLATES WITH ANCHORS AND ANCHORS REQUIRED TO COLUMN OR WALL UNDER

MASONRY S23

CONNECT STRUCTURAL STEEL TO CAST-IN-PLACE CONCRETE.

THE ENDS OF ALL TUBULAR MEMBERS ARE TO BE SEALED WITH 5mm THICK PLATES AND

PRECAST FLOOR AND PANEL AND OVER.

M1 ALL MASONRY CONSTRUCTION SHALL CONFORM TO BS 6073, BS 5628 AND SPECIFICATIONS. CONTINUOUS FILLET WELDS UNLESS NOTED OTHERWISE. PROVIDE WEEP HOLES IN TUBULAR

MEMBERS USED IN AN EXTERIOR ENVIRONMENT. END PLATES SHALL MATCH TUBE SHAPE UNO.

DESIGN AND CONSTRUCTION CARRIED

COLUMN OR WALL OVER.

M2 ALL CONTROL JOINTS ARE TO BE FILLED WITH COMPRESSIBLE/ EXPANDABLE FILLER, TO MEET

S24 MAINTAIN TEMPORARY BRACING UNTIL COMPLETION OF THE ENTIRE STRUCTURE INCLUDING

A 2 HOUR FIRE RATING. CP1 PRECAST, PRESTRESSED CONCRETE ELEMENTS SHALL BE USED TO FORM THE DECKS WHERE

STEEL DECK AND GRATING OR OTHER ELEMENTS WHICH ARE PART OF THE LATERAL LOAD

M3 ALL WALL FINISHES MUST BE JOINTED AT THE WALL JOINTS TO PREVENT UNCONTROLLED SHOWN ON THE DRAWINGS. ALL GAPS BETWEEN UNITS SHALL BE FILLED WITH GROUT AND UPSTAND

RESISTING SYSTEM.

CRACKS IN THE WALL FINISHES. REINFORCED AS REQUIRED. THE CONTRACTOR SHALL BE RESPONSIBLE FOR THE DESIGN OF

S25 DETAILED STRUCTURAL STEEL SHOP DRAWINGS, CONNECTION DETAILS AND CALCULATIONS

M4 GREAT CARE MUST BE TAKEN TO ENSURE THAT MORTAR DROPPINGS AND OTHER HARD SHALL BE PREPARED BY THE CONTRACTOR IN ACCORDANCE WITH BS 449 AND SUBMITTED AS THE ELEMENTS AS A WHOLE. LAYOUT DRAWINGS AND DETAILS SHALL BE FORWARDED TO THE

MATERIALS DO NOT FALL OR REMAIN IN THE CONTROL JOINTS. POLYSTYRENE TO BE PLACED DEFINED IN THE CONTRACT. FABRICATION OR INSTALLATION SHALL NOT COMMENCE UNTIL ENGINEER FOR REVIEW & AGREEMENT PRIOR TO CASTING THE ELEMENTS.

IN ALL VERTICAL JOINTS DURING CONSTRUCTION IN MASONRY TO AVOID MORTAR DROPPINGS REVIEWED AND ACCEPTED. REVIEW OF THESE DRAWINGS DOES NOT ALLEVIATE THE CP2 REFER TO THE SPECIFICATION FOR REQUIREMENTS.

SECTION

FILLING THE JOINTS. CONTRACTOR'S RESPONSIBILITIES. COORDINATE THE INPUT OF ALL TRADES ON THE SHOP

M5 ALL JOINTS ARE TO BE REVIEWED AND AGREED BY THE ENGINEER OR HIS REPRESENTATIVE NUMBER

DRAWINGS.

PRIOR TO USE. SURFACE FINISH A

S26 REFER TO ARCHITECTS DRAWINGS FOR ARCHITECTURAL DETAILS/ REQUIREMENTS OF

M6 WHERE FILLER MATERIALS ARE NOT SPECIFIED BY A TRADE NAME, THE CONTRACTOR SHALL FIXINGS & CONNECTIONS. 004

SUBMIT THE NAME OF HIS PROPOSED FILLERS TO THE ENGINEER FOR REVIEW PRIOR TO USE. TOP - ROUGH(TO RECEIVE STRUCTURAL TOPPING)

CP3

M7 THE CONTRACTOR'S ATTENTION IS DRAWN TO THE MANUFACTURER'S REQUIREMENTS WITH MOVEMENT JOINTS BOTTOM - SMOOTH (OFF STEEL FORMS)

DRAWING REFERENCE

NUMBER

A ISSUED FOR TENDER RBU BM* AH* 08.03.15

REGARD TO THE POSITION OF THE FLEXIBLE ANCHORS WHEN FIXED. THE MANUFACTURER'S No Revision

Job Project

Drawn Manager Director Date

WRITTEN RECOMMENDATIONS SHALL BE FOLLOWED STRICTLY. MJ1 THE CONTRACTOR SHALL NOT FILL ANY STRUCTURAL MOVEMENT JOINTS UNTIL THE

PERIMETER INNER LEAF WALLS HAVE BEEN CONSTRUCTED AND SEALED. CUTOUTS AND OPENINGS

M8 THE CONTRACTOR IS TO TAKE PARTICULAR CARE TO ENSURE THAT ALL PERPENDS AND BEDS

ARE PROPERLY FILLED WITH MORTAR. SECTION MARK Note: * indicates signatures on original issue of drawing or last revision of drawing

M9 REFER TO ARCHITECTURAL PLANS AND ELEVATIONS FOR LOCATIONS OF CONTROL JOINTS. REINFORCED CONCRETE CP4 ONLY LARGE OPENINGS ARE SHOWN ON THE STRUCTURAL DRAWINGS. THE CONTRACTOR SHALL

COORDINATE ALL BUILDERS WORK REQUIREMENTS FOR OTHER OPENINGS REQUIRED FOR

Conditions of Use. This document may only be used by GHD's client (and any other

person who GHD has agreed can use this document) for the purpose for which it was

M10 PROVIDE RESTRAINT TO ALL MASONRY AT SOFFIT OF SLAB OVER AS REQUIRED. VERTICAL SERVICES AND ENSURE THAT SUCH OPENINGS ARE PROPERLY ALLOWED FOR IN THE prepared and must not be used by any other person or for any other purpose.

DETAIL

C1 ALL WORKMANSHIP AND MATERIALS SHALL COMPLY WITH THE SPECIFICATION DESIGN AND FORMING OF THE PRECAST ELEMENTS. NUMBER

M11 WHERE STARTER BARS, ANCHOR BOLTS, ETC. ARE SHOWN PROJECTING INTO MASONRY,

C2 ALL CONCRETE SHALL BE PREMIXED BY A REVIEWED AND ACCEPTED SUPPLIER CP5 ELEMENTS ARE TO BE NOTCHED AROUND COLUMNS TO SUIT THE LAYOUT.

BUILD THESE TIGHTLY INTO MASONRY VOIDS WITH MASONRY GROUT.

C3 ALL REINFORCEMENT SHALL BE HIGH YIELD DEFORMED TYPE 2 CLASSIFICATION AND MEET THE

A

M12 PROVIDE LINTELS OVER ALL OPENINGS OR RECESSES IN MASONRY WALLS, INCLUDING THOSE CP6 ALL LIFTING AND HANDLING DEVICES SHALL BE DESIGNED TO CARRY MAXIMUM LOAD RESULTING

FOR MECHANICAL OR ELECTRICAL SERVICES OR EQUIPMENT. SEE TYPICAL DETAILS FOR

REQUIREMENTS OF THE SPECIFICATION FROM LIFTING, HANDLING AND ERECTION PLUS AN IMPACT ALLOWANCE OF ATLEAST 100 PERCENT. - Master Developper / Owner

LINTEL SIZES FOR NON-LOAD BEARING MASONRY WALLS. C4 LAPS AND SPLICES SHALL BE MADE ONLY WHERE SHOWN OR NOTED. BARS SHOWN LONGER

THAN STOCK LENGTHS SHALL BE LAPPED IN ACCORDANCE WITH THE NOTES HEREIN. MAXIMUM CP7 WHERE SHOWN ON THE DRAWINGS, THE CONTRACTOR IS REQUIRED TO DESIGN & ERECT Abu Dhabi Airports Company PJSC

M13 BLOCKS ARE TO BE LAID IN STRETCHER BOND PATTERN OVER FULL HEIGHT, INCLUDING AT STOCK LENGTHS SHALL BE USED WHERE POSSIBLE AND LAPS IN ADJACENT BARS SHALL BE SECONDARY STEEL MEMBERS SUPPORTING THE PRECAST PANELS. DRAWING Planning & Development

TOP OF WALL. STAGGERED. REFERENCE PO Box 94449, Abu Dhabi, U.A.E

C5 ALL STARTER BARS TO BE PROTECTED FROM DUST AND CORROSION BY COVERING WITH NUMBER T: +971 (0) 2 505 5000

WATER TESTING AND CHECKING

F: +971 (0) 2 575 8300

REVIEWED AND ACCEPTED PROTECTION MATERIAL UNTIL COMMENCEMENT OF NEXT PHASE OF

GROUND SLAB & FOUNDATION CONCRETE WORKS. STARTER BARS TO BE UN BENT, MARKED FOR SAFETY REASONS AND DETAIL MARK

PROTECTED FROM CONSTRUCTION TRAFFIC.

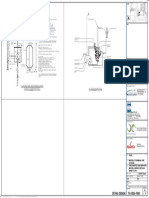

W1 THE FOLLOWING IS ENTIRELY SEPARATE TO THE REQUIREMENTS FOR HYDROSTATIC TESTING

F1 THE ENGINEER IS TO BE ADVISED IMMEDIATELY UPON DISCOVERY OF ANY SOFT SPOTS OR C6 CONCRETE QUALITY: REFER TO THE SPECIFICATION FOR TESTING REQUIREMENTS. OF ANY LIQUID FILLED TANKS, ALTHOUGH THE TWO OPERATIONS MAY BE COMBINED.

SERVICES IN THE GROUND C7 CONCRETE STRENGTH AND COVER W2 FILLING SHALL BE DONE UNDER CONTROLLED CONDITIONS TO ENSURE THAT FAILURE DOES NOT

OCCUR DURING FILLING. Lead Consultant

F2 POSITION OF ALL CONSTRUCTION JOINTS TO BE REVIEWED BY THE ENGINEER WHERE THESE

DIFFER FROM THOSE PROPOSED. W3 EACH TANK TO BE FILLED GRADUALLY WITH WATER AT CONSTANT RATE OVER 3 MONTHS.

F3 ON NO ACCOUNT SHOULD ANY HOLES, OPENINGS OR REINFORCEMENT BE CUT WITHOUT GRADE STRENGTH, CEMENT TARGET MINIMUM LEVELS AROUND THE TANK TO BE CHECKED WEEKLY DURING FILLING. LEVELS INSIDE THE TANK ABBREVIATIONS

PRIOR REVIEW OF THE ENGINEER. ELEMENT Fcu U.N.O. (Mpa) TYPE COVER (mm) CAN THEN BE CHECKED.

CTS CENTRES

F4 RETAINING WALLS AND WALLS OF BURIED STRUCTURES HAVE BEEN DESIGNED AS PROPPED W4 IN CARRYING OUT SUCH TEST PROCEDURE ADEQUATE ARRANGEMENTS SHOULD BE MADE

FOUNDATION / FOR THE EMERGENCY DISPOSAL OF WATER IF OFF LOADING BECOMES NECESSARY. DISCHARGE BTM. BOTTOM

CANTILEVERS AND NO BACK FILLING TO THE RETAINING WALLS SHOULD TAKE PLACE UNTIL C40/20 CEM1 + GGBS 75

SLAB ON GRADE SHOULD BE CLEAR OF TANK TO AVOID EROSION. SHOULD ANY OF THE RESULTS BE

THE FLOOR SLABS ARE CONSTRUCTED, UNLESS OTHERWISE AGREED BY THE ENGINEER. GHD GLOBAL PTY LTD

BUILDING FRAME NSATISFACTORY, THE ENTIRE PROCEDURE IS TO BE REPEATED, AT THE DISCRETION OF THE NF NEAR FACE

F5 DO NOT USE COMPACTION METHODS THAT WILL CAUSE DAMAGE TO ADJACENT STRUCTURES 50 FOR EXTERNAL ENGINEER, UNTIL SATISFACTORY RESULTS ARE OBTAINED FOLLOWING REMEDIAL WORKS.

3rd Floor, Guardian Tower, Danet Community

IN CONTACT C40/20 CEM1 + GGBS FF FAR FACE PO Box 45921 Abu Dhabi United Arab Emirates

OR SERVICES.SELECTION OF METHODS SHALL BE THE CONTRACTORS RESPONSIBILITY.CARE FACE LEVELS OF ALL TANKS AT 4 REFERENCE POINTS PER TANK ARE TO BE CHECKED WEEKLY UNTIL

WITH GROUND T 971 2 6968700 F 971 2 4472915

SHALL BE TAKEN IN COMPACTION BEHIND RETAINING WALLS. THE FIRST MONTH OF SERVICE OF THE NEWEST TANK IS OVER, THENCEFORTH TO BE CHECKED EF EACH FACE E abumail@ghd.com W www.ghd.com

F6 SAND MATERIAL EXCAVATED FROM SITE MAY BE SUITABLE FOR BACKFILL PROVIDED IT IS FREE BUILDING FRAME C40/20 CEM1 40 MONTHLY FOR A FURTHER 2 MONTHS.

OF ALL DELETERIOUS MATTER AND COMPLIES WITH THE SPECIFICATION REQUIREMENT. EW EACH WAY

SUSPENDED Specialist Consultant

F7 THE CONTRACTOR SHALL BE ENTIRELY RESPONSIBLE FOR ENSURING THAT THE EXCAVATIONS C40/20 CEM1 35 STAG. STAGGERED BARS

ARE SUITABLE, SAFE AND STABLE. (i.e. TEMPORARY WORKS) ALTHOUGH SUCH PRECAUTIONS

SLAB

WATERTIGHT CONSTRUCTION

MAY HAVE ALREADY BEEN REVIEWED IN PRINCIPLE BY THE ENGINEER. ALT. ALTERNATING BARS

BLINDING C20/20 - -

F8 IT SHALL REMAIN THE CONTRACTOR'S OBLIGATION TO PROVIDE DRY WORKING CONDITIONS W5 THE FOLLOWING STRUCTURAL ELEMENTS ARE TO BE CONSTRUCTED IN ACCORDANCE WITH L.V. LENGTH VARIES

CONCRETE THE SPECIFICATION Fire Life Safety, Planning

BY ANY MEANS HE MIGHT SEE EFFECTIVE AND UTILIZING THE INSTALLED DEWATERING C60/20 CEM1 35

TOPPING - FOUNDATIONS UNO UNLESS NOTED OTHERWISE

SYSTEM. EXCAVATION SHALL BE AT ALL TIMES CARRIED OUT IN DRY CONDITIONS. GROUND and Regulatory Specialist

WATER SHALL BE MAINTAINED AT LEAST 500mm BELOW THE DEEPEST POINT IN THE - TANK WALLS U/S UNDERSIDE

EXCAVATION WHILE IT REMAINS OPEN. W6 REFER TO THE ARCHITECTURAL DRAWINGS AND SPECIFICATION FOR DETAILS OF

DEWATERING SHALL NOT BE DISCONTINUED WITHOUT THE WRITTEN AGREEMENT OF THE C8 REINFORCEMENT IS SHOWN DIAGRAMATICALLY ON THE DRAWINGS AND NOT NECESSARILY IN E.G.L. EXISTING GROUND LEVEL

TRUE POSITION. WATERPROOFING.

ENGINEER.

G.L. GROUND LEVEL

F9 FORMATION TO BASEMENT AND GROUND SLABS CAST ON THE GROUND TO BE COMPACTED C9 ALL REINFORCEMENT SHALL BE SECURELY SUPPORTED IN ITS CORRECT POSITION BY REVIEWED

IN ACCORDANCE WITH THE SPECIFICATION AND ADEQUATELY BLINDED WITH ROLLED-IN AND ACCEPTED MEANS BEFORE PLACING CONCRETE R.L. REDUCED LEVEL Specialist Consultant

CLEAN SAND. C10 WELDING AND/OR SITE CUTTING OF REINFORCING SHALL NOT BE PERMITTED UNLESS REVIEWED

AND ACCEPTED IN WRITING BY THE ENGINEER.

LOADING PARAMETER FFL FINISHED FLOOR LEVEL

F10 THE BACKFILLING MATERIAL SHALL BE SELECTED GRANULAR MATERIAL COMPACTED TO

AT LEAST 98% OF ITS MAXIMUM DRY DENSITY AND IN ACCORDANCE WITH THE C11 ALL PROPRIETARY FIXINGS SHALL BE INSTALLED IN ACCORDANCE WITH MANUFACTURER'S L1 THE STRUCTURAL HAS BEEN DESIGNED TO ALLOW FOR THE UNFACTORED LOADS GIVEN SSL STRUCTURAL SURFACE LEVEL

SPECIFICATIONS. INSTRUCTIONS. ON THE LOADING PLANS, IN ADDITION TO THE FLOOR SELF-WEIGHT Third Party

R.C. REINFORCED CONCRETE Operational Advisor

F11 FOR ALLOWABLE SOIL BEARING CAPACITY REFER TO GEOTHECHNICAL REPORT NO. ATGP-13-0327 C12 ALL CONCRETE SHALL BE COMPACTED USING A MECHANICAL VIBRATION PROCESS

L2 WIND LOADS TO ASCE/SCI 7-05

PREPARED BT MS. TERRASEARCH GULF. C13 CONCRETE SHALL BE CURED IN ACCORDANCE WITH THE SPECIFICATION M.C. MASS CONCRETE

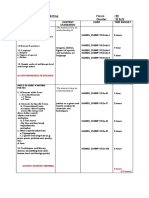

C14 STANDARD REINFORCEMENT LAP LENGTHS (UNO) BASIN WIND SPEED = 40m/s

STRUCTURALSTEEL MESH - 1 PANEL +25mm DIRECTIONALITY FACTOR

OCCUPANCY CATEGORY

= 0.85 (TABLE 6.4-1)

= IV (TABLE 1)

T&B TOP & BOTTOM

CJ CONSTRUCTION JOINT

S1 ALL WORKMANSHIP AND MATERIALS SHALL BE IN ACCORDANCE WITH BS 5950 AND THE IMPORTANCE FACTOR = 1.15 (TABLE 6-1)

SPECIFICATION. REQUIRED LAP SPLICE LENGTH FOR DEFFERENT BAR SIZE IN (mm)

EXPOSURE CATEGORY = C (SECTION 6.4.2.2) MJ MOVEMENT JOINT Client

ADAC

TOPOGRAPHIC FACTOR (Kzt) = 1 (FIGURE 6.4-2)

S2 ALL DESIGN OF STEELWORK SHALL BE IN ACCORDANCE WITH THE STRUCTURAL STEEL TOB TOP OF BEAM

SPECIFICATION. STEEL SHALL BE GRADE S 275 UNLESS NOTED OTHERWISE. Fcu = 40Mpa fy = 460Mpa L3 SEISMIC LOAD ACCORDING TO ASCE/SEI 7-05

S3 ALL SECTIONS USED SHALL BE OF ROLLED STEEL SECTIONS FROM THE SOURCE REVIEWED AND NOTE:

Project

MIDFIELD TERMINAL FIRE

AGREED WITH THE ENGINEER. BUILT UP SECTIONS OR FABRICATED SECTIONS SHALL NOT BE BAR DIA. 12 16 20 25 32 40 OCCUPANCY CATEGORY = IV

USED UNLESS ADVISED BY THE ENGINEER. SEISMIC IMPORTANCE FACTOR = 1.5 (TABLE 11.5-1) WHEN A FINISH LEVEL IS THE SAME AS THE STRUCTURAL

LEVEL AND NO APPLIED FINISH IS PRESENT ONLY THE

STATION

S4 BOLTS AND NUTS SHALL HAVE ISO METRIC COARSE THREAD. 12 575 575 875 1100 1400 1750 SEISMIC GROUND MOTION VALUES:

SITE CLASS - D STRUCTURAL LEVEL WILL BE SHOWN Title

S5 MILD STEEL BOLTS AND NUTS SHALL COMPLY WITH THE REQUIREMENTS OF BS 5950 PART 1,

BS 4190 AND BS 4320 RESPECTIVELY. 16 750 875 1100 1400 1750 0.2 SEC SPECTRAL RESPONSE ACCELERATION

STRUCTURAL GENERAL

1 - SEC SPECTRAL RESPONSE ACCELERATION

S6 HIGH STRENGTH FRICTION GRIP BOLTS, NUTS AND WASHERS SHALL COMPLY WITH THE 20 1150 1150 1400 1750 SEISMIC DESIGN CATEGORY

REQUIREMENTS OF BS 4395 PART 1 AND BS 4604 PART 1. Fa = 1.14 (ASSUMING SITE CLASS C) NOTES & DETAILS SHEET 1

S7 WASHERS ARE TO BE PROVIDED UNDER ALL NUTS ON BEVELLED SURFACES. SQUARE TAPER 25 1425 1425 1750 Fv - 1.605 (ASSUMING SITE CLASS C)

WASHERS OF 5mm. MEAN THICKNESS SHALL BE UNDER NUT OR HEAD AS APPROPRIATE. SMS = FaSS = 1.14 x 0.65 = 0.741 Scale 1 : 100 DO NOT SCALE

S8 ALL WELDING SHALL BE TO BS-639 32 1825 1825 SM1 = FvS1 = 1.605 x 0.195 = 0.313

SDS = 2/3 SM1 = 0.494 Drawn R. BUDUAN Designer R. EDNALINO

ALL WELDS SHALL BE APPLIED WITH E48XX ELECTRODES AND CARRIED OUT BY A CERTIFIED

WELDER. STEELWORK SHALL BE CLEANED BACK TO WHITE METAL SURFACE AND FREE OF RUST , 40 2300 SD1 = 2/3 SM1 = 0.209

Drafting Design

SCALE ETC., PRIOR TO WELDING. SUPERVISION AND TESTING OF WELDS SHALL BE DONE IN SEISMIC DESIGN CATEGORY C Check Check

ACCORDANCE WITH BS-709 REFER TO SPECIFICATIONS FOR FURTHER DETAILS. Approved

NOTE: BASIC SEISMIC FORCE RESISTING SYSTEM

S9 UNLESS OTHERWISE SHOWN ALL GUSSET PLATES SHALL BE 10mm THICK AND ALL END PLATES BEARING WALL SYSTEMS, ORDINARY REINFORCED CONCRETE SHEAR WALLS: (Project Director)

SHALL BE 8mm THICK THE CONTRACTOR MAY REPLACE THE LAP LENGTH WITH AN APPROVED COUPLER IN Date

CONGESTED AREAS. RESPONSE MODIFICATION CO-EFIICIENT R = 6.0

S10 PROTECTIVE SURFACE TREATMENT SHALL BE AS STATED IN THE SPECIFICATIONS. SYSTEM OVER STRENGTH FACTOR = 0 = 2.5 This Drawing must not be used for Construction unless signed as Approved

DEFLECTION AMPLIFICATION FACTOR, Cd = 5.0

ACCIDENTAL TORSION, ecc = 5.0% Original Size

Drawing No:

Ss AND S1 Ss = 0.56 S1 = 0.23

A1

DETAIL DESIGN 76-10526- S001 Rev: A

Plot Date: 5/03/2015 10:39:21 PM Cad File No: C:\Users\rbuduan\Documents\76-10526_Midfield Fire Station-Central_rbuduan.rvt

Das könnte Ihnen auch gefallen

- Sample Drainage Plan PDFDokument1 SeiteSample Drainage Plan PDFAredal Semreh100% (1)

- PlanDokument8 SeitenPlanMark Christian EsguerraNoch keine Bewertungen

- 20171003-Beam & Slab Schedule-01Dokument1 Seite20171003-Beam & Slab Schedule-01Atul ShrivastavaNoch keine Bewertungen

- Gutter DetailDokument1 SeiteGutter DetailarkikuNoch keine Bewertungen

- Structural General NotesDokument1 SeiteStructural General Notesjuan camiloNoch keine Bewertungen

- Roof Panel Side Lap Detail: Ceiling LNDokument1 SeiteRoof Panel Side Lap Detail: Ceiling LNJuan IstilNoch keine Bewertungen

- Structural Report of Proposed Fencing and ExtensionDokument21 SeitenStructural Report of Proposed Fencing and ExtensionLester LazoNoch keine Bewertungen

- Roof 7Dokument1 SeiteRoof 7Bekaar AadameeNoch keine Bewertungen

- 1007-ZN01-BM-102 - Reflected Ceiling PlanDokument1 Seite1007-ZN01-BM-102 - Reflected Ceiling PlanMHD MKNoch keine Bewertungen

- Typical Beam Details Typical Footing Details: Schedule of Footings Schedule of BeamsDokument1 SeiteTypical Beam Details Typical Footing Details: Schedule of Footings Schedule of BeamsRenel GarciaNoch keine Bewertungen

- General Notes 2Dokument1 SeiteGeneral Notes 2Wilbert ReuyanNoch keine Bewertungen

- Industrial Buildings: Case Study: (Suhana Masale Warehouse, Yewat)Dokument1 SeiteIndustrial Buildings: Case Study: (Suhana Masale Warehouse, Yewat)Rajeshwari YeoleNoch keine Bewertungen

- CHB Connection Details: 1.0 General NotesDokument1 SeiteCHB Connection Details: 1.0 General NotesSabling DritzcNoch keine Bewertungen

- 10 PDFDokument29 Seiten10 PDFAndriNoch keine Bewertungen

- General Structural/Construction Notes and Specifications: Proposed 4-Storey Residential Building W/FenceDokument1 SeiteGeneral Structural/Construction Notes and Specifications: Proposed 4-Storey Residential Building W/FenceWilbert ReuyanNoch keine Bewertungen

- S 1 Structural NotesDokument1 SeiteS 1 Structural NotesJBFPNoch keine Bewertungen

- S3 PDFDokument1 SeiteS3 PDFhampshireiii100% (1)

- Water Supply Isometric: C-DesignsDokument1 SeiteWater Supply Isometric: C-DesignsJenselle CarzaNoch keine Bewertungen

- BOQ - Repainting WorksDokument1 SeiteBOQ - Repainting WorksJeramel P. Lopez100% (1)

- Rain Water Drainage Design Calculation SheetDokument2 SeitenRain Water Drainage Design Calculation SheetMohamed SewelamNoch keine Bewertungen

- Bernard D. Marquez Eduardo M. Axalan Engr. William A.L.T. NGDokument1 SeiteBernard D. Marquez Eduardo M. Axalan Engr. William A.L.T. NGRhon Nem KhoNoch keine Bewertungen

- JJ Cruz + Associates S-02: Standard HooksDokument1 SeiteJJ Cruz + Associates S-02: Standard HooksCarlo GarciaNoch keine Bewertungen

- Beam Schedule: 250 3Rd FloorDokument1 SeiteBeam Schedule: 250 3Rd FloorNhel AlbrechtNoch keine Bewertungen

- STEEL Standard SpecificationsDokument4 SeitenSTEEL Standard SpecificationsTATATAHERNoch keine Bewertungen

- 467 Monroe Street - Dob Approval Plans - 2014.07.10 PDFDokument24 Seiten467 Monroe Street - Dob Approval Plans - 2014.07.10 PDFmgdrivenNoch keine Bewertungen

- Chapteer 2 Bolted ConnectionDokument30 SeitenChapteer 2 Bolted ConnectionNamrata PalNoch keine Bewertungen

- mcc2 PDFDokument1 Seitemcc2 PDFSravyaSree100% (2)

- StructDesign (GFSST - LRFD - TIA222G) 3GT-40-330C-Z-340DDokument55 SeitenStructDesign (GFSST - LRFD - TIA222G) 3GT-40-330C-Z-340DMIHDI PALAPUZNoch keine Bewertungen

- Swimming Pool 3Dokument1 SeiteSwimming Pool 3Arpit Jain100% (1)

- General Notes & SpecificationsDokument6 SeitenGeneral Notes & SpecificationsDon Santos100% (1)

- Metal Deck PDFDokument1 SeiteMetal Deck PDFabet hilarioNoch keine Bewertungen

- Portland Cement Plaster - SpecDokument7 SeitenPortland Cement Plaster - Speclinga2014Noch keine Bewertungen

- Structural Steel Shapes: Image Description Nomen. NotesDokument3 SeitenStructural Steel Shapes: Image Description Nomen. NotesJose Gino GutierrezNoch keine Bewertungen

- PLUMBINGDokument9 SeitenPLUMBINGBryan Rudolph PascualNoch keine Bewertungen

- Aac LayoutDokument1 SeiteAac Layoutveem riveraNoch keine Bewertungen

- Philippine Swimming PoolsDokument4 SeitenPhilippine Swimming PoolsArbi Llanes100% (1)

- Concrete SpecificationDokument9 SeitenConcrete SpecificationDawit SolomonNoch keine Bewertungen

- Assessment Report Format Sample For Old BuildingsDokument5 SeitenAssessment Report Format Sample For Old BuildingsAndrew Araha0% (1)

- A184 PDFDokument3 SeitenA184 PDFluisNoch keine Bewertungen

- General Construction Notes: Bureau of DesignDokument15 SeitenGeneral Construction Notes: Bureau of DesignRicoyan YanNoch keine Bewertungen

- General NotesDokument12 SeitenGeneral NotesShekh Muhsen Uddin AhmedNoch keine Bewertungen

- ComputationDokument2 SeitenComputationrmrv valdez100% (1)

- General Notes FinalsDokument1 SeiteGeneral Notes FinalsAubrey Rose Dela Peña - Magluyan100% (1)

- p2c Ifc Amalgamated File Structure 221229 110227Dokument46 Seitenp2c Ifc Amalgamated File Structure 221229 110227ZABIHULLAH HABIBNoch keine Bewertungen

- Veran Structural Model2Dokument1 SeiteVeran Structural Model2mr. oneNoch keine Bewertungen

- Acknowledgement ReceiptDokument1 SeiteAcknowledgement ReceiptEhm ManlayaNoch keine Bewertungen

- New Fulcrum Canopies - Structural Drawings - PermitDokument6 SeitenNew Fulcrum Canopies - Structural Drawings - PermitJorge Alnerto Perez SanchezNoch keine Bewertungen

- Splicing Requirement of Reinforcing Bars "LS" or "LD": NoteDokument7 SeitenSplicing Requirement of Reinforcing Bars "LS" or "LD": NoteAugust PongeNoch keine Bewertungen

- Bedroom 2 Bedroom 1: Ground Floor Mechanical LayoutDokument4 SeitenBedroom 2 Bedroom 1: Ground Floor Mechanical LayoutO. QuiritNoch keine Bewertungen

- PP03B - Asep - NSCP 2015 Update On CH2 Section 207 Wiind LoadsDokument77 SeitenPP03B - Asep - NSCP 2015 Update On CH2 Section 207 Wiind LoadsjimNoch keine Bewertungen

- Z-Purlin Data Sheet Rev06. 19-2-17Dokument19 SeitenZ-Purlin Data Sheet Rev06. 19-2-17Akhil VN100% (1)

- Shell Canopy Standard (Toll Type - 8.2M Span) : Rowena M. Garcia Christopher S. ValdezDokument4 SeitenShell Canopy Standard (Toll Type - 8.2M Span) : Rowena M. Garcia Christopher S. ValdezRobert RiveraNoch keine Bewertungen

- LMW Engineering Group, LLC.: Revision Comment No. DateDokument16 SeitenLMW Engineering Group, LLC.: Revision Comment No. DatenelsonNoch keine Bewertungen

- Bill of Materials - Cost and ESTIMATESDokument38 SeitenBill of Materials - Cost and ESTIMATESmnmusorNoch keine Bewertungen

- 01-Sheet List: Sheet Number Sheet Name Revision StatusDokument13 Seiten01-Sheet List: Sheet Number Sheet Name Revision StatusVen HaldosNoch keine Bewertungen

- 1301 Pme PDFDokument11 Seiten1301 Pme PDFCassie GraceNoch keine Bewertungen

- Swimming Pool General RequirementsDokument23 SeitenSwimming Pool General RequirementsVee KeeNoch keine Bewertungen

- Typical Fence DetailDokument1 SeiteTypical Fence DetailGelbert SilotNoch keine Bewertungen

- Sewer & Drainage Layout: IsometricDokument1 SeiteSewer & Drainage Layout: IsometricAubrey ManelleNoch keine Bewertungen

- General Notes: Nashville BMWDokument1 SeiteGeneral Notes: Nashville BMWAli KhalafNoch keine Bewertungen

- Section E Section E1: Adac Midfield Terminal Fire Station Section and Details Sheet 3Dokument1 SeiteSection E Section E1: Adac Midfield Terminal Fire Station Section and Details Sheet 3Mazen IsmailNoch keine Bewertungen

- S110 76-10526-Detail Design: U1 U2 U3 U5 U6 U7 U4Dokument1 SeiteS110 76-10526-Detail Design: U1 U2 U3 U5 U6 U7 U4Mazen IsmailNoch keine Bewertungen

- S300 76-10526-Detail Design: Typical Footing PlanDokument1 SeiteS300 76-10526-Detail Design: Typical Footing PlanMazen IsmailNoch keine Bewertungen

- 76 10526 F301 RaDokument1 Seite76 10526 F301 RaMazen IsmailNoch keine Bewertungen

- S303 76-10526-Detail Design: Wall ScheduleDokument1 SeiteS303 76-10526-Detail Design: Wall ScheduleMazen IsmailNoch keine Bewertungen

- F123 76-10526-Detail Design: Fire Protection Services - Ground Level Plan - Part 3ADokument1 SeiteF123 76-10526-Detail Design: Fire Protection Services - Ground Level Plan - Part 3AMazen IsmailNoch keine Bewertungen

- F200 76-10526-Detail Design: Fire Protection Services - Pump Room 3D ViewDokument1 SeiteF200 76-10526-Detail Design: Fire Protection Services - Pump Room 3D ViewMazen IsmailNoch keine Bewertungen

- F121 76-10526-Detail Design: Fire Protection Services - Ground Level PlanDokument1 SeiteF121 76-10526-Detail Design: Fire Protection Services - Ground Level PlanMazen IsmailNoch keine Bewertungen

- F122 76-10526-Detail Design: Fire Protection Services - Ground Level PlanDokument1 SeiteF122 76-10526-Detail Design: Fire Protection Services - Ground Level PlanMazen IsmailNoch keine Bewertungen

- F127 76-10526-Detail Design: Fire Protection Services - Level 3 Plan - Part 1Dokument1 SeiteF127 76-10526-Detail Design: Fire Protection Services - Level 3 Plan - Part 1Mazen IsmailNoch keine Bewertungen

- F005 76-10526-Detail DesignDokument1 SeiteF005 76-10526-Detail DesignMazen IsmailNoch keine Bewertungen

- F101 76-10526-Detail Design: U1 U2 U3 U4 U5 U6 UCDokument1 SeiteF101 76-10526-Detail Design: U1 U2 U3 U4 U5 U6 UCMazen IsmailNoch keine Bewertungen

- H112 76-10526-Detail Design: 2 3 4 K U1 U2 U3 U4 U5 U6 UC U7Dokument1 SeiteH112 76-10526-Detail Design: 2 3 4 K U1 U2 U3 U4 U5 U6 UC U7Mazen IsmailNoch keine Bewertungen

- F002 76-10526-Detail DesignDokument1 SeiteF002 76-10526-Detail DesignMazen IsmailNoch keine Bewertungen

- F004 76-10526-Detail Design: 13 - Alarm Check Valve AssemblyDokument1 SeiteF004 76-10526-Detail Design: 13 - Alarm Check Valve AssemblyMazen IsmailNoch keine Bewertungen

- F003 76-10526-Detail DesignDokument1 SeiteF003 76-10526-Detail DesignMazen IsmailNoch keine Bewertungen

- H111 76-10526-Detail Design: U1 U2 U3 U4 U5 U6 U7Dokument1 SeiteH111 76-10526-Detail Design: U1 U2 U3 U4 U5 U6 U7Mazen IsmailNoch keine Bewertungen

- The Architecture of Greece Amp Rome 1902 William Anderson PDFDokument478 SeitenThe Architecture of Greece Amp Rome 1902 William Anderson PDFkarma2011100% (1)

- American History XDokument110 SeitenAmerican History XNick LaurNoch keine Bewertungen

- Article CssDokument3 SeitenArticle Cssshalini0220Noch keine Bewertungen

- Flat SlabDokument11 SeitenFlat SlabMasroor Ansari100% (2)

- A Journey in Self-Discovery - John HarricharanDokument193 SeitenA Journey in Self-Discovery - John HarricharanDr Muhammad AsifNoch keine Bewertungen

- Verbs in Past Simple and ParticipleDokument6 SeitenVerbs in Past Simple and Participleapi-289324159Noch keine Bewertungen

- Literary Criticism Lecture Two& ThreeDokument23 SeitenLiterary Criticism Lecture Two& ThreeJana WaelNoch keine Bewertungen

- Vernacular Building Material - LimeDokument16 SeitenVernacular Building Material - LimeShine You100% (1)

- What Are The Elements of A BiographyDokument3 SeitenWhat Are The Elements of A BiographyEstelle Nica Marie Dunlao100% (2)

- Sponsorship Letter LeoDokument4 SeitenSponsorship Letter LeoLeopold BrayNoch keine Bewertungen

- TSD Rev.'9', Jan' 15 CoveringDokument55 SeitenTSD Rev.'9', Jan' 15 CoveringLingaraj NaikNoch keine Bewertungen

- EENADU No 1 NewspaperDokument25 SeitenEENADU No 1 NewspaperPradip PandaNoch keine Bewertungen

- Eco-Resort PresentationDokument9 SeitenEco-Resort PresentationArchi-Leo100% (5)

- Hegel Philosophy Application On Aeschylus AgamemnonDokument5 SeitenHegel Philosophy Application On Aeschylus AgamemnonMuhammad MohsinNoch keine Bewertungen

- Selected Poems by Saigyo PDFDokument16 SeitenSelected Poems by Saigyo PDFVladimir NabokovNoch keine Bewertungen

- Painting Faces Redux PDFDokument4 SeitenPainting Faces Redux PDFhardy100% (1)

- English Speaking Board Entry Level Award ESOL Skills For Life (Reading) (Entry 2)Dokument10 SeitenEnglish Speaking Board Entry Level Award ESOL Skills For Life (Reading) (Entry 2)Miu GabrielaNoch keine Bewertungen

- Slovenian Urban Landscape Under Socialism 1969-1982Dokument16 SeitenSlovenian Urban Landscape Under Socialism 1969-1982SlovenianStudyReferences100% (1)

- Creative WritingDokument15 SeitenCreative WritingRoderick BabatuanNoch keine Bewertungen

- Experimentation of Composite Repair Techniques For PipelinesDokument13 SeitenExperimentation of Composite Repair Techniques For Pipelinesusto2014Noch keine Bewertungen

- CineWinds Core ManualDokument9 SeitenCineWinds Core ManualWally Scharold100% (1)

- Sigmar HeldenhammerDokument2 SeitenSigmar HeldenhammerAgustin Valente100% (1)

- Children's Sabbath 2012Dokument2 SeitenChildren's Sabbath 2012paheadbandNoch keine Bewertungen

- Features/Principles of Indian EthosDokument16 SeitenFeatures/Principles of Indian EthosSIDDHANT TYAGI100% (1)

- MantraDokument3 SeitenMantraMukesh SonkarNoch keine Bewertungen

- Achievers A1 Diagnostic Test 111 AngeloDokument3 SeitenAchievers A1 Diagnostic Test 111 AngeloAngelo David Muñoz Semanate50% (2)

- Pinata Unit Plan and Lessons PortfolioDokument7 SeitenPinata Unit Plan and Lessons Portfolioapi-281759709Noch keine Bewertungen

- Total Recovery - Benny Hinn PDFDokument70 SeitenTotal Recovery - Benny Hinn PDFcahuen89% (9)

- Pre Colonial PeriodDokument13 SeitenPre Colonial PeriodAngelica Dyan MendozaNoch keine Bewertungen