Beruflich Dokumente

Kultur Dokumente

Metallurgical Failure Analysis of Various Implant

Hochgeladen von

diegomez84Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Metallurgical Failure Analysis of Various Implant

Hochgeladen von

diegomez84Copyright:

Verfügbare Formate

JFAPBC (2004) 3:17-23 ASM International

DOI: 10.1361/15477020419794 1547-7029 / $19.00

O R TH O P E D I C S by B. Aksakal, .S.Yildirim, and H. Gul

Metallurgical Failure Analysis of Various Implant

Materials Used in Orthopedic Applications

Failure is one of the most

important aspects of implant

materials behavior and directly

influences the choice of materials

and production methods in

manufacturing.

Introduction

This study investigated implants

made of titanium alloy Ti6Al4V and

316L steel that were obtained from

revision operations between 1993 and

2002. The operations were required

because of various types of implant

failures. This paper illustrates nine

cases of metallurgical failures of a total

hip prosthesis, femoral compression

plates, femoral nail plates, spinal rods,

vertebral implants, and intramedullar

nails fabricated from stainless steel

and titanium alloy. The most common

causes of the implant failures eval-

uated were stress-corrosion fatigue

and wear. The other contributing

factors for the implant failures were

production errors, existence of

inclusions, stress gaps from manu- implant failure analysis is a complex provides information for improve-

facturing routes, and loosening of area of study. Despite the care taken ments in design, operating procedures,

implant material from bone due to in their design, installation, operation, and the use of components. The

lack of osseointegration. and machining, components fail. causes of failure of implant com-

Failure is one of the most impor- Although only a small fraction of im- ponents can be broken down into

tant aspects of implant materials plants fail, failure is a common occur- several categories: misuse; assembly or

behavior and directly influences the ence because of the large number of implantation errors; design errors,

choice of materials and production implants; thus, failure analysis re- including improper selection of

methods in manufacturing. Because mains an extremely important sub- materials; corrosion; corrosion fatigue;

of the many variables involved, ject. Establishing the causes of failure and wear.

Journal of Failure Analysis and Prevention Volume 4(3) June 2004 17

Metallurgical Failure Analysis of Various Implant Materials (continued)

According to statistical data, ap- processes. The implants are coated for and showed that manufacturing de-

proximately 100 million metallic better wear, with osseointegration fects and the use of nonstandard

implants were installed in humans plasma spray, sol-gel dipping, electro- materials led to failure. Implant

between 1940 and 1975.[1] The most chemical, electrophoretic, and sput- failure of a nail was investigated

important markets for medical pro- tering methods commonly used as metallurgically, and it was shown that

ducts are the United States, where surface treatments. [4-13] The full fatigue zones around distal locking

annual revenues are approximately success of an implant depends on vari- holes and screws were predominant

$62 billion, the European Union, ous factors, such as proper indication in the failure process. [20] Edwin et

with revenue of $40 billion, and of the case, surgical techniques and al.[21] showed that closed exchange

Japan, where the revenues are approx- equipment, patient rehabilitation, nailing with fibulectomy was a

imately $20 billion.[2] biocompatibility, as well as manufac- reasonable option for treatment when

Biomedical materials must not turing routes, mechanical properties, the initial nails supporting a tibial

damage the body, must sustain mini- biological stabilization, and the sur- fracture failed.

mal damage from the body, and must rounding environment. Wear and corrosion of the counter-

provide the required strength, espec- parts in sliding hip screwplates pro-

ially high fatigue strength and tough-

Selected Cases duce debris. Corrosion changes the

ness, for joints and other applications. from the Literature chemical environment around the

The essence of a biomaterial is an Gilbert et al.[14] investigated two implant, inducing an acidic pH[22]

economic (cheap) implant with the modular hip implants with a cobalt- and thus increasing the likelihood of

mechanical, physical, and chemical alloy head and a

properties that provide structural cobalt-alloy stem Corrosion changes the chemical environment

capability without deleterious effects after a fracture around the implant, inducing an acidic pH and

on the body. Metallic materials such occurred in the neck thus increasing the likelihood of corrosion.

as stainless steel, 316L, cobalt- region of the femoral

chromium alloys, and pure titanium component. It was

and its alloys have been used for sur- concluded that the fracture occurred corrosion. Surgically removed stainless

gical implant materials. The +-type due to intergranular corrosive attack steel sliding hip screwplates have

titanium alloy, such as Ti6Al4V, has and cyclic fatigue loading of the stem. shown significant wear, corrosion, and

been most widely used as an implant A numerical method (finite element) damage to the surrounding tissue.[23]

material for artificial hip joints and was developed by Chaodi et al. to Similar work with implant alloys

dental implants due to its high predict the progressive failure of a such as titanium and 316L steel[24-

26]

strength and excellent corrosion resis- thick, laminated composite femoral has supported these observations.

tance. Pure titanium and other +- component for total hip arthroplasty Additionally, Toshikazu and Mit-

type titanium alloys were originally under in vivo loading conditions.[15] suo[27] showed a relationship between

designed for use as general structural fatigue damage and mechanical

Jaffe and Scott[16] considered the

materials, especially for aerospace properties in Ti6Al4V alloy.

relationship between fatigue and

structures, but have also been adapted A review work by McGee et al.[28]

hydroxyapatite coating thickness.

for biomedical applications. The showed that early loosening is related

Lynn and DuQuesney [17] showed

development of titanium alloys espec- to poor initial fixation and design,

that residual stress generated during

ially intended to be used in living and that late loosening of a joint

plasma spray coating helps to initiate

bodies began with the introduction replacement is related to wear of the

cracks and enhance crack propagation.

of new alloys using biocompatible [18] prosthetic components. Berger et

Howie et al. showed the biological

stabilizer elements, such as iron, al. [29] showed another failure case

effects of cobalt-chromium in animal

tantalum, zirconium, tin, and occurring due to dissolution of hy-

cells and pointed out that in vitro and

niobium.[3] droxyapatite of coated implants.

in vivo findings should be compared

The manufacturing of implant with the results from human studies. These selected studies illustrate the

materials generally requires advanced Akoy et al.[19] also investigated a frac- number of variables involved in the

casting and/or continuous forging tured partial Thompson prosthesis implant failure process. However, it

18 Volume 4(3) June 2004 Journal of Failure Analysis and Prevention

is important to note that most im- removed the failed materials, they cases were due to lack of osseointe-

plants are successfully used and that were investigated metallurgically gration.[1,2] Many failures occur be-

although there are numerous failures, through a scanning electron micro- cause of bad design, misuses, improper

failure is a relatively rare event. scope (SEM). The type of implant production, and nonstandard com-

materials, their survival time in the positions and/or mechanical proper-

Materials and Methods body, their chemical composition, and ties, for example, the implant fails to

The experimental procedures used the reasons for failure are summarized fulfill the requirements of an Inter-

to investigate the failures reported in Table 1. The analysis showed that national Organization for Standard-

here include visual inspection and the reasons for implant failures were ization (ISO) standard.

both macroscopic and microscopic corrosive attack, improper manufac- Metal fatigue has been studied

characterization. The materials turing, and fatigue. extensively, and the fatigue strengths

studied in this work were six implants of common metallic implant alloys

that were extirpated from revision Results and Discussion used in orthopedic applications, such

patients. None of the patients had Surgical implants are exposed to as stainless steel, cobalt, and titanium

septic symptoms. These implants aggressive working conditions in alloys, and their relations to their

were located in patients for an average terms of corrosion, wear, and mech- microstructure, surface, and corrosion

time period of 2 to 3 years (minimum, anical loading (static and dynamic). properties have also been reported.[32-

6 months; maximum, 7 years). The The possibility of premature failure 34]

Despite numerous investigations,

application time together with the exists, and such failures are influenced the occurrence of such failures is still

causes of failure are summarized in by factors such as materials selection, a major problem. A variety of micro-

Table 1. manufacturing practice, medical graphic features were observed on the

installation procedure, postoperative fractured or mechanially damaged

Failed implant materials removed

complications, and patient mis- surfaces and through microscopic

from patients undergoing coxarthrosis

use.[30,31] The systematic investigation indications. These features include

and scoliosis revision operations were

of retrieved surgical implants in- intergranular/transgranular cracking,

the core of the investigations. A total

creases the knowledge regarding fatigue striations, and cleavage or

hip prosthesis was implanted in 1993,

clinical implant performance, demon- cleavagelike surface topography.

and after 7 years, a fracture occurred

strates interactions between implants

in the femoral stem. In three other Several implant failure cases that

and the body, provides a basis for the

cases, fractures occurred in less than occurred in the authors patients over

development of biocompatible im-

2 years. Observations showed that for a 9 year period are shown in Fig. 1.

plant materials, encourages design

nearly all fracture cases, improper Between 1993 and 2002, 37 osteo-

optimization, and assists medical

osseointegration accelerated the synthesis reimplantations were made;

device research.

implant failure. In a case of implanta- in six of the cases, the implant

tion due to scoliosis, a spinal rod fail- Statistical analysis shows that 5 to loosened due to biological wear, and

ure occurred 3 years after the opera- 10% of the 6.2 million implants crack three of the cases were due to infec-

tion. After the revision operations while in service and that many of the tion. A total hip prosthesis was

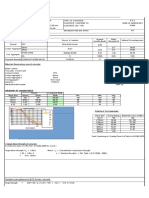

Table 1 Type of Implant Material, Chemical Composition, Survival Time

in Body, and Reasons for Failure

Type of Implant Composition Survival Time, yr Failure Reason

Total hip prosthesis 17Cr-14Ni 7 Inclusions, shrinkage cavities,

segregations

Intramedullar nails 15Cr-10Ni-15Nb 1.5 Wear, fatigue

Spinal rods 17Cr-15Ni-3Mn 3 Corrosive attack, pitting, wear

Compression plates Ti-6Al-4V 1 Inclusions,

multiorigined ductile fracture

Vertebral implant 316L 2 Erosion-corrosion, stress corrosion Fig. 1 Several implant failures that occurred

Femoral nail plate 316L 2.5 Wear, fatigue, stress corrosion in the authors patients

Journal of Failure Analysis and Prevention Volume 4(3) June 2004 19

Metallurgical Failure Analysis of Various Implant Materials (continued)

replaced because of pain. After re- Figure 2(a) shows a fractured spinal The SEM micrograph in Fig. 3

moving the prosthesis, it was seen that rod postoperated from a 2-year-old shows that the fracture surface that

the implant was broken at the stem. boy due to thoracal scoliosis. Figure caused the failure is due to a combined

Segregation, inclusions, and micro- 2(b) is an intramedullar nail osteo- effect of inclusions and perhaps a

constituents are aligned and elongated synthesis femur diaphyseal fracture shrinkage cavity from casting. Intra-

in directions determined by the metal failure postoperated from a 2-year- medullar rods failed in the body and

flow, resulting in mechanical fibering. old boy. A plate (jewet) osteosynthesis were replaced. After microstructural

Centerline segregation in the ingot and subtrochanteric fracture failure examination, it was determined that

caused center cracks in forging oper- postoperated from a 3-year-old boy failure occurred due to low fatigue

ations, and this acted as a stress con- is shown in Fig. 2(c), while Fig. 2(d) strength. The SEM fractograph in

centrator or crack initiator. shows a postoperated osteosynthesis Fig. 4 shows striation lines and secon-

Radiographs of some of the failed femur diaphyseal fracture failure from dary fatigue cracks. In addition, a

implants are shown in Fig. 2(a-d). a 2-year-old boy. fretting effect also took place, and this

is an indication of wear assisted by

selective attack. Figure 5 shows an

intergranular fracture surface with a

triple point at the grain juncture due

to stress corrosion. For hexagonal

close-packed metals, the dislocation

structure and cyclic behavior are more

sensitive to crystal orientation than

are cubic metals because their aniso-

tropic properties produce diverse

microfractographic features.[35-37]

Figure 6 shows the fracture surfaces

of a vertebral implant made of 316L,

where stress corrosion caused brit-

tleness and resulted in brittle fracture.

Some of the factors that cause stress

corrosion are misalloying, aggressive

body environment, and residual

stresses. The latter caused this type

of failure. In nearly all prosthetic

devices, and particularly those having

multicomponents, the regions of stress

concentration often coincide with

crevice areas, where localized corro-

sion is more likely. [32] The adverse

effects of implant-derived wear par-

ticles on periprosthetic tissues are also

important in bone loss and loosening

of implant prostheses. Early loosening

is related to poor initial fixation and

design; late loosening, which is the

major problem and principal cause of

failure, is related to wear of the pros-

Fig. 2 Radiographs of failed implants. (a) Spinal rod failure. (b) Intramedullar nail fracture and thetic components.[28]

osteosynthesis failure. (c) Subtrochanteric plate (jewet) fracture failure. (d) Femur diaphyseal

fracture failure of a compression plate The conjoint degradation processes

20 Volume 4(3) June 2004 Journal of Failure Analysis and Prevention

of corrosion and wear of metal sur- 13Zr and highest for Ti6Al4V.[24] spinal hollow rod was removed from

faces is clearly of great importance in The clinical consequences of at least another patient. Through SEM

the design of orthopedic prostheses. partially corroding implants are well observations, it was seen that a typical

In a situation in which corrosion and known. The release of solutes, that is, pitting-type failure occurred due to

wear are both possible degradation corrosion products, at an implant site corrosive attack, which originated the

mechanisms, each could have a pro- may cause histological changes in the fracture from inside the hollow rod,

found effect on the other. However, local tissue by either direct toxic as shown in Fig. 8.

overall degradation when both corro- effects or a local hypersensitivity reac- The failure during use of a titanium

sion and wear processes are occurring tion, because elemental nickel, cobalt, reconstruction plate for osteosynthesis

is shown to be lowest for Ti-13Nb- and chrome as well as their com- was investigated through SEM, and

pounds are known allergens.[25] In Fig. the fractured surfaces are shown in

7, a typical surface resulting from Fig. 9(a-c). From the micrographs, it

erosion-corrosion damage is seen. A can be observed that the crack ori-

ginated from inclusions (Fig. 9a),

appears mainly in brittle regions (Fig.

9b), and resulted in multiorigined

ductile fracture with dimples (Fig.

Fig. 3 Scanning electron micrograph showing

combined effect of inclusions and

shrinkage cavity during casting

Fig. 6 Scanning electron micrograph of stress

corrosion

Fig. 4 Scanning electron micrograph showing

fatigue striations and secondary fatigue

cracks Fig. 7 Typical surface resulting from erosion-

corrosion damage c

Fig. 9 (a) The crack originated from

Fig. 5 Intergranular fracture surface showing inclusions. (b) The crack propogated

a triple point at the grain juncture due Fig. 8 Pitting-type failure occurred due to and resulted in multiorigined style.

to stress corrosion corrosive attack (c) Ductile fracture with dimples

Journal of Failure Analysis and Prevention Volume 4(3) June 2004 21

Metallurgical Failure Analysis of Various Implant Materials (continued)

9c). Selective attack and intergranular The study revealed that the failure Failure Modes in Orthopaedic Implants,

cracking on the external surface of the of the stainless steel femoral com- Proc. Int. Symp. on Retrieval and Analysis

of Orthopaedic Implants, NBS special publ.

plate occur mainly near the fracture pression plates occurred by a 472, National Bureau of Standards, MD,

origin (Fig. 10). fretting-fatigue mechanism under 1976, pp. 11-21.

From the analysis, it can be con- the action of low nominal stresses 6. P. Ducheyne, J. Beight, J. Cuckler, B.

cluded that implant failures most and unidirectional bending. Evans, and S. Radin: Effect of Calcium

Phosphate Coating Characteristics on

often result in ductile fracture forms The failure of femoral compression

Early Post-Operative Bone Tissue

due to excessive dynamic loading in titanium plates occurred by corro- Ingrowth, Biomaterials, 1990, 11, pp. 531-

which a high amount of plastic sion fatigue promoted by the pres- 40.

energy is absorbed. Inadequate im- ence of intense localized corrosion 7. S. Ban and S. Maruno: Effect of Temp-

plant material as well as nonstandard and intergranular cracking. erature on Electrochemical Deposition of

composition and manufacturing pro- The failure of hollow spinal rods

Calcium Phosphate Coatings in a Simu-

cesses, improper design and heat lated Body Fluid, Biomaterials, 1995, 16,

occurred by overload caused by the pp. 977-81.

treatment, and faulty coating meth- intense formation of pitting corro-

ods are the main reasons for failure. 8. J.A. Jansen, J.G. Wolke, S. Swann, J.P.

sion during service. The pitting was Van der Waerden, and K. deGroot:

associated with the presence of Application of Magnetron Sputtering for

Conclusions superficial manufacturing routes. Producing Ceramic Coatings on Implant

Through metallurgical SEM anal- Materials, Clin. Oral Implants Res., 1993,

ysis, it was found that 42% of failures As a result of the analysis of various 4, pp. 28-34.

occurred due to corrosion plus ero- implant materials, the main reasons 9. C.S. Kim and P. Ducheyne: Compo-

sion-corrosion, 16.5% were due to in- for failure are corrosive attack, manu- sitional Variations in the Surface and Inter-

clusions and stress gaps that could be facturing defects, and nonstandard- face of Calcium Phosphate Ceramic

caused failures. Biocompatible Coatings on Ti and Ti-6Al-4V due to

correlated to fatigue, 16.5% had traces Sintering and Immersion, Biomaterials,

of production impurities, and 25% inorganic materials, such as hydroxy- 1991, 12, pp. 461-69.

showed fatigue via ductile-type fail- apatite coating with some binders,

10. P. Cheang and K.A. Khor: Addressing

ures. The results/reasons correlation would make the dissolution of metal Processing Problems Associated with Plas-

can be summarized as follows: ions difficult and so may delay corro- ma Spraying of Hydroxyapatite Coatings,

sion and wear and also minimize the Biomaterials, 1996, 17, pp. 537-44.

In the investigation of a total hip loosening of implants from bone. 11. C.P.A.T. Klein, J.G.C. Wolke, J.M.A. de

prosthesis, the fracture was multi- Blieck-Hogervorst, and K. deGroot:

origined, probably due to the pres- References Features of Calcium Phosphate Plasma-

ence of manufacturing defects in 1. G.K Smith and J. Black: Models for Sprayed Coatings: An In Vitro Study, J.

both surfaces of the device; was Systemic Effects of Metallic Implants, Biomed. Mater. Res., 1994, 28, pp. 961-

Proc. Int. Symp. on Retrieval and Analysis 67.

associated with poor design of the

of Orthopaedic Implants, NBS special publ. 12. K. Ishikawa, M. Kon, S. Tenshin, and N.

component; and introduced points 472, National Bureau of Standards, MD, Kuwayama: Effect of Preparation Condi-

of high stress concentration. 1976, pp. 23-30. tions in Aqueous Solution on Properties

2. C.R.F. Azevedo and E. Hippert, Jr.: of Hydroxyapatite, Dent. Mater., 1990, 9,

Failure Analysis of Surgical Implants in pp. 58-69.

Brazil, J. Eng. Failure Analys., 2002, 9, 13. P. Ducheyne, W. Van Raemdonck, J.C.

pp. 621-33. Heughebaert, and M. Heughebaert:

3. C.R.F. Azevedo: Failure Analysis of a Structural Analysis of Hydroxyapatite

Commercially Pure Titanium Plate for Coatings on Titanium, Biomaterials, 1986,

Osteosynthesis, J. Eng. Failure Analys., 7, pp. 97-103.

2003, 10, in press. 14. J.L. Gilbert, C.A.Buckley, et al.: Inter-

4. G. Pitrowski: Clinical Biomedics, Proc. granular Corrosion-Fatigue Failure of

Int. Symp. on Retrieval and Analysis of Cobalt-Alloy Femoral Stems, J. Bone

Orthopaedic Implants, NBS special publ. Joint Surg. Am., 1994, 76(1), pp.110-15.

Fig. 10 Intergranular cracking by selective 472, National Bureau of Standards, MD, 15. L. Chaodi, G. Christopher, et al.: Pro-

attack on the external surface of the 1976, pp. 41-49. gressive Failure Analysis of Laminated

plate near the fracture origin 5. D.F. Williams: A Review of Metallurgical Composite Femoral Prostheses for Total

22 Volume 4(3) June 2004 Journal of Failure Analysis and Prevention

Hip Arthroplasty, Biomaterials, 2002, 23, of Titanium Alloys, Biomaterials, 1999, 33. S. Suresh: Fatigue of Materials, Cambridge

pp. 4249-62. 20, pp. 765-72. University Press, New York, 1998.

16. W.L. Jaffe and D.F. Scott: Total Hip 25. L.Reclaru et al.: Corrosion Behaviour of 34. S.S. Manson: ASTM STP 495, Avoidance,

Arthroplasty with Hydroxyapatite-Coated a Welded Stainless-Steel Orthopedic Control, and Repair of Fatigue Damage,

Prosthesis, J. Bone Joint Surg., 1996, 78- Implant, Biomaterials, 2001, 22, pp. 269- ASTM, Philadelphia, 1971, pp. 254-346.

A(12), pp. 1919-34. 79. 35. R.O. Ritchie, R.H. Dauskardt, and B.N.

17. A.K. Lynn and D.L. DuQuesnay: 26. J. Walczak, F. Shahgaldi, and F. Heatley: Cox: Fatigue of Advanced Materials:

Hydroxyapatite-Coated Ti-6Al-4V, Part In Vivo Corrosion of 316L Stainless-Steel Summary and Future Trends, Proc. of the

1: The Effect of Coating Thickness on Implants, Biomaterials, 1998, 19, pp. 229- Eng. Foundation Int. Conf. (Santa Barbara,

Mechanical Fatigue Behaviour, Bio- 37. CA), 1991, pp. 485-93.

materials, 2002, 23, pp. 1937-46. 27. A. Toshikazu and N. Mitsuo: Fracture 36. G. Haicheng, G. Huifang, C.Shufen, and

18. D.W. Howie, S.D. Rogers, et al.: Bio- Characteristics of Fatigued Ti6Al4V ELI C. Laird: Orientaiton Dependence of

logical Effect of Cobalt Chrome in Cell as an Implant Material, Mater. Sci. Eng. Cyclic Deformation in High Purity

and Animal Models, Clin. Orthop., 1996, A, 1998, 243, pp. 237-43. Titanium Single Crystals, Mater. Sci. Eng.

pp. 217-32. A, 1994, 118, pp. 23-36.

28. M.A. McGee et al.: Implant Retrieval

et al.: Failure Studies of the Wear and Loosening of 37. I. Aitchison and B. Cox: Interpretation

19. M.A. Akoy, M. Baydogan,

Prosthetic Joints: A Review, Wear, 2000, of Fractographs of SSC in Hexagonal

Analysis on a Femur Prosthesis, The Fifth

Turkey), Sept. 241, pp. 158-65. Metals, Corrosion, 1972, 28(3), pp. 83-

Int. Fracture Symp. (Elazig,

87.

2001. 29. G. Berger, U. Ploska, and G. Willmann:

38. J.C. Chesnutt and J.C. Williams: Com-

20. G. Christian, S. Stefanie, et al.: Implant Hydroxyapatites Solubility May Cause

ments on the Electron Fractography of

Failure of the Gamma Nail, Injury, Int. J. Loosening of Coated Implants, Proc. 13th

Alpha Titanium, Metall. Trans. A, 1977,

Care Injured, 1999, 30, pp. 91-99. Int. Symp. on Ceramics in Medicine

8(3), pp. 514-15.

(Bologna, Italy), 2001, pp. 192-95.

21. M.M. Edwin, V.A. Edward, J.S. Peter, and

J.S. Neal: Exchange Nailing for Failure 30. O.E.M. Pohler: Failure of Metallic

of Initially Rodded Tibial Shaft Fractures, Orthopaedic Implants, Materials Charac- B. Aksakal, Atatrk University,

J. Orthop., 2001, 24(8), pp. 757-62. terization, Vol 10, Metals Handbook, 9th

ed., American Society for Metals, Metals

Engineering Faculty, Department of

22. H.G. Willer, L.G. Broback, and G.H. Park, OH, 1986, pp. 668-94. Mechanical Engineering, 25240

Buchorn: Crevice Corrosion of Cemented Erzurum, Turkey. .S.Yildirim,

31. J.H. Dumplenton and E.H. Miller: Failure

Titanium Hip Implants, Clin. Orthop.,

1996, 333, pp. 51-57.

of Metallic Orthopaedic Implants, in Atatrk University, Faculty of

Metals Handbook, 8th ed., ASM Inter- Medicine, Department of Ortho-

23. B.F. Shagaldi and J. Compson: Wear and national, Materials Park, OH, 1993, pp.

Corrosion of Sliding Counterparts of

pedics, Erzurum, Turkey. H. Gul,

571-80.

Stainless-Steel Hip Screw-Plates, Injury, University of Firat,Vocational School

32. K.R. Wheller and L.A. James: Fatigue

Int. J. Care Injured, 2000, 31, pp. 85-92. Behaviour of Type 316 Stainless Steel under of Technical Sciences, Elazig, Turkey.

24. M.A. Khan, R.L. Williams, and D.F. Simulated Body Conditions, J. Biomed. Contact e-mail: baksakal@atauni.

Williams: Conjoint Corrosion and Wear Mater. Res., 1971, pp. 267-81. edu.tr.

What do you want to learn today?

Subscription information on page 2.

Journal of Failure Analysis and Prevention Volume 4(3) June 2004 23

Das könnte Ihnen auch gefallen

- Adiabatic Shear Localization: Frontiers and AdvancesVon EverandAdiabatic Shear Localization: Frontiers and AdvancesBradley DoddNoch keine Bewertungen

- FatigueDokument32 SeitenFatigueNicolau Morar33% (3)

- Article Failure AnalysisDokument25 SeitenArticle Failure AnalysisMd KalamuddinNoch keine Bewertungen

- Other Causes of Fastener FailuresDokument3 SeitenOther Causes of Fastener Failuresmp87_ingNoch keine Bewertungen

- Advances in Fatigue and FractureDokument248 SeitenAdvances in Fatigue and FractureBrandon EricksonNoch keine Bewertungen

- Analysis of Steam Turbine Blade Failure LOW PRESSURE TURBINEDokument7 SeitenAnalysis of Steam Turbine Blade Failure LOW PRESSURE TURBINEpoojaNoch keine Bewertungen

- Corrosion Chemistry PDFDokument429 SeitenCorrosion Chemistry PDFCrissAngelica100% (1)

- Strain Based Evaluation of Dents in Pressurized PipesDokument6 SeitenStrain Based Evaluation of Dents in Pressurized Pipesmaziar60Noch keine Bewertungen

- Interpretation of The Microstructure of SteelsDokument61 SeitenInterpretation of The Microstructure of SteelsCiresica Sanda Cocindau100% (1)

- Failure Analysis of Engineering MaterialsDokument2 SeitenFailure Analysis of Engineering Materialsmahesh0% (1)

- NACE-Stress Corrosion Cracking (SCC)Dokument3 SeitenNACE-Stress Corrosion Cracking (SCC)Mohamed AtefNoch keine Bewertungen

- Metallography in Failure Analysis PDFDokument300 SeitenMetallography in Failure Analysis PDFAbhinandan Admuthe100% (4)

- Mechanism of Failure by Hydrogen-Induced Cracking PDFDokument216 SeitenMechanism of Failure by Hydrogen-Induced Cracking PDFsankhadipNoch keine Bewertungen

- IIW Document XIII-2235-08Dokument11 SeitenIIW Document XIII-2235-08Amanda SmithNoch keine Bewertungen

- Failure AnalysisDokument7 SeitenFailure AnalysisbefoaNoch keine Bewertungen

- Murakami - Analysis of Stress Intensity Factors of Modes I, II and III For Inclined Surface Cracks of Arbitrary ShapeDokument14 SeitenMurakami - Analysis of Stress Intensity Factors of Modes I, II and III For Inclined Surface Cracks of Arbitrary ShapeDavid C HouserNoch keine Bewertungen

- Integrated Approach RLA of Reformer Tubes NDT (ARTiS) PDFDokument8 SeitenIntegrated Approach RLA of Reformer Tubes NDT (ARTiS) PDFSatya RaoNoch keine Bewertungen

- Understanding of TWI J-R CurvesDokument21 SeitenUnderstanding of TWI J-R CurvespcastlesmithNoch keine Bewertungen

- Fatigue Failure of BoltsDokument2 SeitenFatigue Failure of Boltskkaranag100% (1)

- Caustic Stress Corrosion Cracking of A Graphite Cast Iron ComponentDokument8 SeitenCaustic Stress Corrosion Cracking of A Graphite Cast Iron Componentriza9847Noch keine Bewertungen

- Forms of Corrosion PDFDokument74 SeitenForms of Corrosion PDFTruth SeekerNoch keine Bewertungen

- Materials Challenges in Nuclear EnergyDokument24 SeitenMaterials Challenges in Nuclear EnergyW.t. HanNoch keine Bewertungen

- Internal Oxide ApplicationDokument8 SeitenInternal Oxide ApplicationEduardoNoch keine Bewertungen

- STP1165 Eb.1415051 1 PDFDokument450 SeitenSTP1165 Eb.1415051 1 PDFpaola100% (1)

- Eccc Eccc Data Sheets Approved On Behalf of Eccc DateDokument150 SeitenEccc Eccc Data Sheets Approved On Behalf of Eccc DateAlkku100% (1)

- Hydrogen EmbrittlementDokument258 SeitenHydrogen Embrittlementchris nelsonNoch keine Bewertungen

- Inconel Research Paper PDFDokument227 SeitenInconel Research Paper PDFAnonymous OEUUoKHYR100% (1)

- SliversDokument5 SeitenSliversVarun MishraNoch keine Bewertungen

- Carbon Steel HandbookDokument172 SeitenCarbon Steel Handbookmahasiswa lamaNoch keine Bewertungen

- Microstructure Degradation After Prolonged Exploitation of Heatresistant Steel 14mov6-3Dokument5 SeitenMicrostructure Degradation After Prolonged Exploitation of Heatresistant Steel 14mov6-3IJMERNoch keine Bewertungen

- Envirom Cracking&Short Crack GrowthDokument203 SeitenEnvirom Cracking&Short Crack GrowthAndres_Pastor1987Noch keine Bewertungen

- IOW PresentationDokument20 SeitenIOW Presentationbarry nancooNoch keine Bewertungen

- On Site MetallographyDokument7 SeitenOn Site Metallographyhatem jafouraNoch keine Bewertungen

- EpriDokument21 SeitenEprihubert_veltenNoch keine Bewertungen

- Case Study of Bolt FailureDokument13 SeitenCase Study of Bolt FailureJB MadeleineNoch keine Bewertungen

- Centralloy G 4852 Micro R: Material Data SheetDokument8 SeitenCentralloy G 4852 Micro R: Material Data SheetNest NectureNoch keine Bewertungen

- Polythionic Acid Stress Corrosion CrackingDokument9 SeitenPolythionic Acid Stress Corrosion CrackingMedina EldesNoch keine Bewertungen

- Environment Assisted Cracking ME 472: Corrosion EngineeringDokument45 SeitenEnvironment Assisted Cracking ME 472: Corrosion EngineeringEmmanuelNoch keine Bewertungen

- Degradation Internal P WRDokument198 SeitenDegradation Internal P WRAndres_Pastor1987100% (1)

- 1 - A Study Concerning Intercritical HAZ Microstructure and Toughness in ...Dokument10 Seiten1 - A Study Concerning Intercritical HAZ Microstructure and Toughness in ...Filipe RenanNoch keine Bewertungen

- 27964E00Dokument14 Seiten27964E00Ua AnyanhunNoch keine Bewertungen

- Leak Before Break Fracture Mechanics ThesisDokument251 SeitenLeak Before Break Fracture Mechanics ThesisMohamed Elwi MitwallyNoch keine Bewertungen

- Failure Analysis of Helical Gear Shaft in Hot Rolling MillDokument7 SeitenFailure Analysis of Helical Gear Shaft in Hot Rolling Millvasundhara singhNoch keine Bewertungen

- What Is New in 4th Edition of API RP 580Dokument8 SeitenWhat Is New in 4th Edition of API RP 580MOHAMMAD RAMZANNoch keine Bewertungen

- Chapter 10: Failure: Issues To Address..Dokument31 SeitenChapter 10: Failure: Issues To Address..Jhei UploadNoch keine Bewertungen

- Forms of Corrosion Corrosion-Fatigue Erosion-CorrosionDokument105 SeitenForms of Corrosion Corrosion-Fatigue Erosion-CorrosionAnupam Chowdhury100% (1)

- COE10102, Forms of CorrosionDokument60 SeitenCOE10102, Forms of CorrosionامينNoch keine Bewertungen

- Failure Analysis of Reformer Tubes: Technicalarticle-Peer-ReviewedDokument6 SeitenFailure Analysis of Reformer Tubes: Technicalarticle-Peer-ReviewedOwais MalikNoch keine Bewertungen

- Keys To Maintenance and Repair of Coke Drums Derrick RogersDokument34 SeitenKeys To Maintenance and Repair of Coke Drums Derrick RogersNatrajiNoch keine Bewertungen

- Alloy 625Dokument369 SeitenAlloy 625Luis Jose Duran100% (2)

- Asset Intelligence Report - A Primer On High Temperature Hydrogen AttackDokument9 SeitenAsset Intelligence Report - A Primer On High Temperature Hydrogen AttackVajid MadathilNoch keine Bewertungen

- Sintap Procedure Version 1aDokument231 SeitenSintap Procedure Version 1aAnonymous tLUB9IQhbNoch keine Bewertungen

- Creep & SpheroidizationDokument10 SeitenCreep & Spheroidizationabet_singkong8930Noch keine Bewertungen

- Lesson 2 - Types of Failure and Stress PDFDokument75 SeitenLesson 2 - Types of Failure and Stress PDFJavier Ayala Huaman100% (1)

- Mechanism of SCCDokument10 SeitenMechanism of SCCAPI100% (1)

- Residual Stress Analysis of Pipeline Girth Weld JointsDokument289 SeitenResidual Stress Analysis of Pipeline Girth Weld JointsGabriel Vazquez Vega100% (1)

- Procedures For Assessing The FitnessDokument12 SeitenProcedures For Assessing The FitnessRaja HoneNoch keine Bewertungen

- Corrosion Failures: Theory, Case Studies, and SolutionsVon EverandCorrosion Failures: Theory, Case Studies, and SolutionsNoch keine Bewertungen

- XRDDokument19 SeitenXRDதமிழன்Noch keine Bewertungen

- Converter Atomic Percent To Weight PercentDokument6 SeitenConverter Atomic Percent To Weight Percentdiegomez84Noch keine Bewertungen

- XRDDokument19 SeitenXRDதமிழன்Noch keine Bewertungen

- Astm F139Dokument5 SeitenAstm F139diegomez84Noch keine Bewertungen

- Cause of An Implant Fracture Material - or Fabrication FailureDokument10 SeitenCause of An Implant Fracture Material - or Fabrication Failurediegomez84Noch keine Bewertungen

- Failure Analysis of A Ti6Al4V Cementless HIP ProsthesisDokument9 SeitenFailure Analysis of A Ti6Al4V Cementless HIP Prosthesisdiegomez84Noch keine Bewertungen

- Biocompatibility of Polyethylene Terephthalate Knee LigamentDokument8 SeitenBiocompatibility of Polyethylene Terephthalate Knee Ligamentdiegomez84Noch keine Bewertungen

- 036 000 380Dokument84 Seiten036 000 380diegomez84Noch keine Bewertungen

- Lesson 1 XRD and Rietveld RefinementDokument34 SeitenLesson 1 XRD and Rietveld Refinementdiegomez84Noch keine Bewertungen

- Prestige Cervical DiskDokument4 SeitenPrestige Cervical Diskdiegomez84Noch keine Bewertungen

- In-Body Corrosion Fatigue Failure of A Stainless SteelDokument10 SeitenIn-Body Corrosion Fatigue Failure of A Stainless Steeldiegomez84Noch keine Bewertungen

- ASTM A 751 - 07aDokument6 SeitenASTM A 751 - 07analakasaNoch keine Bewertungen

- Macross 30 Translation GuideDokument113 SeitenMacross 30 Translation Guidediegomez84100% (6)

- Hankil RetractorDokument12 SeitenHankil Retractordiegomez84Noch keine Bewertungen

- C158.5527-1 2007Dokument9 SeitenC158.5527-1 2007diegomez84Noch keine Bewertungen

- D3776.617737-1 Peso Por Unidad de ÁreaDokument5 SeitenD3776.617737-1 Peso Por Unidad de Áreadiegomez84Noch keine Bewertungen

- D0695-08 Com Pres Ion en PlasticosDokument8 SeitenD0695-08 Com Pres Ion en Plasticosdiegomez84Noch keine Bewertungen

- Effect of Operating Conditions On COP of VCRDokument9 SeitenEffect of Operating Conditions On COP of VCRSatheesh ChandranNoch keine Bewertungen

- Remote Control Programming GuideDokument47 SeitenRemote Control Programming GuideArslan Saleem0% (1)

- Planetary GearboxDokument5 SeitenPlanetary GearboxMark Glenn ManzanoNoch keine Bewertungen

- Spaulding Lighting Ventura Spec Sheet 8-84Dokument2 SeitenSpaulding Lighting Ventura Spec Sheet 8-84Alan MastersNoch keine Bewertungen

- HSE Guide For Hot Tapping Part 1-13Dokument4 SeitenHSE Guide For Hot Tapping Part 1-13abhisheknharanghat100% (1)

- Methanol PresentationDokument29 SeitenMethanol PresentationCristina OzarciucNoch keine Bewertungen

- BITZER Output Data: Created On: 16/05/2017 16:44:22Dokument5 SeitenBITZER Output Data: Created On: 16/05/2017 16:44:22Hasan Syaiful INoch keine Bewertungen

- 01CB1S01Dokument5 Seiten01CB1S01raobabar21Noch keine Bewertungen

- K 5 Premium Full Control Plus: Operating InstructionsDokument84 SeitenK 5 Premium Full Control Plus: Operating Instructionsronald DNoch keine Bewertungen

- Pressure Vessel Exm QuestionsDokument4 SeitenPressure Vessel Exm QuestionsJithuJohn100% (1)

- Changshu Walsin Specialty Steel Co., LTD: Company ProfileDokument1 SeiteChangshu Walsin Specialty Steel Co., LTD: Company ProfileHarish KrishnamoorthyNoch keine Bewertungen

- Hybrid Geosynthetic Paving Mat For Highway ApplicationsDokument4 SeitenHybrid Geosynthetic Paving Mat For Highway ApplicationsmithileshNoch keine Bewertungen

- Artigo - Contribuição em Estudos Reológicos de Autonivelante Com Adição de Resíduo Rocha OrnamentalDokument12 SeitenArtigo - Contribuição em Estudos Reológicos de Autonivelante Com Adição de Resíduo Rocha OrnamentalDjalma NetoNoch keine Bewertungen

- Automobile Waste and Its Management PDFDokument7 SeitenAutomobile Waste and Its Management PDFBojan TanaskovskiNoch keine Bewertungen

- Inhibitor Choice & DosageDokument6 SeitenInhibitor Choice & DosagemnasiroleslamiNoch keine Bewertungen

- Project Report On GearsDokument40 SeitenProject Report On Gearsjai70% (27)

- Documents - MX - Fisher Desuperheaters Bulletin April 2008 PDFDokument12 SeitenDocuments - MX - Fisher Desuperheaters Bulletin April 2008 PDFsaji_t1984Noch keine Bewertungen

- M 237Dokument4 SeitenM 237Katerin Hernandez0% (1)

- MacReburBrochure WebDokument16 SeitenMacReburBrochure WebYarSakawatuNoch keine Bewertungen

- Ductless Fume Hood Brochure - FEB19Dokument2 SeitenDuctless Fume Hood Brochure - FEB19Musz MusaNoch keine Bewertungen

- Ce 326 Principles of Environmental Engineering: SPRING 2010Dokument2 SeitenCe 326 Principles of Environmental Engineering: SPRING 2010Jorge Gomez RamirezNoch keine Bewertungen

- Fast Moving Consumer Goods (FMCG) Products and ProjectsDokument4 SeitenFast Moving Consumer Goods (FMCG) Products and ProjectsMurali Krishna ThotaNoch keine Bewertungen

- Thermal Lab PPT - Heat Balance SheetDokument10 SeitenThermal Lab PPT - Heat Balance SheetAyush SinghalNoch keine Bewertungen

- 2.1 Testing MachineDokument3 Seiten2.1 Testing MachinekoushipriyathamNoch keine Bewertungen

- Friction and Lubrication in Medieval Europe The Emergence of Olive Oil As A Superior AgentDokument23 SeitenFriction and Lubrication in Medieval Europe The Emergence of Olive Oil As A Superior AgentstankevichijusNoch keine Bewertungen

- IRENA Biogas For Road Vehicles 2017Dokument64 SeitenIRENA Biogas For Road Vehicles 2017bulutysnNoch keine Bewertungen

- M25 (PPC)Dokument2 SeitenM25 (PPC)Jagdev GuleriaNoch keine Bewertungen

- Material Safety Data Sheet: Silicomanganese SlagDokument8 SeitenMaterial Safety Data Sheet: Silicomanganese SlagbamboNoch keine Bewertungen

- Packing ListDokument1 SeitePacking ListanuNoch keine Bewertungen