Beruflich Dokumente

Kultur Dokumente

64-Laser Safety Manual

Hochgeladen von

ROSSIOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

64-Laser Safety Manual

Hochgeladen von

ROSSICopyright:

Verfügbare Formate

CALIFORNIA INSTITUTE OF

TECHNOLOGY

LASER SAFETY

MANUAL

A Publication of the Caltech Safety Office

1200 E. California Boulevard

Mail Code 25-6

Pasadena, CA 91125

(626) 395-6727

safety@caltech.edu

http://www.safety.caltech.edu

Laser Safety Manual 1

1. INTRODUCTION

INTRODUCTION This manual describes the Institutes laser safety program.

The purpose of this program is to protect Caltech

personnel, guests, and property from the hazards associated

with lasers and laser systems.

This manual does not describe the theory behind lasers or

the various types and uses of lasers. It is assumed that

researchers operating lasers have sufficient knowledge in

those areas. However, resources are available through the

Safety Office which covers these topics.

PRINCIPAL INVESTIGATORS The primary responsibility for ensuring the safe use of

lasers belongs to Principal Investigators (PIs). Specifically,

PIs are responsible for ensuring:

Only authorized individuals operate lasers or have

access to controlled areas during laser operations.

Individuals authorized to use lasers have received

adequate training.

Appropriate personal protective equipment (PPE) is

available and worn when necessary.

Operating procedures include adequate safety measures.

Lasers manufactured or modified at Caltech are

properly classified and labeled.

Proper laser warning signs are posted.

All class 3b and 4 lasers have been registered with the

Safety Office.

OPERATORS Persons operating lasers are responsible for following

proper operating and safety procedures and only performing

operations authorized by the PI. Operators are also

responsible for restricting access to controlled areas during

operations.

SAFETY OFFICE Members of the Safety Office are available to provide

support in all aspects of laser safety, including:

Providing training and/or training materials to laser

operators.

Classifying lasers and providing appropriate signs and

labels.

Determining proper protective eye wear and other PPE.

Reviewing operating and safety procedures.

Laser Safety Manual 2

2. LASER HAZARDS

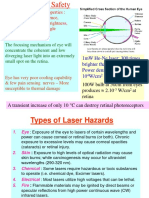

EYE Different structures of the eye can be damaged from laser

light depending on the wavelength. Retinal burns, resulting

in partial or complete blindness are possible in the visible

(400 - 700 nm) and near-infrared (700 - 1400 nm) regions.

At these wavelengths, the eye will focus the beam or a

specular reflection on a tiny spot on the retina. This

focusing increases the irradiance of the beam by a factor of

about 100,000.

Laser emissions in the ultraviolet (< 400 nm) and far-

infrared (> 1400 nm) regions are primarily absorbed by and

cause damage to the cornea. In the near-ultraviolet range

(315 - 400 nm), some of the radiation reaches the lens of

the eye.

SKIN Skin damage can occur from exposure to infrared or

ultraviolet light. For infrared exposure, the results can be

thermal burns or excessively dry skin depending on the

intensity of the radiation. In the 230 - 380 nm range of

ultraviolet light, erythema (sunburn), skin cancer, or

accelerated skin aging are possible. The most damaging

region of ultraviolet is 280 - 315 nm, also known as UV-B.

ELECTRICAL Many lasers contain high-voltage components which can

present a potentially lethal hazard. Proper lockout

procedures should be followed when working on high-

voltage components. (See the Caltech Lockout Program.)

FIRE Many class 4 lasers are capable of igniting combustible

materials. Care should be taken when choosing beam stops

and shielding material.

HAZARDOUS MATERIALS Laser laboratories contain many of the same hazards found

in many chemical laboratories and therefore the same

precautions should be taken. (See the Caltech Chemical

Hygiene Plan.) In addition, most laser dyes are considered

to be hazardous materials and should be handled

accordingly. Laser interactions with certain materials may

produce toxic fumes which must be properly vented.

Laser Safety Manual 3

3. LASER CLASSIFICATION (2007)

Lasers and laser systems are classified by potential hazard

according to a system described in the American National

Standards Institute (ANSI) standard Z136.1, and in 21 CFR

part 1040. A lasers classification is based on several

factors including its wavelength, power output, accessible

emission level, and emission duration. The level of hazard

associated with each class of lasers is listed below.

The ANSI Z136.1 standard was updated in 2007 and

current classifications are as follows:

CLASS 1 These are low-power lasers and laser systems that cannot

emit radiation levels greater than the maximum permissible

exposure (MPE). Class 1 lasers and laser systems are

incapable of causing eye injury under normal operating

conditions. This class may include lasers of a higher class

whose beam are confined within a suitable enclosure so that

access to laser radiation is physically prevented.

CLASS 1M Class 1M lasers produce large-diameter beams, or beams

that are divergent. The MPE for a Class 1M laser can not

normally be exceeded unless focusing or imaging optics are

used to narrow down the beam. If the beam is refocused,

the hazard of Class 1M laser may be increased and the

product class may be changed.

CLASS 2 A Class 2 laser emits in the visible region. It is presumed

that the human blink reflex (<0.25 seconds) will be

sufficient to prevent damaging exposure, although

prolonged viewing may be dangerous. Class 2 lasers are

limited to 1 mW when operating in the continuous wave

mode, or more if the emission time is less than 0.25

seconds.

CLASS 2M A Class 2M laser emits in the visible portion of the

spectrum in the form of a large diameter or divergent beam.

It is presumed that the human blink reflex will be sufficient

to prevent damaging exposure, but if the beam is focused

down, damaging levels of radiation may be reached and

may lead to a reclassification of the laser.

CLASS 3R A Class 3R laser is potentially hazardous under some direct

and specular reflection viewing condition if the eye is

appropriately focused and stable, but the probability of an

actual injury is small. This laser will not pose either a fire

hazard or diffused-reflection hazard. Class 3R visible

Laser Safety Manual 4

lasers (0.4 to 0.7 um) are limited to 5 mW when operating

in continuous wave mode. For other wavelengths and pulse

lasers, other limits apply.

CLASS 3b Class 3b lasers are capable of causing eye damage from

short-duration (< 0.25s) viewing of the direct or specularly-

reflected beam. Diffuse reflections from these lasers are

generally not hazardous, except for intentional staring at

distances close to the diffuser.

CLASS 4 Lasers in this class are high powered and capable of

causing severe eye damage with short-duration exposure to

the direct, specularly-reflected, or diffusely-reflected beam.

They are also capable of producing severe skin damage.

Flammable or combustible materials may ignite if exposed

to the direct beam.

LASER CLASSIFICATION

(Prior to 2007) All lasers purchased before 2007 may still display the

former classifications.

CLASS 1 Lasers in this class are incapable of causing eye damage.

These lasers are exempt from labeling requirements.

CLASS 2 Lasers in this class emit visible light only. They are only

capable of producing eye damage if the beam is stared at

directly for longer than the normal human aversion

response time to bright light (0.25 second). This means a

person would naturally turn away from the beam before any

damage is done.

CLASS 2a This is a special category of class 2 lasers which are not

hazardous if viewed directly for up to 1000 seconds.

Supermarket barcode scanners are in this class.

CLASS 3a Lasers in this class are capable of causing eye damage from

short-duration (< 0.25s) viewing of the direct beam.

CLASS 3b No change

CLASS 4 No change

EMBEDDED LASERS A laser system of one class may contain a laser of a higher

class. For example, a class 3a system might contain a class

4 laser in an interlocked protective housing which

incorporates design features to limit the accessible emission

level to the class 3a level.

Laser Safety Manual 5

4. CONTROL MEASURES

GENERAL This section describes administrative, procedural and

engineering measures which can reduce the chance of a

laser-related incident. These measures should be

considered when evaluating a class 3 or 4 laser facility.

Although some items are appropriate for all facilities (e.g.

posting proper warning signs), others may not be practical

for some operations.

BEAM CONTROL Enclose as much of the beam path as possible. If practical,

the entire beam path should be enclosed. As a minimum,

beam stops must be used to ensure no direct or specularly

reflected laser light leaves the experiment area.

Laser beams should be limited to a horizontal plane which

is well below or well above normal eye level. Securely

fasten the laser and all optics on a level, firm, and stable

surface.

REFLECTIONS Remove unnecessary reflective items from the vicinity of

the beam path. Do not wear reflective jewelry such as rings

or watches while working near the beam path.

Be aware that lenses and other optical devices may reflect a

portion of the beam from their front or rear surfaces.

Avoid placing the unprotected eye along or near the beam

axis. The probability of a hazardous specular reflection is

greatest in this area.

POWER LEVEL Operate a laser at the minimum power necessary for any

operation. Beam shutters and filters can be used to reduce

the beam power. Use a lower power laser when possible

during alignment procedures.

SIGNS AND LABELS The entrance to a class 3b or 4 laser facility must be posted

with the appropriate warning sign. Each laser must be

labeled as required by 21 CFR part 1040. These labels

show the classification of the laser and identify the

aperture(s) where the laser beam is emitted. Signs and

labels may be obtained through the Safety Office.

WARNING DEVICES Class 4 laser facilities where the beam is not fully enclosed

should have a visible warning device (e.g. a flashing red

light) at the outside of the entrance which indicates when a

laser is in operation.

Laser Safety Manual 6

CONTROL OF AREA Except for fully enclosed and interlocked systems, an

authorized user must be present or the room kept locked

during laser operations.

INTERLOCKS Many laser systems have interlocked protective housings

which prevent access to high-voltage components or laser

radiation levels higher than those accessible through the

aperture. These interlocks should not be bypassed without

the specific authorization of the Principal Investigator.

Additional control measures must be taken to prevent

exposure to the higher radiation levels or high voltage

while the interlock is bypassed.

PERSONAL PROTECTIVE Eye protection designed for the specific wavelength of laser

EQUIPMENT light should be available and worn when there is a chance

that the beam or a hazardous reflection could reach the eye.

Protective eye wear should be marked by the manufacturer

with the wavelength range over which protection is

afforded and the minimum optical density within that

range. Eye wear should be examined prior to each use and

discarded if there is damage which could reduce its

effectiveness.

Protective eye wear generally will not provide adequate

protection against viewing the direct beam of a high-

powered laser. Wearing protective eye wear should not be

used as an excuse for performing an unsafe procedure.

TRAINING All operators must receive training in the safe and proper

use of lasers by the PI (or a person designated by the PI)

before being allowed to operate a laser.

OPERATING PROCEDURES Written operating procedures should be available which

include applicable safety measures.

MAINTENANCE/SERVICE Maintenance, servicing, or repair of a laser should be

performed only by a knowledgeable person who has been

specifically authorized by the PI to perform such work.

Whenever such work involves accessing an embedded laser

of a higher class, the controls appropriate to the higher class

must be applied.

Any laser which is significantly modified must be

reevaluated to determine its classification.

Laser Safety Manual 7

5. EMERGENCY/INCIDENT PROCEDURES

EMERGENCIES For any emergency:

Call x5000 and follow the CALTECH

EMERGENCY RESPONSE GUIDE posted in the

laboratory.

EMERGENCIES OR INCIDENTS In the event of an accident or unusual incident involving a

INVOLVING LASERS laser:

1. TURN OFF THE LASER.

2. If there is a serious injury or fire, call x5000 and request

paramedics or the fire department.

3. Notify the Safety Office (x6727). If after working

hours, call x5000 and have the operator contact a Safety

Office representative.

4. Notify the laboratory supervisor or Principal

Investigator.

5. Report all injuries to the Workers Compensation

Administrator (x4577).

Laser Safety Manual 8

APPENDIX A. LASER REGISTRATION FORM

California Institute of Technology

Class 3b and Class 4 Laser Registration Form

Date

Principal Investigator (PI) Department Mail Code Extension

Laser Safety Contact Person (if other than PI) Mail Code Extension

Manufacturer Model ANSI Classification

3b 4

Type (Laser Medium) Operational Wave Length(s) CW Maximum Power (W) or Energy (J)

Pulsed

Location In Active Use System Contains Separate

In Storage Aiming Laser

Manufacturer Model ANSI Classification

3b 4

Type (Laser Medium) Operational Wave Length(s) CW Maximum Power (W) or Energy (J)

Pulsed

Location In Active Use System Contains Separate

In Storage Aiming Laser

Manufacturer Model ANSI Classification

3b 4

Type (Laser Medium) Operational Wave Length(s) CW Maximum Power (W) or Energy (J)

Pulsed

Location In Active Use System Contains Separate

In Storage Aiming Laser

Manufacturer Model ANSI Classification

3b 4

Type (Laser Medium) Operational Wave Length(s) CW Maximum Power (W) or Energy (J)

Pulsed

Location In Active Use System Contains Separate

In Storage Aiming Laser

Manufacturer Model ANSI Classification

3b 4

Type (Laser Medium) Operational Wave Length(s) CW Maximum Power (W) or Energy (J)

Pulsed

Location In Active Use System Contains Separate

In Storage Aiming Laser

Manufacturer Model ANSI Classification

3b 4

Type (Laser Medium) Operational Wave Length(s) CW Maximum Power (W) or Energy (J)

Pulsed

Location In Active Use System Contains Separate

In Storage Aiming Laser

Laser Safety Manual 9

APPENDIX B. GLOSSARY

Accessible Emission Level The magnitude of laser radiation to which human access is possible.

Usually measured in watts for continuous wave lasers and in joules for

pulsed lasers.

Accessible Emission Limit The maximum accessible emission level permitted within a particular

(AEL) class.

Aperture An opening through which laser radiation can pass. This term usually

refers to the opening on the laser (or a protective housing) where the

beam is emitted.

Aversion Response Movement of the eyelid or the head to avoid exposure to a bright light.

For laser light, this response is assumed to occur within 0.25 second.

Continuous Wave (CW) Laser A laser which has a continuous output for greater than or equal to 0.25

second.

Controlled Area An area where the occupancy and activity of those within are subject to

control and supervision for the purpose of protection from hazards.

Diffuse Reflection A reflection where different parts of the beam are reflected over a wide

range of angles, such as when hitting a matted surface.

Embedded Laser A laser with an assigned class number higher than the classification of

the laser system in which it is incorporated, where the system's lower

classification is appropriate because of the engineering features limiting

accessible emission.

Enclosed Laser System Any laser or laser system located within an enclosure which does not

permit hazardous optical radiation emission from the enclosure.

Erythema Redness of the skin caused by distention of the capillaries with blood.

Fiber Optics A system of flexible quartz or glass fibers with internal reflective

surfaces that passes light through thousands of glancing (total internal)

reflections.

Fluorescence The emission of light of a particular wavelength resulting from

absorption of energy typically from light of shorter wavelengths.

Infrared Radiation (IR) Invisible Electromagnetic radiation with wavelengths which lie within

the range of 0.70 to 1000 micrometers.

Irradiance The optical power per unit area reaching a surface (W/cm2).

Laser A device which produces an intense, coherent, directional beam of light.

Also an acronym for Light Amplification by Stimulated Emission of

Radiation.

Laser Safety Manual 10

Laser System An assembly of electrical, mechanical, and optical components which

includes a laser.

Optical Density (OD) A logarithmic expression for the attenuation produced by an attenuating

medium, such as an eye protection filter. OD = log 10 (I i /I t ) where I i is

the incident irradiance and I t is the transmitted irradiance.

Protective Housing A device designed to prevent access to radiant power or energy.

Pulsed Laser A laser that delivers its energy in the form of a single pulse or a train of

pulses, with a pulse duration of less than 0.25 s.

Scanning Laser A laser having a time-varying direction, origin or pattern of propagation

with respect to a stationary frame of reference.

Specular Reflection A mirror-like reflection. The exact definition of a specular surface is one

in which the surface roughness is smaller than the wavelengths of the

incident light.

Tunable Laser A laser system that can be "tuned" to emit laser light over a continuous

range of wavelengths or frequencies.

Ultraviolet (UV) Radiation Electromagnetic radiation with wavelengths between soft X-rays and

visible violet light, often broken down into UV-A (315-400 nm), UV-B

(280-315 nm), and UV-C (100-280 nm).

Visible Radiation (light) Electromagnetic radiation which can be detected by the human eye. It is

commonly used to describe wavelengths which lie in the range between

400 nm and 700 nm.

Wavelength The length of the light wave, usually measured from crest to crest, which

determines its color. Common units of measurement are the micrometer

(micron) and the nanometer (nm).

Laser Safety Manual 11

APPENDIX C. REFERENCES

American National Standards Institute, 1993, Safe Use of Lasers, ANSI Z136.1, ANSI, New York.

California Institute of Technology/Massachusetts Institute of Technology, Laser Interferometer Gravitational-wave

Observatory (LIGO) Project, 1996, LIGO Laser Safety Program, Pasadena, California.

Code of Federal Regulations, Title 21, Part 1040, Performance Standards for Light-emitting Products.

Laser Institute of America, 1996, Guide for the Selection of Laser Eye Protection, Orlando, Florida.

Laser Institute of America, 1993, Laser Safety Guide, Orlando, Florida.

Argonne National Laboratory - West

Environment, Safety, and Health Manual

Section 5.22, Laser Safety

http://anlpub.anlw.anl.gov/esh/sec5/5-22.html

Laser Institute of America

http://www.creol.ucf.edu/~lia/

Occupational Safety & Health Administration

OSHA PUB 8-1.7 - Guidelines for Laser Safety and Hazard Assessment

http://gabby.osha-slc.gov/OshDoc/Directive_data/DIRECT_19910805.html

Rockwell Laser Industries

LaserNet Web Server

http://www.rli.com/

University of California

Lawrence Livermore National Laboratory

Health & Safety Manual

Chapter 28, Lasers

http://www.llnl.gov/es_and_h/hsm/chapter_28/chap28.html

University of California, San Diego

Environment, Health & Safety Department

Laser Safety Guide

http://www-vcba.ucsd.edu/EHS/LASERS.HTM

University of Illinois at Urbana-Champaign

Radiation Safety Section

Laser Safety

http://phantom.ehs.uiuc.edu/~rad/laser/laser.html

University of Pennsylvania

Office of Environmental Health & Safety

Laser Safety Manual

http://www.oehs.upenn.edu/laser/laser_manual.html

Laser Safety Manual 12

Das könnte Ihnen auch gefallen

- Laser Safety Handbook-TntDokument12 SeitenLaser Safety Handbook-Tnt42mhNoch keine Bewertungen

- GN09 Laser SafetyDokument9 SeitenGN09 Laser Safetysezgin bayramNoch keine Bewertungen

- Laser Safety Training: For Users of The Pilot™ Class 4 LaserDokument42 SeitenLaser Safety Training: For Users of The Pilot™ Class 4 LaserCAO Group, Inc.Noch keine Bewertungen

- Laser Manual LS-2137U DESYDokument36 SeitenLaser Manual LS-2137U DESYandrea0% (1)

- Laser Module 3Dokument15 SeitenLaser Module 3Luis Enrique B GNoch keine Bewertungen

- Lase Rules 2008Dokument27 SeitenLase Rules 2008LoveNoch keine Bewertungen

- Introduction To Laser Safety - Unit 01Dokument90 SeitenIntroduction To Laser Safety - Unit 01TEBATSONoch keine Bewertungen

- (2017) Laser SafetyDokument400 Seiten(2017) Laser SafetyDennis MokNoch keine Bewertungen

- Laser SafetyDokument3 SeitenLaser SafetyEbaa BarghouthiNoch keine Bewertungen

- Laser Safety PDFDokument13 SeitenLaser Safety PDFManoj Nehra100% (1)

- Laser Module 2Dokument24 SeitenLaser Module 2Luis Enrique B GNoch keine Bewertungen

- Laser Radiation HazardsDokument16 SeitenLaser Radiation HazardsLarryKnappNoch keine Bewertungen

- Laser Safety HandbookDokument20 SeitenLaser Safety Handbookgfit100Noch keine Bewertungen

- Laser Module 1Dokument24 SeitenLaser Module 1Luis Enrique B GNoch keine Bewertungen

- Rockwell Laser Industries - Laser Safety Training and Consulting BrochureDokument16 SeitenRockwell Laser Industries - Laser Safety Training and Consulting Brochurer_paura100% (1)

- Technical Users Manual Fraxel Re Store DUAL Wavelength SystemDokument80 SeitenTechnical Users Manual Fraxel Re Store DUAL Wavelength SystemCamila LopezNoch keine Bewertungen

- Topcon OMS 800-850 enDokument8 SeitenTopcon OMS 800-850 enNacer IzriNoch keine Bewertungen

- Ehs Laser Safety ManualDokument11 SeitenEhs Laser Safety ManualSaffet BORANoch keine Bewertungen

- Introduction To Laser Safety: Ian Gillett Safety Director Imperial CollegeDokument37 SeitenIntroduction To Laser Safety: Ian Gillett Safety Director Imperial CollegejamesborNoch keine Bewertungen

- Safe Use of LasersDokument18 SeitenSafe Use of LasersSaid A AttiaNoch keine Bewertungen

- Laser Safety Program: ScopeDokument6 SeitenLaser Safety Program: ScopeAhmedAhmedNoch keine Bewertungen

- SOP Use of Lasers in Schools Part 1 Laser Pointers - 0Dokument5 SeitenSOP Use of Lasers in Schools Part 1 Laser Pointers - 0travis harutoNoch keine Bewertungen

- Laser Module 5Dokument25 SeitenLaser Module 5Luis Enrique B GNoch keine Bewertungen

- Technology White Paper: Executive SummaryDokument3 SeitenTechnology White Paper: Executive SummaryAnonymous 1MjHWwNoch keine Bewertungen

- Continuous-Wave Fiber Laser User Guide: RFL-C3000SDokument38 SeitenContinuous-Wave Fiber Laser User Guide: RFL-C3000SSergej PokhilkoNoch keine Bewertungen

- Raycus C6600SDokument52 SeitenRaycus C6600SLeandro PotrinoNoch keine Bewertungen

- Fact-Sheet-No.-19-Dec-2018 LASER WELDING AND CUTTING SAFETYDokument3 SeitenFact-Sheet-No.-19-Dec-2018 LASER WELDING AND CUTTING SAFETYCarlos BustamanteNoch keine Bewertungen

- Laser Safety ManualDokument9 SeitenLaser Safety Manualheba.abouessaNoch keine Bewertungen

- MedicineDokument4 SeitenMedicineJyotiNoch keine Bewertungen

- Laser and Fiber Optics Safety: Phys 3616E, Winter 2017 Dr. Bassam AharmimDokument15 SeitenLaser and Fiber Optics Safety: Phys 3616E, Winter 2017 Dr. Bassam AharmimjohnNoch keine Bewertungen

- Laser Safe Operation ProtocolDokument4 SeitenLaser Safe Operation Protocolchaitra rNoch keine Bewertungen

- Continuous-Wave Fiber Laser User Guide: RFL-C1500X/RFL-C2000XDokument40 SeitenContinuous-Wave Fiber Laser User Guide: RFL-C1500X/RFL-C2000XNicolas2458Noch keine Bewertungen

- LASER C1000-6000-E Maintenance Manual B-70265EN02 PDFDokument348 SeitenLASER C1000-6000-E Maintenance Manual B-70265EN02 PDFLê Trọng ÂnNoch keine Bewertungen

- Fs19 Soldadura LaserDokument3 SeitenFs19 Soldadura LaserAntonio AntezanaNoch keine Bewertungen

- OSUlaser Safety ManualDokument14 SeitenOSUlaser Safety ManualUrología GinecológicaNoch keine Bewertungen

- 70315EN ManualDokument384 Seiten70315EN ManualWilliams LeonNoch keine Bewertungen

- Raycus 1000wDokument37 SeitenRaycus 1000wGustavo BittencourtNoch keine Bewertungen

- OAJDS16000156Dokument7 SeitenOAJDS16000156Sushma DhimanNoch keine Bewertungen

- Fiber-Laser-Source RFL c1000Dokument43 SeitenFiber-Laser-Source RFL c1000Amru Franky NawawiNoch keine Bewertungen

- Laser Safety Manual 9-1-2017Dokument36 SeitenLaser Safety Manual 9-1-2017Urología GinecológicaNoch keine Bewertungen

- Laser Control Measures 2018Dokument3 SeitenLaser Control Measures 2018Mediatrix DevianiNoch keine Bewertungen

- Laser Safety JSP-392 - CH - 34 - Web - VersionDokument2 SeitenLaser Safety JSP-392 - CH - 34 - Web - VersionFirdaus Mohd IdrisNoch keine Bewertungen

- Laser ClassificationDokument2 SeitenLaser ClassificationmrdangquanNoch keine Bewertungen

- Laser Safety ManualDokument34 SeitenLaser Safety ManualNiranjanNoch keine Bewertungen

- User Guide-Raycus-1000W-1500W-CW - V1.1Dokument41 SeitenUser Guide-Raycus-1000W-1500W-CW - V1.1서승원Noch keine Bewertungen

- International Journal of Computational Engineering Research (IJCER)Dokument7 SeitenInternational Journal of Computational Engineering Research (IJCER)International Journal of computational Engineering research (IJCER)Noch keine Bewertungen

- Lasers 2002Dokument2 SeitenLasers 2002THEOPHILUS THEOPHILUSNoch keine Bewertungen

- User Guide-Raycus-Single-Module Laser ManulDokument49 SeitenUser Guide-Raycus-Single-Module Laser ManulMateusz ŻurawskiNoch keine Bewertungen

- RFL-P200 User's Guide V1.0Dokument32 SeitenRFL-P200 User's Guide V1.0shrusNoch keine Bewertungen

- Laser Pointer Safety 0Dokument2 SeitenLaser Pointer Safety 0cosmofloydNoch keine Bewertungen

- Laser Safety Manual UTHealth Houston 2023Dokument29 SeitenLaser Safety Manual UTHealth Houston 2023Firdaus Mohd IdrisNoch keine Bewertungen

- 4 - Laser Safety and Classification PDFDokument39 Seiten4 - Laser Safety and Classification PDFshaymaa alabassiNoch keine Bewertungen

- Hazard Classification For LasersDokument2 SeitenHazard Classification For Laserssama EmadNoch keine Bewertungen

- LaserSafety Medical&ClinicalAppsDokument12 SeitenLaserSafety Medical&ClinicalAppsRavish BangreNoch keine Bewertungen

- Sokkia Total Station Laser ManualDokument2 SeitenSokkia Total Station Laser ManualKochiNoch keine Bewertungen

- Laser Module 4Dokument31 SeitenLaser Module 4Luis Enrique B GNoch keine Bewertungen

- Laser Welding and CuttingDokument7 SeitenLaser Welding and CuttingeliiiiiiNoch keine Bewertungen

- Laser QuizDokument1 SeiteLaser QuizAhmed AboelataNoch keine Bewertungen

- Laser SafetyDokument50 SeitenLaser SafetylecturioNoch keine Bewertungen

- Health Risks From The Use of Laser Pointers: Fact Sheet No 202 July 1998Dokument4 SeitenHealth Risks From The Use of Laser Pointers: Fact Sheet No 202 July 1998Gayathri BhatNoch keine Bewertungen

- Chromophare® D 300: Minor Surgical and Examination Light Pre-Installation GuideDokument14 SeitenChromophare® D 300: Minor Surgical and Examination Light Pre-Installation GuideROSSINoch keine Bewertungen

- FactsheetDokument1 SeiteFactsheetROSSINoch keine Bewertungen

- Oxygen Gas MsdsDokument2 SeitenOxygen Gas MsdsROSSI100% (4)

- Guidance HG 2013Dokument34 SeitenGuidance HG 2013ROSSINoch keine Bewertungen

- MSDS Rinse Aid Getinge CleanDokument4 SeitenMSDS Rinse Aid Getinge CleanROSSINoch keine Bewertungen

- MSDS Universal Detergent Getinge CleanDokument4 SeitenMSDS Universal Detergent Getinge CleanROSSINoch keine Bewertungen

- Datasheet SFH 608 Low Current OptocouplerDokument3 SeitenDatasheet SFH 608 Low Current OptocouplerROSSINoch keine Bewertungen

- Registratsi Alat Kes PDFDokument193 SeitenRegistratsi Alat Kes PDFROSSINoch keine Bewertungen

- Resmed Vpap S and Vpap STDokument2 SeitenResmed Vpap S and Vpap STROSSI100% (1)

- Terumo Advanced Perfusion System 1Dokument8 SeitenTerumo Advanced Perfusion System 1ROSSI0% (1)

- Structure and Function of EyesDokument11 SeitenStructure and Function of EyesSamar Ameen SialNoch keine Bewertungen

- K Olle ThesisDokument197 SeitenK Olle ThesisAndreas NeoNoch keine Bewertungen

- Refraction of LightDokument12 SeitenRefraction of LightLiza Nova DewiNoch keine Bewertungen

- Unit. 6.WDM Concepts and ComponentsDokument31 SeitenUnit. 6.WDM Concepts and ComponentsNandan GowdaNoch keine Bewertungen

- Trinity RPG QuickstartDokument28 SeitenTrinity RPG QuickstartiPinteus100% (3)

- Amphenol Antel LPA LPD AntennasDokument79 SeitenAmphenol Antel LPA LPD AntennasJuan C LeonNoch keine Bewertungen

- Fermat's Principle - Wikipedia PDFDokument105 SeitenFermat's Principle - Wikipedia PDFSanjai KannaNoch keine Bewertungen

- The Microscope PowerpointDokument26 SeitenThe Microscope Powerpointapi-250530867Noch keine Bewertungen

- 06 08 2023 SR STAR CO SCMODEL B Jee Main CTM 1 KEY&SOLDokument18 Seiten06 08 2023 SR STAR CO SCMODEL B Jee Main CTM 1 KEY&SOLDinesh BabuNoch keine Bewertungen

- Refractive DisorderDokument39 SeitenRefractive Disorderalvi kamal fikriNoch keine Bewertungen

- Physics Advanced Level Problem Solving (ALPS-8) - PaperDokument14 SeitenPhysics Advanced Level Problem Solving (ALPS-8) - PaperSwapnil MandalNoch keine Bewertungen

- Dust Explosion Protection For Machines and Equipment - Collection of ExamplesDokument44 SeitenDust Explosion Protection For Machines and Equipment - Collection of Examplestonipos100% (1)

- M & M MCQ QPDokument34 SeitenM & M MCQ QPtamilselvan n100% (2)

- Flashlight (Jessie J) Flashlight (Jessie J) : Reff ReffDokument1 SeiteFlashlight (Jessie J) Flashlight (Jessie J) : Reff ReffRiny'e LovingScoutforeverNoch keine Bewertungen

- Chapter 14 Visual 2 Wave PropertiesDokument2 SeitenChapter 14 Visual 2 Wave Propertiesra.yakout85Noch keine Bewertungen

- Worksheet 4 Plane MirrorsDokument3 SeitenWorksheet 4 Plane MirrorsJoseph LeeNoch keine Bewertungen

- FTIR and SEMEDS in Identification of Unknown Materials97Dokument4 SeitenFTIR and SEMEDS in Identification of Unknown Materials97saynexNoch keine Bewertungen

- The Wireless Channel 1Dokument43 SeitenThe Wireless Channel 1Anil FkNoch keine Bewertungen

- Ol80 - Bea 220265 en 04Dokument32 SeitenOl80 - Bea 220265 en 04Ds KuzmenkoNoch keine Bewertungen

- Jamnabai PrelimDokument6 SeitenJamnabai PrelimaashiNoch keine Bewertungen

- Fresnel PDFDokument6 SeitenFresnel PDFJyotirmoy BanerjeeNoch keine Bewertungen

- Simple XRD Crystallite Calculator: Scherrer's Formula: Crystallite Size DP KDokument3 SeitenSimple XRD Crystallite Calculator: Scherrer's Formula: Crystallite Size DP KJennifer León CarvajalNoch keine Bewertungen

- Physics Presentation Created by Md. Salem Sabbir Khan Id 20192017021Dokument17 SeitenPhysics Presentation Created by Md. Salem Sabbir Khan Id 20192017021NuhashNoch keine Bewertungen

- Sph4uc Unit 4 Lesson 14Dokument18 SeitenSph4uc Unit 4 Lesson 14Akif Prasla0% (1)

- Radar SystemsDokument455 SeitenRadar SystemssethiaashishNoch keine Bewertungen

- Fs Zeiss Operating Microscopes 1Dokument20 SeitenFs Zeiss Operating Microscopes 1Juan ChatoNoch keine Bewertungen

- Nikon XS DatasheetDokument2 SeitenNikon XS DatasheetGraha NurdianaNoch keine Bewertungen

- Microbiology Lecture 2Dokument68 SeitenMicrobiology Lecture 2marcNoch keine Bewertungen

- Wall Light WLM13Dokument1 SeiteWall Light WLM13EliasNoch keine Bewertungen

- Optical Vortex Phase Plate Application NotesDokument5 SeitenOptical Vortex Phase Plate Application NotesDu RoyNoch keine Bewertungen