Beruflich Dokumente

Kultur Dokumente

Evaporative Emission Control Systems: Section 5

Hochgeladen von

Elias Nassif GomezOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Evaporative Emission Control Systems: Section 5

Hochgeladen von

Elias Nassif GomezCopyright:

Verfügbare Formate

Section 5

Evaporative Emission Control Systems

Pressure Valve

ORVR Vacuum Ball Check Valve Charcoal Canister

Valve

Purge

VSV

Fuel Tank Airdrain Air Inlet Valve

T852f244

Lesson Objectives 1. Determine the condition of the EVAP system operation based on engine

data

2. Determine the condition of the EGR system based on engine data

3. Determine the root cause of a failure(s) in the EGR system using

appropriate diagnostic procedures

Engine Control Systems I - Course 852

Section 5

TOYOTA Technical Training

Section 5

EMISSION SYSTEMS

Evaporative Approximately 20% of all hydrocarbon (HC) emissions from the automo-

Emissions bile originate from evaporative sources. The Evaporative Emission

Control Control (EVAP) system is designed to store and dispose of fuel vapors

Systems normally created in the fuel system and prevent their escape to the

atmosphere.

The EVAP system is a fully closed system designed to maintain stable

fuel tank pressures without allowing fuel vapors to escape to the atmos-

phere. Fuel vapor is normally created as fuel temperature rises. It is

then transferred to the EVAP system charcoal canister as tank vapor

increases. When the engine can tolerate additional enrichment, these

stored fuel vapors are purged into the intake manifold and added to the

incoming air/fuel mixture.

There are two basic types of evaporative emission control systems:

Non-ECM controlled EVAP systems use solely mechanical control

devices to collect and purge stored fuel vapors. Typically, these systems

use a ported vacuum purge port and a Thermo Vacuum Valve (TVV) to

prohibit cold engine operation.

ECM controlled EVAP systems use a manifold vacuum purge source in

conjunction with a duty cycled Vacuum Switching Valve (VSV). This type

of EVAP system has the ability to provide more precise control of purge

flow volume and inhibit operation. This is the only type on current mod-

els.

Non-ECM TVV

Controlled EVAP Purge (P) Point

System

Fuel Tank Cap

Check

Valve (3) (2)

(1)

Charcoal

Canister

Fuel Tank

Fuel Vapor Fig. 5-01

Fresh Air T852f242

Engine Control Systems I - Course 852 5-1

Section 5

Non-ECM Non-ECM controlled EVAP systems typically use the following compo-

Controlled EVAP nents:

Systems

Fuel tank.

Fuel tank cap (with vacuum check valve).

Charcoal canister (with vacuum & pressure check valves).

Thermo Vacuum Valve (TVV).

Ported vacuum purge port (port P; on throttle body).

Under some conditions, the fuel tank operates under a slight pressure

to reduce the possibility of pump cavitation due to fuel vaporization.

Pressure is created by unused fuel returning to the tank and is main-

tained by check valve No. 2 in the charcoal canister and the check valve

in the fuel tank cap.

Under other conditions; as fuel is drawn from the tank, a vacuum can

be created in the tank causing it to collapse. This is prevented by allow-

ing atmospheric pressure to enter the tank through check valve No. 3 in

the charcoal canister or the fuel tank cap check valve. The EVAP system

is designed to limit maximum vacuum and pressure in the fuel tank in

this manner.

When the engine is running, stored fuel vapors are purged from the

canister whenever the throttle has opened past the purge port (port P)

and coolant temperature is above a certain point (usually around 54C

(129F )). Fuel vapors flow from the high pressure area in the canister,

past check valve No.1 in the canister, through the Thermo Vacuum

Valve (TVV), to the low pressure area in the throttle body. Atmospheric

pressure is allowed into the canister through a filter located on the bot-

tom of the canister. This ensures that purge flow is constantly main-

tained whenever purge vacuum is applied to the canister. When coolant

temperature falls below a certain pointusually around 35C (95F), the

TVV prevents purge from taking place by blocking the vacuum signal to

check valve No.1.

5-2 TOYOTA Technical Training

Evaporative Emission Control Systems

ECM Controlled EVAP System

The Purge VSV is duty ratio controlled by

the ECM.

From Air Cleaner

Purge Port

From Fuel Tank

Throttle VSV

Valve Charcoal

Canister

Intake Air ECM Fig. 5-02

Chamber

T852f243

ECM Controlled ECM controlled EVAP systems were introduced to provide a more precise

EVAP Systems control and maintain driveability. The ECM will adjust the fuel injection

duration based on oxygen sensor or air/fuel ratio sensor signal.

ECM controlled EVAP systems typically use the following components:

Fuel tank.

Fuel tank cap (with vacuum check valve).

Charcoal canister (with vacuum & pressure check valves).

Purge VSV (manifold vacuum purge port).

Early ECM EVAP systems used a ported vacuum purge port with

in-line check valve (port A; on throttle body).

When the engine has reached predetermined parameters (closed loop,

engine temp. above 52C (125F), stored fuel vapors are purged from the

canister whenever the purge VSV is opened by the ECM. At the appropri-

ate time, the ECM will turn on the purge VSV. This will allow the low

pressure in the intake manifold to draw the fuel vapors out of the char-

coal canister. The vapors will then be burned in the combustion chamber.

The ECM will change the duty ratio cycle of the purge VSV thus control-

ling purge flow volume. Purge flow volume is determined by manifold

pressure and the duty ratio cycle of the purge VSV. Atmospheric pressure

is allowed into the canister to ensure that purge flow is constantly main-

tained whenever purge vacuum is applied to the canister.

Engine Control Systems I - Course 852 5-3

Section 5

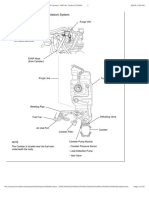

EVAP System with ORVR Pressure Valve

ORVR Vacuum Ball Check Valve Charcoal Canister

Valve

Purge

VSV

Fuel Tank Air Drain Air Inlet Valve

Fig. 5-03

T852f244

Tank Tank

Air Inlet Fill Check

Condition Purge Port Vacuum Pressure Air Drain

Valve Valve

Ball Check Port

VSV Purge OPEN (V) OPEN (V) CLOSED CLOSED CLOSED CLOSED

Valve On

VSV Purge CLOSED CLOSED

CLOSED CLOSED CLOSED CLOSED

(NV) (NV)

Valve Off

Pressure In CLOSED CLOSED CLOSED OPEN CLOSED CLOSED

Tank

Vacuum In Tank OPEN CLOSED CLOSED CLOSED

Refill CLOSED CLOSED OPEN OPEN

5-4 TOYOTA Technical Training

Evaporative Emission Control Systems

Charcoal Canister The charcoal canister is filled with activated charcoal. This charcoal has

the ability to absorb gasoline vapors and release these vapors when fresh

air passes through the canister. Mounted on the charcoal canister are

check valves to control vapor flow. The table on the previous page shows

the action of each valve according to engine operation and fuel tank

conditions.

Pressure in Fuel Tank

Fuel vapor pressure is vented into the

charcoal canister when vapor pressure forces

the tank pressure control valve open.

Tank Inside Pressure

Differential Control Valve (OPEN)

Pressure Canister

Valve Breather Line for Fueling

Check Valve

Engine Compartment

Purge VSV

From Air

Cleaner

Purge Line Fuel Tank Fresh Air Intake Line Atmospheric

Pressure Valve

Fig. 5-04

T852f245

Engine Control Systems I - Course 852 5-5

Section 5

Vacuum in Fuel Tank

Vacuum in the tank can be relieved by

allowing air to enter through the charcoal

canister or fuel tank cap. OPEN

Rear of Vehicle Tank Inside Pressure

Control Valve (CLOSED)

Differential

Pressure Canister

Valve

Check Valve

Purge VSV

From Air

Cleaner

Engine Compartment

Purge Line Fuel Tank Fresh Air Intake Line Atmospheric Pressure Valve

OPEN

Rear of Vehicle Tank Inside Pressure

Control Valve (CLOSED)

Differential

Pressure Canister

Valve

Check Valve

Purge VSV

From Air

Cleaner

Engine Compartment

Fig. 5-05

Purge Line Fuel Tank Fresh Air Intake Line

T852f246/T852f334

5-6 TOYOTA Technical Training

Evaporative Emission Control Systems

Purge Mode

During purge, vapors are drawn out of

canister and burned in the engine. Rear of Vehicle

Differential

Pressure

Valve Canister

Check Valve

OPEN

Purge VSV

From Air

Cleaner

OPEN

Engine Compartment Air Inlet Valve Fig. 5-06

Purge Line Fuel Tank Fresh Air Intake Line

(OPEN) T852f247

Refueling Mode

During refueling, the differential pressure

valve and air drain valve are open. Fuel

vapors are absorbed by the charcoal

canister and excess air is vented to the

atmosphere. Rear of Vehicle

Differential

Pressure

Valve Canister

Check Valve

Purge VSV

From Air

Cleaner

Engine Compartment Purge Line Fuel Tank Atmospheric Pressure Fig. 5-07

Fresh Air Intake Line Valve (OPEN) T852f248

EVAP There is no routine maintenance for the EVAP system. It is critical that

System Service the proper diameter hoses and parts are used. Failure to do so can result

in driveability problems. There are diagnostic procedures for checking the

valves listed in the Repair Manual.

Engine Control Systems I - Course 852 5-7

Section 5

Exhaust Gas The Exhaust Gas Recirculation (EGR) system is used for reducing oxides of

Recirculation nitrogen and for engine knock control. By recirculating a controlled

System amount of exhaust gases into the intake air-fuel mixture, combustion tem-

perature is lowered. This, in turn, reduces the amount of NO X emission.

Basic EGR System

Exhaust gases are directed to the intake

manifold to lower oxides of nitrogen emissions.

Throttle Body

Engine coolant temperature Air

Engine Load

Engine RPM

Throttle valve position

Intake manifold

ECM EGR Valve Cylinders

EGR control

Exhaust manifold

Exhaust

gases

Fig. 5-08

T852f249

EGR Valve Intake

When the EGR valve opens, exhaust

gasses enter the intake manifold.

Diaphragm

Vacuum

EGR Valve

Engine Exhaust

Fig. 5-09

T852f250

5-8 TOYOTA Technical Training

Evaporative Emission Control Systems

EGR Valve Also, the exhaust gases help prevent engine knock and allow for more

advanced ignition timing.

The EGR valve opens and closes the passage between the exhaust mani-

fold and intake manifold. Vacuum is used to move the EGR valves.

Inside the vacuum actuated EGR valve is a valve, diaphragm, and spring.

When vacuum is applied to the diaphragm the diaphragm lifts the valve

off its seat allowing exhaust gases into the intake air stream. When vacu-

um is removed the spring forces the diaphragm and valve downward clos-

ing the exhaust passage.

For proper engine operation, the EGR valve must open to the proper

height, and when closed seal the intake manifold from exhaust gases.

CAUTION The EGR valve can get very hot. Handle with care.

Cut-Off Control EGR System

EGR Operating (VSV OFF)

Throttle Body

Engine

Speed

R Port

Throttle Valve Coolant Temperature

E Port ECM Throttle Opening

Inlet Air Valve

EGR Valve

Diaphragm

EGR

Vacuum

Modulator

! Constant

Intake Air Exhaust Pressure

Chamber Gas Chamber

O

A Passage

Fig. 5-10

T852f251

Engine Control Systems I - Course 852 5-9

Section 5

Cut-Off Some EGR valve's are water cooled and this is done to cool the exhaust

Control EGR gases. Cooling the exhaust gases increases the exhaust gases effective-

System ness in reducing NOX and engine knock.

Operation

In the Cutoff Control EGR system, the amount of exhaust gas to be

recirculated is controlled by the EGR vacuum modulator. The EGR mod-

ulator is needed because of the changes in engine vacuum and exhaust

backpressure. The vacuum available at ports E and R changes with

throttle opening. As the throttle valve opens and intake air

volume/speed increases, the vacuum signals from ports E and R

increases. As engine load increases the amount of exhaust backpres-

sure increases.

For the above reasons, an EGR vacuum modulator controls the amount

of vacuum reaching the EGR valve lifting the EGR valve to the correct

height.

As determined by the ECM, the EGR VSV is closed to atmospheric pres-

sure allowing the modulated vacuum to reach the EGR valve.

EGR Signal Logic Table

Port Throttle Valve Opening Vacuum Signal

E Position Less than E Port No Vacuum Present

E Position More than E Port Near Manifold Vacuum

R Position Less than R Port No Vacuum Present

R Position More than R Port Near Manifold Vacuum

Fig. 5-11

5-10 TOYOTA Technical Training

Evaporative Emission Control Systems

EGR Cut-Off

When the EGR VSV is

on, the vacuum line is

open to atmosphere,

preventing the EGR from EGR Operating (VSV ON)

opening.

Engine

Speed

E Port R Port Coolant Temperature

ECM Throttle Opening

Inlet Air Valve

Fig. 5-12

T852f252

EGR Cut-Off To close the EGR valve, the VSV is turned on by a signal from the ECM.

Operation This opens the vacuum line to atmospheric pressure closing the EGR

valve and shutting off the exhaust gas flow. This is done when EGR is not

needed and to maintain driveability. This operation (EGR cut-off) is imple-

mented when the following conditions exist:

Coolant temperature below 57C (134F).

During deceleration (throttle valve closed).

Light engine load (amount of intake air very small).

Engine speed approximately 4000 RPM or more.

Engine racing (neutral start switch turned on).

Engine Control Systems I - Course 852 5-11

Section 5

EGR Gas Flow

Variations in exhaust

pressure. Large Load without EGR gas

Small Load Large Load with a lot of EGR gas

+

+

Positive

Pressure

Exhaust

Negative

Atmospheric

Pressure

_

Crankshaft Angle

Fig. 5-13

T852f253

EGR Vacuum

Modulator

Filter

Modulated

Vacuum To Q P

EGR Valve Throttle Body Port E

Diaphragm Throttle Body Port R

R

Orifice

Chamber A

A Passage

Exhaust Pressure

Chamber

Fig. 5-14

T852f254

EGR Vacuum The exhaust gas pressure increases in proportion to the amount of

Modulator intake air. As the throttle valve opens and the amount of intake air vol-

ume increases, a higher exhaust gas pressure is applied to the constant

pressure chamber of the EGR vacuum modulator. It pushes the

diaphragm of the EGR vacuum modulator upward to narrow the "A"

passage. Since vacuum acts then on the E and R ports of the throttle

body, the vacuum is modulated by the size of the "A" passage. This

5-12 TOYOTA Technical Training

Evaporative Emission Control Systems

modulated vacuum causes the EGR valve to open, which, in turn, allows

exhaust gas into the intake manifold. This also causes the gas pressure

inside the exhaust pressure chamber to go down, which in turn, lowers

the EGR vacuum modulator diaphragm.

The EGR valve is now under less vacuum and the valve moves until the

vacuum balances with the spring tension and the amount of EGR gas is

regulated. Therefore, the amount of EGR is regulated according to the

exhaust gas pressure and the vacuum signal strength.

Constant Vacuum System

Intake VCV

VSV

Atmosphere

EGR Valve Position Sensor

ECM

Vacuum

Surge Tank Mass Air Flow

Meter

EGR Valve Engine Coolant

Temp. Sensor

Engine Exhaust Crankshaft

Position

Fig. 5-15

T852f255

Constant This type of ECM EGR controlled system uses a Vacuum Control Valve

Vacuum System (VCV), an EGR VSV, and an EGR valve position sensor to regulate

Operation exhaust gas flow.

Engine Control Systems I - Course 852 5-13

Section 5

Vacuum Control

Valve (VCV) Filter

When diagnosing the VCV,

remember that the vacuum

output is very low. An

accurate vacuum gauge is Valve

needed.

Spring

Diaphragm

S Port Z Port

To VSV Fig. 5-16

From Intake Manifold T852f256

Vacuum Control The VCV is a valve that regulates the intake manifold vacuum applied to

Valve (VCV) the VSV to a constant level (-17 kPa, -l30 mmHg, -5 inHg).

The intake manifold vacuum that is supplied through the S port is

applied to the diaphragm. If this force becomes greater than the spring

force, the diaphragm moves downward allowing the valve to close the S

port and the atmosphere supplied through the filter.

Conversely, if the vacuum that is applied to the diaphragm becomes

weaker, the diaphragm moves upward causing the valve to open and to

shut off the atmosphere and supply the intake manifold vacuum. This

process is repeated to regulate the vacuum in the Z port to a constant level.

5-14 TOYOTA Technical Training

Evaporative Emission Control Systems

EGR Valve EGR Valve Position Sensor

Position Sensor

This sensor measures

EGR valve height.

EGR Valve Fig. 5-17

T852f056

EGR Valve The EGR valve position sensor is a potentiometer sensor mounted on the

Position Sensor EGR valve. The EGR valve and signal arm in the position sensor move

together. As the EGR valve opens, the voltage signal of the EGR valve

position sensor increases.

EGR VSV

The EGR VSV is a three

way VSV. When the VSV

is off, atmospheric

pressure is applied to the To EGR Valve

EGR valve keeping the

valve closed. When the

engine has reached the

appropriate conditions, From VCV

the ECM will turn on the

EGR VSV applying

vacuum to the EGR

valve.

Atmosphere

Fig. 5-18

T852f257

Engine Control Systems I - Course 852 5-15

Section 5

Operation The ECM uses the EGR valve position sensor signal to control EGR

valve position height and to detect excessive EGR flow. EGR valve height

is controlled by the strength of the vacuum signal and the ECM controls

vacuum signal strength by varying the pulsewidth signal sent to the

EGR VSV. If greater EGR flow is needed, the ECM increases the

pulsewidth signal to the EGR VSV. This applies more vacuum to the

EGR valve.

Under the following conditions the ECM turns off the VSV and closes

the EGR valve:

Coolant temperature below 57C (134F).

During deceleration (throttle valve closed).

Light engine load (amount of intake air very small).

Engine speed approximately 4000 rpm or more.

Engine idling.

5-16 TOYOTA Technical Training

WORKSHEET 51

EVAP Systems

(Instructor Copy)

Vehicle Year/ Prod. Date Engine Transmission

Technician Objectives

With this worksheet, you will learn to test EVAP systems using the required tools and equipment, retrieve and

apply the needed service information, retrieve and interpret service data information.

Tools and Equipment

Vehicle Repair Manual & Vehicle EWD

Diagnostic Tester

Hand Tool Set

Vacuum Gauge

Section 1

EVAP Identification

Use the Repair Manual and Technician Handbook to answer the following questions on the vehicle you are

working on.

1. Is the EVAP system the Intrusive or Non-Intrusive type?

_________________________________________________________________________________________________________

2. Is the EVAP system equipped with the ORVR system?

_________________________________________________________________________________________________________

3. Identify on the canister the tank valve assembly.

4. Identify on the canister the air inlet valve assembly.

5. If equipped, identify the ORVR vent line.

Section 2

Purge VSV Operation

1. Select ACTIVE TEST.

2. Set to EVAP VSV and turn the VSV ON using the left and right arrow keys.

3. Disconnect the purge hose from the canister side of the purge VSV and listen for a duty cycle pulsing

sound from the VSV.

Engine Control Systems I - Course 852 5-17

Worksheet 5-1

4. If a pulsing sound is heard, will vacuum be present at the purge hose?

_________________________________________________________________________________________________________

5. Turn the purge VSV OFF using the left and right arrow keys. Check for vacuum on the VSV with a

vacuum gauge. If vacuum is present, the purge VSV is

_________________________________________________________________________________________________________

Note: If a purge valve were stuck, open or closed, the following steps are recommended:

1. If the valve is stuck open or closed, this could be the result of active charcoal contamination or metal

flakes from manufacturing inside the purge VSV.

2. If charcoal is found in the purge lines, all hoses must be cleaned of charcoal and the canister and purge

VSV must be replaced.

3. If metal is found in the purge VSV, blow the metal lines out between canister and engine and replace the

VSV.

Section 3

Vapor Pressure Sensor

1. Refer to SF section in the Repair Manual on vapor pressure sensor inspection.

2. Turn the ignition switch ON.

3. Disconnect the vacuum hose (the one connected to EVAP pressure).

4. Connect a voltmeter to terminals PTNK and E2. According to the RM, measure the voltage under specified

conditions.

Condition Applied Pressure PTNK Voltage

Below Atmospheric

Pressure

Atmospheric Pressure

Above Atmospheric

Pressure

As pressure increase, voltage increases. ____________

5. Predict the PTNK signal voltage if the PTNK wire were to become disconnected. Voltage will

_________________________________________________________________________________________________________

6. Disconnect the vps electrical connector.

7. Record the voltage between PTNK and E2 terminals at the ECM: ____________

8. Why did this happen?

_________________________________________________________________________________________________________

_________________________________________________________________________________________________________

5-18 TOYOTA Technical Training

EVAP Systems

Name ____________________________________________________________ Date ________________________________

Review this sheet as you are doing the worksheet. Check each category after completing the worksheet and

instructor presentation. Ask the instructor if you have questions. The comments section is for you to write where

to find the information, questions, etc.

I have questions I know I can

Topic Comment

Locate components in the EVAP system

using the EWD and RM

Find wire colors, pin numbers in the EVAP

electrical circuits using the EWD and RM

Visually inspect tank, fuel cap, lines,

canister

Activate purge VSV with Active Test

Test purge VSV and compare to

specifications to determine condition

Check and retrieve relevant DTCs

Locate in the RM three sections related to

EVAP system concerns

Test vapor pressure sensor

Engine Control Systems I - Course 852 5-19

Worksheet 5-1

5-20 TOYOTA Technical Training

WORKSHEET 52

EGR Cutoff Control System

(Instructor Copy)

Vehicle Year/ Prod. Date Engine Transmission

Technician Objectives

With this worksheet, you will learn to test the EGR cutoff control system using the required tools and

equipment, retrieve and apply the needed service information, retrieve and interpret service data

information.

Tools and Equipment

Vehicle Repair Manual

Vehicle EWD

Diagnostic Tester

Hand Tool Set

Vacuum pump with gauge

Section 1

Component Tests

VSV Component Check

1. Connect a DVOM to the EGR VSV terminal at the ECM.

2. According to the Repair Manual, perform the Inspect VSV operation test procedure. Test procedure

and specifications are found in what section?

_____________________________________________________________________________________________________

3. When the engine is cold, does the EGR valve have vacuum applied to it?

Circle the correct words in the following statements.

4. When cold, the EGR VSV is ON/OFF and OPEN/CLOSED to atmosphere.

5. When the EGR valve is open, the EGR VSV is ON/OFF and OPEN/CLOSED to atmosphere.

EGR Vacuum Modulator

1. Check the EGR Vacuum Modulator according to the Repair Manual.

2. With the engine OFF and Ports P and R blocked, should air pass freely from Port Q to atmosphere?

Why? _______________________________________________________________________________________________

3. With the engine ON and Ports P and R blocked, should air pass freely from Port Q to atmosphere?

Why? ________________________________________________________________________________________________

Engine Control Systems I - Course 852 5-21

Worksheet 52

4. If the atmospheric port were blocked, what would be the engine symptoms?

_________________________________________________________________________________________________

EGR Valve

1. With the engine idling and warm, slowly apply vacuum to the EGR valve, so that the engine runs

rough. What happened to EGR temperature?

_________________________________________________________________________________________________

2. On MAP sensor equipped engines, what happens to intake manifold pressure when the EGR valve

is opened?

_________________________________________________________________________________________________

_________________________________________________________________________________________________

5-22 TOYOTA Technical Training

EGR Cutoff Control System

Name ____________________________________________________________ Date ________________________________

Review this sheet as you are doing the worksheet. Check each category after completing the worksheet and

instructor presentation. Ask the instructor if you have questions. The comments section is for you to write where

to find the information, questions, etc.

I have questions I know I can

Topic Comment

Locate components in the EGR system

using the EWD and RM

Find wire colors, pin numbers in the EGR

electrical circuits using the EWD and RM

Visually inspect EGR valve, modulator,

hoses

Activate EGR VSV with Active Test

Test EGR VSV and compare to

specifications to determine condition

Test vacuum modulator and compare to

specifications to determine

condition

Check and retrieve relevant DTCs

Locate in the RM three sections related to

EGR system concerns

Engine Control Systems I - Course 852 5-23

Worksheet 5-2

5-24 TOYOTA Technical Training

WORKSHEET 53

EGR Constant Vacuum System

(Instructor Copy)

Vehicle Year/ Prod. Date Engine Transmission

Technician Objectives

With this worksheet, you will learn to test the EGR constant vacuum system using the required tools and

equipment, retrieve and apply the needed service information, retrieve and interpret service data information.

Tools and Equipment

Vehicle Repair Manual

Vehicle EWD

Diagnostic Tester

Hand Tool Set

Vacuum pump with gauge

Section 1

Component Tests:

VCV Component Check

1. According to the Repair Manual, perform the VCV test procedure for operation.

_________________________________________________________________________________________________________

2. What port has vacuum applied to it? Did it match the Repair Manual?

_________________________________________________________________________________________________________

3. A good VCV puts out:

_________________________________________________________________________________________________________

EGR Valve Position Sensor

1. Using the vacuum pump, apply the vacuum specified and record EGR valve position sensor voltage.

0 inHG 2 inHG 4 inHG

2. From the voltage readings, is the EGR valve position sensor voltage signal normal?

EGR VSV

1. Connect the positive (+) lead of the DVOM to EGR VSV, terminal.

2. Connect the negative (-) lead to ground.

Engine Control Systems I - Course 852 5-25

Worksheet 53

3. Start the engine and record voltage.

_________________________________________________________________________________________________________

Is the EGR VSV open to atmosphere pressure with the EGR valve off?

_________________________________________________________________________________________________________

Section 3

EGR Operation

1. With the DT, go to Active Test and select EGR. In User Data select EGR Temp, EGR valve position sensor.

2. Connect the positive (+) lead of the DVOM to EGR VSV connector/terminal.

3. Connect - lead to ground.

4. Record the following.

Engine RPM EGR Temperature EGR Valve Position VSV Voltage EGR Gas Flow (Y/N)

5. Activate the EGR system and record the following.

Engine RPM EGR Temperature EGR Valve Position VSV Voltage

6. Increase engine RPM and record the following.

Engine RPM EGR Temperature EGR Valve Position VSV Voltage

7. What happened to EGR temperature?

_________________________________________________________________________________________________________

8. What happened to EGR valve position sensor voltage?

_________________________________________________________________________________________________________

9. What happened to EGR VSV voltage as the EGR valve height increased?

_________________________________________________________________________________________________________

10. If the EGR VSV were disconnected, what would be common engine symptoms, and what DTC would set?

_________________________________________________________________________________________________________

5-26 TOYOTA Technical Training

EGR Constant Vacuum System

Name ____________________________________________________________ Date ________________________________

Review this sheet as you are doing the worksheet. Check each category after completing the worksheet and

instructor presentation. Ask the instructor if you have questions. The comments section is for you to write where

to find the information, questions, etc.

I have questions I know I can

Topic Comment

Locate components in the EGR system

using the EWD and RM

Find wire colors, pin numbers in the EGR

electrical circuits using the EWD and RM

Visually inspect EGR valve, modulator,

hoses

Activate EGR VSV with Active Test

Test EGR VSV and compare to

specifications to determine condition

Test VCV and compare to specifications

to determine condition

Test EGR valve position sensor and

compare to specifications to determine

condition

Test EGR temperature sensor and

compare to specifications to determine

condition

Check and retrieve relevant DTCs

Locate in the RM three sections related to

EGR system concerns

Engine Control Systems I - Course 852 5-27

Das könnte Ihnen auch gefallen

- CAT Trouble Shooting C4.4Dokument236 SeitenCAT Trouble Shooting C4.4Bradley Stewart100% (23)

- Common Rail System (CRS) : Toyota 1Kd/2Kd EngineDokument31 SeitenCommon Rail System (CRS) : Toyota 1Kd/2Kd EngineJuan Alberto Bucaro100% (30)

- Marvel-Schebler Carburetor Repair ManualDokument21 SeitenMarvel-Schebler Carburetor Repair Manualbedford24100% (14)

- Wiring DiagramDokument19 SeitenWiring DiagramOlga PlohotnichenkoNoch keine Bewertungen

- Lexus Engine 1UZ FE Service and Repair ManualDokument80 SeitenLexus Engine 1UZ FE Service and Repair Manualeamon100% (2)

- SSP 941903 - EVAP Operation and Diagnosis PDFDokument39 SeitenSSP 941903 - EVAP Operation and Diagnosis PDFtahiriNoch keine Bewertungen

- Solar Centaur Turbine Engine Startup ProcessDokument32 SeitenSolar Centaur Turbine Engine Startup ProcessFarhanNoch keine Bewertungen

- Aircraft Fuel System Components and DistributionDokument243 SeitenAircraft Fuel System Components and DistributionAndres Parra Navarro100% (4)

- TOYOTA Technical Training - Exhaust Gas Recirculation (EGR) System DiagnosisDokument12 SeitenTOYOTA Technical Training - Exhaust Gas Recirculation (EGR) System DiagnosisEbag333100% (2)

- Fault Code SID 146 - EGR SystemDokument6 SeitenFault Code SID 146 - EGR Systemvictor manuel50% (2)

- FOTON Section Two ENG PDFDokument884 SeitenFOTON Section Two ENG PDFRichard Zea100% (2)

- 06 Sistema de Control de EmisionesDokument29 Seiten06 Sistema de Control de EmisionesmongongoNoch keine Bewertungen

- Evaporative Emission Control System: Ls430 - New Features 9Dokument12 SeitenEvaporative Emission Control System: Ls430 - New Features 9bob loblawNoch keine Bewertungen

- Evaporative Systems Diagnosis: Section 5Dokument40 SeitenEvaporative Systems Diagnosis: Section 5sungjoo75Noch keine Bewertungen

- Evaporative Emission Control System DescriptionDokument1 SeiteEvaporative Emission Control System Description08088338Noch keine Bewertungen

- EVAP SystemDokument11 SeitenEVAP SystemEmanuel FlorinNoch keine Bewertungen

- Evaporative Emission (EVAP) SystemsDokument3 SeitenEvaporative Emission (EVAP) SystemsJosé AntonioNoch keine Bewertungen

- Emission Control Systems Guide for 5S-FE EnginesDokument19 SeitenEmission Control Systems Guide for 5S-FE EnginesMuhammad SafdarNoch keine Bewertungen

- Evaporative Systems DiagnosisDokument40 SeitenEvaporative Systems DiagnosisVASEKNoch keine Bewertungen

- Evaporative Emission Control System: GeneralDokument5 SeitenEvaporative Emission Control System: Generalbob loblawNoch keine Bewertungen

- EVAP Leak Check Monitor GuideDokument5 SeitenEVAP Leak Check Monitor GuideJosé AntonioNoch keine Bewertungen

- Emission Control SystemsDokument13 SeitenEmission Control SystemsСергейУ-УNoch keine Bewertungen

- Tucson Emission Control System 2.0Dokument19 SeitenTucson Emission Control System 2.0wilder0l0pezNoch keine Bewertungen

- EvapDokument12 SeitenEvapNilson BarbosaNoch keine Bewertungen

- DTC P043E Rav4Dokument6 SeitenDTC P043E Rav4miguelNoch keine Bewertungen

- 85249898-Santa-Fe-service-Manual.docDokument384 Seiten85249898-Santa-Fe-service-Manual.docMihaita PrepelitaNoch keine Bewertungen

- Item Specification: Emission Control SystemDokument19 SeitenItem Specification: Emission Control SystemZM OhnNoch keine Bewertungen

- Item Specification: Emission Control SystemDokument20 SeitenItem Specification: Emission Control SystemZM OhnNoch keine Bewertungen

- Subaru evaporative emissions systems explainedDokument8 SeitenSubaru evaporative emissions systems explainedpivillamilNoch keine Bewertungen

- Supplementary Notes Qute BS IVDokument7 SeitenSupplementary Notes Qute BS IVjoeorcaleNoch keine Bewertungen

- Van Orvr 2Dokument1 SeiteVan Orvr 2BearNoch keine Bewertungen

- Manuali Officina Yj/Xj 1993Dokument10 SeitenManuali Officina Yj/Xj 1993stormchid100% (1)

- Elantra 91 Emission Control SystemDokument49 SeitenElantra 91 Emission Control Systemahmad adelNoch keine Bewertungen

- Frame 9e Gas Turbine Presentation OverviewDokument98 SeitenFrame 9e Gas Turbine Presentation Overviewmujeebtalib100% (5)

- JourneyDokument194 SeitenJourneyjuan carlos garciaNoch keine Bewertungen

- DTC P0441 Evaporative Emission Control System Incorrect Purge FlowDokument6 SeitenDTC P0441 Evaporative Emission Control System Incorrect Purge FlowlabowlingNoch keine Bewertungen

- Genesis Coupe Emission Control SystemsDokument18 SeitenGenesis Coupe Emission Control SystemsNacho MowjiNoch keine Bewertungen

- Reduce Emissions with Proper Emission Control System MaintenanceDokument16 SeitenReduce Emissions with Proper Emission Control System MaintenancevixentdNoch keine Bewertungen

- 04-Emission Control SystemDokument28 Seiten04-Emission Control SystemangelNoch keine Bewertungen

- Emission Control SystemDokument28 SeitenEmission Control Systemsled novaNoch keine Bewertungen

- 2.4 Regulating System 2.4.1: Instruction ManualDokument6 Seiten2.4 Regulating System 2.4.1: Instruction Manualwelltest vspNoch keine Bewertungen

- Engine and Emission ControlDokument4 SeitenEngine and Emission ControlEl OhmimetroNoch keine Bewertungen

- Emission Control Systems: Efi EngineDokument69 SeitenEmission Control Systems: Efi EngineWilmer HuangaNoch keine Bewertungen

- 1GR-FE ENGINE CONTROL SYSTEM - SFI SYSTEM - EVAP System 2007 MY Tundra (11 - 2006 - )Dokument3 Seiten1GR-FE ENGINE CONTROL SYSTEM - SFI SYSTEM - EVAP System 2007 MY Tundra (11 - 2006 - )عبدالله عبداللهNoch keine Bewertungen

- Emissions Control SystemsDokument15 SeitenEmissions Control SystemsTharsikan singamNoch keine Bewertungen

- DTC Summary: 2Gr-Fe Engine Control System - Sfi SystemDokument11 SeitenDTC Summary: 2Gr-Fe Engine Control System - Sfi Systemcarlos Gutierrez De La HozNoch keine Bewertungen

- LO3 - Engine Monitoring, Indication, Fuel, Lubrication and CoolingDokument51 SeitenLO3 - Engine Monitoring, Indication, Fuel, Lubrication and Coolingalii70732Noch keine Bewertungen

- Toyota Ecu 39Dokument8 SeitenToyota Ecu 39mike chenNoch keine Bewertungen

- Elantra 2.0 EC (137) G 2.0 MPIDokument23 SeitenElantra 2.0 EC (137) G 2.0 MPIjoan velaNoch keine Bewertungen

- Gas Turbine Fuel Systems OverviewDokument124 SeitenGas Turbine Fuel Systems Overviewadriana100% (1)

- Industrial Resources, Inc.: Solar Taurus 60 Gas TurbineDokument28 SeitenIndustrial Resources, Inc.: Solar Taurus 60 Gas TurbineIsabel PaixaoNoch keine Bewertungen

- Manage change to flare systemsDokument4 SeitenManage change to flare systemsjackrzysNoch keine Bewertungen

- Crew Training Presentation v3.0Dokument61 SeitenCrew Training Presentation v3.0Mikhail NazarovNoch keine Bewertungen

- Technical Training SeriesDokument8 SeitenTechnical Training SeriesMubashiryyy mehmoodNoch keine Bewertungen

- Fta Eta Hazop ExerciseDokument3 SeitenFta Eta Hazop ExerciseMarouane AdamNoch keine Bewertungen

- Emission Control SystemDokument26 SeitenEmission Control SystemnahomNoch keine Bewertungen

- Combustion Turbine Performance FactorsDokument52 SeitenCombustion Turbine Performance FactorsAwadhesh Kumar SinghNoch keine Bewertungen

- 0-System PhilosopyDokument4 Seiten0-System PhilosopydazcornishNoch keine Bewertungen

- Evaporative Emissions SystemDokument1 SeiteEvaporative Emissions SystemUzziel MendezNoch keine Bewertungen

- QSM11 Engine Components and StructureDokument14 SeitenQSM11 Engine Components and StructureTaha RdmanNoch keine Bewertungen

- GT Frame 9 ManualDokument102 SeitenGT Frame 9 ManualSSC & GSC of LebanonNoch keine Bewertungen

- Petrofac Fuel Gas System Training DocumentDokument11 SeitenPetrofac Fuel Gas System Training Documentbelil206Noch keine Bewertungen

- Intake Air SystemsDokument8 SeitenIntake Air SystemsJosé AntonioNoch keine Bewertungen

- DTC P2401 Evaporative Emission Leak Detection Pump Stuck OFF Evaporative Emission Leak Detection Pump Stuck ONDokument6 SeitenDTC P2401 Evaporative Emission Leak Detection Pump Stuck OFF Evaporative Emission Leak Detection Pump Stuck ONvanhostingwebNoch keine Bewertungen

- Chapter 3 - Emission ControlDokument38 SeitenChapter 3 - Emission Controlmohamad fitri F2008Noch keine Bewertungen

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesVon EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesBewertung: 1 von 5 Sternen1/5 (2)

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SVon EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNoch keine Bewertungen

- Hermetic CompressorsDokument102 SeitenHermetic CompressorsMalau Arief100% (1)

- Hermetic CompressorsDokument102 SeitenHermetic CompressorsMalau Arief100% (1)

- CAN Bus IntroDokument28 SeitenCAN Bus IntroElias Nassif Gomez100% (1)

- Hermetic CompressorsDokument102 SeitenHermetic CompressorsMalau Arief100% (1)

- Hermetic CompressorsDokument102 SeitenHermetic CompressorsMalau Arief100% (1)

- LS400 Engine UpdatesDokument8 SeitenLS400 Engine UpdatesElias Nassif GomezNoch keine Bewertungen

- P0406-Egr Position Sensor Circuit HighDokument8 SeitenP0406-Egr Position Sensor Circuit HighElias Nassif GomezNoch keine Bewertungen

- Egr Sensor St9972Dokument2 SeitenEgr Sensor St9972Elias Nassif GomezNoch keine Bewertungen

- Siemens Sirius 3RW30 3RW40 Manual PDFDokument212 SeitenSiemens Sirius 3RW30 3RW40 Manual PDFElias Nassif GomezNoch keine Bewertungen

- 4a-Fe EngineDokument13 Seiten4a-Fe Engineanto_jo100% (5)

- CDS11412 M142 Toyota GR Yaris Plug-In ECU KitDokument19 SeitenCDS11412 M142 Toyota GR Yaris Plug-In ECU KitVitor SegniniNoch keine Bewertungen

- Hyundai Excel X2 1989-1998 Air ConditioningDokument53 SeitenHyundai Excel X2 1989-1998 Air ConditioningaurbinaeNoch keine Bewertungen

- 2012 ENGINE Engine Mount Control System - TLDokument16 Seiten2012 ENGINE Engine Mount Control System - TLsoftallNoch keine Bewertungen

- Tests With CodesDokument268 SeitenTests With CodesAnimemanuel MuñozNoch keine Bewertungen

- Appendices: 15.2 Appendix 2 - List of Diagnostic and Event CodesDokument2 SeitenAppendices: 15.2 Appendix 2 - List of Diagnostic and Event CodesMichael Maluenda CastilloNoch keine Bewertungen

- Manual Perkins 1106d 1104d ElectronicDokument90 SeitenManual Perkins 1106d 1104d Electroniccamby2262983% (6)

- Sae Technical Paper Series: Ernest Schwarz, Michael Reid, Walter Bryzik, and Eugene DanielsonDokument18 SeitenSae Technical Paper Series: Ernest Schwarz, Michael Reid, Walter Bryzik, and Eugene Danielsonliaqat37_763886179Noch keine Bewertungen

- Cummins All Series Engine SpecificationsDokument10 SeitenCummins All Series Engine Specificationsmarion98% (44)

- Устройство PMS часть 1Dokument9 SeitenУстройство PMS часть 1Achmad AminNoch keine Bewertungen

- ASE 2010 L2 Composite VehicleDokument20 SeitenASE 2010 L2 Composite VehicleSeven See67% (3)

- Annexes 032-CQB Release 10Dokument21 SeitenAnnexes 032-CQB Release 10Eliezer Planes100% (3)

- Manuale Seq Instal 1 3 enDokument67 SeitenManuale Seq Instal 1 3 enalgreatNoch keine Bewertungen

- Interpreting Generic OBD Scan DataDokument6 SeitenInterpreting Generic OBD Scan DatasurfsandNoch keine Bewertungen

- 777DDokument3 Seiten777DsuperbludnikNoch keine Bewertungen

- Vacuum Brakes Systems (1944) TM 9-1827BDokument152 SeitenVacuum Brakes Systems (1944) TM 9-1827BNitin Sakpal100% (1)

- LV37-Petrol Fuel SystemsDokument57 SeitenLV37-Petrol Fuel SystemsĐức HòangNoch keine Bewertungen

- 420E y 430E PDFDokument19 Seiten420E y 430E PDFRICHARDNoch keine Bewertungen

- PB4Y-1 Liberator Pilots GuideDokument91 SeitenPB4Y-1 Liberator Pilots GuideDavid Eckert100% (1)

- 6CTA 450 New Engine Performance SheetDokument2 Seiten6CTA 450 New Engine Performance SheetAgus Yudi100% (1)

- Perkins Troubleshooting 1104d 1106d Industrial EngineDokument20 SeitenPerkins Troubleshooting 1104d 1106d Industrial Engineorlando100% (44)

- Perkins 1204e E44ta 1204e E44tta 71206e E66ta Industrial Engine TroubleshootingDokument20 SeitenPerkins 1204e E44ta 1204e E44tta 71206e E66ta Industrial Engine Troubleshootingallen100% (53)

- Esquema Electrico 336dl Serie m4t023XXDokument24 SeitenEsquema Electrico 336dl Serie m4t023XXrjan7pe100% (1)

- Cat Electronic Technician 2018A v1.0 Product Status ReportDokument4 SeitenCat Electronic Technician 2018A v1.0 Product Status ReportRachmatSanusiNoch keine Bewertungen

- Automotive Control Systems 2012-Trang-43-63Dokument21 SeitenAutomotive Control Systems 2012-Trang-43-63Nguyễn Minh ĐứcNoch keine Bewertungen