Beruflich Dokumente

Kultur Dokumente

Digitaltachometer 2

Hochgeladen von

Harun WidodoOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Digitaltachometer 2

Hochgeladen von

Harun WidodoCopyright:

Verfügbare Formate

GENERAL INTEREST

tachometer

for mopeds and

(motor) scooters

There are people who

feel that every moped

and motor scooter

should be fitted with

a tachometer (rev

counter) as standard.

There are others who

find it a dodgy instru-

ment since it tends to

distract the riders

attention from the

road. If you belong to

the first category and

have a scooter or

moped without a rev

counter, this article is

for you. It describes a

straightforward

design of such an

instrument that can

be fitted to any model Like many low-priced cars and motor- venience of a rev counter argue that

of moped or scooter. cycles, mopeds and (motor) scooters gear changing is done by ear, but the

tend not to have a rev counter fitted compulsory safety helmet does not

by the manufacturer, presumably on always allow this: the sound insulation

grounds of economy. However, such of some helmets is very good indeed!

an instrument is relatively inexpensive Best is, of course, to have an automatic

and may be very useful, particularly gearbox, fortunately chosen by more

on vehicles with manual gear change. and more riders. Second best is to

For instance, the combined readings of build and fit the present tachometer.

the speedometer and tachometer give The combined readings of speedo-

a good indication of whether the right meter and rev counter may also be

gear has been selected. A falling read- useful in improving fuel consumption,

ing on the rev counter is a sign to but this implies that the power curve

change down, while a rising one of the engine is known.

points to the need of changing up.

Design by L. Lemmens Many riders who do not have the con-

Elektor Electronics 10/98

34

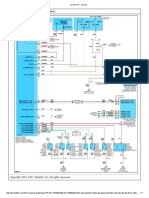

SENSOR

Ideally, the sensor should produce a

1 5V pulse for each engine revolution and

5V

D1 this is most easily achieved with the

D2

aid of an inductor (coil) to pick up the

5V ignition pulses inductively. Since the

5V

3 D3 voltage in the ignition pulses is fairly

1

9

MODE

L1

18 D4

high, it suffices to construct the coil

L2

P1 5

SIG

L3

17 from 1020 turns of insulated circuit

50k 6

7

RHI

L4

16 D5 wire around the spark-plug cable.

REFOUT 15

R3 R5

R1

IC1

L5

14 D6

While the voltage level of the igni-

L6

tion pulses is fairly high, their shape

22k

green

22M

22k

LM3914 L7 13

8 4

8 L8

12 D7 groen

varies appreciably. Therefore, the sen-

R REFADJ 11 grn

7

DIS

4

RLO

L9

10 D8

sor is followed by a pulse shaper to

IC3 L10

C3

2

TR OUT

3 transform the ignition pulses into sta-

10n 6

TLC555 R6 2 D9 ble, uniform count pulses. This ensures

100k

THR

CV D10

that random variations in the width

R7

5 1 JP1 and amplitude of the ignition pulses

22k

R4 5V

D11 do not affect the readout.

15M

C4 C2 C1

D12

100n 10n 10 6000 rpm CIRCUIT DESCRIPTION

16V 3 D13 The complete circuit diagram of the

1

9

MODE

L1

18 D14

tachometer is shown in Figure 1. The

L2

5

SIG

L3

17 yellow pick-up coil (sensor) is linked to capac-

6

7

RHI

L4

16 D15 geel

itor C3. This capacitor, in conjunction

REFOUT 15 gelb

IC2

L5

14 D16

with resistors R3 and R4, forms a dif-

L6

4805

LM3914 L7 13

8000 rpm ferentiating circuit that narrows the

6...7V IC4 5V 12 D17

ignition pulses into usable trigger

8 L8

REFADJ 11

C5 C6 C7

R2 4

RLO

L9

10 D18

pulses an arrangement that prevents

L10

2k2

red double triggering of the rev counter.

10 10 100n

25V 10V 2 D19 rood

The reshaped pulses are applied to the

rot

D20

trigger input of monostable (multivi-

980077 - 11

10000 rpm brator) IC3. This circuit outputs pulses

whose width can be preset with P1.

The pulses output by IC3 are inte-

grated by a simple low-pass filter

formed by R6 and C1. This filter also

Figure 1. The circuit of removes any short-duration variations

the tachometer con- of the output which otherwise might

sists of a pulse make the readout unstable.

DESIGN shaper, an integrating The only other item The LED readout is driven by two

There are various ways circuit, and a readout. that is needed is an display drivers, IC1 and IC2. These cir-

of constructing a The sensor is placed electronic circuit with a cuits are specially designed for this

tachometer, that is, the around the spark plug sensor that provides purpose and contain a reference volt-

manner of its readout. cable. pulses in proportion to age source and an accurate decade

Basically, there are three the number of engine scaler.

ways of achieving this: revolutions. These Each of the drivers can control a

in figures via a seven-segment display, pulses are converted by the electronic maximum of ten LEDs, so that the

via an analogue scale consisting of circuit into an analogue direct voltage tachometer can use up to 20 diodes

light-emitting diodes (LEDs), or via a to drive the LED bar. which gives a sufficiently accurate

traditional moving coil meter with readout. Each of the LEDs represents

pointer. about 500 engine revolutions. The

The moving-coil type is the sim-

plest construction, but is also vulnera-

ble to shocks and vibrations. This

makes it not really suitable for use on Setting up

a moving vehicle.

A readout via a seven-segment dis- The pulse width of the output of the pulse shaper, and thus the drive voltage

play is highly accurate, but perhaps for the readout, can be set within a wide band with P1.

too sophisticated for use on a moped. Calibrating the scale may be done in a number of ways: with another

The high accuracy is not needed and tachometer as reference, with a pulse generator, and also without any special

would make the design more complex equipment. This is possible by using the pick-up coil to sense the frequency

of the mains voltage (in a safe manner!). This very stable signal at 50 Hz is

than necessary.

excellent for calibration purposes, since it corresponds to 5060=3000 rev/min.

An analogue (LED) readout is both

So, if the proposed maximum of 10000 rev/min is adopted, P1 should be

simple and robust. It can make use of adjusted at 50 Hz so that D6 (3000 rev/min) lights.

several types of control IC that enable An ideal source for the 50 Hz mains frequency is a demagnetizer for a

an analogue voltage to be displayed cassette deck. The electric field radiated by this is readily picked up by the

on a bar of LEDs with only a few tachometer sensor. Never, never connect the input of the rev counter sirectly

external components. If the bar con- to the mains: this may be lethal and, even if youre lucky to survive, will destroy

sists of, say, 20 diodes, the readout is the tachometer.

sufficiently accurate for most purposes.

Elektor Electronics 10/98 35

2 980077-1 980077-1 1-770089

R7

R1

IC1

IC2

R2

C2

C1

C3

R3

C4

IC3

D1

R6

R5

R4 T P1

(C) ELEKTOR 0 + ROTKELE )C(

LEDs may be of different colours to Figure 2. Construction means that the circuit cannot be con-

create, say, a safe (green) range of rev- of the tachometer is nected directly to the battery terminals

olutions of 5006000 rev/min (D1D12); straightforward when of the moped or scooter. A stable sup-

a caution (yellow) range of 60008000 this printed-circuit ply is obtained by the use of a 5 V reg-

rev/min (D13D16); and a danger (red) board is used. It is ulator between the battery and the rev

range above 8000 rev/min (D17D20). available through our counter as shown in Figure 1. Since

Different ranges may, of course, be Readers services. the voltage at the battery terminals is

chosen to individual requirements. only about 67 V, the regulator must be

Comparators are driven via each of a low-drop type such as the 4805: a

the junctions of the scaler in the dis- standard 7805 will not do!

play drivers in such a way that every P O W E R S U P P LY It is also possible to power the

time the input voltage to the display The tachometer needs tachometer indepen-

driver increases the next comparator is a power supply of Figure 3. The com- dently by a pack of

enabled. The comparator outputs are 56 V. The supply rails pleted board in the

capable of driving an LED directly. should be stable, which Conrad enclosure

The LED bar may be operated in mentioned in the text.

the dot or bar mode. In the dot mode,

pin 9 of the IC must be left open, and

in the bar mode it should be linked to 3

the positive supply rail. In the present

application the bar mode is used.

Parts list

Resistors:

R1, R5, R7 = 22 k

R2 = 2.2 k

R3 = 22 M

R4 = 15 M

R6 = 100 k

P1 = 47 k (50 k) preset

Capacitors:

C1 = 10 F, 16 V, radial

C2, C3 = 0.01 F, pitch 5 mm

C4 = 0.1 F, pitch 5 mm

Semiconductors:

D1D13 = low-current LED, green

D14D16 = low-current LED, yellow

D17D20 = low-current LED, red

Integrated circuits:

IC1, IC2 = LM3914

IC3 = TLC555

Miscellaneous:

JP1 = 2-terminal 2.54 mm pin strip

and pin jumper (Maplin)

Enclosure: Conrad Type 842230-55

(see text)

Sensor: see text

PCB Order No. 980077 (see Readers

services towards the end of this

issue).

36 Elektor Electronics 10/98

Figure 4. This photo

4 clearly shows how the

pick-up coil is wound

(25 turns) auround the

ignition cable.

a check, the jumper should be

removed.

When pulses are applied to capac-

itor C3, it should be possible to vary

the low direct voltage at the terminal

of JP1 linked to junction R6-C1 with P1.

If this is so, the pulse shaper operates

correctly.

When a variable direct voltage at a

level of a few volts is applied to the

other terminal of JP1, one of the dis-

play diodes should light.

Forming the pick-up coil around

the spark plug cable (1020 turns of

thin insulated circuit wire) should not

present undue difficulties. The coil

should be linked to the input pin of

the tachometer via insulated stranded

circuit wire.

four series-connected chargeable or dry ure 2. It is generally agreed that a cir- In some areas it may be possible to

1.5 V batteries (AA=HP7=LR6 or cular readout is to be preferred and obtain a round enclosure to house the

C=HP11=LR14). A regulator is then, this is why the 20 LEDs have been rev counter. A suitable one is produced

of course, not needed. The life of such arranged in a circle on the board. In by Conrad (Germany) and may be

batteries is lengthened by using the view of the sparsity of components, available from our regular advertiser

display drivers in the dot mode (in populating the board is simplicity itself Stippler Elektronik via another regular

which pin 9 of the devices is left open). if the circuit diagram and the parts list advertiser, Viewcom Electronics. The

are followed carefully. model number of the enclosure is

CONSTRUCTION Pin strip and jumper JP1 enables given in the parts list.

The electronics is best built on the the circuit to be checked on comple- [980077]

printed-circuit board shown in Fig- tion of the construction. During such

Elektor Electronics 10/98 37

Das könnte Ihnen auch gefallen

- LS055R1SX04 PDFDokument33 SeitenLS055R1SX04 PDFRoman Beránek100% (1)

- Catalogo de Pecas Mirage 650Dokument114 SeitenCatalogo de Pecas Mirage 650Valtenor SilvaNoch keine Bewertungen

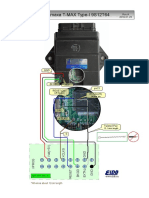

- Yamaxa T-MAX Type-I 9S12T64: Rev.A 2016.01.29Dokument1 SeiteYamaxa T-MAX Type-I 9S12T64: Rev.A 2016.01.29cairo carNoch keine Bewertungen

- Direção - Kia Picanto 2012Dokument16 SeitenDireção - Kia Picanto 2012kiwel.01Noch keine Bewertungen

- SC15ADokument2 SeitenSC15Asugeda100% (1)

- Modulo Taramp T400 X4Dokument3 SeitenModulo Taramp T400 X4az31t0n4Noch keine Bewertungen

- TC 32a400bDokument16 SeitenTC 32a400bAlexandredeAguiar0% (1)

- MC2100 Rev Engrd PDFDokument1 SeiteMC2100 Rev Engrd PDFMaria VochinNoch keine Bewertungen

- SPM1202 1502Dokument9 SeitenSPM1202 1502sugedaNoch keine Bewertungen

- 315 ManualDokument119 Seiten315 ManualLizardo Astudillo CruzNoch keine Bewertungen

- BN44-00340A Power Supply Backlight Inverter Repair Kit PDFDokument3 SeitenBN44-00340A Power Supply Backlight Inverter Repair Kit PDFDa ElNoch keine Bewertungen

- Pioneer Deh-P600ub Deh-P7150ub Crt4090Dokument78 SeitenPioneer Deh-P600ub Deh-P7150ub Crt4090Ramil IsmayilovNoch keine Bewertungen

- Samsung LCD Monitor 2032BW 2232BW 2232GW Plus Parts and Service ManualDokument51 SeitenSamsung LCD Monitor 2032BW 2232BW 2232GW Plus Parts and Service ManualroldskiNoch keine Bewertungen

- Fiat V11.30 Diagnostics ListDokument21 SeitenFiat V11.30 Diagnostics Listmilton villalbaNoch keine Bewertungen

- Battery Replacement Manual (DOC0945) R01-000Dokument21 SeitenBattery Replacement Manual (DOC0945) R01-000874895Noch keine Bewertungen

- REV. DESCRICAO VISTOS DATA PR- ENTDokument1 SeiteREV. DESCRICAO VISTOS DATA PR- ENTEdilberto Francisco de MouraNoch keine Bewertungen

- Microsquirt Hardware 3.3Dokument154 SeitenMicrosquirt Hardware 3.3Charlie Buffalo50% (2)

- Manual de Serviço Comet GT650 EfiDokument94 SeitenManual de Serviço Comet GT650 EfiGeraldo Fappi100% (1)

- Manual Rontan - Winglux - Rev 0Dokument25 SeitenManual Rontan - Winglux - Rev 0mcginity0% (1)

- Cb250fa-2016 2017Dokument278 SeitenCb250fa-2016 2017Repuestos VitacuraNoch keine Bewertungen

- Esquema Elétrico GOLF 1995 PDFDokument11 SeitenEsquema Elétrico GOLF 1995 PDFLeandro RibeiroNoch keine Bewertungen

- Audi A3 Air Conditioning System Wiring DiagramDokument17 SeitenAudi A3 Air Conditioning System Wiring DiagramJohn PNoch keine Bewertungen

- Diagrama Electro R 1200 GsDokument11 SeitenDiagrama Electro R 1200 GsFelipe Tudela DfgNoch keine Bewertungen

- E85001-0655 - Signature Series Diagnostic ToolDokument4 SeitenE85001-0655 - Signature Series Diagnostic ToolRavi100% (1)

- Pioneer DEH546Dokument77 SeitenPioneer DEH546Alessandro SilvaNoch keine Bewertungen

- Esquema - LL Ir600r2 - Sub - Pro2600 - Dx2800Dokument1 SeiteEsquema - LL Ir600r2 - Sub - Pro2600 - Dx2800Oficina do Músico Luthieria e Eletrônica100% (2)

- GT 650Dokument210 SeitenGT 650Szabolcs MártonNoch keine Bewertungen

- Digipro 1000S amplifier specs and manualDokument5 SeitenDigipro 1000S amplifier specs and manualHenry PalNoch keine Bewertungen

- Pi NuevaDokument5 SeitenPi NuevaLau BenalcazarNoch keine Bewertungen

- Pioneer Avh-P5950dvd Crt3916Dokument193 SeitenPioneer Avh-P5950dvd Crt3916boroda24100% (1)

- Captiva 2010 - Direção Elétrica - Diagrama ElétricoDokument1 SeiteCaptiva 2010 - Direção Elétrica - Diagrama ElétricoWiterMarcosNoch keine Bewertungen

- Gefran GTF ManualDokument37 SeitenGefran GTF ManualLavanyaNoch keine Bewertungen

- 9619 RCA L32NXSMART Fuente PLE55 Televisor LCD DiagramaDokument1 Seite9619 RCA L32NXSMART Fuente PLE55 Televisor LCD Diagramajmolina666100% (1)

- Honda Radio CD Service ManualDokument14 SeitenHonda Radio CD Service ManualJuan Carlos RuizNoch keine Bewertungen

- Manual Taller Honda - CBDokument2 SeitenManual Taller Honda - CBSamii AnguloNoch keine Bewertungen

- LV112 Rev03Dokument2 SeitenLV112 Rev03Júlio AlbertoNoch keine Bewertungen

- Colged ManualDokument168 SeitenColged ManualSinisa MalesevicNoch keine Bewertungen

- Pioneer Xdj-AeroDokument156 SeitenPioneer Xdj-Aeroboroda241050% (2)

- Design Max: 2A DC power supply input boardDokument16 SeitenDesign Max: 2A DC power supply input boardyhyzhjNoch keine Bewertungen

- WFH150cc-D Wiring Diagram PDFDokument1 SeiteWFH150cc-D Wiring Diagram PDFSaša Kostić100% (1)

- 2007 HHR Antitheft Wiring PDFDokument1 Seite2007 HHR Antitheft Wiring PDFDiego HenaoNoch keine Bewertungen

- Chery Manual de MotorDokument49 SeitenChery Manual de Motorcarlitox1192100% (1)

- DP801 system overview in 38 charactersDokument2 SeitenDP801 system overview in 38 charactersJoão ValentimNoch keine Bewertungen

- Manual Kozumi Air Force One 5Dokument214 SeitenManual Kozumi Air Force One 5Sal Ie EmNoch keine Bewertungen

- Manual Lavadora DaewoDokument36 SeitenManual Lavadora DaewoJuan Carlos Sanchez GomezNoch keine Bewertungen

- Fonte POW1200BDokument2 SeitenFonte POW1200Bsergio3aparecido3quiNoch keine Bewertungen

- 2005 Seadoo Rotax 1503 4 Tech Shop Manual - 26 50Dokument25 Seiten2005 Seadoo Rotax 1503 4 Tech Shop Manual - 26 50Oscar Eduardo GomezNoch keine Bewertungen

- 1/16 E-Revo VXL (71076-3) ManualDokument36 Seiten1/16 E-Revo VXL (71076-3) ManualakqxjeolpegzhijuibNoch keine Bewertungen

- Pioneer Deh-P690ub P6900ub P7950ub SMDokument82 SeitenPioneer Deh-P690ub P6900ub P7950ub SMMiguel AmaristaNoch keine Bewertungen

- Tacometro Motocicleta PDFDokument4 SeitenTacometro Motocicleta PDFciguaNoch keine Bewertungen

- Royer Back Light CCFLDokument12 SeitenRoyer Back Light CCFLPeter MossNoch keine Bewertungen

- A Digital Tachnograph For RC Model CarsDokument5 SeitenA Digital Tachnograph For RC Model CarsSentral AvrNoch keine Bewertungen

- Heart Attack Detection Walking StickDokument36 SeitenHeart Attack Detection Walking StickAbeer ShahidNoch keine Bewertungen

- Digital TachometerDokument11 SeitenDigital TachometerDwi Muhchamad YusufNoch keine Bewertungen

- Gearless Inglés K2 ECO+ 001-R00Dokument35 SeitenGearless Inglés K2 ECO+ 001-R00Elevateur Elevateur100% (1)

- Ngineering ATA: Fan Performance Troubleshooting GuideDokument10 SeitenNgineering ATA: Fan Performance Troubleshooting GuidePranpath NarupantawartNoch keine Bewertungen

- UntitledDokument135 SeitenUntitledcianeto liteNoch keine Bewertungen

- RC ROAD HUMPrDokument98 SeitenRC ROAD HUMPrVijayKumarVijayNoch keine Bewertungen

- Energy Meters-EnDokument13 SeitenEnergy Meters-EnDan TimisoaraNoch keine Bewertungen

- Simulation of Three Level Inverter Using Sinusoidal Pulse Width Modulation Technique by MatlabDokument5 SeitenSimulation of Three Level Inverter Using Sinusoidal Pulse Width Modulation Technique by MatlabANKIT PRAJAPATINoch keine Bewertungen

- Configure OpenVPN and DNS settings on MikroTik routerDokument2 SeitenConfigure OpenVPN and DNS settings on MikroTik routerHarun WidodoNoch keine Bewertungen

- ScriptDokument1 SeiteScriptHarun WidodoNoch keine Bewertungen

- Script Wifi - IdDokument1 SeiteScript Wifi - IdHarun WidodoNoch keine Bewertungen

- ScriptDokument1 SeiteScriptHarun WidodoNoch keine Bewertungen

- PROBABILITY ANALYSISDokument119 SeitenPROBABILITY ANALYSISAnonymous bZtJlFvPtpNoch keine Bewertungen

- Cantilever Calculation ToolDokument10 SeitenCantilever Calculation ToolEnoch Twumasi50% (2)

- Rockwell Scale PDFDokument5 SeitenRockwell Scale PDFFortune FireNoch keine Bewertungen

- Learning Objectives-2: Uniform MotionDokument7 SeitenLearning Objectives-2: Uniform MotionBryanHarold BrooNoch keine Bewertungen

- P Block - PDF 61Dokument6 SeitenP Block - PDF 61SurajNoch keine Bewertungen

- Thermocouple Temperature Sensors ExplainedDokument2 SeitenThermocouple Temperature Sensors ExplainedRaymond Yonathan HutapeaNoch keine Bewertungen

- Jan Corné Olivier - Linear Systems and Signals (2019)Dokument304 SeitenJan Corné Olivier - Linear Systems and Signals (2019)fawNoch keine Bewertungen

- 11P Trusses ProblemsDokument39 Seiten11P Trusses ProblemsHoward Johann Gomez VNoch keine Bewertungen

- Volumes by Cylindrical ShellsDokument7 SeitenVolumes by Cylindrical Shellseomer1968Noch keine Bewertungen

- Suntech STP225-20 WD 225Wp ENDokument2 SeitenSuntech STP225-20 WD 225Wp ENmax2503Noch keine Bewertungen

- Chapter 11Dokument2 SeitenChapter 11naniac raniNoch keine Bewertungen

- ConvectionDokument4 SeitenConvectionFaheem Fiaz ChohanNoch keine Bewertungen

- Chemistry Dictionary PDFDokument356 SeitenChemistry Dictionary PDFMuhammad YounusNoch keine Bewertungen

- Introduction To Random MatricesDokument508 SeitenIntroduction To Random Matricesjorelex100% (1)

- Cascho Modelo DDokument16 SeitenCascho Modelo Dfrankz89Noch keine Bewertungen

- Harmonic excitation of 1-degree-of-freedom systemsDokument1 SeiteHarmonic excitation of 1-degree-of-freedom systemsLetty VianaNoch keine Bewertungen

- 1 Rack and PinionDokument6 Seiten1 Rack and PinionMectrosoft Creative technologyNoch keine Bewertungen

- An Introduction To Fractional CalculusDokument29 SeitenAn Introduction To Fractional CalculusFredrik Joachim GjestlandNoch keine Bewertungen

- Chap3 (D) MillDokument22 SeitenChap3 (D) MilljojoNoch keine Bewertungen

- 01 - The Freerider Free Energy Inverter Rev 00DDokument18 Seiten01 - The Freerider Free Energy Inverter Rev 00Dpeterfoss791665Noch keine Bewertungen

- Well Control CourseDokument140 SeitenWell Control CourseAli Boubenia67% (3)

- BKI Vol2 - Section38Dokument5 SeitenBKI Vol2 - Section38Erwin Paulian SihombingNoch keine Bewertungen

- Qa TableDokument9 SeitenQa Tableapi-299403846Noch keine Bewertungen

- Siniloan Integrated National High SchoolDokument4 SeitenSiniloan Integrated National High SchoolKimberlyn VelascoNoch keine Bewertungen

- Weather ElementsDokument6 SeitenWeather ElementsFrenzie Mae Vasquez RiveraNoch keine Bewertungen

- Quality ControlDokument27 SeitenQuality ControlDe DeNoch keine Bewertungen

- 6 +ok+MEASURE+MENT+OF+SEQUENCE+REACTANCES+OF+SALIENT+POLE+SYNCHRONOUS+MACHINEDokument3 Seiten6 +ok+MEASURE+MENT+OF+SEQUENCE+REACTANCES+OF+SALIENT+POLE+SYNCHRONOUS+MACHINEaissmsNoch keine Bewertungen

- Chapter 6 - Cementing - Part 1 PDFDokument32 SeitenChapter 6 - Cementing - Part 1 PDFfadz607Noch keine Bewertungen

- 1.2 Student Workbook ESSDokument7 Seiten1.2 Student Workbook ESSTanay shahNoch keine Bewertungen

- Torque NotesDokument3 SeitenTorque NotesKudzai MashayaNoch keine Bewertungen