Beruflich Dokumente

Kultur Dokumente

Pages From E206-236 - Sprocket - Technical - Section PDF

Hochgeladen von

Anonymous oTrMzaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Pages From E206-236 - Sprocket - Technical - Section PDF

Hochgeladen von

Anonymous oTrMzaCopyright:

Verfügbare Formate

Sprocket Technical Section

Sprocket Hardening and Materials

Tsubaki can manufacture sprockets to meet your specific

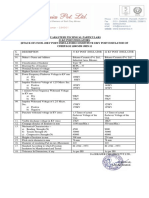

Hardness Conversion Table

needs. The results are sprockets designed to maximize the

Rockwell Hardness Number

life of your chain. Chains and sprockets must work together,

Brinell Approx.

C Scale A Scale Scleroscope 10mm ball Tensile

so buying them from the same source makes sense. When

330 lbs. 130 lbs. Shore 6600 lbs. Strength

chains and sprockets articulate correctly, the life of the chain

Load Load Model C Load (psi)

is extended. That means long term savings and real value for

10 56 28 190 93,000

your application.

12 56 29 195 96,000

13 57 30 200 98,000

15 57 31 205 100,000

Tsubaki sprockets can be made in a variety of grades of

16 58 32 210 103,000

carbon, stainless, and alloy steels, as well as other metals.

18 59 33 216 106,000

Since chain loadings are

20 60 34 222 109,000

distributed over all engaged

21 61 35 228 112,000

sprocket teeth, tooth

22 61 35 234 115,000

breakage or distortion is

23 62 36 240 118,000

24 62 37 247 121,000

not normally a problem. It

25 62 38 253 124,000

is seldom necessary to use

26 63 39 258 126,000

special high strength

27 63 40 264 129,000

material. Diameter, pitch

28 64 41 271 133,000

and strands of the sprocket

29 64 41 279 137,000

Bronze Idler Sprocket

determine the specific

30 65 42 286 140,000

grade of carbon steel used. Many of our wide range of

31 65 43 294 144,000

32 66 44 301 147,000

carbon steel sprockets are heat treated as a standard. For

33 66 46 311 152,000

other sprockets, heat-treating can be specified as an option.

34 67 47 319 156,000

Heat-treated carbon steel provides long wear life and resists

35 67 48 327 160,000

abrasion.

36 68 49 336 165,000

37 68 50 344 169,000

The hardening process of small diameter, small pitch

38 69 51 353 173,000

sprockets is usually a one step procedure using electrical

39 69 52 362 177,000

40 70 54 371 182,000

induction heat-treating. Large diameter, large pitch sprockets

S 41 70 55 381 187,000

are usually heat-treated using direct flame hardening. These

e

42 71 56 390 191,000

methods are used to provide high hardness at the wear areas

c

t 43 72 57 400 196,000

of each tooth maintaining

i

44 72 58 409 200,000

o

a ductile tooth core that is

n 45 73 60 421 206,000

tough and resilient. The

46 73 62 432 212,000

E

hubs and bore remain soft

47 74 63 442 217,000

48 74 64 451 221,000

to permit reworking.

49 75 66 464 227,000

50 75 67 475 233,000

51 76 68 487 239,000

Direct Flame Hardening Process 52 76 69 500 245,000

53 77 71 525 257,000

54 78 72 543 266,000

55 78 74 560 274,000

56 79 75 577 282,000

57 79 76 595 290,000

58 80 78 615 300,000

59 80 80 634 310,000

60 81 81 654 320,000

61 81 83 670 ---

62 82 85 688 ---

63 82 87 705 ---

Electrical Induction Hardening Process 64 83 88 722 ---

Tsubaki stock sprocket hardness is:

65 83 91 739 ---

Rockwell A Scale: 68-76

66 84 92 --- ---

Rockwell C Scale: 35-50

67 85 95 --- ---

Tighter ranges, or higher minimum

68 85 97 --- ---

hardness can be supplied at your

69 86 99 --- ---

request.

70 86 101 --- ---

Sprockets E218 Tsubaki of Canada Limited, 1630 Drew Road, Mississauga, ON L5S 1J6 Tel: 905-676-0400 Fax: 905-676-0904 Toll-Free: 800-263-7088 www.tsubaki.ca e-mail: info@tsubaki.ca

Das könnte Ihnen auch gefallen

- Sprockets Information 1Dokument8 SeitenSprockets Information 1Ashley DeanNoch keine Bewertungen

- Rebar CalculationDokument8 SeitenRebar CalculationEr Pranabesh SenNoch keine Bewertungen

- Electronics for Technicians: The Commonwealth and International Library: Electrical Engineering DivisionVon EverandElectronics for Technicians: The Commonwealth and International Library: Electrical Engineering DivisionBewertung: 5 von 5 Sternen5/5 (1)

- Filled Kashere - Gombe BemeDokument1 SeiteFilled Kashere - Gombe BemeEze UkiweNoch keine Bewertungen

- Westermann Table 8Dokument1 SeiteWestermann Table 8muhd.qasimNoch keine Bewertungen

- Chapter 22 Ductile IronDokument28 SeitenChapter 22 Ductile IronValeria Sánchez MoralesNoch keine Bewertungen

- Needle BearingDokument80 SeitenNeedle Bearinglaurentiucos18100% (1)

- Kashipur, Loop and Settlement ZoneDokument6 SeitenKashipur, Loop and Settlement ZoneVijayakumar.HiremathNoch keine Bewertungen

- Singly Reinforced Beam: Design For ShearDokument16 SeitenSingly Reinforced Beam: Design For ShearArbaz AhmedNoch keine Bewertungen

- Ali Bhaii RBSOLDokument1 SeiteAli Bhaii RBSOLzaka chNoch keine Bewertungen

- KV Xlpe PVC CableDokument2 SeitenKV Xlpe PVC CableHisham TharwatNoch keine Bewertungen

- 4) Double Reinforced BeamDokument3 Seiten4) Double Reinforced BeamVanessa Rosal PalerNoch keine Bewertungen

- Beton Ari 8Dokument4 SeitenBeton Ari 8ghina hidayatullahNoch keine Bewertungen

- Design of Machine Elements 1E52Dokument29 SeitenDesign of Machine Elements 1E52Thirumal K SNoch keine Bewertungen

- KrishnaCafe UGCableDokument16 SeitenKrishnaCafe UGCableAEunit4Noch keine Bewertungen

- Phe GSR - 2023Dokument245 SeitenPhe GSR - 2023Neil AgshikarNoch keine Bewertungen

- 6350 - Sanitary Unit Description Unit Qty Unit Rate TotalDokument2 Seiten6350 - Sanitary Unit Description Unit Qty Unit Rate TotalPrasadNoch keine Bewertungen

- Absolute Roughness (MM) Coefficient of Maning Hazen Williams (C)Dokument6 SeitenAbsolute Roughness (MM) Coefficient of Maning Hazen Williams (C)Cesar PachacamaNoch keine Bewertungen

- 2 65 66 Abstract Part BDokument2 Seiten2 65 66 Abstract Part Bbd9networkNoch keine Bewertungen

- MS C A Roofed Skeleton BOQDokument2 SeitenMS C A Roofed Skeleton BOQBrighton MUZAHURANoch keine Bewertungen

- Sector Group Sub - GroupDokument5 SeitenSector Group Sub - GroupPradip KhatriNoch keine Bewertungen

- Needle Roller Bearings Handbook Cat 9013-E Lowres PDFDokument80 SeitenNeedle Roller Bearings Handbook Cat 9013-E Lowres PDFMayank UkaniNoch keine Bewertungen

- Cost EstimateDokument1 SeiteCost EstimateKriengsak RuangdechNoch keine Bewertungen

- NGR SpecsDokument1 SeiteNGR SpecsGemey 95Noch keine Bewertungen

- Span Intermediate Position: Uniform Loading 2Dokument8 SeitenSpan Intermediate Position: Uniform Loading 2fredy2212Noch keine Bewertungen

- Typical Material BQS - 055508Dokument2 SeitenTypical Material BQS - 055508ivan kyamukamaNoch keine Bewertungen

- Final Abstract NEWDokument1 SeiteFinal Abstract NEWtaywadeNoch keine Bewertungen

- No of Bricks Calculation For Line III KilnDokument3 SeitenNo of Bricks Calculation For Line III Kilnhmaza shakeelNoch keine Bewertungen

- Conductor Cross Sectional AreaDokument10 SeitenConductor Cross Sectional AreaGaurav Agarwal0% (1)

- S/N QTY Description of Item Unit Price (N) Total Price (N)Dokument4 SeitenS/N QTY Description of Item Unit Price (N) Total Price (N)ramonNoch keine Bewertungen

- Quotation of Instrument WorkDokument1 SeiteQuotation of Instrument Workprima mandiriNoch keine Bewertungen

- Memdsx NovDokument2 SeitenMemdsx NovTyron RebellonNoch keine Bewertungen

- BOQ FORMAT PER SCOPE of Work Project - ConcreteDokument2 SeitenBOQ FORMAT PER SCOPE of Work Project - ConcreteReddenn RiveraNoch keine Bewertungen

- Bills of Materials Aerobics StudioDokument4 SeitenBills of Materials Aerobics StudioAmpumuza AdrianNoch keine Bewertungen

- 05 ColumnsDokument4 Seiten05 ColumnsJefreyMatuanMondranoNoch keine Bewertungen

- Physics IGCSE SolutionsDokument11 SeitenPhysics IGCSE SolutionsabhiyendraNoch keine Bewertungen

- WSP ISP Wazir AkbarkhanDokument1 SeiteWSP ISP Wazir AkbarkhanSayed Rahim NaderiNoch keine Bewertungen

- TABLE 3 Mechanical Requirements of NutsDokument1 SeiteTABLE 3 Mechanical Requirements of NutsanishNoch keine Bewertungen

- Bill of Quantities: No. Job No. DRG No. Sheet No. 1 of 1 Rev. Designed Checked DateDokument2 SeitenBill of Quantities: No. Job No. DRG No. Sheet No. 1 of 1 Rev. Designed Checked DateSitche ZisoNoch keine Bewertungen

- 33kV Post Insulator Stack GTPDokument1 Seite33kV Post Insulator Stack GTPHitesh PatelNoch keine Bewertungen

- 5KW On GridDokument1 Seite5KW On Gridzaka chNoch keine Bewertungen

- Variation Order PH0200462Dokument9 SeitenVariation Order PH0200462Angel SalaganNoch keine Bewertungen

- 006 - Design of Tension MemberDokument5 Seiten006 - Design of Tension MemberVAIBHAVNoch keine Bewertungen

- 6KW Hybrid Sardar AyazDokument1 Seite6KW Hybrid Sardar Ayazzaka chNoch keine Bewertungen

- Bushings PDFDokument32 SeitenBushings PDFRacha AmelNoch keine Bewertungen

- Flexible Busbar Tie Distance 2Dokument2 SeitenFlexible Busbar Tie Distance 2m.ramadanNoch keine Bewertungen

- Sector Group Sub - GroupDokument5 SeitenSector Group Sub - GroupPradip KhatriNoch keine Bewertungen

- Acsr Conductors AccessoriesDokument7 SeitenAcsr Conductors Accessoriesashok10577Noch keine Bewertungen

- Quotation For Construction of Swimming Pool of 3M × 6M Weights PDFDokument2 SeitenQuotation For Construction of Swimming Pool of 3M × 6M Weights PDFVictor ChukwuekeNoch keine Bewertungen

- Estimate FormatDokument1 SeiteEstimate FormatGuwahati RangeNoch keine Bewertungen

- C1 W12x65 Summary CalculationDokument2 SeitenC1 W12x65 Summary CalculationShadin Asari ArabaniNoch keine Bewertungen

- Magnetic Sensors SMC-SMP Series and MagnetsDokument2 SeitenMagnetic Sensors SMC-SMP Series and MagnetsleandroNoch keine Bewertungen

- 3 Waaree Series Ws 230-Ws 400Dokument1 Seite3 Waaree Series Ws 230-Ws 400bhansalianiket96Noch keine Bewertungen

- Larsen & Toubro Limited: Water & Effluent Treatment ICDokument7 SeitenLarsen & Toubro Limited: Water & Effluent Treatment ICMUKESH RAJENDRANoch keine Bewertungen

- Organized PDFDokument20 SeitenOrganized PDFJEAN-YVES TRONCONoch keine Bewertungen

- Building Documents PDFDokument27 SeitenBuilding Documents PDFJEAN-YVES TRONCONoch keine Bewertungen

- Container Lift and Wheed AddonDokument10 SeitenContainer Lift and Wheed AddonAnonymous oTrMzaNoch keine Bewertungen

- Publications CatalogDokument60 SeitenPublications CatalogAnonymous oTrMzaNoch keine Bewertungen

- Design Analysis and Comparison Between The Conventional Materialswith Composite Material of The Leaf Springs Fmoa 1000127Dokument20 SeitenDesign Analysis and Comparison Between The Conventional Materialswith Composite Material of The Leaf Springs Fmoa 1000127Anonymous oTrMzaNoch keine Bewertungen

- Caase18 Preliminary Agenda Mar20 v1Dokument277 SeitenCaase18 Preliminary Agenda Mar20 v1Anonymous oTrMzaNoch keine Bewertungen

- AOMEI Backupper UserManual PDFDokument64 SeitenAOMEI Backupper UserManual PDFAnonymous oTrMzaNoch keine Bewertungen

- Operator's Manual For Arc Welding: Motoman XRC 2001 ControllerDokument436 SeitenOperator's Manual For Arc Welding: Motoman XRC 2001 ControllerAnonymous oTrMzaNoch keine Bewertungen

- Cross Asset Investment Strategy Special Focus 201103 enDokument5 SeitenCross Asset Investment Strategy Special Focus 201103 enAnonymous oTrMzaNoch keine Bewertungen

- On Karl Popper's Liberal Principle of Freedom: The Individual and Social AspectsDokument7 SeitenOn Karl Popper's Liberal Principle of Freedom: The Individual and Social AspectsAnonymous oTrMzaNoch keine Bewertungen

- Handbook of Plastic FilmsDokument422 SeitenHandbook of Plastic FilmsStefan Boiadjiev100% (18)

- Design of Shaft PDFDokument5 SeitenDesign of Shaft PDFAnonymous oTrMzaNoch keine Bewertungen

- Finishes For Stainless Steel: Astm A480 ASTM A480 Description Roughness Ra (In) Roughness Ra (M) Bs en 10088-2 ISO 1302Dokument1 SeiteFinishes For Stainless Steel: Astm A480 ASTM A480 Description Roughness Ra (In) Roughness Ra (M) Bs en 10088-2 ISO 1302Anonymous oTrMzaNoch keine Bewertungen

- Mil DTL 45932 - 1DDokument6 SeitenMil DTL 45932 - 1DAnonymous oTrMzaNoch keine Bewertungen

- Design of ShaftDokument5 SeitenDesign of ShaftAnonymous oTrMzaNoch keine Bewertungen

- DELTA Start UpDokument3 SeitenDELTA Start UpAnonymous oTrMzaNoch keine Bewertungen

- Fea LeverDokument174 SeitenFea LeverAnonymous oTrMzaNoch keine Bewertungen

- ASME B1 1 2003 Unified Inch Screwed Threads PDFDokument189 SeitenASME B1 1 2003 Unified Inch Screwed Threads PDFAnonymous oTrMzaNoch keine Bewertungen

- Delta VFD WiringDokument6 SeitenDelta VFD WiringAnonymous oTrMzaNoch keine Bewertungen

- X RAY Residual StressDokument36 SeitenX RAY Residual StressAnonymous oTrMza100% (1)

- Bos 20080311Dokument155 SeitenBos 20080311Anonymous oTrMzaNoch keine Bewertungen

- Food Contant MaterialsDokument142 SeitenFood Contant MaterialsAnonymous oTrMzaNoch keine Bewertungen

- Alloy Steel, Chromium Molybdenum E: Specification For Pressure Vessel PlatesDokument8 SeitenAlloy Steel, Chromium Molybdenum E: Specification For Pressure Vessel PlatesAnonymous oTrMzaNoch keine Bewertungen

- HP Photosmart Premium User ManualDokument163 SeitenHP Photosmart Premium User ManualAnonymous oTrMzaNoch keine Bewertungen

- Potash Environmental Review Document Revised FinalDokument77 SeitenPotash Environmental Review Document Revised FinalAnonymous oTrMzaNoch keine Bewertungen

- Rolling Fig Q A AnalysisDokument11 SeitenRolling Fig Q A AnalysisRavinder Antil100% (9)

- Classification of Tooth StainingDokument4 SeitenClassification of Tooth StainingYAMUNA M.D.S. PAEDODONTICS & PREVENTIVE DENTISTRYNoch keine Bewertungen

- Bendable ConcreteDokument21 SeitenBendable ConcreteJulia Sebastian0% (1)

- Air Tunnels: Submitted By: Priyanka Sinha SK MD Sibli Akram Ananya Sreyansri NandaDokument8 SeitenAir Tunnels: Submitted By: Priyanka Sinha SK MD Sibli Akram Ananya Sreyansri NandaPriyanka SinhaNoch keine Bewertungen

- Critical Thinking and It's Importance in Education: I. Lenin Assistant Professor Auce KaraikudiDokument5 SeitenCritical Thinking and It's Importance in Education: I. Lenin Assistant Professor Auce KaraikudiPABLO RAMIRO AGUILAR GONZALEZNoch keine Bewertungen

- NoahDokument2 SeitenNoahapi-302505193Noch keine Bewertungen

- Wolfi Landstreicher - Willful Disobedience - Number 3Dokument32 SeitenWolfi Landstreicher - Willful Disobedience - Number 3populaererNoch keine Bewertungen

- Yamaha MG16 PDFDokument2 SeitenYamaha MG16 PDFmiskoyu027Noch keine Bewertungen

- 5-2 Sem2 Phys ExamDokument7 Seiten5-2 Sem2 Phys ExamNayLinNoch keine Bewertungen

- Radiant ThinkingDokument4 SeitenRadiant Thinkingeehwa88Noch keine Bewertungen

- Gayatri Mantras of Several GodDokument10 SeitenGayatri Mantras of Several GodAnup KashyapNoch keine Bewertungen

- Amendment No. 2 To AS 2047-2014 Windows and External Glazed Doors in BuildingsDokument2 SeitenAmendment No. 2 To AS 2047-2014 Windows and External Glazed Doors in BuildingsTommy AndersNoch keine Bewertungen

- Version 2 Dog Legged Stair ES EN 1992-1-1 2015Dokument29 SeitenVersion 2 Dog Legged Stair ES EN 1992-1-1 2015Khaja100% (2)

- Darmoatmodjo 2023Dokument7 SeitenDarmoatmodjo 2023mayaNoch keine Bewertungen

- Mucosal Adjuvants: Charles O. Elson Mark T. DertzbaughDokument1 SeiteMucosal Adjuvants: Charles O. Elson Mark T. DertzbaughPortobello CadısıNoch keine Bewertungen

- Ufm Interpretation SynopsisDokument1 SeiteUfm Interpretation SynopsispipegamoNoch keine Bewertungen

- MCQ Rewriting 1Dokument10 SeitenMCQ Rewriting 1Quỳnh Anh NguyễnNoch keine Bewertungen

- History of Journalism With Whiteboard StyleDokument56 SeitenHistory of Journalism With Whiteboard StyleXeon JupiterNoch keine Bewertungen

- Thermal Imaging Tech ResourceDokument20 SeitenThermal Imaging Tech Resourceskimav86100% (1)

- Mechanical Smoke Ventilation Calculations For Basement (Car Park)Dokument7 SeitenMechanical Smoke Ventilation Calculations For Basement (Car Park)Mahmoud Abd El-KaderNoch keine Bewertungen

- Civil 416Dokument2 SeitenCivil 416tskh11Noch keine Bewertungen

- Fagor CNC 8025 - 8030Dokument255 SeitenFagor CNC 8025 - 8030alvhann_1Noch keine Bewertungen

- Medical BiotechnologyDokument4 SeitenMedical Biotechnologyعمر بن عليNoch keine Bewertungen

- Kasuti of KarnatakaDokument2 SeitenKasuti of KarnatakarhlkNoch keine Bewertungen

- Sawla - Laska (Lot - I) Road Project Hydrology - Hydraulics MDokument64 SeitenSawla - Laska (Lot - I) Road Project Hydrology - Hydraulics Mashe zinab100% (2)

- 7UM512 CatalogueDokument12 Seiten7UM512 Cataloguebuianhtuan1980Noch keine Bewertungen

- Acid Alkaline Food ChartDokument3 SeitenAcid Alkaline Food Chartgime2013Noch keine Bewertungen

- BMC IV - Module 02 Finishes 200912Dokument56 SeitenBMC IV - Module 02 Finishes 200912Fidha SulfiNoch keine Bewertungen

- ME4542/ME4542-G: N and P-Channel 30-V (D-S) MOSFETDokument7 SeitenME4542/ME4542-G: N and P-Channel 30-V (D-S) MOSFETfelipe ayalaNoch keine Bewertungen

- Roadmap: B1+ Students' Book Audio ScriptsDokument44 SeitenRoadmap: B1+ Students' Book Audio ScriptsThanh Dat Phan100% (4)