Beruflich Dokumente

Kultur Dokumente

Ai B) C) D) E) : The Kill Will The

Hochgeladen von

andrewOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ai B) C) D) E) : The Kill Will The

Hochgeladen von

andrewCopyright:

Verfügbare Formate

Well Control School, -JDT-ONGC

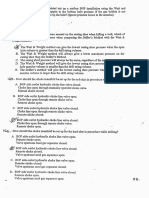

3.7.4 Trapped Gas Below Preventer After Killing

After the kill operation, some gas will remain trapped below the closed preventer.

Volume of this gas can be significant if the closed preventer is an annular preventer. ln

surface operations this trapped gas does not pose any problem because pressure of the

gas (being at surface) is nrinirnal. Vl$rereas in Subsea stacks pressure of the gas

trapped below tlie pi'eventer is equal to the hydrostatic head of the kill mud in the choke

line. ln order to p;event a rapid unloading of risei- mud due to trapped gas when the

preventer is opened, following actions are advised.

ai Close the upper nrost rarn below the choke line.

b) Circulate chore and kill lines with water .

c) Close the Clvert,:r and open il're preventer and allow the riser mud to

reverse flow up the choke line due to difference in hydrostatic head.

d) Fill the risei-froni t:p rruith kili mud, so that the gas can be quickly flushed

i into choke line.

e) After ail the trapped gas has been removed through choke line, displace

the riser with l..iil n:ud thi'ough kiil !ii.ie.

3.8 STRIPPING AND SNUBBING OPERATICT.TS

The operation is teri;':ed as stripping r,vheii the resuitant of upv,rai"d and downward forces

is acting downward, tlrus forcing the string into the well.

The operation is terrned as snubbing v;hen the resultant of upward and down forces is

i acting upward, thus fcrcing the string or-ri of the rryell. Additionai force will be required in

I

\/ this case to force the st:'lng into the weli. The snubbing operations require the use of a

I snubbing unit.

v

r 3.8.1 Selecti ono f BOP for

o Stri n

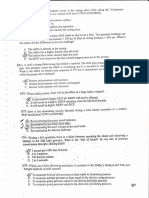

[t .. S.N, Well nressure Lenqth for st;'ippinq Preventer required

1. 1000 psi or less Anv lenqth Annular preventer

IY 2. -

1000 1500 psi 1000 ft Annular preventer

i':

p J. -

1000 1500 psi Mo;'e than i000 fI Annular pi'eventer +Ram

tt. preventer

t 4, 1500 psi oi' above Anv lenqth Ram oreventer +Ram preventer

r

r

r

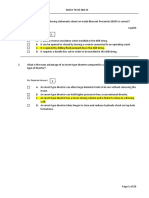

While stripping in the hole to maintain bottom hole pressure constant, mud is to be bled

off at regular interval. The amount of mud which is to be bled off should be equal to the

iv

r

I closed end volume of the pipe striped in. lf more mud is bled off than the calculated

volume the hydrostatic pressure in the annulus decreases causing the bottonr hole

r

a. pressure to reduce. The string is also to be kept full by filling mud at regular intervals.

t Care should be taken when the bit starts entering into the influx, as the increase in

f

height of the infiux shall increase the surface casing pressure.

E

t

v

I

iI -74

ll

f.

:

:-

Das könnte Ihnen auch gefallen

- Pressr:re: Well?' R@Dokument1 SeitePressr:re: Well?' R@andrewNoch keine Bewertungen

- Cannon (1934) PDFDokument7 SeitenCannon (1934) PDFmucoNoch keine Bewertungen

- 6.mud Hydraulics Fundamentals PDFDokument11 Seiten6.mud Hydraulics Fundamentals PDFمعلومات ممتعه mohammedNoch keine Bewertungen

- 12 PDFDokument76 Seiten12 PDFmjm_1365Noch keine Bewertungen

- 2008 Workover and Completion Practice TestDokument14 Seiten2008 Workover and Completion Practice TestWaOne PrabowoNoch keine Bewertungen

- B. VQ-D.: T:?Siffit'l Inff::'j:lDokument1 SeiteB. VQ-D.: T:?Siffit'l Inff::'j:landrewNoch keine Bewertungen

- WellcontrolDokument1 SeiteWellcontrolandrewNoch keine Bewertungen

- 1,9lpsi.z: Lij Speed String Psi Annulus Nozzles O' 5Dokument1 Seite1,9lpsi.z: Lij Speed String Psi Annulus Nozzles O' 5andrewNoch keine Bewertungen

- When using the Driller's Method for casing pressureDokument1 SeiteWhen using the Driller's Method for casing pressureandrewNoch keine Bewertungen

- M Cavitation1Dokument8 SeitenM Cavitation1Ade RizkiNoch keine Bewertungen

- Chapter 5 Drilling ProblemsDokument23 SeitenChapter 5 Drilling ProblemsAlind doskyNoch keine Bewertungen

- When can maximum pressure occur at the casing shoe while using the volumetric methodDokument1 SeiteWhen can maximum pressure occur at the casing shoe while using the volumetric methodandrewNoch keine Bewertungen

- Down-The-Hole Pressure Surges and Their Effect On Loss of CirculationtDokument8 SeitenDown-The-Hole Pressure Surges and Their Effect On Loss of CirculationtmucoNoch keine Bewertungen

- Well Control PresentationDokument57 SeitenWell Control PresentationmissaouiNoch keine Bewertungen

- WellcontrolDokument1 SeiteWellcontrolandrewNoch keine Bewertungen

- O? N - Hofcoperr/13:: Pressure: Speed:30 Fap Gga IDokument1 SeiteO? N - Hofcoperr/13:: Pressure: Speed:30 Fap Gga IandrewNoch keine Bewertungen

- Collar - Hole - Hole - : Full The ToDokument1 SeiteCollar - Hole - Hole - : Full The ToandrewNoch keine Bewertungen

- موارد مائية-ماجستيرDokument5 Seitenموارد مائية-ماجستيرTahaNoch keine Bewertungen

- Essential Well Control FormulasDokument89 SeitenEssential Well Control FormulasKIESSENoch keine Bewertungen

- WelcontrolDokument1 SeiteWelcontrolandrewNoch keine Bewertungen

- ESCHandbook Chapter3 3.18Dokument12 SeitenESCHandbook Chapter3 3.18Larry Wayne Sumpter, JrNoch keine Bewertungen

- Well Control Causes of Kicks Detection Techniques EquipmentsDokument49 SeitenWell Control Causes of Kicks Detection Techniques EquipmentsLaxmi Kant PrasadNoch keine Bewertungen

- Well Control - Driller's MethodDokument7 SeitenWell Control - Driller's MethodJohnny Fabian MolinaNoch keine Bewertungen

- Faizan Naikwadi PA 12 IWCF L3 & 4 Day 1 HomeworkDokument16 SeitenFaizan Naikwadi PA 12 IWCF L3 & 4 Day 1 Homeworkparesh pawarNoch keine Bewertungen

- Annular Pressure During Well ControlDokument9 SeitenAnnular Pressure During Well ControlGilbert ThemanNoch keine Bewertungen

- (2.1.592) Volumetric Stripping With Gas MigrationDokument6 Seiten(2.1.592) Volumetric Stripping With Gas MigrationMuhammed SulfeekNoch keine Bewertungen

- Gas Lift - Unloading (Leslie Thompson)Dokument59 SeitenGas Lift - Unloading (Leslie Thompson)Reza RamadhanNoch keine Bewertungen

- Maintain and troubleshoot air compressorsDokument1 SeiteMaintain and troubleshoot air compressorsramseyNoch keine Bewertungen

- Trex 05854Dokument8 SeitenTrex 05854OSDocs2012Noch keine Bewertungen

- Dynamic and Momentum KillingDokument20 SeitenDynamic and Momentum Killingمصطفى مجدي100% (1)

- Shen Informe PresionesDokument8 SeitenShen Informe PresionesJorge Vásquez CarreñoNoch keine Bewertungen

- KickDokument22 SeitenKickyarra suryatejaNoch keine Bewertungen

- Basic Drilling Problems & Their Solutions (Part - I) Pipe Sticking, Sloughing Shales & Lost CirculationDokument11 SeitenBasic Drilling Problems & Their Solutions (Part - I) Pipe Sticking, Sloughing Shales & Lost CirculationPradyumna Singh RathoreNoch keine Bewertungen

- Hyd 413Dokument45 SeitenHyd 413MehriNoch keine Bewertungen

- Rotating EquipmentDokument235 SeitenRotating EquipmentpraSHANT2331100% (5)

- Optimize Oil Production with Gas LiftDokument34 SeitenOptimize Oil Production with Gas LiftBhavesh ChudasamaNoch keine Bewertungen

- 28 - IWCF Study GuideDokument7 Seiten28 - IWCF Study GuideBabi LakhdariNoch keine Bewertungen

- 803 Subsea L4 EquiptDokument25 Seiten803 Subsea L4 EquiptKen ANoch keine Bewertungen

- Plunger lift performance and operating experience in Ventura Avenue FieldDokument17 SeitenPlunger lift performance and operating experience in Ventura Avenue FieldnicolasbelliniNoch keine Bewertungen

- Exercise 3 AnswersDokument13 SeitenExercise 3 AnswersadeelsnNoch keine Bewertungen

- Stimulation 4Dokument27 SeitenStimulation 4DVScherbakovNoch keine Bewertungen

- 03 - WellSharp WC Methods and Subsea - Day 2 Pre - CourseDokument5 Seiten03 - WellSharp WC Methods and Subsea - Day 2 Pre - CourseAdolfo AnguloNoch keine Bewertungen

- 1965, Foss e Gaul PDFDokument17 Seiten1965, Foss e Gaul PDFJoão GadelhaNoch keine Bewertungen

- Cement Plug Placement Using Stinger DynamicsDokument3 SeitenCement Plug Placement Using Stinger DynamicsDouadi AbderraoufNoch keine Bewertungen

- Types L H PumpsDokument22 SeitenTypes L H PumpsDimitry SilinshNoch keine Bewertungen

- Well Control Leak-Off Test & Kick Circulation MethodsDokument45 SeitenWell Control Leak-Off Test & Kick Circulation MethodsLaxmi Kant PrasadNoch keine Bewertungen

- Engineering Vol 56 1893-12-15Dokument33 SeitenEngineering Vol 56 1893-12-15ian_newNoch keine Bewertungen

- 6 Well Control System CDokument64 Seiten6 Well Control System CHamid Reza BabaeiNoch keine Bewertungen

- 29!541 Transient Aspects of Unloading Oil and Gas Wells With Coiled TubingDokument6 Seiten29!541 Transient Aspects of Unloading Oil and Gas Wells With Coiled TubingWaode GabriellaNoch keine Bewertungen

- Clark (1956) PDFDokument15 SeitenClark (1956) PDFmucoNoch keine Bewertungen

- Well Control - Combined Stripping and Volumetric MethodDokument3 SeitenWell Control - Combined Stripping and Volumetric MethodAbdul Hameed Omar100% (1)

- Choke PDFDokument32 SeitenChoke PDFobumuyaemesi100% (1)

- L1 - Pumps ReviewerDokument3 SeitenL1 - Pumps ReviewerJamie RapajonNoch keine Bewertungen

- WellSharp Drilling Exam ReviewDokument5 SeitenWellSharp Drilling Exam ReviewAdolfo Angulo100% (1)

- Hyd 560Dokument28 SeitenHyd 560Bhaskar ReddyNoch keine Bewertungen

- Net Positive Suction Head for Rotodynamic Pumps: A Reference GuideVon EverandNet Positive Suction Head for Rotodynamic Pumps: A Reference GuideBewertung: 5 von 5 Sternen5/5 (1)

- Scientific American Supplement, No. 446, July 19, 1884Von EverandScientific American Supplement, No. 446, July 19, 1884Noch keine Bewertungen

- Img 0165 PDFDokument1 SeiteImg 0165 PDFandrewNoch keine Bewertungen

- Slip and CutDokument1 SeiteSlip and CutandrewNoch keine Bewertungen

- Li,: Ti ., #: I Notincrease NDokument1 SeiteLi,: Ti ., #: I Notincrease NandrewNoch keine Bewertungen

- WelcontrolDokument1 SeiteWelcontrolandrewNoch keine Bewertungen

- The Configuration Illustrated Figure GivenDokument1 SeiteThe Configuration Illustrated Figure GivenandrewNoch keine Bewertungen

- Img 0111 PDFDokument1 SeiteImg 0111 PDFandrewNoch keine Bewertungen

- Img 0140Dokument1 SeiteImg 0140andrewNoch keine Bewertungen

- The BOP Below: Using Configuration Illustrated Figure GivenDokument1 SeiteThe BOP Below: Using Configuration Illustrated Figure GivenandrewNoch keine Bewertungen

- Of/'tY: Suest'O'/Js Superv'SorsDokument1 SeiteOf/'tY: Suest'O'/Js Superv'SorsandrewNoch keine Bewertungen

- WellcontrolDokument1 SeiteWellcontrolandrewNoch keine Bewertungen

- WellDokument1 SeiteWellandrewNoch keine Bewertungen

- WellDokument1 SeiteWellandrewNoch keine Bewertungen

- V Loxelrl'Oxfu) : O.O2Gzubvft 'Dokument1 SeiteV Loxelrl'Oxfu) : O.O2Gzubvft 'andrewNoch keine Bewertungen

- WellcontrolDokument1 SeiteWellcontrolandrewNoch keine Bewertungen

- Well ControlDokument1 SeiteWell ControlandrewNoch keine Bewertungen

- WellcontrolDokument1 SeiteWellcontrolandrewNoch keine Bewertungen

- P" P, BQ To% - R I. Zooox Il-3ooo-3bo 21oo: Tu/ Sb-Arcl!Dokument1 SeiteP" P, BQ To% - R I. Zooox Il-3ooo-3bo 21oo: Tu/ Sb-Arcl!andrewNoch keine Bewertungen

- WellcontrolDokument1 SeiteWellcontrolandrewNoch keine Bewertungen

- ..O.+romr/n# Ffit: Ffi Ffiusineprcssure-'Ioqqq'i...Dokument1 Seite..O.+romr/n# Ffit: Ffi Ffiusineprcssure-'Ioqqq'i...andrewNoch keine Bewertungen

- When using the Driller's Method for casing pressureDokument1 SeiteWhen using the Driller's Method for casing pressureandrewNoch keine Bewertungen

- Gas kick procedures and bottom hole pressure changesDokument1 SeiteGas kick procedures and bottom hole pressure changesandrewNoch keine Bewertungen

- When can maximum pressure occur at the casing shoe while using the volumetric methodDokument1 SeiteWhen can maximum pressure occur at the casing shoe while using the volumetric methodandrewNoch keine Bewertungen

- WelcontrolDokument1 SeiteWelcontrolandrewNoch keine Bewertungen

- WellcontrolDokument1 SeiteWellcontrolandrewNoch keine Bewertungen

- Img 0120Dokument1 SeiteImg 0120andrewNoch keine Bewertungen

- Match Following of Fluids Control Formation By: Each One Pressure The Spaces'Dokument1 SeiteMatch Following of Fluids Control Formation By: Each One Pressure The Spaces'andrewNoch keine Bewertungen

- Img 0151Dokument1 SeiteImg 0151andrewNoch keine Bewertungen

- Img 0149Dokument1 SeiteImg 0149andrewNoch keine Bewertungen

- P" P, BQ To% - R I. Zooox Il-3ooo-3bo 21oo: Tu/ Sb-Arcl!Dokument1 SeiteP" P, BQ To% - R I. Zooox Il-3ooo-3bo 21oo: Tu/ Sb-Arcl!andrewNoch keine Bewertungen

- Rapport DharaviDokument23 SeitenRapport DharaviUrbanistes du MondeNoch keine Bewertungen

- Srimanta Sankaradeva Universityof Health SciencesDokument3 SeitenSrimanta Sankaradeva Universityof Health SciencesTemple RunNoch keine Bewertungen

- Shouldice Hospital Ltd.Dokument5 SeitenShouldice Hospital Ltd.Martín Gómez CortésNoch keine Bewertungen

- TJUSAMO 2013-2014 Modular ArithmeticDokument4 SeitenTJUSAMO 2013-2014 Modular ArithmeticChanthana ChongchareonNoch keine Bewertungen

- LIST OF ENROLLED MEMBERS OF SAHIWAL CHAMBER OF COMMERCEDokument126 SeitenLIST OF ENROLLED MEMBERS OF SAHIWAL CHAMBER OF COMMERCEBASIT Ali KhanNoch keine Bewertungen

- Kaydon Dry Gas SealDokument12 SeitenKaydon Dry Gas Sealxsi666Noch keine Bewertungen

- PHY210 Mechanism Ii and Thermal Physics Lab Report: Faculty of Applied Sciences Uitm Pahang (Jengka Campus)Dokument13 SeitenPHY210 Mechanism Ii and Thermal Physics Lab Report: Faculty of Applied Sciences Uitm Pahang (Jengka Campus)Arissa SyaminaNoch keine Bewertungen

- Crystallizers: Chapter 16 Cost Accounting and Capital Cost EstimationDokument1 SeiteCrystallizers: Chapter 16 Cost Accounting and Capital Cost EstimationDeiver Enrique SampayoNoch keine Bewertungen

- Business Case PresentationDokument27 SeitenBusiness Case Presentationapi-253435256Noch keine Bewertungen

- Philippine Population 2009Dokument6 SeitenPhilippine Population 2009mahyoolNoch keine Bewertungen

- USDA Guide To CanningDokument7 SeitenUSDA Guide To CanningWindage and Elevation0% (1)

- Hipotension 6Dokument16 SeitenHipotension 6arturo castilloNoch keine Bewertungen

- Beauty ProductDokument12 SeitenBeauty ProductSrishti SoniNoch keine Bewertungen

- Exercise-01: JEE-PhysicsDokument52 SeitenExercise-01: JEE-Physicsjk rNoch keine Bewertungen

- LSMW With Rfbibl00Dokument14 SeitenLSMW With Rfbibl00abbasx0% (1)

- Ovr IbDokument27 SeitenOvr IbAriel CaresNoch keine Bewertungen

- Technical Manual - C&C08 Digital Switching System Chapter 2 OverviewDokument19 SeitenTechnical Manual - C&C08 Digital Switching System Chapter 2 OverviewSamuel100% (2)

- SolBridge Application 2012Dokument14 SeitenSolBridge Application 2012Corissa WandmacherNoch keine Bewertungen

- Composite Structures: A. Grimaldi, A. Sollo, M. Guida, F. MaruloDokument15 SeitenComposite Structures: A. Grimaldi, A. Sollo, M. Guida, F. MaruloSharan KharthikNoch keine Bewertungen

- KPUPDokument38 SeitenKPUPRoda ES Jimbert50% (2)

- Chapter 4 DeterminantsDokument3 SeitenChapter 4 Determinantssraj68Noch keine Bewertungen

- CTR Ball JointDokument19 SeitenCTR Ball JointTan JaiNoch keine Bewertungen

- Emergency Management of AnaphylaxisDokument1 SeiteEmergency Management of AnaphylaxisEugene SandhuNoch keine Bewertungen

- Uniform-Section Disk Spring AnalysisDokument10 SeitenUniform-Section Disk Spring Analysischristos032Noch keine Bewertungen

- Breaking NewsDokument149 SeitenBreaking NewstigerlightNoch keine Bewertungen

- Indian Journal of Natural Products and Resources Vol 1 No 4 Phytochemical pharmacological profile Cassia tora overviewDokument8 SeitenIndian Journal of Natural Products and Resources Vol 1 No 4 Phytochemical pharmacological profile Cassia tora overviewPRINCIPAL BHILWARANoch keine Bewertungen

- Test Bank For Fundamental Financial Accounting Concepts 10th by EdmondsDokument18 SeitenTest Bank For Fundamental Financial Accounting Concepts 10th by Edmondsooezoapunitory.xkgyo4100% (48)

- Get Oracle Order DetailsDokument4 SeitenGet Oracle Order Detailssiva_lordNoch keine Bewertungen

- Empanelment of Architect-Consultant - Work Costing More Than 200 Lacs. (Category-B)Dokument6 SeitenEmpanelment of Architect-Consultant - Work Costing More Than 200 Lacs. (Category-B)HARSHITRAJ KOTIYANoch keine Bewertungen