Beruflich Dokumente

Kultur Dokumente

Tube Rolling Worksheet

Hochgeladen von

micheld1964Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Tube Rolling Worksheet

Hochgeladen von

micheld1964Copyright:

Verfügbare Formate

(800) 230-2636 or fax (718) 361-2872 or tcwilson@tcwilson.

com

Guidelines for Tube Expansion

Unproperly rolled joints create considerable additional expense: Here is an example of the application of this method for a 2-inch

under-rolled joints must be re-rolled, and over-rolled tubes must Outer Diameter 10 Gauge tube in a boiler.

be removed and replaced.The optimum joint is one that develops

a leak-tight joint with adequate strength for the intended service, 2.010

Tubesheet Hole: __________

but with the minimum amount of cold working (or tube wall -2.000

Tube Outer Diameter : __________

reduction). .010

Clearance: __________

Application Tube Wall Reduction* 1.732

Tube Inner Diameter : __________

+.010

Clearance: __________

Nonferrous tubes

1.742

Tube Inner Diameter @ Metal-to-Metal: __________

in surface condensers 3% to 4%

Steel tubes .035

13% of .134 x 2: __________

in heat exchangers 5% to 10% +1.742

Tube Inner Diameter @ Metal-to-Metal: __________

Soft copper and aluminum 1.777

Expanded Tube Inner Diameter: __________

tubes in heat exchangers 8% to 12%

Boiler tubes 12% to 14%

*After metal-to-metal contact of the tube Outer Diameter with

the tubesheet hole.

Tube Rolling Worksheet

1. Tubesheet Hole _________

Tube Outer Diameter = - _________

Clearance _________

2. Tube Inner Diameter _________

Clearance = +_________

Inner Diameter @ Metal to Metal _________

3. ___% of ____(Wall) x 2 _________

Tube Inner Diameter

@ Metal to Metal = +_________

Expanded Tube Inner Diameter _________

TUBE WALL THICKNESS OF WALL IN BIRMINGHAM WIRE GAUGE

GA 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Inch .028 .032 .035 .042 .049 .058 .065 .072 .083 .095 .109 .120 .134 .148 .165 .180 .203 .220 .238 .259 .284 .300 .340

mm .7 .8 .9 1.1 1.2 1.5 1.7 1.8 2.1 2.4 2.8 3.0 3.4 3.8 4.2 4.6 5.2 5.6 6.0 6.6 7.2 7.6 8.6

Das könnte Ihnen auch gefallen

- The Complete Guide to Telephone Interview Questions and AnswersVon EverandThe Complete Guide to Telephone Interview Questions and AnswersNoch keine Bewertungen

- ASME Pressure VesselDokument13 SeitenASME Pressure Vesselamechmar5935Noch keine Bewertungen

- Catalog - Texas FlangesDokument76 SeitenCatalog - Texas FlangesVicky GautamNoch keine Bewertungen

- ASME B31.3 Questions and Answers-SignedDokument5 SeitenASME B31.3 Questions and Answers-Signedpradip panthaNoch keine Bewertungen

- ASME BPVC CODE TRAINING-onlineDokument3 SeitenASME BPVC CODE TRAINING-onlineRahaman khanNoch keine Bewertungen

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AVon EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANoch keine Bewertungen

- ASME B31.3 InterpretationsDokument44 SeitenASME B31.3 InterpretationsChickenChick07Noch keine Bewertungen

- Methods of Tube Expansion in Tube To TubDokument19 SeitenMethods of Tube Expansion in Tube To Tubkurcek100% (1)

- ASTM A106 GR.B Steel TubeDokument2 SeitenASTM A106 GR.B Steel TubeSpicyNoch keine Bewertungen

- Welcome To: Training Program On ASME Sec. VIII Div. 1Dokument120 SeitenWelcome To: Training Program On ASME Sec. VIII Div. 1Wilson Wilfredo Yucra Paco100% (1)

- 2019 ASME Section VIII Division 1 SynopsisDokument58 Seiten2019 ASME Section VIII Division 1 SynopsisCristian Xavier Avendaño BelloNoch keine Bewertungen

- Weld Cladding Overlay - Topics by ScienceDokument73 SeitenWeld Cladding Overlay - Topics by ScienceMichael TayactacNoch keine Bewertungen

- Tube Expander Design UsageDokument19 SeitenTube Expander Design UsageJaroslaw PoplawskiNoch keine Bewertungen

- ASME Pressure VesselsDokument41 SeitenASME Pressure VesselsJawed Akhter100% (1)

- GB 150.2-2010 固定式压力容器 第2部分:材料(征求意见稿)Dokument53 SeitenGB 150.2-2010 固定式压力容器 第2部分:材料(征求意见稿)Guan WilliamNoch keine Bewertungen

- ASTM A182 - Standard Specification For Forged or Rolled Alloy Steel Pipe Flanges, Forged Fittings and Valves and Parts For High Temperature ServiceDokument16 SeitenASTM A182 - Standard Specification For Forged or Rolled Alloy Steel Pipe Flanges, Forged Fittings and Valves and Parts For High Temperature ServiceKok WaiNoch keine Bewertungen

- Calculate Weld Metal VolumeDokument7 SeitenCalculate Weld Metal VolumeChris De La Torre0% (1)

- Welding of Duplex Stainless SteelDokument48 SeitenWelding of Duplex Stainless SteelГригорий МатвеевNoch keine Bewertungen

- ASTM F1545 Plastic Lined Pipe 0803 PDFDokument6 SeitenASTM F1545 Plastic Lined Pipe 0803 PDFdavi rodriguesNoch keine Bewertungen

- Threads - Metric ISO 724Dokument5 SeitenThreads - Metric ISO 724laleesamNoch keine Bewertungen

- ASME SA240 Stainless SteelDokument5 SeitenASME SA240 Stainless SteelAndaru MahayektiNoch keine Bewertungen

- Asme b16.20 StandardsDokument1 SeiteAsme b16.20 StandardsJakir HossainNoch keine Bewertungen

- Hydrualic Tube Expansion Vs Metallic Tube ExpansionDokument3 SeitenHydrualic Tube Expansion Vs Metallic Tube ExpansionNath BoyapatiNoch keine Bewertungen

- Api600 Valve Trim ChartDokument2 SeitenApi600 Valve Trim ChartBoankNoch keine Bewertungen

- Tema Online Study Notes PDFDokument10 SeitenTema Online Study Notes PDFumerhayatNoch keine Bewertungen

- BS 4504 Slip On Flanges PDFDokument7 SeitenBS 4504 Slip On Flanges PDFMaclean ArthurNoch keine Bewertungen

- ASME P NumbersDokument2 SeitenASME P NumbersArjun RawatNoch keine Bewertungen

- Ansi B16.5 Flange PDFDokument45 SeitenAnsi B16.5 Flange PDFeldaniel00067416Noch keine Bewertungen

- D10.4 R1986PVDokument7 SeitenD10.4 R1986PVGabriela AxinteNoch keine Bewertungen

- ASTM A262, CorrosietestenDokument2 SeitenASTM A262, CorrosietestenSales HBS Solutions100% (1)

- The ASME Impact Test RequirementDokument7 SeitenThe ASME Impact Test Requirementrosli2503Noch keine Bewertungen

- ASME Training and Development-Spring-Catalog PDFDokument100 SeitenASME Training and Development-Spring-Catalog PDFJiménez Chávez JaimeNoch keine Bewertungen

- Astm A 403 / A 403M - 06Dokument7 SeitenAstm A 403 / A 403M - 06negg 348100% (1)

- Gulf Fasteners & Metal Industries ProfileDokument4 SeitenGulf Fasteners & Metal Industries ProfiledprosenjitNoch keine Bewertungen

- Copiar de Nozzle - Design - ToolDokument2 SeitenCopiar de Nozzle - Design - ToollavascudoNoch keine Bewertungen

- Materials For Cryogenic Service - Engeering Properties of Aus - Decrypté PDFDokument50 SeitenMaterials For Cryogenic Service - Engeering Properties of Aus - Decrypté PDFGOUAREF SAMIRNoch keine Bewertungen

- Asme Section III Div 1 Nca Int Vol 60 - 2010Dokument36 SeitenAsme Section III Div 1 Nca Int Vol 60 - 2010Mario Andres Jimenez AnguloNoch keine Bewertungen

- The Science of Welding Metallurgy: A Brief Word On Filler MetalsDokument2 SeitenThe Science of Welding Metallurgy: A Brief Word On Filler MetalsSandro FerreiraNoch keine Bewertungen

- Asme Pressure Vessel Joint EfficiencyDokument4 SeitenAsme Pressure Vessel Joint EfficiencynasrpkNoch keine Bewertungen

- Seamless Carbon Steel Boiler Tubes For High-Pressure ServiceDokument2 SeitenSeamless Carbon Steel Boiler Tubes For High-Pressure ServiceChandra ClarkNoch keine Bewertungen

- Category of RadiographyDokument9 SeitenCategory of RadiographySAGARNoch keine Bewertungen

- SMAW Electrode IdentificationDokument2 SeitenSMAW Electrode IdentificationAsim AliNoch keine Bewertungen

- Pressure Vessel Dimension InspectionDokument2 SeitenPressure Vessel Dimension InspectionNorman MoralesNoch keine Bewertungen

- Work Instruction FOR: Tensile TestDokument4 SeitenWork Instruction FOR: Tensile TestmahendraNoch keine Bewertungen

- Asme-Bpvc Sec IV Int Vol 44Dokument7 SeitenAsme-Bpvc Sec IV Int Vol 44mostafa aliNoch keine Bewertungen

- Sa 194Dokument14 SeitenSa 194Raju SkNoch keine Bewertungen

- BSEN1092 16 DimensionsDokument2 SeitenBSEN1092 16 DimensionsalfonscarlNoch keine Bewertungen

- Koc Standard FOR Colour Coding of Pipes and Fittings For Material Identification Doc No: Koc-Mp-026Dokument14 SeitenKoc Standard FOR Colour Coding of Pipes and Fittings For Material Identification Doc No: Koc-Mp-026Praveen BabuNoch keine Bewertungen

- ASME IX - 2019 - Addenda - ChangesDokument7 SeitenASME IX - 2019 - Addenda - ChangeszaheerNoch keine Bewertungen

- Difference Between Wrought Fittings and Forged Fittings - Google GroupsDokument1 SeiteDifference Between Wrought Fittings and Forged Fittings - Google Groupsim4uim4uim4uNoch keine Bewertungen

- Thickness MAWP CalculationsDokument1 SeiteThickness MAWP Calculationsramananrv123Noch keine Bewertungen

- Metal Jacketed Gasket Instruction ManualDokument6 SeitenMetal Jacketed Gasket Instruction ManualCalvin WongNoch keine Bewertungen

- Ab 536 Requirements For The Integrity Management of Grade 91 Steel Used Above Currently Permitted Allowable StressesDokument17 SeitenAb 536 Requirements For The Integrity Management of Grade 91 Steel Used Above Currently Permitted Allowable StressesCarlos Maldonado SalazarNoch keine Bewertungen

- Crane Bronze ValveDokument62 SeitenCrane Bronze ValveAritz BilbaoNoch keine Bewertungen

- Joint Efficiency TutorialDokument47 SeitenJoint Efficiency TutorialJignesh ShahNoch keine Bewertungen

- ASME Code General ReviewDokument33 SeitenASME Code General Reviewaike_5Noch keine Bewertungen

- Impact Test RequirementDokument6 SeitenImpact Test RequirementmansurNoch keine Bewertungen

- Lab Report No 6 Bs PhysicsDokument6 SeitenLab Report No 6 Bs PhysicsITZ SUFYANNoch keine Bewertungen

- DPR TemplateDokument5 SeitenDPR TemplateSantoshkumar GurmeNoch keine Bewertungen

- 3D FEM Approach For Laterally Loaded Monopile DesignDokument8 Seiten3D FEM Approach For Laterally Loaded Monopile DesignSunil Ranjan MohapatraNoch keine Bewertungen

- Bellows Sealed Matering Valves BM Series (Ms-01-23) R3Dokument4 SeitenBellows Sealed Matering Valves BM Series (Ms-01-23) R3herysyam1980Noch keine Bewertungen

- Volvo (Dem) and Haldex: History, Function, Diagnosis and RepairsDokument6 SeitenVolvo (Dem) and Haldex: History, Function, Diagnosis and RepairsNecsaszNorbertNoch keine Bewertungen

- HWK 6Dokument2 SeitenHWK 6Pame GarciaNoch keine Bewertungen

- Suspension For Electrathon VehicleDokument55 SeitenSuspension For Electrathon VehicleJulius RojoNoch keine Bewertungen

- df100 InstructionDokument20 Seitendf100 InstructionFranco SNoch keine Bewertungen

- Access - Catalog.805b.Color - DP&Casing Tools-51Dokument1 SeiteAccess - Catalog.805b.Color - DP&Casing Tools-51RICHARDNoch keine Bewertungen

- Valves. Valves and Fittings Pressure Drop CoefficientsDokument270 SeitenValves. Valves and Fittings Pressure Drop CoefficientsJMV100% (1)

- Slapdriver Interference Screwdriver SystemDokument8 SeitenSlapdriver Interference Screwdriver SystemFreddy Churata SuriNoch keine Bewertungen

- Manufacturing Processes Ch.4 (10 and 11) CastingDokument143 SeitenManufacturing Processes Ch.4 (10 and 11) Castingashoku24007Noch keine Bewertungen

- Phase Changes Phase DiagramDokument24 SeitenPhase Changes Phase DiagramNicolette BingtanNoch keine Bewertungen

- Concrete PoolDokument2 SeitenConcrete Pooljorge010% (2)

- Interacción Suelo EstructuraDokument10 SeitenInteracción Suelo EstructuraDar FallNoch keine Bewertungen

- Parallel & Series OperationDokument5 SeitenParallel & Series OperationMayuresh MahajanNoch keine Bewertungen

- Repair Manual ZF 63 Iv - ZF 80 Iv - ZF 80-1 Iv - ZF 85 IV Code 310.01.0009hDokument110 SeitenRepair Manual ZF 63 Iv - ZF 80 Iv - ZF 80-1 Iv - ZF 85 IV Code 310.01.0009hEdwin Enrique OsorioNoch keine Bewertungen

- Mech Seal FundamentalsDokument117 SeitenMech Seal FundamentalsSri Sri100% (1)

- Suction Pile SpecDokument33 SeitenSuction Pile Specriaz16shaik100% (1)

- Get PTC Thermistor and Single Phasing Preventer Series PD 225 - GIC IndiaDokument3 SeitenGet PTC Thermistor and Single Phasing Preventer Series PD 225 - GIC IndiaPrasadPurohitNoch keine Bewertungen

- 02 110 BPS Foam Pump Skid With Foam Pump and RC ControllerDokument8 Seiten02 110 BPS Foam Pump Skid With Foam Pump and RC Controllerarachman297988Noch keine Bewertungen

- Conveyor BeltDokument31 SeitenConveyor BeltsmendozaNoch keine Bewertungen

- HMV 105-02 H2 42559 e 11.10 CDokument9 SeitenHMV 105-02 H2 42559 e 11.10 Cxxsh100% (2)

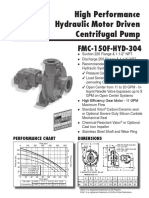

- FMC-150F-HYD-304 - 04-13 Bomba AceDokument2 SeitenFMC-150F-HYD-304 - 04-13 Bomba AceEmerson GomesNoch keine Bewertungen

- Flange TableDokument0 SeitenFlange TablemkstngrNoch keine Bewertungen

- Stair Well Pressurization Design CriteriaDokument2 SeitenStair Well Pressurization Design CriteriaShabeer HamzaNoch keine Bewertungen

- V Clic Workshop ManualDokument44 SeitenV Clic Workshop ManualWG-Friend IvybridgeNoch keine Bewertungen

- Computational Fluid Dynamics (CFD) Modeling of Grain-Water Suspensions in TubeDokument15 SeitenComputational Fluid Dynamics (CFD) Modeling of Grain-Water Suspensions in TubebhuniakanishkaNoch keine Bewertungen

- Farooqi Mohammed Yousuf Saudi Arabia 17.00 YrsDokument5 SeitenFarooqi Mohammed Yousuf Saudi Arabia 17.00 YrsKirkD'costaNoch keine Bewertungen

- Inertia and MassDokument4 SeitenInertia and MassTanNoch keine Bewertungen