Beruflich Dokumente

Kultur Dokumente

Co 2

Hochgeladen von

Ako Si Rhennapot0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

85 Ansichten5 Seitencarbon dioxide

Originaltitel

co2

Copyright

© © All Rights Reserved

Verfügbare Formate

ODT, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldencarbon dioxide

Copyright:

© All Rights Reserved

Verfügbare Formate

Als ODT, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

85 Ansichten5 SeitenCo 2

Hochgeladen von

Ako Si Rhennapotcarbon dioxide

Copyright:

© All Rights Reserved

Verfügbare Formate

Als ODT, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 5

CO2 Properties

Carbon Dioxide can exist in three states; Gas, Liquid & Solid.

Gaseous Carbon Dioxide

CO2 gas is heavier than air with a specific gravity of 1.53 at 70 dF

At normal tempatures and pressures, CO2 is colorless with a slighty pungent odor at high

concentrations. If compressed and cooled to proper tempatures the gas liquifies. Solid

CO2, dry ice sublimates back to the natural gaseous state.

Liquid Carbon Dioxide

Liquid CO2 is produced by compressing and cooling CO2 gas. This liquid is a clear

transparent fluid. Liquid CO2 cannot exsist as a liquid at atmospheric pressure. It must be

pressurized above 60.4 psi to remain as a liquid. At this pressure, Triple Point, CO2 can

exsist as liquid, gas and solid. Below this pressure it will flash to a gas and solid. CO2

above a temperature of 87.9 dF Critical Point cannot exsist as a liquid.

Normally liquid CO2 is delivered and maintaned at 0 dF and 300 psi.

Solid Carbon Dioxide

Solid CO2 is commonly refered to as Dry Ice. It is produced by allowing liquid CO2 to

expand to atmospheric pressure which forms dry ice snow. This snow is then compressed

to form blocks and pellets. Dry ice at atmospheric pressure is -109 dF.

Carbon Dioxide (CO2)

Characteristics:

Not poisonous but too high concentration in the air is unhealthy.

Doesnt support combustion / non - flammable.

Slightly pungent odor

Gas - colorless, solid - white.

Biting taste

USES:

- Widely used in beverage industry as soda water or carbonated water.

- Refrigerant, food preservation, blanketing gas freeing from oxidation in food industry

(e.g.Del Monte Corp.)

- For pressure spraying and aerosol packaging

- Neutralizing agent for pH control and in cement curing

- For the transfer of hazardous and flammable liquids

- As a diluent w/ nitrous oxide in the manufacture of whipped cream

- Inerting agent in fire extinguishers, in canned food products and for shielded arc welding

- Blanketing agent in fire extinguishers

- As shield in arc welding

- Used in chemical industry, such as in making salicylic acid

- In production of urea

- Pressurizing oil well for secondary oil recovery

- Specialty uses: chilling aluminum rivets and shrink-fitting machine parts

PROCESS DESCRIPTION

CO2 is recovered from Alcohol Plant where molasses, a by-product of sugar

manufacturing, is fermented to produced Ethyl Alcohol or Ethanol and Carbon dioxide gas

is liberated so that when brought down to negative temperature and applied with

extremely high pressure, it will liquefy. Thereby, ready for refilling; bulk tank or CO2

cylinder.

GAS COMPOSITION

Industrial Grade: Food Grade:

Carbon Dioxidec 99.9% 99.9%

Oxygen 0.02% max. 0.02% max.

Nitrogen 0.1% max. 0.1% max.

Hydrogen Sulfide 10 ppm, max. 10 ppm, max.

Sulfur Dioxide 2 ppm, max. 2 ppm, max.

Hydrocarbons Ni Nil

Moisture 100 ppm, max. 100 ppm, max.

MATERIAL COMPATIBILITY

Dry carbon dioxide is non- corrosive; hence common material is acceptable (e.g. steel,

iron, copper, brass, plastic)

Moist carbon dioxide is slightly corrosive; hence carbonic acid resistant materials should

be required for its cylinders.

CYLINDER INFORMATION:

Containers Sizes and Color Coding:

Type Content Color-Body Color-Collar

Bantam (34 L) 22 kg Gray Gray/Silver

Standard (42 L) 22 kg Gray Gray/Silver

Note: At normal temperature, CO2 cylinder pressure ranges from 1100 psig to 1150 psig.

SAFETY PRECAUTION

- Liquid CO2 equipment should be kept clean.

- Never let CO2 allow to come in contact with your skin, if so, wash the affected skin with

large quantity of unheated water, then apply cold compress. If skin has blisters & eyes

are afflicted, consult the doctor immediately. Goggles(face shield), gloves, & apron should

be worn. Clothing splashed with CO2 must be promptly removed and aired for at least 1

hr.

- Wear safety glasses, use leather/plastic protective gloves, wear overalls when handling

cylinders

- Use only approved pressure rated equipment

- Always use a regulator to connect to system

- Open cylinder valve slowly

- Close cylinder valve when not in use.

- Liquid carbon dioxide (CO2) should be handled or used only by persons instructed as to

the nature of the material.

- Metals used for liquid CO2 equipment must have satisfactory physical properties at the

low operating temperatures.

- In case where liquid CO2 may be trapped in any valve cavity, venting means should be

provided.

- All safety relief devices should be placed or protected so that water cannot collect or

freeze on them in any way, which would interfere with their proper operation.

- When pouring CO2 from one containing to another, the receiving container must be

cooled gradually to prevent thermal shock, avoid splashes.

- Individuals handling CO2 products must be informed of the safety precautions & the

hazard it may cause .

- Small containers of liquid CO2 must be covered when not in use to avoid moisture and

consequent plugging of the container outlet.

Das könnte Ihnen auch gefallen

- CO2 SafetyDokument90 SeitenCO2 Safetyblackywhite100% (1)

- Asco Dioxido de CarbonoDokument176 SeitenAsco Dioxido de CarbonoErnest Williams100% (1)

- ASCO Catalogue EnglishDokument172 SeitenASCO Catalogue EnglisharygtNoch keine Bewertungen

- COSH Carbon Dioxide PDFDokument7 SeitenCOSH Carbon Dioxide PDFmalisolangiNoch keine Bewertungen

- Phases of CO2 PDFDokument4 SeitenPhases of CO2 PDFMubin Ashraf SheikhNoch keine Bewertungen

- Phases of CO2Dokument4 SeitenPhases of CO2Abdullah FazilNoch keine Bewertungen

- Dryice Manufacturers - Solidco2Dokument3 SeitenDryice Manufacturers - Solidco2solidco2seo100% (1)

- Carbon Dioxide (CO2) Applications and Uses:: 2-Metals IndustryDokument15 SeitenCarbon Dioxide (CO2) Applications and Uses:: 2-Metals Industryahmed atwaNoch keine Bewertungen

- MT Mi Fakuma Datasheet Co2 View Tcm17-166128Dokument2 SeitenMT Mi Fakuma Datasheet Co2 View Tcm17-166128Tu DacNoch keine Bewertungen

- CPI - Industrial Gases (Chap.7)Dokument142 SeitenCPI - Industrial Gases (Chap.7)Ron PascualNoch keine Bewertungen

- Dry Ice PrsentationDokument8 SeitenDry Ice PrsentationManikandan SWMSNoch keine Bewertungen

- Dry Ice PDFDokument18 SeitenDry Ice PDFAli AtwaNoch keine Bewertungen

- Carbon Dioxide: CarbohydrateDokument14 SeitenCarbon Dioxide: CarbohydratePratik AgajNoch keine Bewertungen

- Igcse Biology 2016 PDFDokument92 SeitenIgcse Biology 2016 PDFNerea100% (1)

- Nitric AcidDokument28 SeitenNitric AcidAshkan AbbasiNoch keine Bewertungen

- Air and WaterDokument9 SeitenAir and WaterFrancis EssilfieNoch keine Bewertungen

- Sensorial Application - Presentation - Supercritical FluidDokument13 SeitenSensorial Application - Presentation - Supercritical FluidErkanNoch keine Bewertungen

- Natural Gas ProcessingDokument37 SeitenNatural Gas Processingyadav yadavNoch keine Bewertungen

- Chapter 7 Natural Gas Processing V1Dokument32 SeitenChapter 7 Natural Gas Processing V1LeeMayYanNoch keine Bewertungen

- Carbonated Drinks: Western WorldDokument11 SeitenCarbonated Drinks: Western WorldJanno GironellaNoch keine Bewertungen

- PPPPPPPPP: P P PP PDokument10 SeitenPPPPPPPPP: P P PP PMohammed HassanNoch keine Bewertungen

- Liquid SO2.1Dokument13 SeitenLiquid SO2.1Musyafa WiryantoNoch keine Bewertungen

- Chemical Process Industries: Industrial GasesDokument5 SeitenChemical Process Industries: Industrial GasesjantskieNoch keine Bewertungen

- Natural Gas ProcessingDokument35 SeitenNatural Gas ProcessingAleem AhmedNoch keine Bewertungen

- CO2 Recovery MHIDokument44 SeitenCO2 Recovery MHIAl HattanNoch keine Bewertungen

- Inert Gas: Sugar Grape Must Alcohol Carbonic Maceration Beaujolais Storage Nitrogen ArgonDokument1 SeiteInert Gas: Sugar Grape Must Alcohol Carbonic Maceration Beaujolais Storage Nitrogen ArgontinkuNoch keine Bewertungen

- Science ExperimentDokument9 SeitenScience ExperimentAnil KarnawatNoch keine Bewertungen

- Sodium CyanideDokument6 SeitenSodium CyanideDirceu ValadaresNoch keine Bewertungen

- AquaCritox-SC Whitepaper ENDokument20 SeitenAquaCritox-SC Whitepaper ENGerardo FigueroaNoch keine Bewertungen

- BUSE - CO2 Production - EnG SingleDokument4 SeitenBUSE - CO2 Production - EnG SingleLiviu BalabanNoch keine Bewertungen

- PETE 460 Natural Gas TechnologyDokument34 SeitenPETE 460 Natural Gas TechnologyatiyosdeNoch keine Bewertungen

- HPCO2 Engineering ManualDokument84 SeitenHPCO2 Engineering ManualRicky LimNoch keine Bewertungen

- DCDADokument23 SeitenDCDARushikesh Dhapse80% (5)

- Chapter 7 Natural Gas ProcessingDokument41 SeitenChapter 7 Natural Gas ProcessingJagathisswary SatthiNoch keine Bewertungen

- Production of Arbon DioxideDokument29 SeitenProduction of Arbon DioxideAhmed MajidNoch keine Bewertungen

- Manufacturing Carbon DioxideDokument21 SeitenManufacturing Carbon DioxideMichael Mthulisi NgwenyaNoch keine Bewertungen

- Fire Extinguishers: Presented By, Afiqah Safren BSC BiotechnologyDokument28 SeitenFire Extinguishers: Presented By, Afiqah Safren BSC BiotechnologyAfiqah SafrenNoch keine Bewertungen

- Carbon Dioxide: Name: Raajeshwari Basu Roll Number: 5 Class: VII-C (Day)Dokument8 SeitenCarbon Dioxide: Name: Raajeshwari Basu Roll Number: 5 Class: VII-C (Day)Raajeshwari BasuNoch keine Bewertungen

- Storage and Handling of NEODOL AlcoholsDokument7 SeitenStorage and Handling of NEODOL AlcoholsGonzalo Zoé VázquezNoch keine Bewertungen

- Subject: Gas Processing PresentationDokument20 SeitenSubject: Gas Processing PresentationUsama JahangirNoch keine Bewertungen

- Fire Suppression Without WaterDokument21 SeitenFire Suppression Without Waterpunk cmNoch keine Bewertungen

- Carbon Dioxide (CO) : A Versatile Processing Tool For The Food IndustryDokument4 SeitenCarbon Dioxide (CO) : A Versatile Processing Tool For The Food IndustryShaswat Shovan PandaNoch keine Bewertungen

- RefrigerantDokument25 SeitenRefrigerantShee JaNoch keine Bewertungen

- Gas Treating and ProcessingDokument3 SeitenGas Treating and ProcessingRoger AP100% (1)

- Chemistry Class 12 Project Solvay Processchem PRJ OakDokument5 SeitenChemistry Class 12 Project Solvay Processchem PRJ OakOwais KhanNoch keine Bewertungen

- What Is Soda Ash?: Flux For Silicate. Moreover, They Are AlsoDokument5 SeitenWhat Is Soda Ash?: Flux For Silicate. Moreover, They Are AlsoOwais KhanNoch keine Bewertungen

- What Is Soda Ash?: Flux For Silicate. Moreover, They Are AlsoDokument5 SeitenWhat Is Soda Ash?: Flux For Silicate. Moreover, They Are AlsoOwais KhanNoch keine Bewertungen

- Composition of Air: Radiator CapDokument2 SeitenComposition of Air: Radiator CapHermogenes L. Jr MejiaNoch keine Bewertungen

- Carbon Dioxide Food and BeverageDokument6 SeitenCarbon Dioxide Food and BeverageSHagull AHmadNoch keine Bewertungen

- CHAPTER 4 Jan 2022 Natural Gas 2Dokument67 SeitenCHAPTER 4 Jan 2022 Natural Gas 2Intan HoranNoch keine Bewertungen

- Presentations 15Dokument44 SeitenPresentations 15thirumalaiNoch keine Bewertungen

- Lecture 4 - Refrigeration Basics 4Dokument13 SeitenLecture 4 - Refrigeration Basics 4santiago ValleNoch keine Bewertungen

- Industrial Gases - PPTDokument48 SeitenIndustrial Gases - PPTParul Saxena100% (2)

- 11.4. Sulphuric AcidDokument14 Seiten11.4. Sulphuric AcidIsheba WarrenNoch keine Bewertungen

- RecoveryPlant DistilleryDokument2 SeitenRecoveryPlant DistilleryDimas Eko PrasetyoNoch keine Bewertungen

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsVon EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsBewertung: 5 von 5 Sternen5/5 (1)

- Recover Gold from Gold Plated Items, And Turn It Into 99.995% Pure GoldVon EverandRecover Gold from Gold Plated Items, And Turn It Into 99.995% Pure GoldNoch keine Bewertungen

- Godavari FlowDokument15 SeitenGodavari FlowKhaderbee ShaikNoch keine Bewertungen

- WPL Lamella Separator Technical DatasheetDokument1 SeiteWPL Lamella Separator Technical Datasheettallef001Noch keine Bewertungen

- Mechanical Properties of FluidsDokument3 SeitenMechanical Properties of FluidsSanal BusherNoch keine Bewertungen

- Env107 Lab Report-04: Water Quality Parameters Group-C Section-18Dokument6 SeitenEnv107 Lab Report-04: Water Quality Parameters Group-C Section-18Araby NevaNoch keine Bewertungen

- 02 ChE421 - Flash DistillationDokument4 Seiten02 ChE421 - Flash DistillationAllyana Marie Tiemsim0% (1)

- The Atmosphere: National Weather Service Shreveport WWW - Srh.noaa - Gov/shvDokument34 SeitenThe Atmosphere: National Weather Service Shreveport WWW - Srh.noaa - Gov/shvAnonymous a288X6H20Noch keine Bewertungen

- SATR-A-2009 Rev 2 - System Lay-Up Report (Certificate)Dokument2 SeitenSATR-A-2009 Rev 2 - System Lay-Up Report (Certificate)deepa narayan100% (1)

- Megasan Catalog enDokument108 SeitenMegasan Catalog enMhd Maher Al BairoutiNoch keine Bewertungen

- Mind Mapping (Autosaved)Dokument1 SeiteMind Mapping (Autosaved)Indri FitrianaNoch keine Bewertungen

- Ultrapac MSD Tropical 0050 1000 Heatless Adsorption DryerDokument5 SeitenUltrapac MSD Tropical 0050 1000 Heatless Adsorption DryerCheivid Enriquez AranoNoch keine Bewertungen

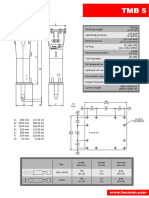

- Tecman TMB5 Web Spec V160921Dokument1 SeiteTecman TMB5 Web Spec V160921thomas.templierNoch keine Bewertungen

- Pulau Indah Power Plant SDN BHD: Data Sheet For Manual Simplex StrainerDokument4 SeitenPulau Indah Power Plant SDN BHD: Data Sheet For Manual Simplex StrainerJung Kyung WooNoch keine Bewertungen

- 1 Checklists Index (Dec 2006-Rev 2 - A SATIP)Dokument2 Seiten1 Checklists Index (Dec 2006-Rev 2 - A SATIP)احمد حسنNoch keine Bewertungen

- Assignment 01: Irrigation EngineeringDokument10 SeitenAssignment 01: Irrigation EngineeringMoudud Ul Islam AwanNoch keine Bewertungen

- Falling Sphere Viscometer - SohailDokument21 SeitenFalling Sphere Viscometer - SohailEngr Ghulam MustafaNoch keine Bewertungen

- Cylinder Manufacturers SymbolsDokument4 SeitenCylinder Manufacturers SymbolsmecambNoch keine Bewertungen

- 2.9 Laminar Flowmeters: R. Siev B. G. Lipták J. B. ArantDokument7 Seiten2.9 Laminar Flowmeters: R. Siev B. G. Lipták J. B. Arantabdulkidwai2009Noch keine Bewertungen

- Multi-Phase Flow Measurment by Orifice MeterDokument8 SeitenMulti-Phase Flow Measurment by Orifice MeterAbdeldjalil AchourNoch keine Bewertungen

- Compressible Flow 3. Flow Through Nozzles and DuctsDokument4 SeitenCompressible Flow 3. Flow Through Nozzles and DuctsRameez FaroukNoch keine Bewertungen

- Haldia Institute of Technology: Name: Sagar Kumar Class Roll No: 17/CHE/029 University Roll No: 10300617029Dokument7 SeitenHaldia Institute of Technology: Name: Sagar Kumar Class Roll No: 17/CHE/029 University Roll No: 10300617029Roshan Kumar LohaniNoch keine Bewertungen

- WATER 150-Water Treatment and Plant Operation I PDFDokument79 SeitenWATER 150-Water Treatment and Plant Operation I PDFzerocool86Noch keine Bewertungen

- Simple Distillation Lab ReportDokument3 SeitenSimple Distillation Lab ReportAparna Bhaskar50% (10)

- US-123218-06 MRB v1Dokument1.726 SeitenUS-123218-06 MRB v1sergioNoch keine Bewertungen

- Sources of WaterDokument16 SeitenSources of Waterfaruq_basriNoch keine Bewertungen

- Lecture31 STORM WATER MANAGEMENT PDFDokument38 SeitenLecture31 STORM WATER MANAGEMENT PDFHoney Grace TizonNoch keine Bewertungen

- Grade 4 WKST - Air, Water&WeatherDokument3 SeitenGrade 4 WKST - Air, Water&WeatherMOHAMMED ASIFALINoch keine Bewertungen

- P-X-Y Diagram For A Mixture of Benzene and Ethylbenzene at 90C As Given by Raoult's LawDokument16 SeitenP-X-Y Diagram For A Mixture of Benzene and Ethylbenzene at 90C As Given by Raoult's LawAhmed AliNoch keine Bewertungen

- ChemEngineering 02 00019 v2Dokument14 SeitenChemEngineering 02 00019 v2Amine HamaouiNoch keine Bewertungen

- Section 1: Theory of Heat Unit 3: Refrigeration and RefrigerantsDokument43 SeitenSection 1: Theory of Heat Unit 3: Refrigeration and Refrigerantslemuel ramirezNoch keine Bewertungen

- A Fixed Quantity of Gas at 21Dokument8 SeitenA Fixed Quantity of Gas at 21nonoytagupa3Noch keine Bewertungen