Beruflich Dokumente

Kultur Dokumente

Welding .... Print

Hochgeladen von

Ignite Tutorial0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

12 Ansichten4 Seitenwelding

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenwelding

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

12 Ansichten4 SeitenWelding .... Print

Hochgeladen von

Ignite Tutorialwelding

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 4

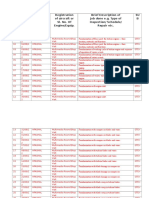

1.

Flux used in welding of Aluminum alloy serves the following purpose:

a)Improves the penetration b)Get rid of oxides c)Slows the flow of molten metal d)Better fusion

2.Soldering technique of aluminum alloy is:

a)Similar to that of other materials b)Different to control the expansion and contraction of metal

c)Low heat input is required d)Both b and c are correct

3.What is the purpose of flux in soldering

a)to remove metallic oxide b)to provide more penetration of solder for free flow solder c)all

4.Poor welding caused due to

a)excessive pressure b)misalignment of electrode c)both a & b d)excessive current

5.Fatigue crack detected by

a)Ultrasonic b)magnetic particle c)eddy current d)all of the above

6.In soldering over flow is avoided by

a)clay material surrounded all the weld area b) chill bars c) welding jigs d) all

7.Brazed welding is

a)called bronze welding b)base material does not fuse

c)it is special welding having between bracing and welding operation d) both a and b

8.Aluminium is welded by

a)oxidizing flame b)reducing c)neutral

10. Hose and a few projecting globules are found in a weld. What action should be taken

a. Re-weld the defective portions b. Remove all the old weld and re-weld the joint

c. Grind the rough surface smooth , inspect and re-weld all gaps / holes

d. Can be used in the same way

11. Which condition indicate a part has cooled too quickly after being welded

a. Cracking adjacent to the weld b. Discoloration of the base metal

c. Gas pockets and porosity d. Slag inclusion

12. Flux used for Commutator wires and electrical connections

a) Zinc chloride b) Zinc chloride by diluting with 50% alcohol

c) Alcoholic solution of rosin d) Rosin

13. Soft solder is the combination of tin and lead in proportion of

a) 2 : 3 b) 3 : 2 c) 1 : 4 d) 4 : 1

14. Which is most suitable for spot welding, in stainless steel?

a) Low-voltage b) High-amperage

c) Low-voltage and High-amperage d) High-voltage and Low-amperage

15. Fusibility of a metal refer to its property that permits

a) Welding b) Drawing into thin sheets

c) Drawing into wires d) Good thermal conductivity

16. Weld ability is poorest in case of

a) Plain carbon steel b) Low carbon steel c) High carbon steel d) Wrought iron

17. Soft solder is the combination of tin and lead in proportion of

a) 2 : 3 b) 3 : 2 c) 1 : 4 d) 4 : 1

18. Oxy acetylene welding process is suitable for joining metal sheets and plates having thickness of

a) 1 to 30mm b) 2 to 50 mm c) 2 to 40mm d) All of these

19. In oxyacetylene welding, welding rod is required as a filter metal when welding is carried out

above-- a) 15mm b) 10mm c) 40mm d) 5mm

20. In oxyacetylene welding, neutral flame produces a maximum temperature of

a) 30000F b) 32000F c) 32000C d) 30000C

21. Standard color for oxygen hose is

a) Black b) Red c) Green d) None of these

22. After welding aluminum parts flux should be removed by

a)Immersing them in Luke warm water for 30 minutes

b)Mechanical means, i.e. Wire brushing as the flux is not soluble in water

c)Washing the parts in boiling water containing 5% HNO3 d)Vacuum blasting

23. For spot welding, in stainless steel, which is most suitable

a)Low-voltage b)High-amperage

c)Low-voltage and High-amperage d)High-voltage and Low-amperage

24.Seam welding is

(a) Pressure welding (b) Non-pressure welding (c) Electric resistance (d) Both (a) & (c)

25.which type of welding, the electrode is non-consumable

(a) TIG (b) MIG (c) Electric resistance (d) Oxyacetylene

26.Spot welding electrodes should be

(a) Good conductor of Electricity (b) Good conductor of heat

(c) High strength & Hardness (d) Both (a) & (c)

27.In leftward welding

(a) Filler rod precedes torch (b) Torch precedes filler rod

(c) A 60 V is prepared at the end of plate (d) Both (a) & (c)

28.The color of acetylene cylinder and oxygen cylinder is

(a) Maroon & Black (b) Black & Maroon (c) Yellow & Black (d) Black & Yellow

29.The normal solder technique of Al is

a)similar to that of other material. b)differ to control the expansion and contraction of matter.

c)differ to the extent a low heat input is required. d)both (b) & (c) are correct.

30.Flux is used in wielding of Al alloy for

(a) better penetration (b) rid to oxidation

(c) for better fusion (d) slow down the flow of molten metal

31.Flux used in silver soldering is

(a) zinc chloride (b) ortho phosphoric acid (c) sulphuric acid (d) all are correct

32.In gas welding of oxygen and acetylene regulators has

a)left hand thread and right hand thread respectively.

b)right hand thread and left hand thread respectively.

c)both have left hand thread. d)both have right hand thread.

33.Spot welding electrode should be

(a) good conductor of electricity (b) good conductor of heat

(c) high strength & hardness (d) all of these

34. For spot welding, in stainless steel, which is most suitable

a)Low-voltage b) High-amperage

c)Low-voltage and High-amperage d)High-voltage and Low-amperage

35. Heat generated in spot welding is measured by

a)Resistance x (Current)2 x Time b)Resistance x Time / (Current)2

(c) (Current) / Resistance x Time

2

d)Resistance x Current

36.In given figure of welding is indicates:

a)V-weld b)U-weld c)Double beveled weld d)J-weld

37.Flux is used

a)Increase conduction of heat b)To reduce strength c)To prevent effect of oxidation

38.Aluminum is welded using

a)neutral or slightly carburizing b)oxidizing c)neutral

39.Which is difficult to solder

a) Aluminium and its alloy b) Mg and its alloy c) Steel and its alloy d) Nickel

40.In which type of soldering localized heating is used:

a) Resistance Brazing b) Induction brazing c) Furnace brazing

41.Aluminum is welded using:

a) Neutral & slightly carburizing b) Oxidizing c) Neutral d) Carburizing

42.Ultrasonic welding is used in:

a) Iron b) Cotin c) Aluminum d) Honeycomb

43.Welding of crack is considered as:

a) Butt joint b) Lap joint c) T joint

44.Mark the correct statement:

a) Spot welding is done by using 2 copper electrodes

b) Seam welding is done by using copper rollers c)(a) & (b) & seam welding is continuous used

45.silver brazing temperature is:

a)200C 400C b)350C 500C c) 1000C 1200C d)500C 800C

46.What is difference between aluminum oxide & iron oxide:

a) Iron oxide is porous b) Aluminum oxide is porous

c) Aluminum oxide is non-porous d) As in (c) & it prevent further corrosion, once formed

47.Electric arc welding:

a) Emits ultra violet rays b)Emits infrared rays at high current c) Poisonous gas d) All

48.In silver soldering, metal melts:

a)200-400 degree C b) 100-1500 degree C c) 600-850 degree C d) none

49.When welding a high carbon steel used:

a) Low carbon rod b) High carbon rod

c) Rod of either low or high carbon content d) Rod of intermediate carbon content

50.Choose the correct statement:

a) Oxy-acetylene flame have more heat energy than oxy-hydrogen flame

b) Oxy-hydrogen flame have more heat energy than oxy-acetylene flame

c) Both have same heat energy

51.Interrupt flux will cause for:

a) Corrosion b) Weak weld c) Lack of penetration d) Porosity

52.Acetylene gas is

a)colorless

b) as in a and if stored above 25 psi it becomes highly unstable

c) as in b and produced by reaction of calcium carbide with water

d) as in a and produces a yellow colored flame and smoky flame

53.Aircraft structural CRS is welded by

a)butt welding b)spot welding & sea welding c) butt and spot welding d) spot welding

54.Repair of the crack in the weld is done by

a) butt weld b) edge joint c) lap joint d) rosette weld

55.In oxy-acetylene welding to extinguish the flame:

a) First close O2 then acetylene b) First close acetylene than O2

c) Close both at a time d) None

56.Pressure of gas on acetylene welding is depend upon

a)area of welding surface b) type of material being welded

c) as the welder will want d) none

57.After welding of butt joint:

a) Heat treatment is required as cold working to be done

b) Heat treatment is not necessary as no cold working is to be performed

c) With torch heat, heating the welded area only slightly d) It is not necessary

58.Where high temperature is used for brazing:

a) For high power solder b) Special type of flux is used

c) Not used for brazing d) None

59.After welding part must be:

a) Hardened b) Normalized c) Annealed d) Tempered

60. For most metals, which oxy-acetylene flame is used

a) neutral flame b) oxidizing flame c) carburizing flame d) none

61.In welding Al-alloy the flux used is:

a) potassium chloride b)potassium fluoride c)potassium bisulphate d)all are incorrect

62.In welding the welded parts are heat treated:

a) to provide greater strength in welded region b)to relieve the stress set up during welding

c) to make soften the welded parts d) all are incorrect

63.In overlap weld joint:

a) flux used between the two parts b) flux is used on upper parts

c) flux is used on the inner parts d) all are incorrect (not exactly, but like that)

64.In welding copper and brass the flame is used:

a) slightly carbonized b) neutral flame used

c) oxidized flame used d) both (a) and (b) are correct

65.In soldering the flux is used: a) to remove and prevent oxidation the metal

b) allowing the solder to flow evenly. c) both (a) & (b) are correct

d) (a) & (b) are correct and to unit more firmly with the surface to be joined

66. The weld is B (Double beveled T-joint)

a) V butt weld b) U butt weld c) Beveled butt weld d) T butt weld

67. Which is preferred in a/c

a) TIG welding b) MIG welding c) both

68.On a fillet weld the penetration requirements an

a) 60 to 80% of the thickness of the base metal b)100% of the thickness of the base metal

c) 200% of the thickness of the base metal d)25 to 50% of the thickness of the base metal

69.The defect in wheel hub is inspected by

a) Dye penetrant process b) Magnetic particle inspection

c) Eddy current testing d) Ultrasonic testing

70.To prevent solder from running away from the surface to be jointed

a) flux is used b) temperature is maintained

c) clay is commonly used to surround the area to be jointed d) all

71.Braze welding is

a)known as force welding (bronze welding) b) a welding in which base metal is not fuse

c) a combination of brazing and welding d) all

72.Which statement is correct

a) low temperature brazing is also known as hard soldering or silver soldering

b) silver welding has equal strength of material

c) after silver soldering, further heat treatment is required d) both a & b

73. Electrical resistance welding is a process in which

a) low voltage , high amperage current used b) low current , high voltage used

c) as in a) metals to be welded through a heavy, low resistance cu conductor

d) as in b) metals to be welded through a heavy, low resistance cu conductor

74.MTCS

a) Welding rods are manufactured in standard 36-in. lengths and in diameters from 3/8 in. to

1/16 in.

b) If the rod is too large, it will not conduct heat away from the puddle rapidly enough, and a

burned weld will result. c) A rod that is too small will chill the puddle. d) all are wrong

75. Forehand welding is the technique of

a) pointing the torch flame forward in the direction in which the weld is progressing.

b) pointing the torch flame backward in the direction in which the weld is progressing.

c) as in a) method is used in welding most of the lighter tubing and sheet metals.

d) as in b) method is used in welding most of the lighter tubing and sheet metals.

76. Backhand welding is the technique of

a) pointing the torch flame toward the finished weld

b)as in a) & moving away in the direction of the un welded area melting the edges of the

joint as it is moved. c)as in b) & seldom used on sheet metal.

d) As in c) & preferred for metals having a thin cross section.

77. A plain butt joint is used for metals-

a) from 1/16 in. to 1/8 in. in thickness. b) from 1/8 in. to 1/16 in. in thickness.

c)as in a) A filler rod is used when making this joint to obtain a strong weld.

d) as in b) A filler rod is used when making this joint to obtain a strong weld.

78. Expansion and contraction can be controlled by.

a) preheating method b) chill bars method c)welding jigs & tack welding methods d) all

79. MTWS regarding characteristics of good weld are

a) The weld should be built up, thus providing extra thickness at the joint.

b) The weld should taper off smoothly into the base metal.

c) No oxide should be formed on the base metal close to the weld.

d) The base metal should show signs of burns, pits, cracks, or distortion.

80. Soft soldering is used for

a) copper, brass, and coated iron in combination with mechanical seams

b) as in a) & used where a leak proof joint is desired.

c) as in c) & alloys of tin and lead & melting points, ranging from 293 to 592 c

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Ame PDFDokument1 SeiteAme PDFIgnite TutorialNoch keine Bewertungen

- Card FrontDokument1 SeiteCard FrontIgnite TutorialNoch keine Bewertungen

- Card BackDokument1 SeiteCard BackIgnite TutorialNoch keine Bewertungen

- Logo VDokument1 SeiteLogo VIgnite TutorialNoch keine Bewertungen

- Letter PadDokument1 SeiteLetter PadIgnite TutorialNoch keine Bewertungen

- Basic Grammar Rules PDFDokument3 SeitenBasic Grammar Rules PDFsakiaslamNoch keine Bewertungen

- Sem 3rd Gte-I 2012 m2Dokument4 SeitenSem 3rd Gte-I 2012 m2Ignite TutorialNoch keine Bewertungen

- True vs. Apparent PowerDokument9 SeitenTrue vs. Apparent PowerAnonymous 9feJpOwNoch keine Bewertungen

- HAL - Pravara Aviation Inst Itute: WeldingDokument3 SeitenHAL - Pravara Aviation Inst Itute: WeldingIgnite TutorialNoch keine Bewertungen

- Science 9 NotesDokument4 SeitenScience 9 NotesIgnite TutorialNoch keine Bewertungen

- Power Factor CalculationDokument13 SeitenPower Factor CalculationkingslyNoch keine Bewertungen

- Manual5 HowToRunYourSchoolDokument59 SeitenManual5 HowToRunYourSchoolIgnite TutorialNoch keine Bewertungen

- Paper 2 June 2013 PDFDokument5 SeitenPaper 2 June 2013 PDFIgnite TutorialNoch keine Bewertungen

- WWW - Dgcaquestionpapers.In - (Paper 2 June 2014) : Download Our Mobile App From Play Store @dgca Question PapersDokument3 SeitenWWW - Dgcaquestionpapers.In - (Paper 2 June 2014) : Download Our Mobile App From Play Store @dgca Question PapersIgnite TutorialNoch keine Bewertungen

- AbbreviationsDokument14 SeitenAbbreviationsIgnite TutorialNoch keine Bewertungen

- Dgca Paper II Feb 2016Dokument8 SeitenDgca Paper II Feb 2016KetanRaoNoch keine Bewertungen

- Paper 2 June 2013Dokument5 SeitenPaper 2 June 2013Ignite TutorialNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Module 8 Welding Metallurgy For The WIDokument39 SeitenModule 8 Welding Metallurgy For The WIMiki Jaksic100% (1)

- CO2 Spec Rev FinalDokument12 SeitenCO2 Spec Rev FinalAti ANoch keine Bewertungen

- Vinoth CVDokument5 SeitenVinoth CVNikhatRizaviNoch keine Bewertungen

- Determining The Cost of WeldingDokument19 SeitenDetermining The Cost of WeldingkapurrrnNoch keine Bewertungen

- ASFP TGD 16 - Code of Practice For Off-Site Applied Thin Film Intumescent CoatingsDokument50 SeitenASFP TGD 16 - Code of Practice For Off-Site Applied Thin Film Intumescent CoatingsAnselmo Ribeiro100% (4)

- Lincoln Electric ChinaDokument59 SeitenLincoln Electric ChinaKhurshid Marwat0% (1)

- Complete Roofing CatalogueDokument24 SeitenComplete Roofing CatalogueJuan MansillaNoch keine Bewertungen

- PDF Applicationtechnique Hdpe 1 PDFDokument43 SeitenPDF Applicationtechnique Hdpe 1 PDFCristian DumitruNoch keine Bewertungen

- TWM - Total Welding Management - Barckhoff 2005Dokument197 SeitenTWM - Total Welding Management - Barckhoff 2005lazaroccs100% (5)

- ASTM A500 Covers Carbon Steel Cold Formed Welded and Seamless Structural TubeDokument6 SeitenASTM A500 Covers Carbon Steel Cold Formed Welded and Seamless Structural TubeZahoor AhmedNoch keine Bewertungen

- Welding, Solved Problems PDFDokument2 SeitenWelding, Solved Problems PDFEzekielNoch keine Bewertungen

- WPS-46 - Gtaw & Smaw Tig + SmawDokument8 SeitenWPS-46 - Gtaw & Smaw Tig + SmawAvinash ShrivastavaNoch keine Bewertungen

- SHS-WWW Polsteel Co - Uk-Nr-Str PDFDokument5 SeitenSHS-WWW Polsteel Co - Uk-Nr-Str PDFMuhammad ArslanNoch keine Bewertungen

- Pressure Vessel Series Pressure Vessel Series: ASME VIII Division 1 & 2 ASME VIII Division 1 & 2Dokument6 SeitenPressure Vessel Series Pressure Vessel Series: ASME VIII Division 1 & 2 ASME VIII Division 1 & 2process processNoch keine Bewertungen

- AMTEC Threaded Inserts PDFDokument36 SeitenAMTEC Threaded Inserts PDFdlstoneNoch keine Bewertungen

- PDF Chapter 1 MEC 218 Welding Overview Student ResourceDokument9 SeitenPDF Chapter 1 MEC 218 Welding Overview Student ResourceShamsudeen Abubakar SodangiNoch keine Bewertungen

- Las SMAW DCSP Dan DCRPDokument4 SeitenLas SMAW DCSP Dan DCRPYoga PranataNoch keine Bewertungen

- Service Manual BW161Dokument1.174 SeitenService Manual BW161Danila1991Noch keine Bewertungen

- 3.HDPE Pipes CatalogueDokument30 Seiten3.HDPE Pipes CatalogueZain ZulfiqarNoch keine Bewertungen

- 09 Samss 091Dokument30 Seiten09 Samss 091Aravind BabuNoch keine Bewertungen

- 7100 XXXX HDPEDokument2 Seiten7100 XXXX HDPEIgor IvanovskiNoch keine Bewertungen

- International Standard: Specification and Qualification of Welding Procedures For Metallic Materials - General RulesDokument8 SeitenInternational Standard: Specification and Qualification of Welding Procedures For Metallic Materials - General RulesRudi DaNoch keine Bewertungen

- US Army - Engineer Diving Operations FM 5-490Dokument38 SeitenUS Army - Engineer Diving Operations FM 5-490Jared A. Lang100% (3)

- Asnt Level Iii Basic Review:: Materials and Processes For NDT TechnologyDokument215 SeitenAsnt Level Iii Basic Review:: Materials and Processes For NDT TechnologyTapan Kumar Nayak100% (7)

- Garbage Sorting Machine BrochureDokument21 SeitenGarbage Sorting Machine BrochureJohnNoch keine Bewertungen

- PAUT - Full Notes PDFDokument118 SeitenPAUT - Full Notes PDFRamesh mudunuri100% (5)

- ANSI-NEMA GR1-2007 - FinalDokument27 SeitenANSI-NEMA GR1-2007 - FinalJunior AvalosNoch keine Bewertungen

- R160LC 7 PDFDokument500 SeitenR160LC 7 PDFГригорий ГригорянNoch keine Bewertungen

- Frischdampfeinstroemleitungen Aus Dem Werkstoff 14MoV63 - enDokument23 SeitenFrischdampfeinstroemleitungen Aus Dem Werkstoff 14MoV63 - enilham_metallurgy6744Noch keine Bewertungen

- 304 Grade SteelDokument6 Seiten304 Grade SteelShashank SaxenaNoch keine Bewertungen