Beruflich Dokumente

Kultur Dokumente

Asco 551H417 PDF

Hochgeladen von

tree_99Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Asco 551H417 PDF

Hochgeladen von

tree_99Copyright:

Verfügbare Formate

SOLENOID VALVES 5/2

4 2 4 2

14 12 14 12

5 3 5 3

pilot operated, spool type 14

4

1

2

12

14

4

1

2

12

5/3

single/dual solenoid (mono/bistable function) 5

1

3 5

1

3

Series

aluminium body, 1/4 to 1/2 551-552-553

FEATURES

The monostable spool valves, series 551, have TV certified IEC 61508 Functional

Safety data and can be used up to SIL 4/AK 7

The spool valves 3/2 NC have threaded port connections

All the exhaust ports of this spool valve are connectable, providing better environmental

protection, particularly recommended for sensitive areas such as clean rooms, and

applications in the pharmaceutical and food processing sectors

The valve offers environmental protection against the ingress of liquids, dusts or any

other foreign matter (environmentally-protected construction)

Can be externally piloted (external air pilot supply) to convert valve to zero minimum

operation by flipping a gasket

The solenoid valves satisfy all relevant EC Directives

GENERAL

Differential pressure 2 - 10 bar [1 bar = 100 kPa]

Flow (Qv at 6 bar) 1/4 = 860 l/min (5/2) ; 760l/min (5/3) (ANR)

3/8 = 3000 l/min (5/2, 5/3)

1/2 = 3800 l/min (5/2, 5/3)

fluids ( ) temperature range (TS) seal materials ( )

air, inert gas, filtered - 25C to + 60C NBR (nitrile) + PUR (polyurethane)

MATERIALS IN CONTACT WITH FLUID

( ) Ensure that the compatibility of the fluids in contact with the materials is verified

Body Aluminium, black anodized 5/2 function, monostable

End cover (spring) Glass-filled PA

Spool valve internal parts Zamak, stainless steel, (POM), aluminium

Pilot internal parts Refer to specific solenoid catalogue pages

Pilot end covers Aluminium

Core tube Stainless steel 4 2

Core and plugnut Stainless steel

Core spring Stainless steel

Seals NBR 5 1 3

Top disc PA

Disc holder POM 5/3 function

Cartridge (low power) Welded, packless AISI 430

Seat Brass BP

Seat insert POM RP-MP

Shading coil Copper

Rider rings (low power) PTFE LP

UP

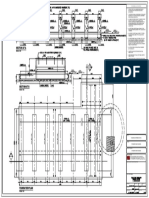

For Control Valve Tag No 154-PV-380 Not

available 0,4W - 1,9W

Not

available 10,5W - 11,2W

Ultra Low Low Reduced and Basic

power power Medium power power

POWER LEVELS - cold electrical holding values (watt)

SPECIFICATIONS

operating pressure

flow prefix optional solenoids

pipe orifice differential (bar) power basic

coefficient

size size max. (PS) level NEMA ATEX/CENELEC (gas/dust) catalogue

kv IP65

min.(3) air ( ) 7 & 9 EEx d EEx em EEx m EEx i EEx nA number

( ) (mm) (m3/h) (l/min) ~ = ~/= EF NF NK EM PV IS ZN SC

5/2 - Solenoid air pilot operated - spring return (monostable)

1/4 6 0,75 12,5 0/2 10 10 BP - - 551B417 (2)

1/4 6 0,75 12,5 0/2 10 10 BP - - - - - - - 551H417 (2)

1/4 6 0,75 12,5 0/2 10 10 LP - - 551B317

1/4 6 0,75 12,5 0/2 10 10 LP - - - - - - - 551H317

3/8 12 2,49 41,5 0/2 10 10 BP - - 552A417

3/8 12 2,49 41,5 0/2 10 10 BP - - - - - - - 552G417

3/8 12 2,49 41,5 0/2 10 10 LP - - 552A317

3/8 12 2,49 41,5 0/2 10 10 LP - - - - - - - 552G317

1/2 13 3,15 52,5 0/2 10 10 BP - - 553A417

1/2 13 3,15 52,5 0/2 10 10 BP - - - - - - - 553G417

1/2 13 3,15 52,5 0/2 10 10 LP - - 553A317

1/2 13 3,15 52,5 0/2 10 10 LP - - - - - - - 553G317

Select 8 for NPT ANSI 1.20.3 or select G for ISO G (228/1) Available feature Available feature in DC only - Not available

2007/R01

(2) Certified IEC 61508 Functional Safety data, use suffix "SL".

(3) Zero minimum is only achieved if external pressure is applied.

All leaflets are available on: www.asco-process-scope.com

5-30-7

SERIES 551-552-553

SPECIFICATIONS

operating pressure

flow prefix optional solenoids

pipe orifice differential (bar) power basic

coefficient

size size max. (PS) level NEMA ATEX/CENELEC (gas/dust) catalogue

kv IP65

min.(3) air ( ) 7 & 9 EEx d EEx em EEx m EEx i EEx nA number

( ) (mm) (m3/h) (l/min) ~ = ~/= EF NF NK EM PV IS ZN SC

5/2 - Solenoid air pilot operated and return (bistable)

1/4 6 0,75 12,5 0/2 10 10 BP - - 551B418

1/4 6 0,75 12,5 0/2 10 10 BP - - - - - - - 551H418

1/4 6 0,75 12,5 0/2 10 10 LP - - 551B318

1/4 6 0,75 12,5 0/2 10 10 LP - - - - - - - 551H318

3/8 12 2,49 41,5 0/2 10 10 BP - - 552A418

3/8 12 2,49 41,5 0/2 10 10 BP - - - - - - - 552G418

3/8 12 2,49 41,5 0/2 10 10 LP - - 552A318

3/8 12 2,49 41,5 0/2 10 10 LP - - - - - - - 552G318

1/2 13 3,15 52,5 0/2 10 10 BP - - 553A418

1/2 13 3,15 52,5 0/2 10 10 BP - - - - - - - 553G418

1/2 13 3,15 52,5 0/2 10 10 LP - - 553A318

1/2 13 3,15 52,5 0/2 10 10 LP - - - - - - - 553G318

5/3 - W1 - pressure held, solenoid air pilot operated and return

1/4 6 0,66 11 0/2 10 10 BP - - 551B467

1/4 6 0,66 11 0/2 10 10 BP - - - - - - - 551H467

1/4 6 0,66 11 0/2 10 10 LP - - 551B367

1/4 6 0,66 11 0/2 10 10 LP - - - - - - - 551H367

3/8 12 2,49 41,5 0/2 10 10 BP - - 552A467

3/8 12 2,49 41,5 0/2 10 10 BP - - - - - - - 552G467

3/8 12 2,49 41,5 0/2 10 10 LP - - 552A367

3/8 12 2,49 41,5 0/2 10 10 LP - - - - - - - 552G367

1/2 13 3,15 52,5 0/2 10 10 BP - - 553A467

1/2 13 3,15 52,5 0/2 10 10 BP - - - - - - - 553G467

1/2 13 3,15 52,5 0/2 10 10 LP - - 553A367

1/2 13 3,15 52,5 0/2 10 10 LP - - - - - - - 553G367

5/3 - W3 - pressure release, solenoid air pilot operated and return

1/4 6 0,66 11 0/2 10 10 BP - - 551B468

1/4 6 0,66 11 0/2 10 10 BP - - - - - - - 551H468

1/4 6 0,66 11 0/2 10 10 LP - - 551B368

1/4 6 0,66 11 0/2 10 10 LP - - - - - - - 551H368

3/8 12 2,49 41,5 0/2 10 10 BP - - 552A468

3/8 12 2,49 41,5 0/2 10 10 BP - - - - - - - 552G468

3/8 12 2,49 41,5 0/2 10 10 LP - - 552A368

3/8 12 2,49 41,5 0/2 10 10 LP - - - - - - - 552G368

1/2 13 3,15 52,5 0/2 10 10 BP - - 553A468

1/2 13 3,15 52,5 0/2 10 10 BP - - - - - - - 553G468

1/2 13 3,15 52,5 0/2 10 10 LP - - 553A368

1/2 13 3,15 52,5 0/2 10 10 LP - - - - - - - 553G368

Select 8 for NPT ANSI 1.20.3 or select G for ISO G (228/1) Available feature Available feature in DC only - Not available

(3) Zero minimum is only achieved if external pressure is applied.

2007/R01

All leaflets are available on: www.asco-process-scope.com

5-30-8

SERIES 551-552-553

PREFIX TABLE PRODUCT SELECTION GUIDE

prefix power level STEP 1

description Select the fluid temperature range and

1 2 3 4 5 6 7 LP RP MP BP

S C D U Dustproof ATEX (EN 50281-1-1)* - - - seal material from the general table on

E F Explosionproof - NEMA 3, 4, 6, 7, 9 - - page 7. Select basic catalogue number,

E M Encapsulated ATEX (EN 50019 & EN 50028)* - - including pipe thread identification let-

E T Threaded conduit/hole (M20 x 1.5) - - ter. Refer to the specifications tables on

I S S C Intrinsically safe with SC coil ATEX (EN 50020)* - - - pages 7 and 8.

N F Flameproof - Alum. ATEX (EN 50018)* - - Example : G552A417

N L Flameproof - Cast Iron ATEX (EN 50018)* - -

N K Flameproof - Alum. ATEX (EN 50018) * - - - STEP 2

- - Select prefix (combination). Select the

P V Encapsulated ATEX (EN 50028)*

- - appropriate operator from the specifica-

S C Solenoid with spade plug connector (EN 60730)

- - tions table on page 7 and the prefix table

W P Waterproof IP67 - Metal enclosure (EN 60730)

- - - on page 8. Select for this operator in the

W P D U Dustproof ATEX (EN 50281-1-1) - Metal enclosure* electrical characteristics table on page

W P I S I.S. with Metal IP67 enclosure ATEX (EN 50020)* - - -

10: the power level (LP, BP), the type of

W P Z N N.S. metal enclosure ATEX (EN 50021)* - -

- - electrical enclosure protection and the

W S Waterproof IP67 - 316 SS enclosure desired temperature class.

W S D U Dustproof ATEX (EN 50281-1-1) - 316 SS enclosure* - - -

- -

Warning: The ambient temperature

W S E M 316 SS "EM" enclosure ATEX (EN 50019, EN 50020)* range of your application may not

W S N F Flameproof - Stainless steel 316 ATEX (EN 50018) * - -

exceed the temperature range of your

W S Z N N.S. 316 SS enclosure ATEX (EN 50021)* - - operator.

Z N Encapsulated Non Sparking ATEX (EN 50021)* - -

Example : EM

T Threaded conduit (1/2" NPT) - -

H T Class H - High temperature - - - STEP 3

M F Low temperature -40C (series 551) - - Select suffix (combination) if required.

X Other special constructions - - Example : MO

SUFFIX TABLE STEP 4

suffix power level Select voltage. Refer to standard volt-

description ages on page 10.

1 2 3 4 5 LP RP MP BP

M O Push type or screw type manual operator - - Example : 230V / 50Hz

S L Certified IEC 61508 Functional Safety data (1) - -

STEP 5

* ATEX solenoids are also approved to EN 50281-1-1 (dust)

and EN 13463-1 (non electrical valves) Final catalogue / ordering number.

Available feature Example :

Available feature in DC only EM G552A417MO 230 V / 50 Hz

- Not available

(1) Not to use with MO suffix

OPTIONS & ACCESSORIES ORDERING EXAMPLES:

exhaust protector SC G 551 B 417 230V / 50 Hz

pipe (stainless steel) SC G 551 B 417 SL 230V / 50 Hz

series

size SC G 551 B 418 MO 230V / 50 Hz

(G) (NPT) -

SCHT 8 551 B 418 MO 230V / 50 Hz

551/552/553 1/8 34600418 (2) 34600482 (2) - ISSC G 553 A 318 MO 24V / DC

551 1/4 34600419 (2) 34600483 (2) - WPIS 8 552 A 317 24V / DC

552 3/8 34600478 34600480 - EM 8 552 A 418 MO 230V / 50 Hz

553 1/2 34600479 34600481 - EF G 551 H 417 MO 240V / 60 Hz

(2) Provided with "SL" suffix. prefix (3)

pipe thread voltage

basic number (3) suffix

2007/R01

(3) Prefix EF should always be used with the letter H in the basic number.

All leaflets are available on: www.asco-process-scope.com

5-30-9

SERIES 551-552-553

EXPLANATION OF TEMPERATURE RANGES OF SOLENOID VALVES

Valve temperature range The valve temperature range is determined by the selected seal material, the temperature range

for proper operation of the valve and sometimes by the fluid (e.g. steam)

Operator ambient temperature The operator ambient temperature range is determined by the selected power level (LP, RP, MP or

range BP) and the ATEX safety code

Total temperature range The temperature range of the complete solenoid valve is determined by the limitations of both

temperature ranges above

ELECTRICAL CHARACTERISTICS

Coil insulation class F

Electrical safety IEC 335

Standard voltages DC (=) 24V - 48V

AC (~) 24V - 48V - 115V - 230V/50Hz; other voltages and 60Hz are available on request

power ratings operator electrical

hot/ ambient replacement coil

prefix inrush holding temperature enclosure

cold safety code type (2)

option ~ ~ = range (TS) protection ~ =

(VA) (VA) (W) (W) (C) (EN 60529) 230 V / 50 Hz 24 V DC

Basic power = BP

SC 55 23 10,5 9/11,2 -40 to +75 EN 60730 moulded IP65 400-425-117 400-425-142 01

SCDU 55 23 10,5 9/11,2 -40 to +75 II 3D IP65 T 135C(~)/T 200C(=) moulded IP65 - (4) - (4) 01

WP/WS 55 23 10,5 9/11,2 -40 to +75 EN 60730 steel IP67 400-405-117 400-405-142 04

WPDU/WSDU 55 23 10,5 9/11,2 -40 to +75 II 3D IP67 T 200C steel IP67 - (4) - (4) 04

(WS)NF/NL 55 23 10,5 - [-60](1) -40 to +25/40/60 II 2G/D EEx d IIC T6/T5/T4 alu./SS/steel IP67 400-405-117 - 02

(WS)NF/NL - - - 9/11,2 [-60](1) -40 to +40/60/75 II 2G/D EEx d IIC T6/T5/T4 alu./SS/steel IP67 - 400-405-142 02

NK 55 23 10,5 9/11,2 -40 to +50/60 II 2G/D EEx d IIB+H2 T4(~/=) aluminium IP65 400-405-117 400-405-142 03

EM/WSEM 55 23 10,5 9/11,2 -40 to +40 II 2G/D EEx em II T3 steel IP67 400-909-117 400-913-142 04

PV 55 23 10,5 9/11,2 -40 to +65 II 2G/D EEx m II T3(~)/T4(=) moulded IP65 - (4) - (4) 05

EF 55 23 10,5 9/11,2 -40 to +54/40 NEMA types 7 and 9 NEMA 4X 238-610-058 238-710-006 06

ZN 55 23 10,5 9/11,2 -20 to +50 II 3G/D EEx nA II T3 moulded IP65 - (4) - (4) 01

WP(WS)ZN 55 23 10,5 9/11,2 -40 to +50/60 II 3G/D EEx nA II T3(~)/T4(=) steel/SS IP67 - (4) - (4) 04

Low power = LP

SC 1,5 1,5 1,5 1,7/1,7 -40 to +60 EN 60730 moulded IP65 400-925-097 400-925-042 07

WP/WS 1,5 1,5 1,5 1,7/1,7 -40 to +60 EN 60730 steel IP67 400-926-097 400-926-042 09

(WS)NF/NL - - 1,9 - /1,8 [-60](1) -40 to +75/80 II 2G/D EEx d IIC T6/T5 alu./SS/steel IP67 - (4) - (4) 08

EM/WSEM 1,5 1,5 1,5 1,7/1,7 -40 to +40/55 II 2G/D EEx em II T6/T5 steel IP67 - (4) - (4) 09

PV - - - 1,7/1,7 -40 to +60 II 2G/D EEx m II T6 moulded IP65 - - (4) 10

EF - - - 1,7/1,7 -40 to +40 NEMA types 7 and 9 NEMA 4X - - (4) 11

ISSC (3) - - - 0,4/04 -40 to +60 II 2G/D EEx ia IIC T6 moulded IP65 - 268-976-001 12

WPIS (3) - - - 0,4/04 -40 to +60 II 2G/D EEx ia IIC T6 steel IP67 - 268-900-001 09

ZN - - - 1,7/1,7 -20 to +50 II 3G/D EEx nA II T3 moulded IP65 - - (4) 07

WP(WS)ZN 1,5 1,5 1,5 1,7/1,7 -40 to +60 II 3G/D EEx nA II T6 steel/SS IP67 - (4) - (4) 09

safety parameters (1) The certified minimum temperature of this operator

prefix (2) Refer to the dimensional drawings on pages 11 to 14 .

UI = (DC) II PI LI CI

option (3) Intrinsically safe pilots: Check the electrical characteristics in the corresponding catalogue pages

(V) (mA) (W) (F) (mF) (ISSC/WPIS operators).

Low power = LP (4) Multiple coil kits available under ATEX, contact us

ISSC 32 500 1,5 0 0 - Not available

WPIS 32 500 1,5 0 0

ELECTRICAL CONNECTIONS

prefix connection

SC, SCDU, ZN Spade plug connector with cable gland EN175301-803A (ISO 4400) for cables with an outer diameter from 6 to 10 mm

WP, WS, EM, WSEM, WPDU, M20 cable gland for cables with an outer diameter from 7 to 12 mm. With an internal and external facility for an

WSDU earthing or bonding conductor

NF, WSNF, NL 1/2" NPT threaded cable entry. Enclosures are supplied without cable gland

NK 3/4" NPT threaded cable entry. Enclosures are supplied without cable gland

PV Moulded-in cable, standard length 2 m

EF 1/2" NPT conduits, standard length 35 cm

2007/R01

All leaflets are available on: www.asco-process-scope.com

5-30-10

SERIES 551-552-553

ADDITIONAL OPTIONS

Valves configured for external pilot air supply, TPL 20547

Other pipe threads are available on request

EEx m (prefix "PV") execution can be supplied in various cable lengths

Compliance with "UL", "CSA" and other local approvals available on request

1/2" NPT (prefix "T") and M20 x 1.5 (prefix "ET") conduits (aluminium or 316 SS) available for steel solenoid housing

INSTALLATION

Installation/maintenance instructions are included with each valve

The solenoid valves can be mounted in any position without affecting operation

IEC 61508 Functional Safety (Suffix SL), allowable temperature range: -40C to +60C. Probability of failure on demand, contact us

It is necessary to connect pipes or fittings to the exhaust ports to protect the internal parts of the spool valve and its pneumatic

operator if used outside or in harsh environments (dusts, liquids etc.)

Threaded pipe connection identifier is: 8 = NPT (ANSI 1.20.3); G = G (ISO 228/1)

EEx d (prefix "NF") enclosure is provided with a 1/2" NPT threaded entry hole [optionally, M20 x 1,5 (prefix "ET")] and is sup-

plied without cable gland

EEx d (prefix "NK") enclosure is provided with a 3/4" NPT threaded entry hole [optionally, 1/2" NPT (prefix "T") or M20 x 1,5 (prefix

"ET")] and is supplied without cable gland

EEx em (prefix "EM") execution: solenoid enclosure has a cable gland with integral strain relief for cables with an o.d. from 7 to

12 mm and is provided with an internal and external connection facility for an earthing or bonding conductor

DIMENSIONS (mm), WEIGHT (kg)

Series 551 Series 552-553

34,5

=

27,5

= =

40,2

44

5 4 1 2 3

=

1/8 68,5 32 5 x 1/4 1/8 5xV

22

= = 96,5 43

T U

=

4 2 B

= =

32

45

5 1 3 4 2

=

=

=

72,3

51

41

=

= = A

=

91

5 1 3

143,5

183 X Y

W

179,5

225

A 2 mounting holes dia. 5,3; Spotfacing: dia. 9, depth 5 mm type T U V W X Y

B 2 mounting holes dia. 6,5; Spotfacing: dia. 11, depth 6 mm 01 to 11 94 29,6 3/8 111,5 29,6 29,7

552 12 to 19 76 29,6 3/8 93,5 29,6 29,7

01 to 11 93 31,6 1/2 112,5 31,6 31,8

553 12 to 19 75 31,6 1/2 94,5 31,6 31,8

2007/R01

All leaflets are available on: www.asco-process-scope.com

5-30-11

SERIES 551-552-553

DIMENSIONS (mm), WEIGHT (kg)

TYPE 01: Prefixes SC: IP65, ZN: II 3 G/D, IP65, TYPE 02: Prefixes NF/NL/WSNF: II 2 G/D, IP67,

EEx nA II, SCDU: II 3 D, IP65, T100C to 200C EEx d IIC

Basic power Basic power

Epoxy moulded Aluminium, epoxy coated (NF)

IEC 335 / ISO 4400 Cast iron, epoxy coated (NL)

Stainless steel AISI 316 (WSNF)

EN 50018 and EN 50281-1-1

551B417/B418/B417MO/B418MO/B467/B468/B467MO/B468MO 551B417/B418/B417MO/B418MO/B467/B468/B467MO/B468MO

552A417/A418/A417MO/A418MO/A467/A468/A467MO/A468MO 552A417/A418/A417MO/A418MO/A467/A468/A467MO/A468MO

553A417/A418/A417MO/A418MO/A467/A468/A467MO/A468MO 553A417/A418/A417MO/A418MO/A467/A468/A467MO/A468MO

6

G 1/8

360

360 1/2

C

C

90 NPT

2

8 8 5 1 3

5 1 3

9 9

A D A 48 54

B E B 102 56

TYPE 03: Prefix NK: II 2 GD, IP65, EEx d IIB + H2 TYPE 04: Prefixes WP/WS: IP67, EM/WSEM:

Basic power II 2 G/D, IP67, EEx em II, WPDU/WSDU: II 3 D,

Aluminium, epoxy coated IP67, T85C to 200C, WPZN/WSZN: II 3 G/D,

EN 50018 and EN 50281-1-1 IP67, EEx nA II

Basic power

Steel, epoxy coated (EM, WP, WPDU, WPZN)

Stainless steel AISI 316 SS (WS, WSDU, WSEM, WSZN)

IEC 335 / EN 50019, EN 50028 and 50281-1-1

551B417/B418/B417MO/B418MO/B467/B468/B467MO/B468MO 551B417/B418/B417MO/B418MO/B467/B468/B467MO/B468MO

552A417/A418/A417MO/A418MO/A467/A468/A467MO/A468MO 552A417/A418/A417MO/A418MO/A467/A468/A467MO/A468MO

553A417/A418/A417MO/A418MO/A467/A468/A467MO/A468MO 553A417/A418/A417MO/A418MO/A467/A468/A467MO/A468MO

1/8

1/8 NPT

2

4

360 360

C

C

3/4

NPT

8 5 1 3 8 5 1 3

9

A 35,5 64,5 9

A 38 82

B 100 56 B 120

TYPE 05: Prefix: PV: II 2 G/D, IP65, EEx m II TYPE 06: Prefix: EF: ICS-6 ANSI / NEMA

Basic power types 7 and 9

Epoxy encapsulated Basic power

EN50028 and EN 50281-1-1 Epoxy encapsulated

EN50028 and EN 50281-1-1

NOTE: applicable to solenoid only

551B417/B418/B417MO/B418MO/B467/B468/B467MO/B468MO 551H417/H418/H417MO/H418MO/H467/H468/H467MO/H468MO

552A417/A418/A417MO/A418MO/A467/A468/A467MO/A468MO 552G417/G418/G417MO/G418MO/G467/G468/G467MO/G468MO

553A417/A418/A417MO/A418MO/A467/A468/A467MO/A468MO 553G417/G418/G417MO/G418MO/G467/G468/G467MO/G468MO

1/8 1/8

360 360

C

3 3

8 5 1 3 8 5 1 3

9 9

A D 46 A D 52

B E E

2007/R01

All leaflets are available on: www.asco-process-scope.com

5-30-12

SERIES 551-552-553

DIMENSIONS (mm), WEIGHT (kg)

TYPE 07: Prefixes SC: IP65, ZN: II 3 G/D, IP65, TYPE 08: Prefixes NF/NL/WSNF: II 2 G/D, IP67,

EEx nA II EEx d IIC

Low power Low power

Epoxy moulded Aluminium, epoxy coated (NF)

IEC 335 / ISO 4400 Cast iron, epoxy coated (NL)

Stainless steel AISI 316 (WSNF)

EN 50018 and EN 50281-1-1

551B317/B318/B317MO/B318MO/B367/B368/B367MO/B368MO 551B317/B318/B317MO/B318MO/B367/B368/B367MO/B368MO

552A317/A318/A317MO/A318MO/A367/A368/A367MO/A368MO 552A317/A318/A317MO/A318MO/A367/A368/A367MO/A368MO

553A317/A318/A317MO/A318MO/A367/A368/A367MO/A368MO 553A317/A318/A317MO/A318MO/A367/A368/A367MO/A368MO

1/8 NPT

6

360

360

1/2

C

NPT

C

90 2

8 5 1 3

8 5 1 3

9

9 A 48 54

A D

B 102 56

B E

TYPE 09: Prefixes WP/WS: IP67, EM/WSEM: TYPE 10: Prefix: PV: II 2 G/D, IP65, EEx m II

II 2 G/D, IP67, EEx em II, WPDU/WSDU: II 3 D, IP67, Low power

T85C to 200C, WPZN/WSZN: II 3 G/D, Epoxy encapsulated

IP67, EEx nA II, WPIS: II 2 G/D EEx ia IIC

Low power EN50028 and EN 50281-1-1

Steel, epoxy coated (EM, WP, WPDU, WPZN, WPIS)

Stainless steel AISI 316 SS (WS, WSDU, WSEM, WSZN)

IEC 335 / EN 50019, EN 50028 and 50281-1-1

551B317/B318/B317MO/B318MO/B367/B368/B367MO/B368MO 551B317/B318/B317MO/B318MO/B367/B368/B367MO/B368MO

552A317/A318/A317MO/A318MO/A367/A368/A367MO/A368MO 552A317/A318/A317MO/A318MO/A367/A368/A367MO/A368MO

553A317/A318/A317MO/A318MO/A367/A368/A367MO/A368MO 553A317/A318/A317MO/A318MO/A367/A368/A367MO/A368MO

1/8 NPT

1/8 NPT

4

360

360

C

8 8 5 1 3

5 1 3

9 9

A 38 82 A D 46

B 120 B E

TYPE 11: Prefix: EF: ICS-6 ANSI / NEMA types 7 and 9 TYPE 12: Prefix ISSC: II 2 G/D EEx ia IIC, IP65

Low power Low power

Epoxy encapsulated Polypropylene moulded

EN50028 and EN 50281-1-1 IEC 335 / ISO 4400

NOTE: applicable to solenoid only EN 50020 and EN 50281-1-1

551B317/B318/B317MO/B318MO/B367/B368/B367MO/B368MO 551B317/B318/B317MO/B318MO/B367/B368/B367MO/B368MO

552A317/A318/A317MO/A318MO/A367/A368/A367MO/A368MO 552A317/A318/A317MO/A318MO/A367/A368/A367MO/A368MO

553A317/A318/A317MO/A318MO/A367/A368/A367MO/A368MO 553A317/A318/A317MO/A318MO/A367/A368/A367MO/A368MO

1/8

1/8 NPT

360 6

C

C

360

8 5 1 3 8 5 1 3

9 9

A D 52 A D 67

B E B E

2007/R01

All leaflets are available on: www.asco-process-scope.com

5-30-13

Das könnte Ihnen auch gefallen

- Speechless (Easy Piano - A Minor)Dokument2 SeitenSpeechless (Easy Piano - A Minor)Belle Yong0% (1)

- Vinyl Floor InstallDokument10 SeitenVinyl Floor InstallMoose112Noch keine Bewertungen

- Rays BluesDokument1 SeiteRays BluesJohn MannxiNoch keine Bewertungen

- La Moldau: AllegroDokument2 SeitenLa Moldau: AllegroGuiomNoch keine Bewertungen

- On Wings of Song GDokument3 SeitenOn Wings of Song GLương ViNoch keine Bewertungen

- Appendix L Warrington Risk RegisterDokument2 SeitenAppendix L Warrington Risk RegisterChris Findlay100% (1)

- SONATINA FOR TWO-Primo-1Dokument2 SeitenSONATINA FOR TWO-Primo-1Sonia XiaNoch keine Bewertungen

- Concrete Hinge History and UsesDokument22 SeitenConcrete Hinge History and Useslamkinpark3373Noch keine Bewertungen

- Your Song: Ellie Goulding's CoverDokument2 SeitenYour Song: Ellie Goulding's CoverLeia lealNoch keine Bewertungen

- Sven Ha-385 SCHDokument2 SeitenSven Ha-385 SCHАндрюха КорнNoch keine Bewertungen

- Water Tank FoundationDokument1 SeiteWater Tank FoundationKhurram Shahzad Amjad100% (1)

- Bridge Engineering Assignment ReportDokument31 SeitenBridge Engineering Assignment ReportChiranjaya HulangamuwaNoch keine Bewertungen

- Condensate SystemDokument35 SeitenCondensate SystemSam100% (6)

- Denah Tampak - Detail Pintu JendelaDokument8 SeitenDenah Tampak - Detail Pintu Jendelahansen 97Noch keine Bewertungen

- Fracture MechanicsDokument12 SeitenFracture Mechanicsramachadra122Noch keine Bewertungen

- Reichold, Corrosion Guide 12.15.2010Dokument45 SeitenReichold, Corrosion Guide 12.15.2010Pradeep Srivastava100% (1)

- Cable Tray PDFDokument8 SeitenCable Tray PDFPutra Kusuma HarditoNoch keine Bewertungen

- Control Valve Technical Specification For Severe Service - CCIDokument5 SeitenControl Valve Technical Specification For Severe Service - CCIVikas SinghNoch keine Bewertungen

- Contractors List CurrentDokument8 SeitenContractors List CurrentzefanyaNoch keine Bewertungen

- P91 Welding ProcedureDokument1 SeiteP91 Welding ProcedureJaymin100% (2)

- I.Lídio I.Lydian: 180 AlegreDokument2 SeitenI.Lídio I.Lydian: 180 AlegreDiogo SantosNoch keine Bewertungen

- Piano Study DiabelliDokument1 SeitePiano Study DiabelliLucian Dumitru VasilescuNoch keine Bewertungen

- 551 Series Data Sheet PDFDokument12 Seiten551 Series Data Sheet PDFprabhu_jay23Noch keine Bewertungen

- 551 552 553 Namur AluminiumDokument24 Seiten551 552 553 Namur Aluminiumiqbal chaerulNoch keine Bewertungen

- Solenoid valves pilot operated spoolDokument8 SeitenSolenoid valves pilot operated spooltreborNoch keine Bewertungen

- Integrated Pilot Operated, Spool Type Single/dual Solenoid Aluminium Body, 1/4", NAMUR and THREADED StyleDokument4 SeitenIntegrated Pilot Operated, Spool Type Single/dual Solenoid Aluminium Body, 1/4", NAMUR and THREADED StyleRandy SihombingNoch keine Bewertungen

- WPHT Asco Numatics Solenoid - 00186gbDokument2 SeitenWPHT Asco Numatics Solenoid - 00186gbNCNoch keine Bewertungen

- Solenoid VALVES ASCODokument4 SeitenSolenoid VALVES ASCOGeorgios MariolisNoch keine Bewertungen

- Solenoid Valves 5 2 5 3 Aluminium 551 531C001MSDokument4 SeitenSolenoid Valves 5 2 5 3 Aluminium 551 531C001MSDeshan SingNoch keine Bewertungen

- Solenoid Valves 3 - 2 5 - 2 Stainless Steel Body 551 553 CAT 80114GBDokument8 SeitenSolenoid Valves 3 - 2 5 - 2 Stainless Steel Body 551 553 CAT 80114GBwqs_19Noch keine Bewertungen

- SOLENOID VALVES FEATURES AND SPECIFICATIONSDokument8 SeitenSOLENOID VALVES FEATURES AND SPECIFICATIONSTeddy HariyantoNoch keine Bewertungen

- ASCO Solenoid ValvesDokument2 SeitenASCO Solenoid ValvesSupolNoch keine Bewertungen

- Studio in La Minore 23Dokument1 SeiteStudio in La Minore 23santiago.mancini05Noch keine Bewertungen

- Studio in La Minore 23Dokument1 SeiteStudio in La Minore 23santiago.mancini05Noch keine Bewertungen

- Solenoid Valves-5 - 2-5 - 3-Aluminium body-551-552-553-CAT-00093GBDokument4 SeitenSolenoid Valves-5 - 2-5 - 3-Aluminium body-551-552-553-CAT-00093GBfebri kurniaNoch keine Bewertungen

- Piano Sonatina in C Major William DuncombeDokument2 SeitenPiano Sonatina in C Major William Duncomberesmi muzikantiNoch keine Bewertungen

- 3272421-Teardrops Gabriel Thorn PDFDokument8 Seiten3272421-Teardrops Gabriel Thorn PDFNicolás Nariño AmayaNoch keine Bewertungen

- 3272421-Teardrops Gabriel Thorn PDFDokument8 Seiten3272421-Teardrops Gabriel Thorn PDFNicolás Nariño AmayaNoch keine Bewertungen

- Prelude 1 BachDokument2 SeitenPrelude 1 BachLuis ErnestoNoch keine Bewertungen

- 5 THDokument4 Seiten5 THRose DPNoch keine Bewertungen

- Wirring DiagramDokument34 SeitenWirring DiagramBahman Pour JafariNoch keine Bewertungen

- Christmas Carol From Anjou: No 52 From "L'Organiste" Vol. 1 César FranckDokument1 SeiteChristmas Carol From Anjou: No 52 From "L'Organiste" Vol. 1 César FranckCedric TutosNoch keine Bewertungen

- Chopin Prelude Op28 No15 PsuDokument3 SeitenChopin Prelude Op28 No15 PsuLearner LearnerNoch keine Bewertungen

- 10面板Dokument1 Seite10面板MARIA FERNANDA MORA AREVALONoch keine Bewertungen

- Pideme La Luna: Leo DanDokument4 SeitenPideme La Luna: Leo DanMercedes VignaNoch keine Bewertungen

- eslami aqeedah ke chand aham msayal اسلامى عقيده كى جند أهم مسائلDokument79 Seiteneslami aqeedah ke chand aham msayal اسلامى عقيده كى جند أهم مسائلatasayeidiNoch keine Bewertungen

- Brindisi VerdiDokument7 SeitenBrindisi Verdixipojedetutuapp.bidNoch keine Bewertungen

- Catálogo de Peças - Intruder GN 125H-K7 - 2007 (Arrastado)Dokument1 SeiteCatálogo de Peças - Intruder GN 125H-K7 - 2007 (Arrastado)BrunaYazbekNoch keine Bewertungen

- HalleluiahDokument2 SeitenHalleluiahARILTON JUNIORNoch keine Bewertungen

- Hidraulic SchematicDokument2 SeitenHidraulic SchematicHamilton Miranda100% (1)

- Unchained MelodyDokument3 SeitenUnchained MelodyOmar PérezNoch keine Bewertungen

- Five Spot - Chilly GonzalesDokument1 SeiteFive Spot - Chilly GonzalesGuylaine OuelletNoch keine Bewertungen

- Multan Region Oct2023-1Dokument4 SeitenMultan Region Oct2023-1Shahzad MirzaNoch keine Bewertungen

- Vol3 Chapter03 MapsDokument6 SeitenVol3 Chapter03 Mapsprabhakar_n1Noch keine Bewertungen

- Solenoid Valves 3/2-5/2 551: Single/dual Solenoid (Mono/bistable Function) 1/4Dokument10 SeitenSolenoid Valves 3/2-5/2 551: Single/dual Solenoid (Mono/bistable Function) 1/4Dinesh ChouguleNoch keine Bewertungen

- 3 IiiDokument2 Seiten3 IiiDiogo SantosNoch keine Bewertungen

- Tuba 1Dokument8 SeitenTuba 1arquivoNoch keine Bewertungen

- Chopin Prelude Op 28 No 7 in A MajorDokument1 SeiteChopin Prelude Op 28 No 7 in A MajorMassimo CiacciNoch keine Bewertungen

- CANÇÃO PARA MARISA - Solo PartituraDokument4 SeitenCANÇÃO PARA MARISA - Solo PartituraJoseNoch keine Bewertungen

- Chorale BWV 514Dokument1 SeiteChorale BWV 514Alberto YamamotoNoch keine Bewertungen

- Standard guitar tuning guideDokument2 SeitenStandard guitar tuning guideSam BNoch keine Bewertungen

- Dedicated to the Right-Hand Little Finger: Daniel Gottlob Türk Piece for Developing PianistsDokument1 SeiteDedicated to the Right-Hand Little Finger: Daniel Gottlob Türk Piece for Developing PianistsConstantin Aurel-HermanNoch keine Bewertungen

- Solenoid Valves 3/2 5/2 531Dokument4 SeitenSolenoid Valves 3/2 5/2 531luthfie4uNoch keine Bewertungen

- Parweld Pez 400Dokument1 SeiteParweld Pez 400pablotorres_cNoch keine Bewertungen

- MFS Arduino PDFDokument1 SeiteMFS Arduino PDFDusmantha AnandaratneNoch keine Bewertungen

- Schema Shield Invatare ArduinoDokument1 SeiteSchema Shield Invatare ArduinoTokra2007Noch keine Bewertungen

- Single ParadiddleDokument2 SeitenSingle ParadiddleRuan Pablo BateraNoch keine Bewertungen

- Sonatina For TwoDokument1 SeiteSonatina For TwoSonia XiaNoch keine Bewertungen

- Circuit Diagram For Vacuum Tubular FurnaceDokument2 SeitenCircuit Diagram For Vacuum Tubular FurnaceMuhammad Maratab Ali ZiaiNoch keine Bewertungen

- Couring Song AgayDokument2 SeitenCouring Song AgayMarylene LenoirNoch keine Bewertungen

- Fill Your Glass With Gold-When It's Half-Full or Even Completely ShatteredVon EverandFill Your Glass With Gold-When It's Half-Full or Even Completely ShatteredNoch keine Bewertungen

- Ti115ren PDFDokument14 SeitenTi115ren PDFtree_99Noch keine Bewertungen

- IOM Transmitter T32 PDFDokument33 SeitenIOM Transmitter T32 PDFtree_99Noch keine Bewertungen

- 2%Jhjubm1Ptjujpofs: Otubmmbujpo 0qfsbujpoboe - Bjoufobodf OtusvdujpotDokument40 Seiten2%Jhjubm1Ptjujpofs: Otubmmbujpo 0qfsbujpoboe - Bjoufobodf Otusvdujpottree_99Noch keine Bewertungen

- Mark One General IOM Vlenim0001 (06-Sept-2007) PDFDokument16 SeitenMark One General IOM Vlenim0001 (06-Sept-2007) PDFtree_99Noch keine Bewertungen

- And Manufacturer's Declaration As Per Directive 98/37/ECDokument8 SeitenAnd Manufacturer's Declaration As Per Directive 98/37/ECtree_99Noch keine Bewertungen

- Pfeiffer: Series 14b / Series 14cDokument8 SeitenPfeiffer: Series 14b / Series 14ctree_99Noch keine Bewertungen

- Pfeiffer: Butterfly Valve Series 14b / 14c / 74bDokument8 SeitenPfeiffer: Butterfly Valve Series 14b / 14c / 74btree_99Noch keine Bewertungen

- 8316 Series-Sil IIDokument2 Seiten8316 Series-Sil IItree_99Noch keine Bewertungen

- Product Data SheetsDokument5 SeitenProduct Data Sheetstree_99Noch keine Bewertungen

- Pfeiffer: Butterfly Valve Series 14b / 14c / 74bDokument8 SeitenPfeiffer: Butterfly Valve Series 14b / 14c / 74btree_99Noch keine Bewertungen

- Series 3730 Electropneumatic Positioner Type 3730-2 and Type 3730-3 With HART CommunicationDokument8 SeitenSeries 3730 Electropneumatic Positioner Type 3730-2 and Type 3730-3 With HART Communicationtree_99Noch keine Bewertungen

- Eb8384-3 enDokument128 SeitenEb8384-3 entree_99Noch keine Bewertungen

- Universal Excess Pressure Valve Installation GuideDokument34 SeitenUniversal Excess Pressure Valve Installation Guidetree_99Noch keine Bewertungen

- Mounting - Servicing - Indication AdjustmentDokument1 SeiteMounting - Servicing - Indication AdjustmentTreeNoch keine Bewertungen

- Product Data Sheets PDFDokument12 SeitenProduct Data Sheets PDFtree_99Noch keine Bewertungen

- ManualsDokument16 SeitenManualstree_99Noch keine Bewertungen

- FMHB3 FlowmetersDokument105 SeitenFMHB3 Flowmeterstree_99Noch keine Bewertungen

- Product Data SheetsDokument12 SeitenProduct Data Sheetstree_99Noch keine Bewertungen

- 07 Erection Instructions, Operational Manual, BulletinsDokument63 Seiten07 Erection Instructions, Operational Manual, Bulletinstree_99Noch keine Bewertungen

- Auracast 100 BFLDokument2 SeitenAuracast 100 BFLpeashNoch keine Bewertungen

- Duplex 1400 10100 Basic-N en 2014 06Dokument8 SeitenDuplex 1400 10100 Basic-N en 2014 06chaesar1Noch keine Bewertungen

- Lot Detail for Repair and Renovation work at Langalzora High School Upazilla Kalihati District-TangailDokument8 SeitenLot Detail for Repair and Renovation work at Langalzora High School Upazilla Kalihati District-Tangailfireballhunter646Noch keine Bewertungen

- Shalabny Buonocore - 2022 APSUSDokument9 SeitenShalabny Buonocore - 2022 APSUSFrankie GoodheartNoch keine Bewertungen

- Lamara2018 PDFDokument13 SeitenLamara2018 PDFUmer HayatNoch keine Bewertungen

- Celesta BrochureDokument13 SeitenCelesta BrochurePranavNoch keine Bewertungen

- Downfeed SystemDokument12 SeitenDownfeed SystemcharbelNoch keine Bewertungen

- PFA Vs PTFE in InstrumentationDokument5 SeitenPFA Vs PTFE in InstrumentationArif HakimNoch keine Bewertungen

- SPECIFICATIONS Cable 70mm 4core CableDokument2 SeitenSPECIFICATIONS Cable 70mm 4core CableSaif ul HassanNoch keine Bewertungen

- Accessories For 8 Oc's For TalkalDokument5 SeitenAccessories For 8 Oc's For Talkalhanu sunilNoch keine Bewertungen

- Yıldırım Beyazit University Mechanical Engineering DepartmentDokument7 SeitenYıldırım Beyazit University Mechanical Engineering DepartmentJuanKaNoch keine Bewertungen

- Practice Set - 2 (B) Young's Modulus: ElasticityDokument7 SeitenPractice Set - 2 (B) Young's Modulus: ElasticityWillis ChekovNoch keine Bewertungen

- 2007 Russian Aluminum Alloys For Ultra Deep Water EngDokument8 Seiten2007 Russian Aluminum Alloys For Ultra Deep Water EngHossam Ali RaghebNoch keine Bewertungen

- Cast Steel Y-Strainers ANSI 150-600 LB: 0062 API 6D-0444Dokument1 SeiteCast Steel Y-Strainers ANSI 150-600 LB: 0062 API 6D-0444Camilo SanchezNoch keine Bewertungen

- Burj Al Arab: Cofferdam & RiggingDokument12 SeitenBurj Al Arab: Cofferdam & RiggingazharahmadnazriNoch keine Bewertungen

- DAR 108 Rev 01 TC MS Flushing For CHW SystemDokument65 SeitenDAR 108 Rev 01 TC MS Flushing For CHW SystemMarwan NizarNoch keine Bewertungen

- STM (2022)Dokument49 SeitenSTM (2022)Kaustav Jit BoraNoch keine Bewertungen

- Plexo Catalogue 02 PDFDokument20 SeitenPlexo Catalogue 02 PDFAdinugroho SunardiNoch keine Bewertungen

- Knauf Product Catalogue Aug2019 WEBDokument28 SeitenKnauf Product Catalogue Aug2019 WEBeka suryanaNoch keine Bewertungen