Beruflich Dokumente

Kultur Dokumente

TR E1r15 72 2 PDF

Hochgeladen von

Anonymous 298xlo3uU0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

53 Ansichten2 SeitenOriginaltitel

TR-E1R15-72-2.pdf

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

53 Ansichten2 SeitenTR E1r15 72 2 PDF

Hochgeladen von

Anonymous 298xlo3uUCopyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

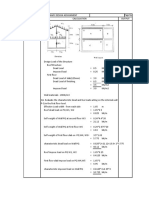

EXPORT CONTROLLED Rolls--Royce

250--B17F SERIES OPERATION AND MAINTENANCE MANUAL

TEMPORARY LIST OF PAGES

Insert this page preceding the List of Effective Pages dated May 1/08.

Temporary Revision Chapter/

Number Section Page Date

E1R15--72--1 72--00--00 608 Jun 10/09

E1R15--73--1 73--10--03 201 Jun 10/09

73--10--03 202 Jun 10/09

73--10--03 203 Jun 10/09

73--10--03 204 Jun 10/09

73--10--03 204A Jun 10/09

E1R15--76--1 76--10--01 203 Oct 9/09

76--10--01 204 Oct 9/09

76--10--01 206 Oct 9/09

76--10--01 206A Oct 9/09

.COPYRIGHT 1989, 2009 Rolls--Royce Corporation

TLP

Oct 9/09

Rolls-Royce Proprietary Data Uncontrolled Printed Copy

EXPORT CONTROLLED Rolls--Royce

250--B17F SERIES OPERATION AND MAINTENANCE

TECHNICAL ASPECTS ARE FAA APPROVED TEMPORARY REVISION E1R15--72--1

Table 602

Item Inspection/Maintenance Action Reference T Initial

300 Hour Inspection (cont)

CAUTION: INSPECTION FREQUENCY SHALL BE BASED ON THE NATURE OF THE EROSIVE

AND/OR CORROSIVE ENVIRONMENT. THE OPERATING ENVIRONMENT MAY DICTATE A

MORE FREQUENT INSPECTION INTERVAL. WHEN OPERATING IN A CORROSIVE

AND/OR EROSIVE ENVIRONMENT FOR NON--COATED COMPRESSOR WHEELS, THE

INSPECTION SHALL NOT EXCEED 300 HOURS OR 6 MONTHS. FOR COATED

COMPRESSOR WHEELS, INSPECTION SHALL NOT EXCEED 300 HOURS OR 12

MONTHS. IF ANY PARENT METAL IS EXPOSED DUE TO CORROSION AND/OR

EROSION, THE INSPECTION REQUIREMENT SHALL REVERT BACK TO 300 HOURS OR 6

MONTHS.

30 Inspect the compressor case when operating in an erosive PARA 1.C.(9),

and/or corrosive environment. this section

CAUTION: WHEN THERE IS EVIDENCE THAT THE FUEL PUMP FILTER HAS BEEN BYPASSED, THE

GAS PRODUCER FUEL CONTROL INLET FILTER, THE FUEL NOZZLE FILTER, THE

GOVERNOR FILTER AND THE HIGH PRESSURE FUEL FILTER, IF APPLICABLE, MUST BE

CLEANED. (REFER TO SPECIAL INSTRUCTIONS, TABLE 603) IF ANY CONTAMINATION

IS FOUND IN THE FUEL NOZZLE FILTER, THIS WILL REQUIRE THAT THE FUEL

CONTROL BE SENT TO AN AUTHORIZED REPAIR FACILITY FOR INTERNAL CLEANING.

REFERENCE MUST ALSO BE MADE TO THE AIRFRAME MAINTENANCE MANUAL FOR

FUEL SYSTEM MAINTENANCE FOLLOWING FUEL CONTAMINATION.

31 If the aircraft is equipped with an engine fuel filter differential PARA 1.F.,

pressure warning system, replace the throw--away filter only 73--10--01

when an indication of contamination is obtained or every 300

hours, whichever comes first. If the aircraft is not equipped

with a differential pressure warning system, replace the fuel

filter every 300 hours unless operating experience

demonstrates that smaller time increments are advisable.

Before discarding filter, inspect for signs of contaminants. If

contaminants are found, examine the entire fuel system and

clean if necessary. Verify Step 32 has been completed before

reassembly.

32 Do a fuel pump bypass valve operational check whenever a PARA 1.D.,

fuel filter is replaced. 73--10--01

33 Purge air from the filter bowl area of the single element pump. PARA 2.F.,

73--00--00

34 Remove and disassemble fuel nozzle. Clean and examine fuel 73--10--03

nozzle filter assembly. Reassemble and install fuel nozzle.

35 Inspect and clean the No. 1 bearing oil pressure reducer. PARA 3.A.(2),

72--30--00

36 Visually inspect turbine external sump. Clean internal PARA 6.E.(2),

carbonous deposits from sump. 72--50--00

37 Inspect the power turbine support scavenge strut. Clean PARA 6.E.,

internal carbonous deposits from strut. 72--50--00

38 Remove, clean and inspect Pc filter every 300 hours or earlier PARA 2.A.,

as engine performance dictates. 73--20--03

39 Examine the thermocouple assembly (TOT/MGT). PARA 2.B.,

77--20--01

72--00--00

.COPYRIGHT 1989, 2009 Rolls--Royce Corporation Page 608

Jun 10/09

Rolls-Royce Proprietary Data Uncontrolled Printed Copy

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Temporary Revision Number Chapter/ Section Date: 250 - B17F Series Operation and Maintenance ManualDokument7 SeitenTemporary Revision Number Chapter/ Section Date: 250 - B17F Series Operation and Maintenance ManualAnonymous 298xlo3uUNoch keine Bewertungen

- Rolls-Royce': Record of Temporary RevisionsDokument5 SeitenRolls-Royce': Record of Temporary RevisionsAnonymous 298xlo3uUNoch keine Bewertungen

- TR PDFDokument3 SeitenTR PDFAnonymous 298xlo3uUNoch keine Bewertungen

- Rev15 PDFDokument65 SeitenRev15 PDFAnonymous 298xlo3uUNoch keine Bewertungen

- Rev16 PDFDokument34 SeitenRev16 PDFAnonymous 298xlo3uUNoch keine Bewertungen

- Rolls-Royce': Record of Temporary RevisionsDokument1 SeiteRolls-Royce': Record of Temporary RevisionsAnonymous 298xlo3uUNoch keine Bewertungen

- Rev14 PDFDokument24 SeitenRev14 PDFAnonymous 298xlo3uUNoch keine Bewertungen

- 77 20 01 PDFDokument4 Seiten77 20 01 PDFAnonymous 298xlo3uUNoch keine Bewertungen

- 73 10 03 PDFDokument6 Seiten73 10 03 PDFAnonymous 298xlo3uUNoch keine Bewertungen

- Operation and Maintenance Manual: 250-B17F 250-B17F/1 250-B17F/2 1 May 2004 Revision 10 First Edition 1 November 1989Dokument17 SeitenOperation and Maintenance Manual: 250-B17F 250-B17F/1 250-B17F/2 1 May 2004 Revision 10 First Edition 1 November 1989Anonymous 298xlo3uUNoch keine Bewertungen

- Rolls-Royce: 250-B17F Series Operation and MaintenanceDokument6 SeitenRolls-Royce: 250-B17F Series Operation and MaintenanceAnonymous 298xlo3uUNoch keine Bewertungen

- Operation and Maintenance Manual: 250-B17F 250-B17F/1 250-B17F/2 1 May 2005 Revision 11 First Edition 1 November 1989Dokument13 SeitenOperation and Maintenance Manual: 250-B17F 250-B17F/1 250-B17F/2 1 May 2005 Revision 11 First Edition 1 November 1989Anonymous 298xlo3uU100% (1)

- Rev10 PDFDokument80 SeitenRev10 PDFAnonymous 298xlo3uUNoch keine Bewertungen

- Rolls-Royce: 250-B17F Series Operation and MaintenanceDokument2 SeitenRolls-Royce: 250-B17F Series Operation and MaintenanceAnonymous 298xlo3uUNoch keine Bewertungen

- Rolls-Royce: 250-B17F Series Operation and MaintenanceDokument2 SeitenRolls-Royce: 250-B17F Series Operation and MaintenanceAnonymous 298xlo3uUNoch keine Bewertungen

- 75 00 00 PDFDokument2 Seiten75 00 00 PDFAnonymous 298xlo3uUNoch keine Bewertungen

- Rolls-Royce: 250-B17F Series Operation and MaintenanceDokument2 SeitenRolls-Royce: 250-B17F Series Operation and MaintenanceAnonymous 298xlo3uUNoch keine Bewertungen

- 76 Cont PDFDokument2 Seiten76 Cont PDFAnonymous 298xlo3uUNoch keine Bewertungen

- 74 Cont PDFDokument2 Seiten74 Cont PDFAnonymous 298xlo3uUNoch keine Bewertungen

- 73 Cont PDFDokument4 Seiten73 Cont PDFAnonymous 298xlo3uUNoch keine Bewertungen

- 73 20 02 PDFDokument12 Seiten73 20 02 PDFAnonymous 298xlo3uUNoch keine Bewertungen

- 74 20 01 PDFDokument4 Seiten74 20 01 PDFAnonymous 298xlo3uUNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Challenger DisasterDokument2 SeitenChallenger DisasterZi ChinNoch keine Bewertungen

- MasonaryDokument4 SeitenMasonaryChiranjaya Hulangamuwa100% (1)

- ATP IndexDokument2.352 SeitenATP IndexRicardo zafra100% (1)

- Performance - WT and Bal: PAX Cargo FuelDokument23 SeitenPerformance - WT and Bal: PAX Cargo FueltomrachNoch keine Bewertungen

- Wind Load Calculation As Per EN1991-1!4!2005 - Rev 01 (By JR)Dokument2 SeitenWind Load Calculation As Per EN1991-1!4!2005 - Rev 01 (By JR)RigonDEC100% (2)

- Round 1Dokument3 SeitenRound 1greyNoch keine Bewertungen

- 3 MW Product BrochureDokument16 Seiten3 MW Product BrochuremaniacfornicNoch keine Bewertungen

- 200905094-Ppt On Classification of Air CompressorsDokument32 Seiten200905094-Ppt On Classification of Air CompressorsPrasanna Kumar100% (4)

- Guidance and Navigation SyllabusDokument3 SeitenGuidance and Navigation Syllabussanjay100% (1)

- Iai SB 365-00-054Dokument18 SeitenIai SB 365-00-054Frank MasonNoch keine Bewertungen

- Tapa AGR Reg App BDokument35 SeitenTapa AGR Reg App Bfoxbat05Noch keine Bewertungen

- Gyroscopic Motion Presentation GCUFDokument15 SeitenGyroscopic Motion Presentation GCUFAhmad ChNoch keine Bewertungen

- ManualDokument90 SeitenManualBhárbara Idk100% (1)

- UHPPDokument24 SeitenUHPPzacklawsNoch keine Bewertungen

- Karnataka Current Affairs 2017 by AffairsCloudDokument13 SeitenKarnataka Current Affairs 2017 by AffairsCloudSinivas ParthaNoch keine Bewertungen

- Aircraft HardwareDokument36 SeitenAircraft HardwareShrawanNoch keine Bewertungen

- Boarding PassDokument1 SeiteBoarding PassSendy Syahria SutarmanNoch keine Bewertungen

- CFM56-7B Fan Blade Lubrication CESM-005Dokument2 SeitenCFM56-7B Fan Blade Lubrication CESM-005Keith Humphrey0% (2)

- 20x102mm Fact SheetDokument2 Seiten20x102mm Fact SheetHossam AliNoch keine Bewertungen

- Structural Analysis: Force Response in Statically Determinate StructuresDokument26 SeitenStructural Analysis: Force Response in Statically Determinate StructuresAshutosh YadavNoch keine Bewertungen

- Falcon 200DX FLTDECK FMSCASDokument20 SeitenFalcon 200DX FLTDECK FMSCAStayo_bNoch keine Bewertungen

- STS-56 Space Shuttle Mission ReportDokument52 SeitenSTS-56 Space Shuttle Mission ReportBob AndrepontNoch keine Bewertungen

- August 2013 PDFDokument52 SeitenAugust 2013 PDFsake1978Noch keine Bewertungen

- Electro Hydraulic Servo ValveDokument8 SeitenElectro Hydraulic Servo ValveabyzenNoch keine Bewertungen

- RTR SyllabusDokument3 SeitenRTR SyllabusNational HeraldNoch keine Bewertungen

- CASA CPL GK Jan 2004Dokument173 SeitenCASA CPL GK Jan 2004Allen Cheng100% (3)

- (Fluid Mechanics and Its Applications 75) Dr. Paul Palo (Auth.), Haym Benaroya, Timothy J. Wei (Eds.)-IUTAM Symposium on Integrated Modeling of Fully Coupled Fluid Structure Interactions Using AnalysiDokument515 Seiten(Fluid Mechanics and Its Applications 75) Dr. Paul Palo (Auth.), Haym Benaroya, Timothy J. Wei (Eds.)-IUTAM Symposium on Integrated Modeling of Fully Coupled Fluid Structure Interactions Using AnalysiShubham ShindeNoch keine Bewertungen

- SA02636SEDokument21 SeitenSA02636SElouisNoch keine Bewertungen

- Airlines IndustryDokument10 SeitenAirlines IndustryAlolika Dutta RoyNoch keine Bewertungen

- R/C Soaring Digest - Aug 2005Dokument40 SeitenR/C Soaring Digest - Aug 2005Aviation/Space History LibraryNoch keine Bewertungen