Beruflich Dokumente

Kultur Dokumente

Worl Plan-Fly Ash

Hochgeladen von

Taran JonnardCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Worl Plan-Fly Ash

Hochgeladen von

Taran JonnardCopyright:

Verfügbare Formate

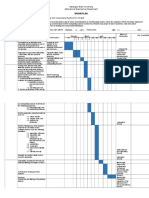

Batangas State University

Mechanical Engineering Department

WORKPLAN

Project Title: Design and Development of Coal Fly Ash Compacting Machine for Oil Spill Adsorption

Project Description: The subject of the study and its development could provide a way to reduce industrial wastes in coal fired power plants, reduce the hazardous effects of improper disposal

of coal fly ash and solve oil spill environmental problem. The design and development of the compacting machine could be beneficial to many people because it produces

a low cost natural adsorbent of oil and replaces the manual and natural recovery used in treating and curing oil spill catastrophes.

Total Duration (in months): _4_ Planned Start: _February_ Year: _2017_ Planned End: Month _May_ Year: _2017_

Means of Key

February March April May Verification Assumptions/

19-25

26-421-27

Objectives Activities Expected Output

12-18

12-18

19-25

16-22

23-29

5-11

29-4

5-11

26-1

9-15

14-20

2-8

30-6

7-13

26-4

Consultation for the

Fabricate the coal fly ash fabrication of the

Autocad file of the

compacting machine for oil compacting machine

machine for the

spill adsorption. including the cost of See attached copy

fabricators guide Availability of the

service and the of the Autocad file

regarding its fabricator

preparation of the and service contract

dimensions and

AutoCad file that will

other parts.

serve as the guide of

the fabricator.

Downpayment and See attachedreceipt

Fabricated Main

start of fabrication of payment and Availability of money

Frame with the

Main frame with the photo of the main and Materials

hydraulic assembly

hydraulic assembly frame

Machine shop of the See attached photo

Fabricated Molder,

molders, main of the fabricated Availability of money

compactor and

compactor and molder, compactor and Materials

template guides

template guides and template guides

Assembly of parts, Final Output of See attached photo Availability of money

Proponents: Signature: Date: Adviser: Signature: Date

de Ocampo, Dyve B. Engr. Rocel D. Gualberto

Gayeta, Donavel S.

Taran, Jonnard M.

calibration of motion

Compacting of the compacting

and controls for the and Materials

machine machine

testing.

Testing of the

Machine with Raw

Materials (if okay, the

output will be pull out

for the preliminary

See attached photo

testing, if not-prior Well-Functioning

of the compacting Availability of money

testing will be Compacting

machine testing with and Materials

performed for its Machine

the raw materials

optimum

utilization)Also, Full

payment will be paid

if the machine is well

functioning.

See attached photo

Minor Modification of Well-Functioning

of the finished Availability of money

the prototype and Compacting

compacting and materials

finishing the output. Machine

machine

Means of Key

February March April May Verification Assumptions/

19-25

26-421-27

Objectives Activities Expected Output

12-18

12-18

19-25

16-22

23-29

29-4

5-11

5-11

26-1

9-15

14-20

2-8

30-6

7-13

26-4

See attached photo

Preparation of Raw Coal Fly Ash and Availability of raw

of the raw material

Materials Clay Mixture materials.

preparation.

1. Conduct preliminary See attached data in

testing to establish the Test the effective Best proportion of determining the best

Availability of raw

following parameters: proportion of coal fly coal fly ash and clay effective proportion

materials.

1.1 proportion of coal fly ash and clay mixture mixture of coal fly ash and

ash and clay mixture; and clay mixture

1.2 operating pressure. See attached data in

Best operating

Test the operating determining best Availability of raw

pressure was

pressure needed operating pressure materials.

obtained.

needed

2. Test the performance of Test the compacting Compacting rate of See attached data Availability of the

the coal fly ash compacting rate of the prototype the prototype was of the compacting panel of examiners.

machine to determine the obtained. rate of the prototype

Proponents: Signature: Date: Adviser: Signature: Date

de Ocampo, Dyve B. Engr. Rocel D. Gualberto

Gayeta, Donavel S.

Taran, Jonnard M.

following parameters: Compacting See attached data

Test the compacting

2.1 compacting rate; and efficiency of the of the compacting Availability of the

efficiency of the

2.2 compacting efficiency. prototype was efficiency of the panel of examiners.

prototype

obtained. prototype

3. Test the properties of

product output in terms of: Evaluate the silicon

3.1 silicon dioxide; dioxide, calcium Desired data was See attached No too much delays

3.2 calcium oxide; and oxide and particle obtained through laboratory testing for releasing

3.3 particle size size distribution of laboratory testing. results. laboratory results.

distribution. the product output

Test for the Desired data was See attached

Availability of the

adsorption efficiency obtained through laboratory testing

finished prototype.

of the product laboratory testing. results.

Test for the Desired data was See attached

Availability of the

4. Test the effectiveness of adsorption rate of the obtained through laboratory testing

finished prototype

the product output to the product laboratory testing. results.

simulated oil and seawater Best number of See attached data

Test for the number

mixture under the following compacted fly ash of the number of

of compacted fly ash Availability of the

conditions: and clay mixture to compacted fly ash

and clay mixture to finished prototype

4.1 adsorption efficiency; be utilized was and clay mixture to

be utilized

4.2 adsorption rate; determined be utilized

4.3 number of compacted Best effective See attached data

Test for the effective

fly ash and clay mixture to contact time of the of the effective

contact time of the Availability of the

be utilized; product to the sea contact time of the

product to the sea finished prototype

4.4 contact time; water was product to the sea

water

4.5 curing time; determined water

4.6 dimensional stability; See attached data

Test for the effective Best effective curing

and of the effective Availability of the

curing time of the time of the product

4.7 effective density. curing time of the finished prototype

product was determined

product

Best dimensional See attached data

Test the dimensional Availability of the

stability of the output of the dimensional

stability of the output finished prototype

was determined stability of the output

Test for the effective Desired data was See attached

Availability of the

density of the obtained through laboratory testing

finished prototype

product laboratory testing. results.

5. Evaluate the quality of

Desired data was See attached Availability of the

water before and after Laboratory Testing obtained through laboratory testing simulated oil and

adsorption. laboratory testing. results. sea water mixture

Proponents: Signature: Date: Adviser: Signature: Date

de Ocampo, Dyve B. Engr. Rocel D. Gualberto

Gayeta, Donavel S.

Taran, Jonnard M.

Results were

Gather the results See attached copy

successfully

Compilation of the from the preliminary of summary results Availability of the

compiled for

Gathered Results testing and and laboratory compiled data

Chapter 4 and 5

laboratory results testing results

writing

Means of

Key Assumptions/

Verification

February March April May

19-25

Objectives Activities Expected Output

26-421-27

12-18

12-18

19-25

16-22

23-29

29-4

26-1

9-15

5-11

5-11

14-20

2-8

30-6

7-13

26-4

Availability of the

Making of the See attached copy

Chapters 4 and 5 proponents and

Chapters 4 and 5 of chapters 4 and 5

data results

See attached photo

Well-Functioning

and video of a well- Availability of the

Performance Testing Compacting

Manuscript Preparation functioning panel of examiners

Machine

compacting machine

See attached copy

Well defended and

of summary of Availability of the

Final Oral Defense successful oral

comments of the panel of examiners

defense

panel of examiners.

See attached copy

Revise the final Revised copy of of summary of Availability of the

manuscript manuscript comments of the panel of examiners

panel of examiners.

Completed See attached copy

Completion of the Availability of the

signatures of the of the completed

final manuscript panel of examiners

approval sheet approval sheet

Bind the final

See attached

Manuscript and Binded copy of the Availability of the

copy/photo of the

submit it to the final manuscript facilities

binded manuscript

respected areas

Develop an operation Making of the Operational Manual See attached copy Availability of the

manual for the fabricated Operational Manual of the Compacting of operational panel of examiners.

Proponents: Signature: Date: Adviser: Signature: Date

de Ocampo, Dyve B. Engr. Rocel D. Gualberto

Gayeta, Donavel S.

Taran, Jonnard M.

of the Compacting

Machine manual

Machine

coal fly ash compacting See attached copies

machine and extend it to of extension forms,

Extending the The machine was

its respective beneficiaries machine to its memorandum of Availability of the

extended and

agreement and adviser.

beneficiary transferred

other supporting

files

Proponents: Signature: Date: Adviser: Signature: Date

de Ocampo, Dyve B. Engr. Rocel D. Gualberto

Gayeta, Donavel S.

Taran, Jonnard M.

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- From Sir A Na SasakyanDokument1 SeiteFrom Sir A Na SasakyanTaran JonnardNoch keine Bewertungen

- Work PlanDokument3 SeitenWork PlanTaran JonnardNoch keine Bewertungen

- VisitaDokument16 SeitenVisitaTaran JonnardNoch keine Bewertungen

- Objectives of The StudyDokument2 SeitenObjectives of The StudyTaran JonnardNoch keine Bewertungen

- Certificate of Appreciation: College of Engineering, Architecture and Fine ArtsDokument2 SeitenCertificate of Appreciation: College of Engineering, Architecture and Fine ArtsTaran JonnardNoch keine Bewertungen

- Design and Development of Saltwater Desalinator Machine Using Solar EnergyDokument1 SeiteDesign and Development of Saltwater Desalinator Machine Using Solar EnergyTaran JonnardNoch keine Bewertungen

- Mechanical Engineering Students' Society (Mess) First Semester AY 2016-2017Dokument1 SeiteMechanical Engineering Students' Society (Mess) First Semester AY 2016-2017Taran JonnardNoch keine Bewertungen

- New Format Student Organizations Accomplishment Report 1Dokument13 SeitenNew Format Student Organizations Accomplishment Report 1Taran Jonnard100% (1)

- Financial Report 16 17 Part1Dokument8 SeitenFinancial Report 16 17 Part1Taran JonnardNoch keine Bewertungen

- Financial Report 16 17 Part1Dokument8 SeitenFinancial Report 16 17 Part1Taran JonnardNoch keine Bewertungen

- Narrative MESSDokument68 SeitenNarrative MESSTaran JonnardNoch keine Bewertungen

- AirconditioningDokument69 SeitenAirconditioningTaran JonnardNoch keine Bewertungen

- 3-One-Dimensional Steady-State Conduction PDFDokument18 Seiten3-One-Dimensional Steady-State Conduction PDFAaron Qin Yuan WongNoch keine Bewertungen

- Calculation of Pipe NetworkDokument6 SeitenCalculation of Pipe NetworkAdib TawfiqNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Book Item 97952Dokument18 SeitenBook Item 97952Shairah May MendezNoch keine Bewertungen

- Rate Con PO#267800 From Parsippany - NJ To Raeford - NCDokument2 SeitenRate Con PO#267800 From Parsippany - NJ To Raeford - NCbiggbioNoch keine Bewertungen

- Wind Energy JapanDokument10 SeitenWind Energy JapanEnergiemediaNoch keine Bewertungen

- Ia Prompt 12 Theme: Knowledge and Knower "Is Bias Inevitable in The Production of Knowledge?"Dokument2 SeitenIa Prompt 12 Theme: Knowledge and Knower "Is Bias Inevitable in The Production of Knowledge?"Arham ShahNoch keine Bewertungen

- Lead The Competition: Latest Current AffairsDokument12 SeitenLead The Competition: Latest Current AffairsSagarias AlbusNoch keine Bewertungen

- 1.1 Cce To Proof of Cash Discussion ProblemsDokument3 Seiten1.1 Cce To Proof of Cash Discussion ProblemsGiyah UsiNoch keine Bewertungen

- Wrongful ForeclosureDokument8 SeitenWrongful Foreclosurefaceoneoneoneone100% (2)

- Hilti 2016 Company-Report ENDokument72 SeitenHilti 2016 Company-Report ENAde KurniawanNoch keine Bewertungen

- British Airways Vs CADokument17 SeitenBritish Airways Vs CAGia DimayugaNoch keine Bewertungen

- ACCT1501 MC Bank QuestionsDokument33 SeitenACCT1501 MC Bank QuestionsHad0% (2)

- China Bank v. City of ManilaDokument10 SeitenChina Bank v. City of ManilaCharles BusilNoch keine Bewertungen

- NRes1 Work Activity 1 - LEGARTEDokument4 SeitenNRes1 Work Activity 1 - LEGARTEJuliana LegarteNoch keine Bewertungen

- Aircraft FatigueDokument1 SeiteAircraft FatigueSharan RajNoch keine Bewertungen

- Assets Misappropriation in The Malaysian Public AnDokument5 SeitenAssets Misappropriation in The Malaysian Public AnRamadona SimbolonNoch keine Bewertungen

- 45-TQM in Indian Service Sector PDFDokument16 Seiten45-TQM in Indian Service Sector PDFsharan chakravarthyNoch keine Bewertungen

- Financial Management: Usaid Bin Arshad BBA 182023Dokument10 SeitenFinancial Management: Usaid Bin Arshad BBA 182023Usaid SiddiqueNoch keine Bewertungen

- UntitledDokument18 SeitenUntitledjake ruthNoch keine Bewertungen

- Eve Berlin PDFDokument2 SeitenEve Berlin PDFJeffNoch keine Bewertungen

- Social Dimensions OF EducationDokument37 SeitenSocial Dimensions OF Educationjorolan.annabelleNoch keine Bewertungen

- Names of PartnerDokument7 SeitenNames of PartnerDana-Zaza BajicNoch keine Bewertungen

- Corporate Social Responsibility (CSR) in GrameenphoneDokument7 SeitenCorporate Social Responsibility (CSR) in GrameenphoneAfrina KarimNoch keine Bewertungen

- Case 1. Is Morality Relative? The Variability of Moral CodesDokument2 SeitenCase 1. Is Morality Relative? The Variability of Moral CodesalyssaNoch keine Bewertungen

- My Portfolio: Marie Antonette S. NicdaoDokument10 SeitenMy Portfolio: Marie Antonette S. NicdaoLexelyn Pagara RivaNoch keine Bewertungen

- Final Technical Documentation: Customer: Belize Sugar Industries Limited BelizeDokument9 SeitenFinal Technical Documentation: Customer: Belize Sugar Industries Limited BelizeBruno SamosNoch keine Bewertungen

- Viking Solid Cone Spray NozzleDokument13 SeitenViking Solid Cone Spray NozzlebalaNoch keine Bewertungen

- Crisis Communications: Steps For Managing A Media CrisisDokument15 SeitenCrisis Communications: Steps For Managing A Media Crisismargarita BelleNoch keine Bewertungen

- 2.1 Song of The Open RoadDokument10 Seiten2.1 Song of The Open RoadHariom yadavNoch keine Bewertungen

- Witherby Connect User ManualDokument14 SeitenWitherby Connect User ManualAshish NayyarNoch keine Bewertungen

- JAR66Dokument100 SeitenJAR66Nae GabrielNoch keine Bewertungen

- Estimating Guideline: A) Clearing & GrubbingDokument23 SeitenEstimating Guideline: A) Clearing & GrubbingFreedom Love NabalNoch keine Bewertungen