Beruflich Dokumente

Kultur Dokumente

Levelstate - DWLG

Hochgeladen von

Dramebaaz SandeepCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Levelstate - DWLG

Hochgeladen von

Dramebaaz SandeepCopyright:

Verfügbare Formate

COLOUR PORT

DIRECT WATER LEVEL GAUGE

Levelstate Solution at all levels

Levelstate

Levelstate provides SOLUTION AT ALL LEVELS for steam

generating plants. Products manufactured are Colour Port Type

Direct Water Level Gauges (DWLG), Electronic Drum Level

Indicators (EDLI) and Electronic Level Switches (ELS).

The guiding philosophy of reliability and user friendly design has

made Levelstate a successful business entity. The user base includes

Power, Petrochemicals, Refinery, Fertiliser, Sugar, Paper, Cement,

Metallurgical and Chemical industries in various countries across

the globe.

Various international agencies have approved Levelstate products.

The quality system has been accredited ISO 9001. All Levelstate

products are also available with CE mark.

With professional marketing efficiency and on-time service delivery,

Levelstate assures its customers value for money. Factory trained

engineers are available on call to provide diagnostic assistance,

pre-engineering support, installation and commissioning services.

COLOUR PORT TYPE LEVEL GAUGE

Levelstate Colour Port Type Direct Water Level Gauges (DWLG) provide a direct reading of the water level and are suitable

for steam/water applications. Levelstate gauges are reliable and maintenance free thereby minimising operating costs

for the user.

Operating Principle

Colour port type direct water level gauges operate on the principle of the differences in refractive index of different

mediums (steam and water) for level indication. The gauge consists of a vertically oriented metal body with a toughened

glass to the front and the rear. The front and rear body surfaces are in non-parallel vertical planes. Behind the gauge body

are light sources - red and green in the illuminator.

When light passes through water, it gets refracted at an angle of approximately 10o. The convex lenses converges the

light sources such that for ports submerged in water, a GREEN indication is observed in the Illuminator viewing panel

and for ports that are not submerged in water, a RED indication is observed.

Figure 1 Insert

Port cover

Glass

Plano convex lens

Red light beam

Green light beam

Red light beam

Green light beam

Features

l Various levels of visibility and centre to centre distance depending on site requirement

l Stainless steel gauge body to prevent buildup of magnetic particles and welding failure

(due to carbide precipitation) thus ensuring long life

l High pressure gauge valves for isolation

l Enhanced safety through orifice spacer in the steam side and ball check valve in the water side

l Internal components specially coated for corrosion protection

l Glass protected by high quality mica

l Option of LED and Halogen illuminator

l Suitable for outdoor weather conditions

l Explosion proof (optional)

Applications

l Boiler drum

l Feedwater heater

l Deaerated feedwater storage tank

l Condenser hotwell

l HP turbine bypass drain sump

l Cold reheat drain sump Figure 2

Levelstate Solution at all levels

GAUGE TYPE 300

Figure 3

GAUGE VALVES

For compact installation &

accessibility of working parts. INSERT

Stellite seat & disc Stainless steel insert for long life, internal components

for longer life specially coated for corrosion resistance

TIE BAR GLASSES

Protected by high quality mica

For re-circulation of steam

condensate and providing VIEW PORTS

strength to the gauge Large port diameters for optimal visibility

assembly

PORT COVER BOLTING

Four bolts hold each cover solidly against the gauge body,

enables easy removal/installation of each cover and its glass

without disturbing the opposite set.

Figure 4

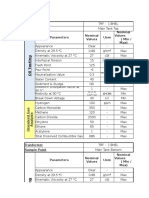

Gauge Specifications

l Upto 3000 psi / 207 bar with service temperature upto 370oC

l Gauge insert and piping manufactured from SS304/SS321 to prevent

weld failure due to carbide precipitation

l Visibility starting from 322mm

l No. of ports starting from 5

l Pitch: 75mm (optional: 65mm)

l Single or double winged to suit site requirement

l Process connections: BW/SW/Flanged options available to suit site

requirement

l Drain connection: BW/SW/Flanged options available to suit site

requirement

l Socket weld connections to ANSI B16.11

l Butt weld connections to B 16.25 or DIN 2559

l Gauge valve:

l Body in forged ASTM A105 material

l Solid stellite seat and disc

l Naval brass yoke nuts to avoid ceasing at elevated temperature

l Stems - grounds are nitrided to ensure long packing life AISI 420/1.4021

l Accessories - ball check valve, orifice spacer, drain valve, vent valve

Levelstate Solution at all levels

HP Gauge configurations

(For ordering, please refer to the gauge code sheet)

L1 L3 L5 L7 L9

L2 L4 L6 L8 L10

Accessories

Ball Check Valve Drain/Vent Valve Orifice Spacer

BALL CHECK VALVE ORIFICE SPACER

Ball Check Valve is installed on the water leg of the If the Ball Check Valve is installed on both the steam

gauge glass. Its function is to stop flow of steam/water and the water legs, then in the event of glass breakage,

instantaneously in the event of gauge glass breakage, complete flow of steam/water to the gauge is stopped

thereby preventing any chance of injury to the service making it will be impossible for the service personnel

personnel. If the glass breaks, the pressure on the gauge to confirm whether there is any glass breakage or not.

side becomes less than that of the drum side resulting To avoid this the Orifice Spacer is installed on the steam

in heavy flow of water from drum to gauge. This flow leg which allows the low pressure steam to come out

lifts the ball in the valve and places it in the ball seat of the breakage point helping the personnel to identify

instantantly stopping the water flow. and locate the failure without safety hazard.

Levelstate Solution at all levels

ILLUMINATOR

Figure 5

LED Illuminator Specifications

l LED technology

l Modular design

l Indoor/outdoor application

l IP65 protection

l No. of ports starting from 5

l High temperature resistant powder coated

MS body (Optional : Electro-polished SS body)

l Rating: 60mA per LED unit

l Power supply : 12V DC through powerpack

(input supply 85-264V AC, output 12V DC)

l Viewing hood (optional)

l Explosion proof (optional)

Halogen Illuminator Specifications

l Reflector type halogen spot lamp

l Modular design

l Indoor / Shaded application

l IP44 protection

l Self ventilated - natural draught cooling

l No. of ports: starting from 5

l High temperature resistant powder coated MS body

l Rating: 20W/12V per lamp

l Power supply : 12V AC through

(input supply 110V/230V AC, output 12V AC)

l Viewing hood (optional)

l Explosion proof (optional)

Figure 6

Levelstate Solution at all levels

Gauge Codification

1 Pressure Rating 4 Illuminator Type

High Pressure - 3000 psi / 207 bar Options

300 : (Standard guage consists of body, tie bar and

gauge valves) LED : LED - IP65

LEX : LED - ExD

2 Type of Guage HAL : Halogen - IP44

Options : Refer Page 3 HEX : Halogen - ExD

3 Ports 5 Special Option

Options

Options

SPL : Special option - To be specified separately

P5 : 5 Port - 322mm

P7 : 7 Port - 472mm

P9 : 9 Port - 622mm

P11 : 11 Port - 772mm

P13 : 13 Port - 922mm

Above 922mm visibility on request

Ordering Example

Designator 1 2 3 4 5

Model No.* 300 L8 P7 LED SPL

Special option

(to be specified

separately)

LED

Type of Illuminator

No. of ports-7

472mm

Double winged

with

orifice and ball

High pressure check * Incase not applicable, put XX

3000 psi

Approvals

l Quality system accredited to ISO 9001

l Design approval of pressure parts, operational and field testing of the system

l Third party inspection, testing and certification by approved international agencies

l Certification of explosion proof to international standard for use in hazardous area

Levelstate Solution at all levels

STEAM GENERATING PLANT

LEVEL MONITORING SOLUTION

Levelstate is a leading global manufacturer of level measuring equipments for steam generating

plants. Products include Colour Port Type Direct Water Level Gauge (DWLG), Electronic Drum

Level Indicator (EDLI) and Electronic Level Switch (ELS).

Applications include boiler drum, feedwater heater, deaerated feedwater storage tank, condenser

hotwell, HP turbine bypass drain sump, cold reheat drain sump among others.

For over two decades, Levelstate has been partnering with boiler OEMs and end users by

offering level indication and switching solutions.

Levelstate products are installed worldwide and are operating successfully in various industries.

Our sales & service network is spread across various countries and we are continuously looking

to expand our reach further.

We have a policy of continuous product development that aims to keep ahead of the anticipated

customer demand. Levelstate can provide innovative and cost effective solutions to customers

without any compromise on quality.

Direct Level Gauge, Drum Level Indicator and Level Switch

HP Direct Water Level Gauge Electronic Drum Level Electronic Level Switch Conductivity Probe

Indicator

Levelstate pursues a policy of continuous technical innovation and product development.

The information given in this document may change without notice. 2014

Please visit us at www.levelstate.com | Email us at info@levelstate.com

Authorised Sales Partner

Levelstate

Levelstate Systems Pvt. Ltd.

Little Kitfield, Gradwell Lane, Four Marks

Hampshire GU34 5AS, United Kindom

Tel: +44 (0) 1962 773829

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Determining The Cost of Electricity of A Natural Gas GeneratorDokument4 SeitenDetermining The Cost of Electricity of A Natural Gas Generatorfadlul akbar herfiantoNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Transformer Oil ReportDokument21 SeitenTransformer Oil ReportDramebaaz SandeepNoch keine Bewertungen

- Determining The Cost of Electricity of A Natural Gas GeneratorDokument4 SeitenDetermining The Cost of Electricity of A Natural Gas Generatorfadlul akbar herfiantoNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- System Advisor Model Report: Financial Model Performance ModelDokument3 SeitenSystem Advisor Model Report: Financial Model Performance ModelDramebaaz SandeepNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- CCTV FinalDokument28 SeitenCCTV FinalDramebaaz SandeepNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- PAS Installation ManualDokument8 SeitenPAS Installation ManualDramebaaz SandeepNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Digsi Manual XML A2 enDokument72 SeitenDigsi Manual XML A2 enLasantha GunatillakeNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- CT2 LD - R0 PDFDokument13 SeitenCT2 LD - R0 PDFDramebaaz SandeepNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Comm Cir 275Dokument35 SeitenComm Cir 275Dramebaaz SandeepNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Siemens - Applications For SIPROTEC Protection RelaysDokument228 SeitenSiemens - Applications For SIPROTEC Protection RelaysFabien Massenet100% (2)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Approved DRGDokument4 SeitenApproved DRGDramebaaz SandeepNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- 7SG15 MicroTAPP Complete Technical ManualDokument104 Seiten7SG15 MicroTAPP Complete Technical ManualDramebaaz SandeepNoch keine Bewertungen

- MAH Conditions of Supply 2010Dokument107 SeitenMAH Conditions of Supply 2010kunalprasadNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- 4000A - 2x100x12mm - CU (OPEN D)Dokument4 Seiten4000A - 2x100x12mm - CU (OPEN D)Dramebaaz SandeepNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Fema SteelDokument315 SeitenFema SteelKakaNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- ABB XLPE Cable Systems Users Guide Rev 3Dokument28 SeitenABB XLPE Cable Systems Users Guide Rev 3vijaypshindeNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- F0126405 PB OLTCsDokument24 SeitenF0126405 PB OLTCsDEADMANNoch keine Bewertungen

- PCM600 2.8 ReadMeDokument3 SeitenPCM600 2.8 ReadMeDramebaaz SandeepNoch keine Bewertungen

- 7.4 Tower Design: Bracing SystemsDokument49 Seiten7.4 Tower Design: Bracing SystemsBoisterous_Girl100% (1)

- Rules of Thumb For Steel StructuresDokument5 SeitenRules of Thumb For Steel StructuresLincs lincoln100% (1)

- PCM600 28 Ig 756450 EnpDokument2 SeitenPCM600 28 Ig 756450 EnpDramebaaz SandeepNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- SIPROTEC Case Studies For Protective Relaying and Power QualityDokument94 SeitenSIPROTEC Case Studies For Protective Relaying and Power QualityFabien Massenet100% (1)

- 10M15 FDN Pass 01 R0Dokument10 Seiten10M15 FDN Pass 01 R0Dramebaaz SandeepNoch keine Bewertungen

- Tutorials 3DDokument159 SeitenTutorials 3DDramebaaz SandeepNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- HT Panel IncomerFlangeDetailsDokument1 SeiteHT Panel IncomerFlangeDetailsDramebaaz SandeepNoch keine Bewertungen

- Fema SteelDokument315 SeitenFema SteelKakaNoch keine Bewertungen

- Po Masstech PDFDokument4 SeitenPo Masstech PDFDramebaaz SandeepNoch keine Bewertungen

- Short Circuit Calculation GuideDokument5 SeitenShort Circuit Calculation Guideashok203Noch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- C&R Panel (Without Automation) - Nov, 2016Dokument73 SeitenC&R Panel (Without Automation) - Nov, 2016Dramebaaz SandeepNoch keine Bewertungen

- Rudolf CT ScanDokument8 SeitenRudolf CT Scanerkamlakar2234Noch keine Bewertungen

- JPCL - TaqiDokument22 SeitenJPCL - TaqiAsad UllahNoch keine Bewertungen

- Q A BoilerDokument19 SeitenQ A Boilerlavpandey8719Noch keine Bewertungen

- Water Handbook - Boiler Blowdown Control - VeoliaDokument8 SeitenWater Handbook - Boiler Blowdown Control - Veoliaحسين مهديNoch keine Bewertungen

- CARRAGA Region. We Select To Build Our Steam Power Plant in Agusan Del Norte and OurDokument44 SeitenCARRAGA Region. We Select To Build Our Steam Power Plant in Agusan Del Norte and OurEngelbert AntodNoch keine Bewertungen

- DEAERATORDokument32 SeitenDEAERATORJagadeesan Sai100% (2)

- Vitec 2000 Antiscalant Datasheet LDokument1 SeiteVitec 2000 Antiscalant Datasheet LChevronelleNoch keine Bewertungen

- Boiler Hydro TestDokument35 SeitenBoiler Hydro TestMoez HamoudiNoch keine Bewertungen

- Condenser PerformanceDokument23 SeitenCondenser PerformanceShambhu MehtaNoch keine Bewertungen

- General - NSTM Publications Index and User Guide: S9086-AA-STM-010/CH-001R46Dokument24 SeitenGeneral - NSTM Publications Index and User Guide: S9086-AA-STM-010/CH-001R46Theodore TsirosNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- About Us: Financial InformationDokument18 SeitenAbout Us: Financial InformationThe SainikNoch keine Bewertungen

- Generation Transmission and Distribution Notes.Dokument88 SeitenGeneration Transmission and Distribution Notes.Abhishek NirmalkarNoch keine Bewertungen

- Boiler Preservation Methods Dry and WetDokument14 SeitenBoiler Preservation Methods Dry and WetTin Aung KyiNoch keine Bewertungen

- PDS Total Guard 16B14 ENDokument2 SeitenPDS Total Guard 16B14 ENhai phanNoch keine Bewertungen

- Reducing Boiler Fuel CostsDokument4 SeitenReducing Boiler Fuel Costsbonginkosi mathunjwaNoch keine Bewertungen

- AP1000 Plant DescriptionDokument31 SeitenAP1000 Plant DescriptionAsier DCNoch keine Bewertungen

- Reducing Corrosion and Potential Boiler Failure With Superior Iron Transport TechnologyDokument46 SeitenReducing Corrosion and Potential Boiler Failure With Superior Iron Transport TechnologymnasiroleslamiNoch keine Bewertungen

- Maharashtra Boiler Rules 1962Dokument34 SeitenMaharashtra Boiler Rules 1962rbdubey2020Noch keine Bewertungen

- How To Trap: Shell and Tube Heat ExchangersDokument14 SeitenHow To Trap: Shell and Tube Heat ExchangersBehroozRaadNoch keine Bewertungen

- Boiler Feed Water CalculationDokument4 SeitenBoiler Feed Water Calculationamit_kt1973Noch keine Bewertungen

- Economiser Optimisation FH-08Dokument9 SeitenEconomiser Optimisation FH-08Martin CorkeryNoch keine Bewertungen

- 001-20160204 Boiler Efficiency PGT ProcedureDokument48 Seiten001-20160204 Boiler Efficiency PGT ProcedureK R Kumar RanjanNoch keine Bewertungen

- Fulton Steam: FB-S SeriesDokument76 SeitenFulton Steam: FB-S Seriesbth8320Noch keine Bewertungen

- BLRBAC Emergency Shutdown Procedure (February 2012)Dokument18 SeitenBLRBAC Emergency Shutdown Procedure (February 2012)SubburajMechNoch keine Bewertungen

- 启动锅炉说明书(用户)中英Dokument39 Seiten启动锅炉说明书(用户)中英Habel KusumaNoch keine Bewertungen

- Introduction To Chemical CleaningDokument28 SeitenIntroduction To Chemical Cleaningmordidomi0% (1)

- Plant Engineering: Performance Diagnostic Test Program For The Nuclear Turbine Cycle at Korea Hydro & Nuclear Power CompanyDokument54 SeitenPlant Engineering: Performance Diagnostic Test Program For The Nuclear Turbine Cycle at Korea Hydro & Nuclear Power CompanyEnrique Lopez De ArroyabeNoch keine Bewertungen

- Failure Analysis of Boiler Cold and Hot Reheater Tubes: Khalil RanjbarDokument6 SeitenFailure Analysis of Boiler Cold and Hot Reheater Tubes: Khalil RanjbarAnand VarmaNoch keine Bewertungen

- Abubakar Tafawa Balewa UniversityDokument62 SeitenAbubakar Tafawa Balewa UniversityIsrael Apeh100% (1)

- Ultra Supercritical BoilerDokument12 SeitenUltra Supercritical BoilerImteyaz AhmadNoch keine Bewertungen

- General Layout of A Thermal Power PlantDokument87 SeitenGeneral Layout of A Thermal Power PlantHarjith Vaibav100% (1)