Beruflich Dokumente

Kultur Dokumente

Sample CHP Feasability Report

Hochgeladen von

eoghan mulliganCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Sample CHP Feasability Report

Hochgeladen von

eoghan mulliganCopyright:

Verfügbare Formate

CHP FEASIBILITY STUDY - sample Table of Contents

1 EXECUTIVE SUMMARY

1.1 Clear delineation of the objective of the feasibility study.

1.2 Brief description of site, energy needs, and recommended CHP equipment

selection.

1.3 Overview of project concept and economics. Simple payback, net present value,

and/or discounted cash flow for various financial arrangements.

1.4 Recommendations and rationale.

2 DESCRIPTION OF EXISTING SITE PLAN AND EQUIPMENT

2.1 Description of existing site and major energy consuming equipment; identify

systems/equipment that could be replaced or impacted by the proposed CHP

system.

2.2 Plot plan of site and proposed location of CHP system.

2.3 Description and location of existing electric feeds, transformers, and meters

including critical parameters such as voltage.

2.4 Description and location of existing gas lines, meters, fuel storage, etc., including

critical parameters such as pressure and capacity.

2.5 Identification of any site/location constraints or restrictions (site access, adjacent

properties, noise/zoning limitations).

2.6 Site expansion plans, if applicable.

2.7 Emergency/back-up power requirements and existing generating equipment.

2.8 Review of any possible power and thermal energy sales arrangements.

3 SITE ENERGY REQUIREMENTS

3.1 Review of recent gas and electric bills.

3.2 Review of current and projected gas (or other fuel) and electric rates.

3.3 Development of average hourly use patterns for each type of energy (on a

seasonal basis if appropriate) with thermal energy uses segregated by type/quality

(e.g., temperature, pressure, form [steam, hot water, hot air]).

3.4 Tables and/or graphs showing daily and annual use profiles for each form of

energy (e.g., electric/steam/hot water/chilled water).

3.5 Breakdown of energy usage, by type of energy, for equipment that is to be

displaced by CHP.

3.6 Review of CHP analysis methodology.

3.6.1 Description of computer modeling methods used.

3.6.2 Displaced thermal loads estimates and methodology

3.6.3 Displaced electrical requirement estimates and methodology.

4 CHP EQUIPMENT SELECTION

4.1 Rationale for equipment selection.

4.1.1 Thermal output

4.1.2 Capacity

4.1.3 Emissions

4.1.4 Site constraints

4.1.5 Other

4.2 Discussion of alternative CHP system configurations

4.3 A quantitative and qualitative comparison of prime movers evaluated, including

model, kW capacity, fuel consumption comparison, seasonal performance,

electric and thermal energy displaced, sound levels, emissions, maintenance

requirements, availability/reliability, net revenue, capital cost, simple pay back,

or other profitability index used by the client.

5 DESCRIPTION OF PREFERRED CHP SYSTEM

5.1 System description prime mover, generator, heat recovery

5.2 Electric and total CHP efficiency, amount of site energy displaced

5.3 Schematic of system detailed layout

5.4 Single line diagram of thermal system

5.5 Single line diagram of electrical system.

5.6 System tie-ins

5.7 Controls and monitoring

5.8 Necessary site modifications

6 SYSTEM OPERATION

6.1 Operating hours per year.

6.2 Recommended operating profile (e.g., thermally base loaded, electric load

following, peaking).

6.3 Stand-alone (islanding) and black start capability needed?

6.3.1 Is load shedding required? If so, how is it implemented? How is

crossover accomplished?

7 REGULATORY AND PERMITTING REQUIREMENTS OVERVIEW

7.1 Review and description of emissions requirements for permitting, including

source(s) of information.

7.2 Review and description of local siting and zoning requirements.

8 TOTAL CHP SYSTEM COSTS

8.1 Total costs Summary of all inclusive or turnkey costs.

8.1.1 Capital costs - equipment

8.1.2 Installations costs engineering, construction, commissioning

8.2 Capital costs - line item breakdown of major equipment/component costs.

8.2.1 Prime mover

8.2.2 Fuel compressor (if needed)

8.2.3 Black start capability (if needed)

8.2.4 Generator

8.2.5 Heat recovery

8.2.6 Cooling tower or other heat dump

8.2.7 Site electric tie-in and grid interconnection (islanding requirements

included if needed)

8.2.8 Controls

8.2.9 Site thermal tie-in

8.2.10 Additional thermal utilization equipment (e.g., absorption chillers)

8.2.11 Other equipment/modifications

8.2.11.1 Sound attenuation

8.2.11.2 Stack

8.2.11.3 Inlet air handling

8.2.11.4 Vibration

8.2.12 Emission controls

8.3 Installation costs line-item breakdown of engineering, permitting, construction,

and contingency costs

8.3.1 Site preparation

8.3.2 Buildings (if needed)

8.3.3 Materials

8.3.4 Engineering

8.3.5 Construction

8.3.6 Permitting fees

8.3.7 Contingency

9 Non-fuel O&M costs (fixed and variable) details on maintenance costs for major

system components and site interfaces; information on costs of turnkey versus self-

maintenance, and major maintenance/overhaul items and schedule

9.1 Prime mover

9.2 Heat recovery equipment

9.3 Thermal utilization equipment

9.4 Emissions control

10 PROJECT SCHEDULING-BREAKDOWN OF EACH PHASE (should include major

subcategories or elements)

10.1 Purchase of equipment.

10.2 Construction

10.3 Permitting

10.4 Commissioning

11 ASSUMPTIONS FOR CASH FLOW ANALYSIS

11.1 Financing options and assumptions

11.1.1 Debt/equity ratio

11.1.2 Discount rate

11.1.3 Interest rate/Cost of debt

11.1.4 Tax rate

11.2 Total installed costs

11.2.1 CHP equipment and installation from Section 8 above

11.2.2 Any capital credit for displaced equipment purchases

11.3 Operation and maintenance

11.3.1 Self maintained

11.3.2 Supplier/vendor maintenance contract

11.4 Fuel and electric rates

11.4.1 Based on detailed tariffs/rates

11.4.1.1 Electric customer charge, demand charge, commodity

charge; peak, off-peak, shoulder

11.4.1.2 Gas commodity, delivery

11.4.2 Provide fuel/electric escalation rates assumed for outyears.

11.4.3 Review any changes to tariffs due to CHP

11.4.3.1 Supplemental electric tariffs

11.4.3.2 Standby rates/exit fees

11.4.3.3 Gas incentive rates

11.5 Any additional costs or credits

11.5.1 Incentives

11.5.2 Value of reliability

11.5.2.1 Cost of facility outages and value of increased power

reliability

11.5.3 Other benefits that can be monetized or assigned value

11.5.3.1 Emission credits

11.5.3.2 Other

11.6 Sensitivity analysis impact of varying:

11.6.1 Fuel costs

11.6.2 Electric rates

11.6.3 Incentives

11.6.4 CHP system availability (impact of CHP outages)

12 DISCOUNTED CASH FLOW ANALYSIS FOR PREFERRED SYSTEM

13 APPENDICES

13.1 Engineering calculations

13.2 Copies of appropriate regulations

13.3 Vendors brochures

13.4 Other pertinent information

Das könnte Ihnen auch gefallen

- Sample CHP Feasibility Study 080405Dokument49 SeitenSample CHP Feasibility Study 080405Muhammad Junaid Anjum100% (1)

- ThermoeconomicAnalysis & DesignOfDomesticRefrigerationSystems PDFDokument8 SeitenThermoeconomicAnalysis & DesignOfDomesticRefrigerationSystems PDFWilliam RuizNoch keine Bewertungen

- I. Principles of Wind EnergyDokument3 SeitenI. Principles of Wind EnergyJohn TauloNoch keine Bewertungen

- Composite WallDokument6 SeitenComposite WallRushabh PatelNoch keine Bewertungen

- Heat Transfer Lab 1 PDFDokument10 SeitenHeat Transfer Lab 1 PDFPeter LauNoch keine Bewertungen

- Wheel N AxleDokument11 SeitenWheel N AxleCarey FernandesNoch keine Bewertungen

- Epm AssignmentDokument20 SeitenEpm AssignmentRahulNoch keine Bewertungen

- Project Sky TaxiDokument23 SeitenProject Sky TaxiSahilNoch keine Bewertungen

- Optimization An Important Stage of Engineering DesignDokument8 SeitenOptimization An Important Stage of Engineering DesignCharlene BillonesNoch keine Bewertungen

- Lecture 26 Thermal Engineering II (03.09.2020)Dokument43 SeitenLecture 26 Thermal Engineering II (03.09.2020)Dr. BIBIN CHIDAMBARANATHANNoch keine Bewertungen

- Project-7 Design of A Connecting RodDokument9 SeitenProject-7 Design of A Connecting Rodhitesh reddyNoch keine Bewertungen

- Practical 10 - Shear CentreDokument4 SeitenPractical 10 - Shear CentreTbyTanNoch keine Bewertungen

- STUCOR Aucr2017 PDFDokument74 SeitenSTUCOR Aucr2017 PDFksbalajiautNoch keine Bewertungen

- (M2-LAB) Lab Activity 2 - The DC Shunt Generator and MotorDokument10 Seiten(M2-LAB) Lab Activity 2 - The DC Shunt Generator and MotorCarlo TabalanzaNoch keine Bewertungen

- 17chp06 Process Heat Transfer LabDokument50 Seiten17chp06 Process Heat Transfer LabpandianvijaybharathiNoch keine Bewertungen

- Stabilizzatori Anti RollDokument47 SeitenStabilizzatori Anti RollSabrinaFuschettoNoch keine Bewertungen

- Compression Test Lab ReportDokument11 SeitenCompression Test Lab ReportRobert K OtienoNoch keine Bewertungen

- Assignment 2: Hands On at The Petroleum Laboratory: (Oil Distillation of RON97 Sample According To ASTM Method)Dokument16 SeitenAssignment 2: Hands On at The Petroleum Laboratory: (Oil Distillation of RON97 Sample According To ASTM Method)Siti Hajar MohamedNoch keine Bewertungen

- Applications of Software in Solar Drying Systems A ReviewDokument12 SeitenApplications of Software in Solar Drying Systems A ReviewGianCarlo Espinoza ParionaNoch keine Bewertungen

- Experiment Instructions: CE 283 Drum Cell FilterDokument20 SeitenExperiment Instructions: CE 283 Drum Cell Filternash2000Noch keine Bewertungen

- Watermill To Microhydropower - EthiopiaDokument28 SeitenWatermill To Microhydropower - Ethiopiafrezer_awolNoch keine Bewertungen

- Modelling Ngong River Final Project 2010Dokument109 SeitenModelling Ngong River Final Project 20101man1bookNoch keine Bewertungen

- MMT I Lab#07Dokument5 SeitenMMT I Lab#07Abdul WahabNoch keine Bewertungen

- High Frequency Transformers For DC-DC ConvertersDokument6 SeitenHigh Frequency Transformers For DC-DC ConvertersÄlî VàráNoch keine Bewertungen

- Advance Fluid Lab ManualDokument55 SeitenAdvance Fluid Lab ManualchristianNoch keine Bewertungen

- WL377e - Natural Convection and Radiation - V0.1Dokument49 SeitenWL377e - Natural Convection and Radiation - V0.1Petrônio PauloNoch keine Bewertungen

- Rail Bhawan ReportDokument34 SeitenRail Bhawan ReportNikhil MohiteNoch keine Bewertungen

- Differential Transformation Method for Mechanical Engineering ProblemsVon EverandDifferential Transformation Method for Mechanical Engineering ProblemsNoch keine Bewertungen

- Thermo Fluid Lab Manual PDFDokument92 SeitenThermo Fluid Lab Manual PDFaben777Noch keine Bewertungen

- Lean Six Sigma Project - Abhishta - BehrDokument16 SeitenLean Six Sigma Project - Abhishta - BehrAbhishta SharmaNoch keine Bewertungen

- (Estrera Final Papers) YAHOODokument95 Seiten(Estrera Final Papers) YAHOOJohn Mark CarpioNoch keine Bewertungen

- Diesel Cycle: P-V Diagram T-S DiagramDokument3 SeitenDiesel Cycle: P-V Diagram T-S DiagramJJ100% (1)

- Power Generation PDFDokument59 SeitenPower Generation PDFyasin100% (1)

- Determing Heat Transfer of CansDokument7 SeitenDeterming Heat Transfer of CanslongNoch keine Bewertungen

- Discussion Shell and TubeDokument3 SeitenDiscussion Shell and TubeFarhah AinNoch keine Bewertungen

- Corrected Experiment Impulse Turbine PDFDokument12 SeitenCorrected Experiment Impulse Turbine PDFAlvi RahmanNoch keine Bewertungen

- Introduction To Measurement SystemsDokument21 SeitenIntroduction To Measurement SystemsAkash JamesNoch keine Bewertungen

- Induction Generators With Squirrel-Cage Rotors Used in Wind TurbinesDokument11 SeitenInduction Generators With Squirrel-Cage Rotors Used in Wind TurbinesFitiu IoanNoch keine Bewertungen

- Experiment No.5 Forced Convection: Heat Transfer Laboratory (MECH3123)Dokument6 SeitenExperiment No.5 Forced Convection: Heat Transfer Laboratory (MECH3123)Raj PratyushNoch keine Bewertungen

- InsulationDokument23 SeitenInsulationcm10edNoch keine Bewertungen

- Mechanical Engineering - Course CurriculumDokument539 SeitenMechanical Engineering - Course CurriculumwnaickerNoch keine Bewertungen

- Experimental Thermodynamics: Experimental Thermodynamics of Non-Reacting FluidsVon EverandExperimental Thermodynamics: Experimental Thermodynamics of Non-Reacting FluidsB. Le NeindreNoch keine Bewertungen

- g3 Thermodynamics ExperimentsDokument42 Seiteng3 Thermodynamics Experimentsarda Максим50% (2)

- Instruction Manual: WL 230 Condensation ProcessDokument48 SeitenInstruction Manual: WL 230 Condensation ProcessSaba ArifNoch keine Bewertungen

- Renewable Energy Engineering: Solar, Wind, Biomass, Hydrogen and Geothermal Energy SystemsVon EverandRenewable Energy Engineering: Solar, Wind, Biomass, Hydrogen and Geothermal Energy SystemsNoch keine Bewertungen

- RacDokument26 SeitenRacgurunakhale123Noch keine Bewertungen

- CELCHA2 Study GuidesDokument7 SeitenCELCHA2 Study GuidesEsther100% (1)

- Machine Design Lab ManualDokument28 SeitenMachine Design Lab ManualEr Raghvendra Singh100% (1)

- Nanocraft - An Aircraft WithDokument6 SeitenNanocraft - An Aircraft WithiaetsdiaetsdNoch keine Bewertungen

- Proposal Lab Thermo Topic 2 COMPLETEDokument10 SeitenProposal Lab Thermo Topic 2 COMPLETEsaperuddinNoch keine Bewertungen

- Optimal Rotor Tip Speed RatioDokument10 SeitenOptimal Rotor Tip Speed RatioHaposan YogaNoch keine Bewertungen

- Mohd Fadhil Musbah FYP Interim Report UTPDokument16 SeitenMohd Fadhil Musbah FYP Interim Report UTPMohd Fadhil Musbah0% (1)

- Literature Review Spur GearDokument3 SeitenLiterature Review Spur Gearthai avvaiNoch keine Bewertungen

- Department of Mechanical Engineering: Machine Design & CAD-II Lab (MEEN-3238)Dokument11 SeitenDepartment of Mechanical Engineering: Machine Design & CAD-II Lab (MEEN-3238)Sarmad HafeezNoch keine Bewertungen

- Heat Engine-GTU-Sem-1Dokument78 SeitenHeat Engine-GTU-Sem-1Khushank MNoch keine Bewertungen

- Advanced Turbo MachineryDokument2 SeitenAdvanced Turbo Machineryjvinod2025Noch keine Bewertungen

- Boiler Automation Using Programmable Logic ControlDokument29 SeitenBoiler Automation Using Programmable Logic Controlx-robot78% (9)

- Integrated Renewable Energy for Rural Communities: Planning Guidelines, Technologies and ApplicationsVon EverandIntegrated Renewable Energy for Rural Communities: Planning Guidelines, Technologies and ApplicationsNoch keine Bewertungen

- Ref1 - l2Dokument15 SeitenRef1 - l2eoghan mulliganNoch keine Bewertungen

- Reflective Practise - Some GuidelinesDokument1 SeiteReflective Practise - Some Guidelineseoghan mulliganNoch keine Bewertungen

- EKC 291 9 Heat ConductionDokument11 SeitenEKC 291 9 Heat ConductionLia HolmanNoch keine Bewertungen

- Renewable Energy in Ireland 2013 UpdateDokument64 SeitenRenewable Energy in Ireland 2013 Updateeoghan mulliganNoch keine Bewertungen

- Fundamentals of MarketingDokument4 SeitenFundamentals of Marketingram lalNoch keine Bewertungen

- WP 1 B&eDokument17 SeitenWP 1 B&eeoghan mulliganNoch keine Bewertungen

- Energy SystemsDokument26 SeitenEnergy Systemseoghan mulligan0% (1)

- Energy Systems - Fuel CellDokument15 SeitenEnergy Systems - Fuel Celleoghan mulliganNoch keine Bewertungen

- Energy Systems - Fuel CellDokument15 SeitenEnergy Systems - Fuel Celleoghan mulliganNoch keine Bewertungen

- Energy Systems - Wind FarmDokument11 SeitenEnergy Systems - Wind Farmeoghan mulliganNoch keine Bewertungen

- Random PDFDokument52 SeitenRandom PDFeoghan mulliganNoch keine Bewertungen

- Random PDFDokument52 SeitenRandom PDFeoghan mulliganNoch keine Bewertungen

- Cash Flow Analysis (Assumptions) : 2. Debt/ Equity RatioDokument5 SeitenCash Flow Analysis (Assumptions) : 2. Debt/ Equity Ratioeoghan mulliganNoch keine Bewertungen

- WP 1 B&eDokument17 SeitenWP 1 B&eeoghan mulliganNoch keine Bewertungen

- CHP Performance Thesis PDFDokument113 SeitenCHP Performance Thesis PDFeoghan mulliganNoch keine Bewertungen

- CHP Performance Thesis PDFDokument113 SeitenCHP Performance Thesis PDFeoghan mulliganNoch keine Bewertungen

- CHP Equipment and Installation From Section 8-2Dokument2 SeitenCHP Equipment and Installation From Section 8-2eoghan mulliganNoch keine Bewertungen

- Total DocumentDokument39 SeitenTotal Documenteoghan mulliganNoch keine Bewertungen

- Steady Flow Energy EquationDokument4 SeitenSteady Flow Energy Equationeoghan mulliganNoch keine Bewertungen

- Report Template - GuideDokument10 SeitenReport Template - Guideeoghan mulliganNoch keine Bewertungen

- GFM Technical ManualDokument14 SeitenGFM Technical ManualsaeedNoch keine Bewertungen

- Xenturic Engineering ProfileDokument47 SeitenXenturic Engineering ProfileOsiNoch keine Bewertungen

- TsiDokument8 SeitenTsiGeorge Van BommelNoch keine Bewertungen

- Fundamentals of Gas Meter StationsDokument6 SeitenFundamentals of Gas Meter StationsRachel BaileyNoch keine Bewertungen

- Financial Information Memorandum GSPC Gas Company Limited: (Strictly Private & Confidential)Dokument97 SeitenFinancial Information Memorandum GSPC Gas Company Limited: (Strictly Private & Confidential)AbhishekKumarNoch keine Bewertungen

- New Research ReportDokument4 SeitenNew Research ReportRaviNoch keine Bewertungen

- IsolatorDokument10 SeitenIsolatorsarkar1981Noch keine Bewertungen

- Go GreenBOV Was Started in 2007 of ACTD To Reduce IndiaDokument85 SeitenGo GreenBOV Was Started in 2007 of ACTD To Reduce IndiaNagarjuna ReddyNoch keine Bewertungen

- Boiler ManufacturerDokument7 SeitenBoiler ManufacturerHARSH PUNMIYANoch keine Bewertungen

- How To Set Barrel Zone Temps - Plastics TechnologyDokument5 SeitenHow To Set Barrel Zone Temps - Plastics TechnologyNitin PatilNoch keine Bewertungen

- Pub004 001 00 - 0508Dokument16 SeitenPub004 001 00 - 0508deppmarkNoch keine Bewertungen

- MERALCODokument6 SeitenMERALCOJiny BautistaNoch keine Bewertungen

- FinalDokument19 SeitenFinalHimika MahajanNoch keine Bewertungen

- Explosives - ANFO (Ammonium Nitrate - Fuel Oil)Dokument3 SeitenExplosives - ANFO (Ammonium Nitrate - Fuel Oil)Mithelesh Purohit100% (1)

- Shriram Pistons & Rings Ltd.Dokument12 SeitenShriram Pistons & Rings Ltd.Vibhor AgnihotriNoch keine Bewertungen

- 5 Day EnMS LAC BrochureDokument4 Seiten5 Day EnMS LAC BrochureintertekmoodyNoch keine Bewertungen

- Enron Scandal - Summary, Explained, History, & Facts - BritannicaDokument4 SeitenEnron Scandal - Summary, Explained, History, & Facts - BritannicaElleNoch keine Bewertungen

- 090 R01Dokument72 Seiten090 R0118085012Noch keine Bewertungen

- Certificado - Inversor SMA SunnyBoy-fusionadoDokument32 SeitenCertificado - Inversor SMA SunnyBoy-fusionadoAlondra AlcazarNoch keine Bewertungen

- Norms For Installation of FGD PDFDokument5 SeitenNorms For Installation of FGD PDFRinjumon RinjuNoch keine Bewertungen

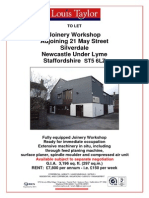

- Joinery Workshop Adjoining 21 May Street Silverdale Newcastle Under Lyme StaffordshireDokument3 SeitenJoinery Workshop Adjoining 21 May Street Silverdale Newcastle Under Lyme StaffordshireBanacu DanielNoch keine Bewertungen

- Choosing The Right PV VoltageDokument1 SeiteChoosing The Right PV Voltagedabs_orangejuiceNoch keine Bewertungen

- 2016CompositeList Web 127 PDFDokument1 Seite2016CompositeList Web 127 PDFAnuranjanNoch keine Bewertungen

- Ultima X Series EC Declaration of ConformityDokument8 SeitenUltima X Series EC Declaration of ConformityRahul DevaNoch keine Bewertungen

- Surge AnalysisDokument4 SeitenSurge Analysischandraprakashhh100% (2)

- Modul Skor A+ Fizik JPNS 2014 - Elektromagnet - SkemaDokument6 SeitenModul Skor A+ Fizik JPNS 2014 - Elektromagnet - SkemaCikita IsmailNoch keine Bewertungen

- V D43 K 1801A 0002 - P&I Diagram LegendDokument2 SeitenV D43 K 1801A 0002 - P&I Diagram LegendkhsaeedNoch keine Bewertungen

- Developing Strategy For Solar Panel Package Business in KupangDokument3 SeitenDeveloping Strategy For Solar Panel Package Business in KupangQuicksilver 1975Noch keine Bewertungen

- Power Shoe: Itzá Linares Brayam Ayala Jhon Vidal Wendy SuarezDokument12 SeitenPower Shoe: Itzá Linares Brayam Ayala Jhon Vidal Wendy Suarezitza linaresNoch keine Bewertungen

- Camelina: Biofuel For Thought: With Alternative Energy in The Arkansas DeltaDokument2 SeitenCamelina: Biofuel For Thought: With Alternative Energy in The Arkansas DeltaMaj M NazzNoch keine Bewertungen