Beruflich Dokumente

Kultur Dokumente

b412hp Ec-Gpa Normal Check List

Hochgeladen von

Edgar Muñoz FernándezOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

b412hp Ec-Gpa Normal Check List

Hochgeladen von

Edgar Muñoz FernándezCopyright:

Verfügbare Formate

EC-GPA

36071

NORMAL CHECK - LIST: BELL 412 HP

Esta lista de comprobaciones/acciones forma parte de la

documentacin del H/C y debe estar a bordo en todo momento.

Se deber usar en todas las fases del vuelo descritas en la misma,

en los helicpteros operados por INAER HELICPTEROS, SA.

NOTAS

PF (Piloto que vuela)

PNF (Piloto que no vuela)

Ambos Pilotos

Pueden realizarse los tems marcados de forma anticipada,

dejando la cabina preparada para una puesta en marcha corta

Se realiza en el primer vuelo del da.

Son limitaciones, comprobaciones/acciones

que deben conocerse de memoria.

Corresponde a datos/limitaciones importantes.

Significa que hay que comprobar antes de cada vuelo.

INDICE NORMAL CHECK LIST

INDICE PAG. 1

INTERIOR CHECK PAG. 2

ENGINE PRE-START CHECK PAG. 3

ENGINE START PAG. 3

ENGINE POST START PAG. 4

ENGINE FAILS TO START PAG. 4

DRY MOTORING RUN PAG. 4

SYSTEMS CHECK PAG. 5

BEFORE TAKE OFF PAG. 5

TAKE OFF PAG. 6

IN-FLIGHT OPERATIONS PAG. 6

DESCENT AND LANDING PAG. 6

AFTER LANDING PAG. 6

ENGINE SHUTDOWN PAG. 7

WEIGHT&FUEL PAG. 8

EFFECTIVE PAGES PAG. 9

PAG. 1 DE 9 EC-GPA 36071

PNF PF RMK INTERIOR CHECK

Cabin interior Cleanliness and security of equipment.

Cargo and baggage (if applicable) Check security.

Protective breathing equipment (if installed) Condition and properly serviced.

Passenger doors Secured.

Seat and pedals Adjust

Seat belt and shoulder harness Fasten and adjust.

Shoulder harness inertia reel and lock Check.

Directional control pedals Check freedom of movement. Position for

engine start.

Flight controls Position for start, friction as desired.

Transmission chip detector indicators Check, reset if required.

Lower pedestal circuit breakers IN.

Collective control head switches OFF.

COMPASS CONTROL panel switches MAG.

Radio equipment OFF.

FUEL INTCOM switch NORM.

FUEL TRANS switches OFF.

BOOST PUMP switches OFF.

FUEL XFEED switch NORM.

ENG 1 and ENG 2 FUEL switches OFF.

PART SEP switches NORM

ENG 1 and ENG 2 GOV switches AUTO

HYDR SYS NO. 1 and NO. 2 switches ON.

STEP switch (if installed) As desired.

ROTOR rpm AUDIO SWITCH Spring loaded to AUDIO.

FORCE TRIM switch ON, cover down.

Instruments Static check.

STATIC SOURCE switch (if installed) PRI.

APPROACH PLATE AND MAP LIGHT knob(s) OFF.

AUX SYS PITOT and STATIC switches (if inst) NORM.

Altimeter(s) Set.

FIRE EXT switch OFF.

FIRE PULL handles IN (forward).

AFT DOME LIGHT rheostat and switch OFF.

PITOT STATIC HEATERS switch OFF.

WIPER select switches OFF.

CARGO RELEASE switch (if installed) OFF.

HEATER switch OFF.

AFT OUTLET switch OFF.

VENT BLOWER switch OFF.

EMERG LT switch (if installed) DISARM.

STBY ATT switch (if installed) ON; check standby attitude indicator

lighting illuminates and OFF flag retracts

momentarily, then switch OFF.

Overhead circuit breakers IN.

All LT rheostats OFF.

UTILITY LIGHT (step light) switch OFF.

POSITION light OFF.

ANTI COLL light ON.

EMER LOAD switch NORMAL.

NON-ESNTL BUS switch Spring loaded to NORMAL.

INV 1 and 2 switches OFF.

GEN 1 and 2 switches OFF.

PAG. 2 DE 9 EC-GPA 36071

PNF PF RMK ENGINE PRE-START CHECK

External power (if used) CONNECT, (EXTERNAL POWER)

(1000 AMPS MAX. AND 271 VDC)

BATTERY BUS 1 BUS 2 switches ON. (Check BATTERY light illuminates).

Test operate all lights if night flight. Use external power or during engine runup

ROTOR BRAKE lights TEST.

FIRE 1 and 2 lights test-button Press to test.

BAGGAGE FIRE light test-button Press to test.

OVER TORQ light Press to test.

CYC CTR lights Press to test.

Caution panel TEST switch PNL then LT.

Caution panel RESET button Press.

INV 1 switch ON.

INV 1 switch OFF

INV 2 switch ON.

INV 1 switch ON.

FUEL SYS test switch FWD TANK, then MID TANK.

FUEL SYS DIGITS TEST button Press.

Clock Set and running.

ENGINE START (1)

Throttles Rotate.

RPM INC/DCR switch DECR for 8 seconds.

ENG FUEL TRANS switch ON.

ENG BOOST PUMP switch ON.

ENG FUEL switch ON.

ENG FUEL PRESS indicator check.

Rotor Clear.

START switch ENG position.

ENG OIL pressure Indicating.

Eng throttle Open to idle at 12% N1 minimum.

ENG ITT Monitor.

Collective pitch Ensure in full down position.

Cyclic Position as necessary (CYC CTR).

START switch Centered at 55% N1.

N1 check 611% when throttle is on idle stop

ENG, XMSN,AND GEAR BOX OIL Check presures.

ENG PART SEP OFF LIGHT Check extinguished.

ENG throttle Increase 77 - 85% N2 (friction).

Rotor RPM Minimum 77 - 85%.

N1 RPM Check 71% minimum.

GEN SWITCH ON. (If battery was used).

AMP indicator Check at or below 150 AMPS.

ENGINE START (2)

ENG FUEL TRANS switch ON.

ENG BOOST PUMP switch ON.

ENG FUEL switch ON.

ENG FUEL PRESS indicator check.

START switch ENG position.

ENG OIL pressure Indicating.

Eng throttle Open to idle at 12% N1 minimum.

ENG ITT Monitor.

START switch Centered at 55% N1.

N1 check 611% when throttle is on idle stop.

ENG throttle Increase slowly to match Engines N2 RPM.

ENG OIL pressure Check.

ENG PART SEP OFF LIGHT Check extinguished.

PAG. 3 DE 9 EC-GPA 36071

PNF PF RMK ENGINE POST START

N1 RPM 71% minimum.

IF EXTERNAL POWER WAS USED: DISCONNECT

GEN 1 switch ON.

GEN 2 switch ON. (BAT BUS 1 will switch off automatically).

NR 85% or above.

Caution lights Check all extinguished except AFCS.

ENG, XMSN,AND GEAR BOX OIL Check temperatures and presures within limits.

AMPS 1 and 2 Within limits.

Radios ON as required.

ELT (if installed) Check for inadvertent transmission.

ENGINE FAILS TO START

IDLE STOP release Actuate.

Throttle Fully close.

Starter Disengage.

FUEL switch OFF.

BOOST PUMP switch OFF.

After N1 has decreased to zero Allow 30 seconds for fuel to drain from engine

Before attempting another start Conduct a DRY MOTORING RUN.

DRY MOTORING RUN

Throttle Fully closed.

BOOST PUMP switch ON.

FUEL switch ON.

IGN circuit breaker Pull out.

Starter Engage for 15 seconds, then disengage.

FUEL switch OFF.

BOOST PUMP switch OFF.

IGN circuit breaker Push in.

Allow the required cooling period for the starter before proceeding.

PAG. 4 DE 9 EC-GPA 36071

PNF PF RMK SYSTEMS CHECK

STICK CENTERING INDICATOR CHECKED.

FORCE TRIM CHECKED.

PRELIMINARY HYDRAULIC CHECKED.

ENGINE FUEL CONTROL CHECKED.

GOVERNOR CHECKED.

FUEL CROSSFEED & INTERCONNECT CHECKED.

ELECTRICAL SYSTEMS CHECKED.

HYDRAULIC SYSTEMS CHECKED.

AFCS CHECKED.

CABIN HEATER CHECKED.

BEFORE TAKE OFF

ENGINE INSTRUMENTS WITHIN OPERATING RANGES

GEARBOX INSTRUMENTS WITHIN OPERATING RANGES

TRANSMISSION INSTRUMENTS WITHIN OPERATING RANGES

HYDRAULIC INSTRUMENTS WITHIN OPERATING RANGES

ELECTRICAL INSTRUMENTS WITHIN OPERATING RANGES

CAUTION AND WARNING LIGHTS EXTINGUISHED

Throttles Full open. Adjust frictions.

RPM switch Minimum beep (DECR for 4-5 seconds).

RPM (trim) switch Minimum trim (-2 for 4-5 seconds).

NR Check 95% or greater.

RPM switch INC to obtain 100%.

RPM (trim) switch 2 or -2 to match torques at 100%.

FLIGHT INSTRUMENTS CHECK OPERATION AND SET.

POSITION lights As required.

ANTI COLL lights ON.

PITOT-STATIC HEATERS switch ON. (observed weather conditions).

Radio(s) Check functioning.

Cyclic control Centered or slightly into the wind.

EMERGENCY COMM panel (if installed) Check for single pilot operations.

AFCS HP1 and HP2 ENGAGED and select ATT

or SAS mode as desired.

FORCE TRIM switch ON in ATT mode, as desired in SAS mode.

COCKPIT VOICE RECORDER TEST

switch (if installed) Press and hold for 3 seconds.

STEP switch (if installed) As desired.

Passenger seat belts Fastened.

All doors Secured.

PAG. 5 DE 9 EC-GPA 36071

PNF PF RMK TAKE OFF

Area Clear.

RPM (trim) switch Adjust to obtain matching torque, N1, or ITT,

as required, and 100% NR.

Hover power Check torque required to hover at 4 feet skid

height.

Cyclic control Apply forward cyclic to accelerate smoothly.

Collective pitch Adjust as desired after reaching 45 KIAS.

Airspeed Within limits (60 KIAS minimum for IFR).

IN-FLIGHT OPERATIONS

Maintain 100% NR/N2 For flight operations above 6000 feet HD.

ENG 97 to 100% (Continuous operation at or below

6000 feet HD) or 100% (Continuous

operation above 6000 feet HD).

Airspeed Within limits for flight altitude.

Engine, gearbox, and transmission

instruments Within limits.

DESCENT AND LANDING

Flight controls Adjust friction as desired.

AFCS Engage ATT or SAS mode as desired.

FORCE TRIM switch ON in ATT mode, as desired in SAS mode.

Throttles Full open.

ENG 100% RPM N2.

Flight path Stay clear of AVOID area of Height-velocity

diagram.

STEP SWITCH (if installed) As desired.

AFTER LANDING

Collective pitch Full down.

Pedals Centered.

FORCE TRIM switch ON.

FORCE TRIM release button Depress and check for actuator centering.

AFCS SAS mode.

PAG. 6 DE 9 EC-GPA 36071

PNF PF RMK ENGINE SHUTDOWN

HP1 and HP2 Disengage.

Cyclic Friction as desired. Maintain cyclic stick as near

as center as possible at all rotors speed.

Throttles Reduce to 77% to 85% NR, as desired.

Stick centering check Complete.

ITT Stabilize for 1 minute.

ELT (if installed) Check for inadvertent transmision.

STBY ATTD switch (if installed) OFF.

EMER LT switch (if installed) DISARM.

Engine instruments Within limits.

IDLE STOP release switch ENG 1 position

Engine 1 throttle Fully closed. Check ITT and N1 decreasing.

BATTERY BUS 1 switch ON.

IDLE STOP release switch ENG 2 position.

Engine 2 throttle Fully closed. Check ITT and N1 decreasing.

GEN 1 and 2 switches OFF.

INV 1 and 2 OFF.

Engine 1 and 2 FUEL switches OFF.

Engine 1 and 2 BOOST PUMP switches OFF.

Engine 1 and 2 FUEL TRANS switches OFF.

Radios OFF.

Rotor brake As desired. Apply at or below 40% ROTOR RPM

Pilot Remain at flight controls until rotor has come

to a complete stop.

Lighting and miscellaneous switches OFF.

BATTERY BUS 1 and BUS 2 switches OFF.

Collective down lock Secured as desired.

PAG. 7 DE 9 EC-GPA 36071

WEIGHT & FUEL

LONGITUDINAL LATERAL

Weight CG MOMENT CG MOMENT

Weight Empty

oil

pilot

copilot

passengers 5 man seat

passengers 4 man seat

passenger 2 man RH seat

passenger 2 man LH seat

cargo

baggage

Basic Operation Weight + Payload

.+ takeoff fuel

Takeoff Condition

Basic Operation Weight + Payload

.+ Critical Forward Fuel

Most Forward Condition

Basic Operation Weight + Payload

.+ Critical Aft Fuel

Most Aft Condition

Basic Operation Weight + Payload

.+ Landing Fuel

Landing Condition

PAG. 8 DE 9 EC-GPA 36071

LISTADO DE PAGINAS EN VIGOR

Edicin Pgina Revisin

01/13 PAG 1 01/13

01/13 PAG.2 01/13

01/13 PAG.3 01/13

01/13 PAG.4 01/13

01/13 PAG.5 01/13

01/13 PAG.6 01/13

01/13 PAG.7 01/13

01/13 PAG.8 01/13

01/13 PAG.9 01/13

Elaborado por Supervisado por Aprobado por

Departamento de Dpto.Seguridad Responsable de

Operaciones Operacional Operaciones

Rafael Crespo Garca J. Carlos

Eugenio Ricote Loeches Daz Otazu

PAG. 9 DE 9 EC-GPA 36071

Das könnte Ihnen auch gefallen

- B1900D Check List PDFDokument3 SeitenB1900D Check List PDFCarlos VillalobosNoch keine Bewertungen

- Preguntas Equipo Bell 212Dokument19 SeitenPreguntas Equipo Bell 212FREDDY100% (3)

- 2.-Manual de Vuelo Bell-412 EpDokument63 Seiten2.-Manual de Vuelo Bell-412 EpAVIATION TRAINING CENTER SCNoch keine Bewertungen

- Checklist Normal AW139 CS-HGU AmendedDokument17 SeitenChecklist Normal AW139 CS-HGU Amendedmarouane berkiaNoch keine Bewertungen

- Curso 212 Cap 01Dokument29 SeitenCurso 212 Cap 01Edy Lopez DonisNoch keine Bewertungen

- Checklist Cessna 172S Circuito de TráficoDokument2 SeitenChecklist Cessna 172S Circuito de TráficoAken Aton100% (1)

- Bell 412Dokument25 SeitenBell 412Felipe Lopez VasquezNoch keine Bewertungen

- Hawker 900Xp 2021Dokument91 SeitenHawker 900Xp 2021DIEGO ORTIZNoch keine Bewertungen

- Manual A109Dokument51 SeitenManual A109DIEGO ORTIZNoch keine Bewertungen

- Bell 212 Capitulo 1. Descripcion General v4Dokument19 SeitenBell 212 Capitulo 1. Descripcion General v4santoyo70100% (2)

- Resumen CaravanDokument20 SeitenResumen CaravanleonardoNoch keine Bewertungen

- Bell 412Dokument52 SeitenBell 412JUAN DAVID FANDINO AGREDO100% (1)

- Diccionario Del HelicopteroDokument6 SeitenDiccionario Del HelicopteroJose FernandezNoch keine Bewertungen

- Examen General Helicoptero MiDokument17 SeitenExamen General Helicoptero MiROCKMANX1981Noch keine Bewertungen

- Examen Del Bell-412Dokument11 SeitenExamen Del Bell-412julio carrilloNoch keine Bewertungen

- Examen General Helicoptero Mi 17Dokument17 SeitenExamen General Helicoptero Mi 17willkobiNoch keine Bewertungen

- 1.-Primer Contacto Con La AeronaveDokument59 Seiten1.-Primer Contacto Con La Aeronavevalentino Centy100% (4)

- 4 - AdministracionDokument49 Seiten4 - AdministracionJorgeCampCamsiPampañaupaNoch keine Bewertungen

- Controles de Vuelo 350Dokument35 SeitenControles de Vuelo 350Yul Sanchez SguerraNoch keine Bewertungen

- Curso de Helicoptero Mi-8mtb-1Dokument154 SeitenCurso de Helicoptero Mi-8mtb-1jorge camposNoch keine Bewertungen

- CESSNA 152 - Aeronaves - Escuela de Aviación MéxicoDokument2 SeitenCESSNA 152 - Aeronaves - Escuela de Aviación MéxicoVicente MasiasNoch keine Bewertungen

- Avionica Mi 17v5Dokument21 SeitenAvionica Mi 17v5Alquimedes CañaNoch keine Bewertungen

- Manual de Patrones de EsperaDokument41 SeitenManual de Patrones de EsperaJuan BarajasNoch keine Bewertungen

- Beechcraft b100Dokument5 SeitenBeechcraft b100Sergio LeivaNoch keine Bewertungen

- Formato RTVDokument4 SeitenFormato RTVPedrito ApoloNoch keine Bewertungen

- Marcelo Castellani Piper Tomahawk Checklist WBDokument26 SeitenMarcelo Castellani Piper Tomahawk Checklist WBLau BouvetNoch keine Bewertungen

- Rotor Principal de Un Helicoptero Bell 412Dokument5 SeitenRotor Principal de Un Helicoptero Bell 412Jesus DominguezNoch keine Bewertungen

- Procedimientos BELL 206Dokument48 SeitenProcedimientos BELL 206CRISTIAN VERGARANoch keine Bewertungen

- Examen 6 Bell 206Dokument2 SeitenExamen 6 Bell 206Ray Contreras100% (1)

- Principios Basicos de La Aerodinamica Del HelicopteroDokument11 SeitenPrincipios Basicos de La Aerodinamica Del HelicopteroAntonio Leos100% (1)

- Super King Air B200 PerformancesDokument1 SeiteSuper King Air B200 PerformancesjsbaesNoch keine Bewertungen

- Planta de Potencia Bell412Dokument47 SeitenPlanta de Potencia Bell412Juan Esteban Villa100% (2)

- Mel Tu206Dokument50 SeitenMel Tu206melzevahcNoch keine Bewertungen

- Capitulo #2 Motor Allison 250 C 30: MDHC Autor: RCMDokument53 SeitenCapitulo #2 Motor Allison 250 C 30: MDHC Autor: RCMRamon Castro MartinezNoch keine Bewertungen

- Aproximacion CircularDokument39 SeitenAproximacion CircularandresNoch keine Bewertungen

- 01 Generalidades Bell-212Dokument21 Seiten01 Generalidades Bell-212Quiana Johnson83% (12)

- Bell 212 MajazDokument309 SeitenBell 212 MajazJesus Ocaña Calderón100% (6)

- Bombardier Learjet 31A Calculo de Combustible y Balance de AeronaveDokument15 SeitenBombardier Learjet 31A Calculo de Combustible y Balance de AeronaveJulio Gaytan100% (1)

- Sistema FenestronDokument3 SeitenSistema FenestronLuis Alberto Muñumel MillanNoch keine Bewertungen

- BTA Course Guide SpanishDokument44 SeitenBTA Course Guide SpanishJavier PuYo100% (1)

- Cessna 172S SKYHAWK SPDokument6 SeitenCessna 172S SKYHAWK SPAlbert Diago (igorres43)Noch keine Bewertungen

- Instructor de Vuelo - Semana 6Dokument38 SeitenInstructor de Vuelo - Semana 6Eduardo CruzadoNoch keine Bewertungen

- Apunte 2 Reglas GeneralesDokument29 SeitenApunte 2 Reglas GeneralesGuidoNoch keine Bewertungen

- MANUALINGENIERIAB206Dokument150 SeitenMANUALINGENIERIAB206Jose Jimenez100% (2)

- Instrumentos Del Avion PresentacionDokument69 SeitenInstrumentos Del Avion PresentacionAlan Irak Ascencio Maldonado0% (1)

- Main Rotor Bell 412EPDokument29 SeitenMain Rotor Bell 412EPPolaris Restaurante-bar100% (3)

- Determinación Del Diagrama H-V Del Helicóptero Robinson R22Dokument19 SeitenDeterminación Del Diagrama H-V Del Helicóptero Robinson R22Bazán Daniel100% (4)

- Ajustes PT6T 3be Bell 412Dokument22 SeitenAjustes PT6T 3be Bell 412EugenioContreras100% (1)

- Sim Com Piper Cheyenne IixDokument7 SeitenSim Com Piper Cheyenne IixapegamNoch keine Bewertungen

- Aerodinamica de Helicopteros II PDFDokument100 SeitenAerodinamica de Helicopteros II PDFLuis Alberto Muñumel Millan100% (1)

- Bell 412Dokument2 SeitenBell 412Felipe Lopez VasquezNoch keine Bewertungen

- Bell 505 Fact SheetDokument2 SeitenBell 505 Fact SheetPancho Rivera100% (1)

- Vuelo Tutorial b200Dokument24 SeitenVuelo Tutorial b200JavierNoch keine Bewertungen

- Reglas de VueloDokument37 SeitenReglas de VueloDario MacielNoch keine Bewertungen

- Manejo de Manuales1Dokument28 SeitenManejo de Manuales1Agustin Limachi100% (1)

- Curso Motor Lycoming DescripcionDokument66 SeitenCurso Motor Lycoming DescripcionJORGE ENRIQUE CHAPA TUMENoch keine Bewertungen

- FDG 2019Dokument1 SeiteFDG 2019OberNoch keine Bewertungen

- PSP Prueba OperativaDokument39 SeitenPSP Prueba OperativaAntonio Del AngelNoch keine Bewertungen

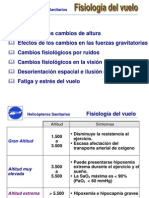

- ALH (74) Ilusiones OpticasDokument12 SeitenALH (74) Ilusiones OpticasEdgar Muñoz Fernández0% (1)

- ALH (73) DisbarismosDokument15 SeitenALH (73) DisbarismosEdgar Muñoz FernándezNoch keine Bewertungen

- ALH (72) AceleracionesDokument19 SeitenALH (72) AceleracionesEdgar Muñoz FernándezNoch keine Bewertungen

- ALH (72) HipoxiaDokument29 SeitenALH (72) HipoxiaEdgar Muñoz FernándezNoch keine Bewertungen

- Radionavegación-Tema 1 PDFDokument13 SeitenRadionavegación-Tema 1 PDFEdgar Muñoz FernándezNoch keine Bewertungen

- ALH (91) GasesDokument7 SeitenALH (91) GasesEdgar Muñoz FernándezNoch keine Bewertungen

- ALH (70) Fisiologia Vuelo (RSM)Dokument12 SeitenALH (70) Fisiologia Vuelo (RSM)Edgar Muñoz FernándezNoch keine Bewertungen

- ALH (90) AtmósferaDokument17 SeitenALH (90) AtmósferaEdgar Muñoz FernándezNoch keine Bewertungen

- ALH (20) Cardio CiculatorioDokument16 SeitenALH (20) Cardio CiculatorioEdgar Muñoz FernándezNoch keine Bewertungen

- ALH (20) Cardio CiculatorioDokument16 SeitenALH (20) Cardio CiculatorioEdgar Muñoz FernándezNoch keine Bewertungen

- ALH (50) LocomotorDokument33 SeitenALH (50) LocomotorEdgar Muñoz FernándezNoch keine Bewertungen

- ALH (30) NerviosoDokument13 SeitenALH (30) NerviosoEdgar Muñoz FernándezNoch keine Bewertungen

- ALH (11) Respiratorio (Fisiología)Dokument11 SeitenALH (11) Respiratorio (Fisiología)Edgar Muñoz FernándezNoch keine Bewertungen

- ALH (11) Respiratorio (Fisiología)Dokument11 SeitenALH (11) Respiratorio (Fisiología)Edgar Muñoz FernándezNoch keine Bewertungen

- Principios de Vuelo PDFDokument300 SeitenPrincipios de Vuelo PDFEdgar Muñoz Fernández100% (1)

- ALH (10) Respiratorio (Anatomia)Dokument8 SeitenALH (10) Respiratorio (Anatomia)Edgar Muñoz FernándezNoch keine Bewertungen

- ALH (03) HomeostasisDokument3 SeitenALH (03) HomeostasisEdgar Muñoz FernándezNoch keine Bewertungen

- ALH (01) Cuerpo HumanoDokument29 SeitenALH (01) Cuerpo HumanoEdgar Muñoz FernándezNoch keine Bewertungen

- Libro de Instrucciones para Estufas CoronaDokument18 SeitenLibro de Instrucciones para Estufas CoronaEdgar Muñoz FernándezNoch keine Bewertungen

- Procedimientos Operacionales PDFDokument2 SeitenProcedimientos Operacionales PDFEdgar Muñoz FernándezNoch keine Bewertungen

- Comunicaciones PDFDokument82 SeitenComunicaciones PDFEdgar Muñoz Fernández100% (2)

- Impresora 3d PDFDokument116 SeitenImpresora 3d PDFEdgar Muñoz Fernández100% (5)

- 40pfl4911 f8 Fur EspDokument5 Seiten40pfl4911 f8 Fur EspRicardo GuzmanNoch keine Bewertungen

- Trabajo Final de Topografia # 2Dokument12 SeitenTrabajo Final de Topografia # 2sujeiry mateoNoch keine Bewertungen

- Embarazo PrecozDokument2 SeitenEmbarazo PrecozRuggery LeonNoch keine Bewertungen

- Ficha Cap. 1 y 2 Del Libro EmprendedorDokument3 SeitenFicha Cap. 1 y 2 Del Libro EmprendedorHanna PrietoNoch keine Bewertungen

- Suelos II - Ensayos de Corte de Particulas de ColuvionesDokument20 SeitenSuelos II - Ensayos de Corte de Particulas de ColuvionesRuben Ñahue RimacheNoch keine Bewertungen

- HISTORIADokument1 SeiteHISTORIADaniela PerezNoch keine Bewertungen

- Facultad de Ciencias Humanas Programa Curricular de Psicología Fundamentos Del ConductismoDokument4 SeitenFacultad de Ciencias Humanas Programa Curricular de Psicología Fundamentos Del ConductismoVivian Samantha Palacios PachonNoch keine Bewertungen

- Aprendizaje, Memoria y Neuroplasticidad.Dokument1 SeiteAprendizaje, Memoria y Neuroplasticidad.Dulce MaríaNoch keine Bewertungen

- Test AEI y Programa ECOSDokument14 SeitenTest AEI y Programa ECOSDesde Adentro Una Mirada Diferente50% (2)

- Producto Academico #1Dokument6 SeitenProducto Academico #1Nicolle Vila GalvanNoch keine Bewertungen

- Morcillo Mochón. Conceptos BásicosDokument4 SeitenMorcillo Mochón. Conceptos BásicosjuanNoch keine Bewertungen

- Educación Del PuebloDokument2 SeitenEducación Del PuebloEvelia AndradeNoch keine Bewertungen

- DiagnósticoDokument3 SeitenDiagnósticoFrancisco ArreazaNoch keine Bewertungen

- Documento 3. Estándares Basicos de Competencias..Dokument184 SeitenDocumento 3. Estándares Basicos de Competencias..diegoNoch keine Bewertungen

- Filosfía Helenistica Carcaterisitcas 3 10o 2022 S 5Dokument3 SeitenFilosfía Helenistica Carcaterisitcas 3 10o 2022 S 5Daniela De La RosaNoch keine Bewertungen

- Hartmann, El Problema Del Ser EspiritualDokument31 SeitenHartmann, El Problema Del Ser EspiritualAmairani P.D.100% (1)

- Fichas Liftket Speed Line H32N32... XLSX - H32N3215Dokument2 SeitenFichas Liftket Speed Line H32N32... XLSX - H32N3215Marcos Patricio Hernàndez NavarroNoch keine Bewertungen

- 1 Corintios 6Dokument2 Seiten1 Corintios 6Selvin SosaNoch keine Bewertungen

- Politicas de Devoluciones Integra E Inversiones PDFDokument3 SeitenPoliticas de Devoluciones Integra E Inversiones PDFDAVID MARTINEZNoch keine Bewertungen

- 2 Catolicismo y ModernismoDokument21 Seiten2 Catolicismo y ModernismohugoNoch keine Bewertungen

- Guantes DielectricosDokument2 SeitenGuantes Dielectricosjesus_malpartida_5Noch keine Bewertungen

- (Acv-S06) Evaluación Calificada en Linea 3 - Calculo Avanzado para Ingenieria (47462)Dokument4 Seiten(Acv-S06) Evaluación Calificada en Linea 3 - Calculo Avanzado para Ingenieria (47462)Josue GarciasNoch keine Bewertungen

- Planificación Estrategica Dirección de Educación PúblicaDokument14 SeitenPlanificación Estrategica Dirección de Educación PúblicaAny OsorioNoch keine Bewertungen

- Ser Felices Sin Ser PerfectosDokument10 SeitenSer Felices Sin Ser PerfectosEduardo FernandezNoch keine Bewertungen

- Unidad 2. El PensamientoDokument18 SeitenUnidad 2. El PensamientoAnthony MoraNoch keine Bewertungen

- Historia de La Puc, Krebs PDFDokument684 SeitenHistoria de La Puc, Krebs PDFOmar Cabezas FloresNoch keine Bewertungen

- Unidades de Medidas TopograficasDokument5 SeitenUnidades de Medidas TopograficasYeiSon CaalNoch keine Bewertungen

- Teorías de AntropologiaDokument13 SeitenTeorías de AntropologiaAlexis MedinaNoch keine Bewertungen

- Evolucion Del Concepto. Periodos HistoricosDokument8 SeitenEvolucion Del Concepto. Periodos HistoricosEstefany Abarca100% (1)

- Proy. Social PPT Sem 2 2021 - 5Dokument11 SeitenProy. Social PPT Sem 2 2021 - 5Luis Leo DomNoch keine Bewertungen