Beruflich Dokumente

Kultur Dokumente

Economic Assessment of Hydroponic Lettuce Production

Hochgeladen von

Molly ChaseOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Economic Assessment of Hydroponic Lettuce Production

Hochgeladen von

Molly ChaseCopyright:

Verfügbare Formate

ECONOMIC ASSESSMENT OF HYDROPONIC LETTUCE PRODUCTION

William Daly, Joseph Fink, and Gina L. Shamshak, Ph.D.

Goucher College, 1021 Dulaney Valley Rd., Baltimore, MD 21204;

Departments of Biology, Economics and Environmental Studies

Abstract Table 1: Key Assumptions of the Enterprise Budget

Hydroponics refers to a form of production where plants are grown in a

nutrient-enriched water solution, rather than in soil. There are a number Crop Variety Total Growth Period (Days) Germination Period (Days)

of benefits and costs associated with hydroponic production versus

MaxiGrow Plant

traditional soil-based agricultural production, both in terms of economic Rex Butterhead Lettuce 42 14

Food, 1.20%

performance and environmental impacts. In order to specifically assess Kilowatts used, 1'' Horticubes

the economic performance of our current hydroponic lettuce production Germination Rate Price Per Head of Lettuce Hourly Wage Per Worker 20.09% Medium, 3.77%

system at Goucher College, we developed a computer-based enterprise

98% $1.50 $7.50

budget using Microsoft Excel. The spreadsheet model incorporates the Explicit Variable

Costs, 9.34%

production costs and expected returns associated with the hydroponic System Capacity Years of Useful Life Labor Costs,

Gallons of Water Required 70.52% Rex Pellet

system that was developed this summer as part of this research project. (Heads of Lettuce) for Capital

Butterhead Lettuce,

The spreadsheet model also allows the user to assess a variety of 112 80 7 4.37%

alternative production scenarios (for example, changing the species

Water in

raised, changing the number of plants raised in the system, or changing Water in

Germination Pit,

the duration of the production cycle) in order to assess the impact of Table 2: Annual Costs of Production for Current System Hydroponic System,

0.03%

0.03%

those changes on various economic performance indicators. In particular,

Explicit Variable Costs Unit Quantity Price Per Unit Annual Production Figure 3: Variable Costs of Production With Existing Hydroponic System

the model identifies the annual profit, break-even prices and break-even

quantities associated with various biological and economic parameters. Rex Pellet Butterhead

Seeds 1,334 $0.04 $47.76

Lettuce Table 3: Break-Even Prices at Different Production Levels

Materials and Methods

MaxiGrow Plant Food Tbsp 60 $0.22 $13.16

The vertical hydroponic system is comprised of six Schedule 40 PVC pipes Break Even Price Break Even Price Break Even Price

Production Level

that are 10 feet long and 3 inches in diameter. Two pipes, that are 1'' Horticubes Medium Cubes 1,334 $0.03 $41.15

(Explicit & Implicit Costs) (Explicit & Labor Costs) (Explicit Only)

designated as the nursery pipes, have 2 inch holes drilled every 4 inches,

56 $1.03 $0.86 $0.26

for a total of 29 holes per pipe. The remaining four pipes have 2 inch holes Subtotal $0.29 $102.07

drilled every 8 inches, for a total of 14 holes per pipe. In total the system 90 $0.71 $0.61 $0.23

can support 56 heads of lettuce per harvest. The system is supported by a Implicit Variable Costs 125 $0.67 $0.52 $0.25

wooden frame that is 8 feet tall and 10.5 feet long.

Labor Costs Hours 102.75 $7.50 $770.63

Figure 1: The vertical Table 4: Annual Profit Above Total Costs at Different Prices

hydroponic system: Water in Germination Pit Gallons 40 $0.01 $0.30 and Production Levels

Test run June 21, 2013 Water in Hydroponic Market Price 56 90 125

Gallons 40 $0.01 $0.30

System

$0.75 -$365.94 $77.64 $232.97

Kilowatt

Total Electricity Used 2,310.57 $0.10 $219.50 $1.50 $600.06 $1,630.14 $2,389.22

Hours

$3.00 $2,532.06 $4,735.14 $6,701.72

Subtotal $7.61 $990.73

Total Variable Costs (Explicit and Implicit) $7.90 $1,092.80

Discussion

Total Fixed Costs (Depreciation) $239.15

Using an enterprise budget, we quantified the costs associated with our

hydroponic system and determined the profit from selling heads of lettuce

at various market prices. We calculated the break-even price, which is

Total Costs of Annual Production $1,331.94

the selling price at which all the costs of production are covered under

Figure 2: The germination pit, different assumptions (Table 3). At the break-even price, profit is zero;

designed as an ebb and flow table Explicit costs refer to costs that require a direct outlay of however, at prices above the break-even price, profits are generated.

that floods every four hours for two Table 4 demonstrates the change in profit associated with different prices

money. Implicit costs refer to costs that do not require a direct

minutes in order to provide the seeds outlay of money. Implicit costs quantify the opportunity cost of and production levels, when taking into account the total costs of annual

water and nutrients to facilitate production.

resources used in the production process including the owners

germination and growth. time. This hydroponic system uses electricity and water, and Acknowledgments

the cost of those resources is not remunerated to the college. We are indebted to Cynthia Kicklighter for providing us with so many resources for our project. We would also like to

Also, the system has traditionally operated without wage thank German Mora for providing devices to collect data. Finally, thank you to Lydia Truitt and Todd Troester for

sharing your experience and knowledge of hydroponic and agricultural systems. This research was supported by

payments for the operators time. the Andrew W. Mellon Foundation and the Goucher Summer Research Program.

Das könnte Ihnen auch gefallen

- EGOV2Dokument16 SeitenEGOV2Ann Carmel AtilloNoch keine Bewertungen

- Chapter 1Dokument37 SeitenChapter 1Momentum PressNoch keine Bewertungen

- Final Evaluation of The NGO Joint Initiative For Urban Zimbabwe Community Based Support For Vulnerable PopulationsDokument40 SeitenFinal Evaluation of The NGO Joint Initiative For Urban Zimbabwe Community Based Support For Vulnerable PopulationsOxfamNoch keine Bewertungen

- P & P Agricultural Extension CourseDokument34 SeitenP & P Agricultural Extension CourseABAYNEGETAHUN getahun100% (2)

- AI & Agriculture. Must Read-1Dokument91 SeitenAI & Agriculture. Must Read-1Sudhansu MahanandNoch keine Bewertungen

- Farmers' Perceptions of Agricultural Extension Agents' Performance in Sub-Saharan African Communities PDFDokument12 SeitenFarmers' Perceptions of Agricultural Extension Agents' Performance in Sub-Saharan African Communities PDFDr. Olayemi Sennuga, PhDNoch keine Bewertungen

- Introduction To AgroforestryDokument16 SeitenIntroduction To AgroforestryBrian JohnsonNoch keine Bewertungen

- PBB in MauritiusDokument7 SeitenPBB in MauritiusnewmadproNoch keine Bewertungen

- E Government PDFDokument16 SeitenE Government PDFSanchithya AriyawanshaNoch keine Bewertungen

- Unit 1 Technology in Early Childhood EducationDokument22 SeitenUnit 1 Technology in Early Childhood EducationStephany BendebelNoch keine Bewertungen

- Postharvest Technology SyllabusDokument8 SeitenPostharvest Technology SyllabusESTHER LANCITANoch keine Bewertungen

- Gender Issues in TVETDokument44 SeitenGender Issues in TVETMic KiiruNoch keine Bewertungen

- Assignment of SM About Fazal MillDokument11 SeitenAssignment of SM About Fazal MillM Bilal K BilalNoch keine Bewertungen

- Hydroponic Lettuce: Cheryl Kaiser and Matt ErnstDokument4 SeitenHydroponic Lettuce: Cheryl Kaiser and Matt ErnstKamal deep100% (1)

- Week 4 - Models of Agricultural Extension DeliveryDokument20 SeitenWeek 4 - Models of Agricultural Extension DeliverySANDIE YEYANoch keine Bewertungen

- Policy Overview: Ethiopia Climate Resilient Green EconomyDokument3 SeitenPolicy Overview: Ethiopia Climate Resilient Green EconomyOxfamNoch keine Bewertungen

- Vulnerability To ExtinctionDokument25 SeitenVulnerability To ExtinctionSoh Yi HanNoch keine Bewertungen

- Comparative Analysis of Greenhouse Versus Open-Field Small-Scale Tomato Production in Nakuru-North District, KenyaDokument84 SeitenComparative Analysis of Greenhouse Versus Open-Field Small-Scale Tomato Production in Nakuru-North District, KenyaBrian Okuku Owinoh50% (2)

- Promoting Financial Inclusion Can The Constraints of Political Economy Be OvercomeDokument98 SeitenPromoting Financial Inclusion Can The Constraints of Political Economy Be OvercomeEti Chiranjeevi100% (1)

- BBA404 SLM Unit 04 PDFDokument19 SeitenBBA404 SLM Unit 04 PDFtahaalkibsiNoch keine Bewertungen

- The Introduction of Agriculture and Extension PDFDokument38 SeitenThe Introduction of Agriculture and Extension PDFIu Anggraini GirlsmantaplgNoch keine Bewertungen

- Internal Marketing in Foreign Bank G-2Dokument29 SeitenInternal Marketing in Foreign Bank G-2majiclover100% (2)

- Vegetables and Fruits Production PDFDokument27 SeitenVegetables and Fruits Production PDFleonard gananNoch keine Bewertungen

- E Government Development StagesDokument2 SeitenE Government Development StagesHellenNdegwa100% (2)

- VEG TRAINING - IIVR - VaranasiDokument33 SeitenVEG TRAINING - IIVR - VaranasiVineetNoch keine Bewertungen

- Economic Liberalization Policy NepalDokument3 SeitenEconomic Liberalization Policy NepalSaroj LamichhaneNoch keine Bewertungen

- Rice Value Chain Analysis: Rice Seed Production As A Profitable Agribusiness in Nueva EcijaDokument9 SeitenRice Value Chain Analysis: Rice Seed Production As A Profitable Agribusiness in Nueva EcijaPoonam KilaniyaNoch keine Bewertungen

- Agricultural ExtensionDokument281 SeitenAgricultural ExtensionjimborenoNoch keine Bewertungen

- Agricultural WasteDokument28 SeitenAgricultural WasteArnoldNoch keine Bewertungen

- Factors Influencing Evaluation On The Performance of Primary Agricultural Cooperative Societies With Reference To Abuna Gindeberet Woreda, Oromia Regional State, EthiopiaDokument8 SeitenFactors Influencing Evaluation On The Performance of Primary Agricultural Cooperative Societies With Reference To Abuna Gindeberet Woreda, Oromia Regional State, EthiopiaInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- Biofortification of Staple Food CropsDokument4 SeitenBiofortification of Staple Food CropsdonbosskissNoch keine Bewertungen

- Development Policies and Agricultural Markets Author(s) - RAMESH CHANDDokument11 SeitenDevelopment Policies and Agricultural Markets Author(s) - RAMESH CHANDRegNoch keine Bewertungen

- Land Suitability Analysis For Wheat Crop by Using Multi-Criteria and Gis Technology in Case of South Gondar, EthiopiaDokument14 SeitenLand Suitability Analysis For Wheat Crop by Using Multi-Criteria and Gis Technology in Case of South Gondar, Ethiopiaiaset123Noch keine Bewertungen

- Enhancing Social Capital During The Pandemic: A Case of The Rural Women in Bukidnon Province, Southern PhilippinesDokument10 SeitenEnhancing Social Capital During The Pandemic: A Case of The Rural Women in Bukidnon Province, Southern PhilippinesPremier PublishersNoch keine Bewertungen

- Lecture Note For Agri. and RDDokument131 SeitenLecture Note For Agri. and RDibsa100% (2)

- MM MMDokument48 SeitenMM MMRicha ஜ GroverNoch keine Bewertungen

- Paddy Farming TheoryDokument170 SeitenPaddy Farming TheoryMohanNoch keine Bewertungen

- MsTeams Environmental Protection With Water Saving TechnologyDokument17 SeitenMsTeams Environmental Protection With Water Saving TechnologyIrish NaragNoch keine Bewertungen

- Itik ChuchuDokument34 SeitenItik ChuchuJurie BalandacaNoch keine Bewertungen

- Agricultural Policy in NigeriaDokument6 SeitenAgricultural Policy in NigeriaEmmanuel Umo Effiong100% (1)

- RA 7308 Hand OutDokument2 SeitenRA 7308 Hand OutAmberChanNoch keine Bewertungen

- Drying PDFDokument4 SeitenDrying PDFTowfiq Ahmed100% (1)

- Linking SDG With Uganda Vision 2040-2016Dokument29 SeitenLinking SDG With Uganda Vision 2040-2016opio felix100% (1)

- Empowering Small Rice FarmersDokument8 SeitenEmpowering Small Rice FarmersNoel SalazarNoch keine Bewertungen

- Wadi Based Livelihood Development Programme 2Dokument6 SeitenWadi Based Livelihood Development Programme 2saket-mehtaNoch keine Bewertungen

- OFf Season Vegetable Farming ProjectDokument14 SeitenOFf Season Vegetable Farming ProjectabrarNoch keine Bewertungen

- Maikil Tesfaye Agri. Econ (Impact of Malaria)Dokument73 SeitenMaikil Tesfaye Agri. Econ (Impact of Malaria)kassahun meseleNoch keine Bewertungen

- Training Disadvantaged &under Privileged YouthDokument15 SeitenTraining Disadvantaged &under Privileged YouthS Ishvara ReddyNoch keine Bewertungen

- Professional Development PlanDokument2 SeitenProfessional Development PlanCarolineNoch keine Bewertungen

- E-Government Principles: J SatyanarayanaDokument45 SeitenE-Government Principles: J SatyanarayanaxhetryNoch keine Bewertungen

- SGP MauritiusDokument2 SeitenSGP MauritiusRahul TripathiNoch keine Bewertungen

- Bangladesh: Skills Development ProjectDokument15 SeitenBangladesh: Skills Development ProjectADBGADNoch keine Bewertungen

- Agricultural Development Planning and Resource MobilizationDokument18 SeitenAgricultural Development Planning and Resource MobilizationReaderNoch keine Bewertungen

- Rice Monitoring and Calendar System Using Android Phone and Arduino MicrocontrollerDokument10 SeitenRice Monitoring and Calendar System Using Android Phone and Arduino MicrocontrollerNomar AnthonyNoch keine Bewertungen

- IT in AgricultureDokument36 SeitenIT in AgricultureSatyawan PabaleNoch keine Bewertungen

- Value Chain Analysis of Large Cardamom in Taplejung District of NepalDokument19 SeitenValue Chain Analysis of Large Cardamom in Taplejung District of NepalIEREKPRESSNoch keine Bewertungen

- Agricultural Innovation SystemDokument16 SeitenAgricultural Innovation SystemAnurag Shankar SinghNoch keine Bewertungen

- Concept NoteDokument3 SeitenConcept Notenikitachotalia27100% (1)

- Impactof Coronaon Textile SectorDokument9 SeitenImpactof Coronaon Textile SectorKanchan AgarwalNoch keine Bewertungen

- Pattillo and Hager - Aquaponic Challenges and Solutions - March2023Dokument8 SeitenPattillo and Hager - Aquaponic Challenges and Solutions - March2023Murat AquaNoch keine Bewertungen

- Identification of - The - Intensity - of - Weeds - in - MaizeDokument6 SeitenIdentification of - The - Intensity - of - Weeds - in - MaizeMolly ChaseNoch keine Bewertungen

- MRT ManualDokument70 SeitenMRT ManualMolly ChaseNoch keine Bewertungen

- Geocoding Tool v3.1Dokument12 SeitenGeocoding Tool v3.1Molly ChaseNoch keine Bewertungen

- Excel2kml AddressDokument5 SeitenExcel2kml AddressMolly ChaseNoch keine Bewertungen

- FW Mapping EnglishDokument264 SeitenFW Mapping EnglishMolly ChaseNoch keine Bewertungen

- CadTools Reference ManualDokument112 SeitenCadTools Reference ManualMolly ChaseNoch keine Bewertungen

- CO RS Tutorial10Dokument18 SeitenCO RS Tutorial10Molly ChaseNoch keine Bewertungen

- Azure Essentials: Module 5: Azure Cost Management and Service Level AgreementsDokument9 SeitenAzure Essentials: Module 5: Azure Cost Management and Service Level Agreementsrajagopalan19Noch keine Bewertungen

- Wel-Come: Heat Treatment Process (TTT, CCT & CCR)Dokument14 SeitenWel-Come: Heat Treatment Process (TTT, CCT & CCR)atulkumargaur26Noch keine Bewertungen

- Pharmacy Incharge JDDokument5 SeitenPharmacy Incharge JDUsman JamilNoch keine Bewertungen

- Leadership Roles and Management Functions in Nursing Theory and ApplicationDokument2 SeitenLeadership Roles and Management Functions in Nursing Theory and Applicationivan0% (3)

- 14.08.22 - OSR - STAR CO-SC - Jee - Adv - 2021 - P1 - GTA-11 (P1) - QPDokument19 Seiten14.08.22 - OSR - STAR CO-SC - Jee - Adv - 2021 - P1 - GTA-11 (P1) - QPPratyek ThumulaNoch keine Bewertungen

- 21-Ent, 45 Notes To PGDokument12 Seiten21-Ent, 45 Notes To PGAshish SinghNoch keine Bewertungen

- Emission Control (2uz-Fe)Dokument15 SeitenEmission Control (2uz-Fe)Abbode HoraniNoch keine Bewertungen

- Deviance, Crime, and Social ControlDokument17 SeitenDeviance, Crime, and Social ControlSaad MaqboolNoch keine Bewertungen

- Pamphlet InsideDokument1 SeitePamphlet Insideapi-2408549370% (1)

- Blake PastoralDokument4 SeitenBlake PastoralSanya AhmedNoch keine Bewertungen

- اطلع علي زتونة 3 ع مراجعة الترم الثاني 2024Dokument60 Seitenاطلع علي زتونة 3 ع مراجعة الترم الثاني 2024ahmad sholokNoch keine Bewertungen

- Lab Risk AssessmentDokument8 SeitenLab Risk Assessmentaqilah haronNoch keine Bewertungen

- 2017-12-27 Final Alcohol Task Force ReportDokument288 Seiten2017-12-27 Final Alcohol Task Force ReportShira SchoenbergNoch keine Bewertungen

- The Man S Bible 50 Essential Tips For Success With Your Mind Body and WomenDokument155 SeitenThe Man S Bible 50 Essential Tips For Success With Your Mind Body and WomenDonStemple100% (4)

- 7 Solidification, Casting Defects.Dokument5 Seiten7 Solidification, Casting Defects.Ahmad AbdNoch keine Bewertungen

- Datasheet Lm311Dokument10 SeitenDatasheet Lm311Ed FreemanNoch keine Bewertungen

- Bar Exam Questions Week 1Dokument30 SeitenBar Exam Questions Week 1Mark Bantigue100% (1)

- XII Biology Practicals 2020-21 Without ReadingDokument32 SeitenXII Biology Practicals 2020-21 Without ReadingStylish HeroNoch keine Bewertungen

- MCQ Questions For Class 10 Science Periodic Classification of Elements With AnswersDokument30 SeitenMCQ Questions For Class 10 Science Periodic Classification of Elements With AnswersAymen WaelNoch keine Bewertungen

- Major Laishram Jyotin SinghDokument3 SeitenMajor Laishram Jyotin SinghSpongebob SquarepantsNoch keine Bewertungen

- Field Study 1-Act 5.1Dokument5 SeitenField Study 1-Act 5.1Mariya QuedzNoch keine Bewertungen

- Improving Communication Skills of Pharmacy StudentDokument13 SeitenImproving Communication Skills of Pharmacy StudentAbdul QadirNoch keine Bewertungen

- Granulation Process Basic UnderstandingDokument3 SeitenGranulation Process Basic UnderstandingRainMan75Noch keine Bewertungen

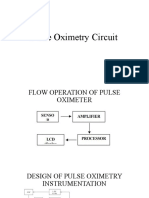

- Pulse Oximetry CircuitDokument19 SeitenPulse Oximetry Circuitنواف الجهنيNoch keine Bewertungen

- ASTM Standards For WoodDokument7 SeitenASTM Standards For WoodarslanengNoch keine Bewertungen

- Chan vs. ChanDokument2 SeitenChan vs. ChanMmm GggNoch keine Bewertungen

- Decommissioning HSE PDFDokument105 SeitenDecommissioning HSE PDFRafael Rocha100% (1)

- Yumiko@Dokument2 SeitenYumiko@api-25886263Noch keine Bewertungen

- Reduce, Reuse, RecycleDokument9 SeitenReduce, Reuse, RecyclemarieangeluNoch keine Bewertungen

- Anthropometric Article2Dokument11 SeitenAnthropometric Article2Lakshita SainiNoch keine Bewertungen