Beruflich Dokumente

Kultur Dokumente

Galgas Extensiometricas

Hochgeladen von

Agustin Aguilar0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

17 Ansichten4 SeitenComo instalarse

Originaltitel

galgas extensiometricas

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenComo instalarse

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

17 Ansichten4 SeitenGalgas Extensiometricas

Hochgeladen von

Agustin AguilarComo instalarse

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 4

Instruction Bulletin B-127-14

Strain Gage Installations with M-Bond 200 Adhesive

INTRODUCTION SHELF AND STORAGE LIFE

Micro-Measurements Certified M-Bond 200 is an

M-Bond 200 adhesive has a minimum pot life of three

excellent general-purpose laboratory adhesive because of

months at +75F [+24C] (not to exceed the date of

its fast room-temperature cure and ease of application.

expiration) after opening and with the cap placed back

When properly handled and used with the appropriate

onto the bottle immediately after each use.

strain gage, M-Bond 200 can be used for high-elongation

tests in excess of 60 000 microstrain, for fatigue studies,

Note: To ensure the cap provides a proper seal, the bottle

and for one-cycle proof tests to over +200 F [+95 C] or

spout should be wiped clean and dry before replacing the

below -300 F [-185C]. The normal operating

cap.

temperature range is -25 to +150F [-30 to +65C]. M-

Bond 200 is compatible with all Micro-Measurements

Unopened M-Bond 200 adhesive may be stored up to

strain gages and most common structural materials.

nine months at +75F [+24C] or twelve months at +40F

When bonding to plastics, it should be noted that for best

[+5C].

performance the adhesive flowout should be kept to a

minimum. For best reliability, it should be applied to

surfaces between the temperatures of +70 and +85F

[+20 to +30C], and in a relative humidity environment of

30% to 65%. HANDLING PRECAUTIONS

M-Bond 200 catalyst has been specially formulated to

control the reactivity rate of this adhesive. The catalyst M-Bond 200 is a modified alkyl cyanoacrylate compound.

should be used sparingly for best results. Excessive Immediate bonding of eye, skin or mouth may result upon

catalyst can contribute many problems; e.g., poor bond contact. Causes irritation. The user is cautioned to: (1)

strength, age-embrittlement of the adhesive, poor glueline avoid contact with skin; (2) avoid prolonged or repeated

thickness control, extended solvent evaporation time breathing of vapors; and (3) use with adequate

requirements, etc. ventilation. For additional health and safety information,

consult the Material Safety Data Sheet, which is available

Since M-Bond 200 bonds are weakened by exposure to upon request.

high humidity, adequate protective coatings are essential.

This adhesive will gradually become harder and more

brittle with time, particularly if exposed to elevated

temperatures. For these reasons, M-Bond 200 is not Note: Condensation will rapidly degrade adhesive

generally recommended for installations exceeding one or performance and shelf life; after refrigeration the adhesive

two years. must be allowed to reach room temperature before

opening, and refrigeration after opening is not

For proper results, the procedures and techniques recommended.

presented here should be used with qualified Micro-

Measurements installation accessory products. Those

used in this procedure are:

GAGE APPLICATION TECHNIQUES

CSM Degreaser or GC-6 Isopropyl Alcohol

Silicon Carbide Paper The installation procedure presented on the following

M-Prep Conditioner A pages is somewhat abbreviated and is intended only as a

M-Prep Neutralizer 5A guide in achieving proper gage installation with M-Bond

GSP-1 Gauze Sponges 200. Micro-Measurements Application Note B-129

CSP-1 Cotton Applicators presents recommended procedures for surface

PCT- 2M Gage Installation Tape preparation, and lists specific considerations which

are helpful when working with most common structural

materials.

Strain Gage Installations with M-Bond 200 Adhesive

Document No.: 11127 1 of 4 ID: BUL11127

Revision 12-30-14 micro-measurements@vpgsensors.com www.micro-measurements.com

Instruction Bulletin B-127-14

Step 1 the surface because this invariably leaves a

contaminating film and reduces chances of a good bond.

Step 3

Thoroughly degrease the gaging area with solvent, such

as CSM Degreaser or GC-6 Isopropyl Alcohol. The former

is preferred, but there are some materials (e.g., titanium

and many plastics) that react with strong solvents. In

these cases, GC-6 Isopropyl Alcohol should be

considered. All degreasing should be done with Now apply a liberal amount of M-Prep Neutralizer 5A and

uncontaminated solvents-thus the use of one-way scrub with a cotton-tipped applicator. With a single, slow

containers, such as aerosol cans, is highly advisable. wiping motion of a gauze sponge, carefully dry this

surface. Do not wipe back and forth because this may

Step 2 allow contaminants to be redeposited.

Step 4

Preliminary dry abrading with 220- or 320-grit silicon-

carbide paper is generally required if there is any surface Using tweezers to remove the gage from the transparent

scale or oxide. Final abrading is done by using 320-grit envelope, place the gage (bonding side down) on a

silicon-carbide paper on surfaces thoroughly wetted with chemically clean glass plate or gage box surface. If a

M-Prep Conditioner A; this is followed by wiping dry with a solder terminal will be used, position it on the plate

gauze sponge. Repeat this wet abrading process with adjacent to the gage as shown. A space of approximately

400-grit silicon-carbide paper, then dry by slowly wiping 1/16 in [1.6 mm] or more where space allows or

through with a gauze sponge. application requires should be left between the gage

backing and terminal. Place a 4- to 6-in [100- to 150-mm]

Using a 4H pencil (on aluminum) or a ballpoint pen (on piece of Micro-Measurements PCT-2M gage installation

steel), burnish (do not scribe) whatever alignment marks tape over the gage and terminal. Take care to center the

are needed on the specimen. Repeatedly apply M-Prep gage on the tape. Carefully lift the tape at a shallow angle

Conditioner A and scrub with cotton-tipped applicators (about 45 degrees to specimen surface), bringing the

until a clean tip is no longer discolored. Remove all gage up with the tape as illustrated above.

residue and Conditioner by again slowly wiping through

with a gauze sponge. Never allow any solution to dry on

Strain Gage Installations with M-Bond 200 Adhesive

Document No.: 11127 2 of 4 ID: BUL11127

Revision 12-30-14 micro-measurements@vpgsensors.com www.micro-measurements.com

Instruction Bulletin B-127-14

Step 5 Step 7

M-Bond 200 catalyst can now be applied to the bonding

surface of the gage and terminal. M-Bond 200 adhesive

Position the gage/tape assembly so that the triangle will harden without the catalyst, but less quickly and

alignment marks on the gage are over the layout lines on reliably. Very little catalyst is needed, and it should be

the specimen. If the assembly appears to be misaligned, applied in a thin, uniform coat. Lift the brush-cap out of

lift one end of the tape at a shallow angle until the the catalyst bottle and wipe the brush approximately 10

assembly is free of the specimen. Realign properly, and strokes against the inside of the neck of the bottle to

firmly anchor at least one end of the tape to the wring out most of the catalyst. Set the brush down on the

specimen. Realignment can be done without fear of gage and swab the gage backing. Do not stroke the brush

contamination by the tape mastic if Micro-Measurements in a painting style, but slide the brush over the entire gage

PCT-2M gage installation tape is used, because this tape surface and then the terminal. Move the brush to the

will retain its mastic when removed. adjacent tape area prior to lifting from the surface. Allow

the catalyst to dry at least one minute under normal

Step 6 ambient conditions of +75F [+24C] and 30% to 65%

relative humidity before proceeding.

Note: The next three steps must be completed in the

sequence shown, within 3 to 5 seconds. Read Steps 8, 9,

and 10 before proceeding.

Step 8

Lift the gage end of the tape assembly at a shallow angle

to the specimen surface (about 45 degrees) until the gage

and terminal are free of the specimen surface. Continue

lifting the tape until it is free from the specimen

approximately 1/2 in [10 mm] beyond the terminal. Tuck

the loose end of the tape under and press to the Lift the tucked-under tape end of the assembly, and,

specimen surface so that the gage and terminal lie flat, holding in the same position, apply one or two drops of M-

with the bonding surface exposed. Bond 200 adhesive at the fold formed by the junction of

Note: Micro-Measurements gages have been treated for the tape and specimen surface. This adhesive application

optimum bonding conditions and require no pre-cleaning should be approximately 1/2 in [13 mm] outside the actual

before use unless contaminated during handling. If gage installation area. This will insure that local

contaminated, the back of any gage can be cleaned with polymerization that takes place when the adhesive comes

a cotton-tipped applicator slightly moistened with M-Prep in contact with the specimen surface will not cause

Neutralizer 5A. unevenness in the gage glueline.

Strain Gage Installations with M-Bond 200 Adhesive

Document No.: 11127 3 of 4 ID: BUL11127

Revision 12-30-14 micro-measurements@vpgsensors.com www.micro-measurements.com

Instruction Bulletin B-127-14

Step 9 be advantageous to use preformed pressure padding

during the operation. Pressure-application time should

again be extended due to the lack of thumb heat which

helps to speed adhesive polymerization. Wait two minutes

before removing tape.

Step 11

Immediately rotate the tape to approximately a 30-degree

angle so that the gage is bridged over the installation

area. While holding the tape slightly taut, slowly and firmly

make a single wiping stroke over the gage/tape assembly

with a piece of gauze bringing the gage back down over

the alignment marks on the specimen. Use a firm

pressure with your fingers when wiping over the gage. A

very thin, uniform layer of adhesive is desired for optimum

bond performance.

The gage and terminal strip are now solidly bonded in

Step 10 place. It is not necessary to remove the tape immediately

after gage installation. The tape will offer mechanical

protection for the grid surface and may be left in place

until it is removed for gage wiring. To remove the tape,

pull it back directly over itself, peeling it slowly and

steadily off the surface. This technique will prevent

possible lifting of the foil on open-faced gages or other

damage to the installation.

FINAL INSTALLATION PROCEDURE

1. Select appropriate solder and attach leadwires. Prior

to any soldering operations, open-faced gage grids

should be masked with PDT-1 drafting tape to

Immediately upon completion of wipe-out of the adhesive, prevent possible damage.

firm thumb pressure must be applied to the gage and

terminal area. This pressure should be held for at least 2. Remove the solder flux with Rosin Solvent, RSK-1.

one minute. In low-humidity conditions (below 30%), or if

the ambient temperature is below +70F [+20C], this 3. Select and apply protective coating according to the

pressure application time may have to be extended to protective coating selection chart found in the Micro-

several minutes. Measurements Strain Gage Accessories Data Book

found at http://www.vishaypg.com/micro-

Where large gages are involved, or where curved measurements/databooks/.

surfaces such as fillets are encountered, it may

Strain Gage Installations with M-Bond 200 Adhesive

Document No.: 11127 4 of 4 ID: BUL11127

Revision 12-30-14 micro-measurements@vpgsensors.com www.micro-measurements.com

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

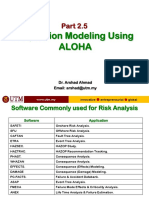

- PLSP 2 6 Aloha PDFDokument35 SeitenPLSP 2 6 Aloha PDFKajenNoch keine Bewertungen

- W201 Wiring DiagramDokument290 SeitenW201 Wiring Diagramilikemyfishbigandblue87% (45)

- Gautam Buddha University: ID Card Form (Please Fill Up The Form in Block Letters)Dokument1 SeiteGautam Buddha University: ID Card Form (Please Fill Up The Form in Block Letters)ATUL SAXENANoch keine Bewertungen

- New Centum VP Dcs With Network Io WhitepaperDokument4 SeitenNew Centum VP Dcs With Network Io WhitepaperFarrukh MajeedNoch keine Bewertungen

- ACCY225 Tri 1 2017 Tutorial 3 Business Processes-2Dokument3 SeitenACCY225 Tri 1 2017 Tutorial 3 Business Processes-2henryNoch keine Bewertungen

- Instrument TechnicianDokument3 SeitenInstrument TechnicianMahabula TypingNoch keine Bewertungen

- Technical Data: Digital and Millivolt Gas HeatersDokument2 SeitenTechnical Data: Digital and Millivolt Gas HeatersDenis CuraNoch keine Bewertungen

- CV 1Dokument3 SeitenCV 1PrateikMenonNoch keine Bewertungen

- Procedimiento de Test & Pruebas Hidrostaticas M40339-Ppu-R10 HCL / Dosing Pumps Rev.0Dokument13 SeitenProcedimiento de Test & Pruebas Hidrostaticas M40339-Ppu-R10 HCL / Dosing Pumps Rev.0José Angel TorrealbaNoch keine Bewertungen

- Operation & Service Manual: Murzan IncDokument38 SeitenOperation & Service Manual: Murzan IncgokulNoch keine Bewertungen

- DOE Cooling Catalogue 2017Dokument164 SeitenDOE Cooling Catalogue 2017Rashaad SheikNoch keine Bewertungen

- p2 A2 Weekend Homework Week 1-KeyDokument4 Seitenp2 A2 Weekend Homework Week 1-KeyaysegulokrNoch keine Bewertungen

- Answers For SummariesDokument6 SeitenAnswers For SummariesDaphneNoch keine Bewertungen

- Eseu EnglezaDokument1 SeiteEseu EnglezaAndreea IoanaNoch keine Bewertungen

- CYMTCC For Windows: User's Guide and Reference ManualDokument290 SeitenCYMTCC For Windows: User's Guide and Reference ManualJosselynGalloMuñozNoch keine Bewertungen

- Python Lab ManualDokument25 SeitenPython Lab ManualMohd TahirNoch keine Bewertungen

- Topic 10 - Advanced Approvals in Salesforce CPQDokument18 SeitenTopic 10 - Advanced Approvals in Salesforce CPQRamkumar Poovalai100% (1)

- 08 PrimingDokument6 Seiten08 PrimingJose RojasNoch keine Bewertungen

- CV hll3220cw Uke PSGDokument17 SeitenCV hll3220cw Uke PSGczarownikivanovNoch keine Bewertungen

- Lesson13ToeIn ToeOut PDFDokument5 SeitenLesson13ToeIn ToeOut PDFNurSafitriNoch keine Bewertungen

- Computer Science Ram PresentationDokument11 SeitenComputer Science Ram Presentationapi-268896185100% (3)

- Technology A Way of RevealingDokument24 SeitenTechnology A Way of RevealingSheena jhane Magana100% (1)

- REST Society For Research International: Rsri Membership Application FormDokument1 SeiteREST Society For Research International: Rsri Membership Application FormmeenasarathaNoch keine Bewertungen

- Segmentation - Ipynb - ColaboratoryDokument8 SeitenSegmentation - Ipynb - ColaboratoryManjot KaurNoch keine Bewertungen

- Graphics in C LanguageDokument8 SeitenGraphics in C LanguagePattabhi RamaraoNoch keine Bewertungen

- Concrete Construction Article PDF - Site Casting Exposed Aggregate WallsDokument1 SeiteConcrete Construction Article PDF - Site Casting Exposed Aggregate WallssonofalexanderNoch keine Bewertungen

- Tutorial Label MatrixDokument66 SeitenTutorial Label MatrixLuisa Adriana Perez GutierrezNoch keine Bewertungen

- Darcy Friction Loss Calculator For Pipes, Fittings & Valves: Given DataDokument2 SeitenDarcy Friction Loss Calculator For Pipes, Fittings & Valves: Given DataMSNoch keine Bewertungen

- 5th Kannada EvsDokument256 Seiten5th Kannada EvsnalinagcNoch keine Bewertungen

- Introduction To CMOS Circuit DesignDokument20 SeitenIntroduction To CMOS Circuit DesignBharathi MuniNoch keine Bewertungen