Beruflich Dokumente

Kultur Dokumente

Risk Ass. - AD 417 - Installation of Socket

Hochgeladen von

nsadnanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Risk Ass. - AD 417 - Installation of Socket

Hochgeladen von

nsadnanCopyright:

Verfügbare Formate

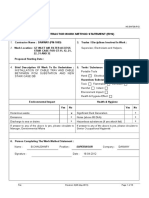

HS.SAF.09.

F12

CONTRACTOR WORK METHOD STATEMENT (EHS)

1. Contractor Name : Danway E & M Engg. 3. Trades / Disciplines Involved In Work :

2. Work Location : Engineer, Supervisor & electricians.

Proposed Starting Date :

4. Brief Description Of Work To Be Undertaken : 5. Tools / Substance

Portable Tools

Socket installation.

Hand Electrical Pneumatic

Hazardous Substances

Toxic Flammable Corrosive

Harmful Irritant

Environment Impact

Health & Hygiene Effect

Environmental Impact Health & Hygiene

Yes No Yes No

Hazardous waste Significant Dust Generation x

Emissions Noise (above 85 DbA) x

Discharge to sea or drains Hazardous substances (if yes attach list) x

If answer to any of the above is yes, please circulate to If answer to any of the above is yes, please circulate to

Manager, Environmental Affairs Senior Occupational Hygienist

6. Person Completing The Work Method Statement :

Name : Joselito Sangco Position : Supervisor Company : Danway

Signature : Date :

Revision: 1 (19-Mar 2012) Page 1 of 6

HS.SAF.09.F12

7. Approvals

Contractor Site Rep. Name Signature : Date :

EMAL Contract Admin. Name Signature : Date :

Area Owner Name Signature : Date :

Name Signature: Date:

EMAL EHS Department

The completed Work Method Statement must be submitted at least seven full working days prior to the

commencement of activities.

Where the Work Method Statement indicates the use of Hazardous Substances, a Material Hazard Data

Sheet must be attached.

After the Area Owners approval the Work Method Statement shall be forwarded to EHS department for

approval

The approved Work Method Statement must be attached to the permit(s) to work and all persons involved

in the job instructed in its requirements.

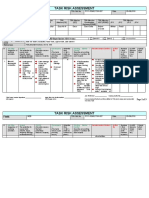

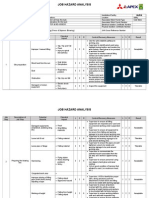

2. RISK ESTIMATOR CHART

The Risk Estimator chart should be used as an assistant for filling out the work

method statement.

Severity

Probability Low x1 Medium x 2 High x3

Low x1 Low Probability x Low LP x MS LP x HS

Severity 1 x 1 = 1 1x2 = 2 1x3 =3

Medium x2 MP x LS MP X MS MP x HS

2x1 =2 2x2 =4

2x3 =6

High x3 HP x LS HP X HS HP x HS

3 x 1 =3 3x2 = 6 3x3=9

Significant Risk = High Risk (6-9) or Medium Risk (3-4) in terms of probability and severity

Tolerable Risk = Risk reduced to an acceptable level = Low Risk (1-2)

Residual Risk = Risk remaining after implementing recommended control actions (usually very

minor).

Revision: 1 (19-Mar 2012) Page 2 of 6

HS.SAF.09.F12

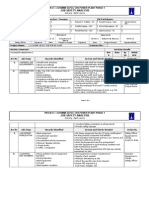

8. Safety Analysis

Severity x

Probability = Risk

Individual Activities To Identified Hazard(s) Persons Exposed Precautions and Plan of actions To Be Taken To Remove / Control

Complete Work. List In Residual Risk

Associated With Activity To Hazard Hazards

Sequence of Activity (Use Risk

Estimator Chart)

Supervisor to ensure approved PTW from

Emal operation is available prior to enter any

Emal facilities.

Unauthorized Activity shall be carried out the personnel

workers at working supervision of receiving activity.

area. Only competent and authorized personnel to

Unauthorized

6.1 Preparations. Lack of be deployed, supervisor to control. 3x1=3

personnel

coordination with Supervisor to give tool box talk prior to start

Emal shift the task and must be documented, this shall cover

supervisor. the method statement and job safety analysis.

Proper coordination with Emal shift

supervisor prior to commencement of the

activity.

Only competent electricians to be deployed

Incompetent for the electrical works.

* Job execution. Electricians 3x1=3

workers Ensure all workers received the Big 5 training

from EMAL training center.

Revision: 1 (19-Mar 2012) Page 3 of 6

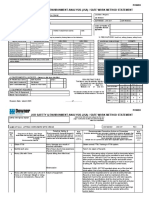

HS.SAF.09.F12

Unauthorized user of Supervisor to ensure that the user of hand power

hand power tools. tool is trained & competent electrician.

Use of bad condition Electrician Supervisor to ensure that the power source to be 3x1=3

of power tools. connected with ELCB and only 110V industrial

Electrocution. socket to be used at site.

Use of bad condition

Inspect all hand tools to be used for the task, do

of hand tools.

not use homemade hand tools.

sharp edges from

Electricians Extra care to be taken while working in the existing 2x1=2

the existing cable

cable tray and from the trunking, use appropriate

tray and from the

hand gloves.

trunking.

Use of bad

condition step Supervisor to give toolbox talk regarding

ladder. Electricians proper use of step ladder, ensure that the step 3x1=3

Fall from the ladder was with color coded.

step ladder.

Supervisor to ensure electrical power source

Electrocution

is 100% isolated, verify / double check LOTO.

while working with

Daily coordination with Emal representative and

existing power cable.

Electricians conduct crew meeting to the group prior to start 3x1=3

Bad condition of

the task.

multi-meter tester

Follow the Golden Rules "TEST BEFORE YOU

for continuity test.

TOUCH" using calibrated multi-meter tester.

During crew meeting, Supervisor to discuss

Manual handling

Electricians and explain the hazards & precaution of manual 3x1=3

hazard

handling.

Revision: 1 (19-Mar 2012) Page 4 of 6

HS.SAF.09.F12

Observe good housekeeping around the

Workers may working area.

Slip, Trip & Fall Supervisor & Walkway and gangway to be kept free of

3x1=3

same ground due to electricians obstruction, hand tools and toolbox to be kept in

poor housekeeping. safe position.

Barricade the working area as required.

All personnel involve in the activities must

Working without

Supervisor & wear P.P.E.'s (e.g. hard hat, appropriate safety

personal protective 3x1=3

electricians glass, safety shoes, appropriate hand gloves,

equipment.

long sleeve shirt etc.).

This sheet must be properly completed detailing all of the steps required to complete the job along with the sequence of events and each of the hazards arising.

Failure to properly complete the form will result in non-approval.

(Additional sheets to be used as required)

9. Chemical Analysis (This form to be used as required)

Product Name

MSDS supplied Yes / No

Dangerous Goods Class

Hazardous Material Yes / No

Nature of Hazard Irritation / Carcinogen / Corrosive / Toxic / Other

Form Solid /Liquid / Gas / Dust / Vapour / Mist

Exposure Route Inhalation / Skin / Eye / Ingestion

Revision: 1 (19-Mar 2012) Page 5 of 6

HS.SAF.09.F12

Number of People Exposed

Duration of Exposure

Frequency of Exposure

Controls to be implemented

Estimate of Exposure Negligible / Marginal / High

This sheet must be properly completed detailing all the necessary information. Failure to properly complete the form will result in non-approval.

Revision: 1 (19-Mar 2012) Page 6 of 6

Das könnte Ihnen auch gefallen

- Cable PullingDokument10 SeitenCable PullingnsadnanNoch keine Bewertungen

- Risk Ass. - Load Current Measurement and Cleaning of Oil CoolerDokument7 SeitenRisk Ass. - Load Current Measurement and Cleaning of Oil CoolernsadnanNoch keine Bewertungen

- Contractor Work Method Statement (Ehs)Dokument11 SeitenContractor Work Method Statement (Ehs)nsadnanNoch keine Bewertungen

- Contractor Work Method Statement (Ehs) : Installation of Wooden ScaffoldingDokument8 SeitenContractor Work Method Statement (Ehs) : Installation of Wooden ScaffoldingnsadnanNoch keine Bewertungen

- Cable Pulling, Glanding and TerminationsDokument6 SeitenCable Pulling, Glanding and TerminationsnsadnanNoch keine Bewertungen

- Fuel Gas Compressor Enclosures: Contractor Work Method Statement (Ehs)Dokument8 SeitenFuel Gas Compressor Enclosures: Contractor Work Method Statement (Ehs)nsadnanNoch keine Bewertungen

- D02 MS Ra Pov PDFDokument35 SeitenD02 MS Ra Pov PDFnsadnanNoch keine Bewertungen

- Risk Ass. - PM - 1009 - INSTALLATION OF CABLE TRAY AND CABLE BETWWEN PCM SUBSTATION AND NEW STAIR CASE DBDokument13 SeitenRisk Ass. - PM - 1009 - INSTALLATION OF CABLE TRAY AND CABLE BETWWEN PCM SUBSTATION AND NEW STAIR CASE DBnsadnanNoch keine Bewertungen

- RA For Fixing Warning LabelsDokument5 SeitenRA For Fixing Warning LabelsnsadnanNoch keine Bewertungen

- Risk Ass - RECTIFICATION FOR DAMAGED CABLE TRAY SUPPORTDokument9 SeitenRisk Ass - RECTIFICATION FOR DAMAGED CABLE TRAY SUPPORTnsadnanNoch keine Bewertungen

- Risk Ass. - INSTALLATION OF CBCT IN SUBSTATION 4730-ESS-001Dokument12 SeitenRisk Ass. - INSTALLATION OF CBCT IN SUBSTATION 4730-ESS-001nsadnanNoch keine Bewertungen

- Risk Ass - INSTALLATION OF PLC CABINET HMI CABINET IPCPDokument20 SeitenRisk Ass - INSTALLATION OF PLC CABINET HMI CABINET IPCPnsadnanNoch keine Bewertungen

- Modification of Cable Ladder in Bath Processing PlantDokument14 SeitenModification of Cable Ladder in Bath Processing PlantnsadnanNoch keine Bewertungen

- PM-1009 Installation of Cable Tray and Cable Betwwen PCM Substation and New Stair Case DBDokument16 SeitenPM-1009 Installation of Cable Tray and Cable Betwwen PCM Substation and New Stair Case DBnsadnanNoch keine Bewertungen

- Risk Ass. - INSTALLATION OF 25 MM G.I. PIPE WITH EXISTING LINEDokument12 SeitenRisk Ass. - INSTALLATION OF 25 MM G.I. PIPE WITH EXISTING LINEnsadnanNoch keine Bewertungen

- Job Hazard Analysis: Format For JHA WorksheetDokument7 SeitenJob Hazard Analysis: Format For JHA WorksheetSalam AlkataluniNoch keine Bewertungen

- Risk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)Dokument3 SeitenRisk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)nsadnan100% (2)

- 4.5.3!01!02 Incedent Injury Report Rev 1 - QTEL CABLE - C1Dokument4 Seiten4.5.3!01!02 Incedent Injury Report Rev 1 - QTEL CABLE - C1loveson709Noch keine Bewertungen

- 4.5.3!01!06 First Aid Property Environmental ReportDokument4 Seiten4.5.3!01!06 First Aid Property Environmental Reportloveson709Noch keine Bewertungen

- Rmdjv-pj74-Hiradc-subc 03 (Hoisting & Rigging)Dokument1 SeiteRmdjv-pj74-Hiradc-subc 03 (Hoisting & Rigging)myn maliQueNoch keine Bewertungen

- Risk Assess - 98-Installation Fuel Oil ConditioniDokument4 SeitenRisk Assess - 98-Installation Fuel Oil ConditioniRochdi BahiriNoch keine Bewertungen

- P111-RSME-TRA-007 - TRA For ExcavationDokument3 SeitenP111-RSME-TRA-007 - TRA For ExcavationDarius DsouzaNoch keine Bewertungen

- GEN-038 Balance Turbine Unit - All TypesDokument3 SeitenGEN-038 Balance Turbine Unit - All Typesacanbasri1980Noch keine Bewertungen

- RA Excessive Noise .Vibration.Dokument11 SeitenRA Excessive Noise .Vibration.Ndifor Dinho0% (1)

- Earth Works JSADokument4 SeitenEarth Works JSARen SalazarNoch keine Bewertungen

- Using Hand Drill (WS)Dokument2 SeitenUsing Hand Drill (WS)John KalvinNoch keine Bewertungen

- JSA G20 Scaffolding Erection DismantlingDokument4 SeitenJSA G20 Scaffolding Erection DismantlingemmyNoch keine Bewertungen

- SOP SOP0022 Concrete Core DrillDokument3 SeitenSOP SOP0022 Concrete Core Drillkristian08Noch keine Bewertungen

- JSA PRE-TEST UploadDokument2 SeitenJSA PRE-TEST UploadDenny Kurniawan PrawiraNoch keine Bewertungen

- De-Com - For Existing 8 12 Inch - Pipeline - TRA1Dokument6 SeitenDe-Com - For Existing 8 12 Inch - Pipeline - TRA1Darius DsouzaNoch keine Bewertungen

- 3.jsa - Arc Welding-NDokument5 Seiten3.jsa - Arc Welding-NVivek NaikNoch keine Bewertungen

- Jsa Unloading LoadingDokument2 SeitenJsa Unloading LoadingRais ZaynNoch keine Bewertungen

- Hazard Identification & Risk Assessment (Hira) /jsa: Hira & Jsa For Tri Butyl Phosphate (TBP) PlantDokument6 SeitenHazard Identification & Risk Assessment (Hira) /jsa: Hira & Jsa For Tri Butyl Phosphate (TBP) PlantShariq KhanNoch keine Bewertungen

- Job Hazard Analysis (Jha) Worksheet: Body Injury 2 2 4 1 1 1 AcceptableDokument2 SeitenJob Hazard Analysis (Jha) Worksheet: Body Injury 2 2 4 1 1 1 Acceptableganeshkanth0% (1)

- Ra FormDokument5 SeitenRa FormEngrHazrat MaazNoch keine Bewertungen

- JSA Format Erection of Column 903-C-02,03Dokument5 SeitenJSA Format Erection of Column 903-C-02,03sakthi venkat100% (1)

- Job Safety Assessment (Jsa)Dokument19 SeitenJob Safety Assessment (Jsa)Saravanan Sara0% (1)

- Job Safety Analysis (Jsa) Work Sheet: Risk Matrix Project /job DetailsDokument4 SeitenJob Safety Analysis (Jsa) Work Sheet: Risk Matrix Project /job Detailsnasar_mahsood100% (1)

- JSA G17 Lift Container With Crane PDFDokument4 SeitenJSA G17 Lift Container With Crane PDFsetiawanaji407100% (1)

- JSA OF Fabrication and Installation Work ApproviedDokument3 SeitenJSA OF Fabrication and Installation Work Approviedsakthi venkatNoch keine Bewertungen

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Dokument4 SeitenRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanNoch keine Bewertungen

- Job Safety Analysis: Client: ContractorDokument7 SeitenJob Safety Analysis: Client: Contractorloveson709Noch keine Bewertungen

- 2.8c Risk Assessment - 074 Construction of Substation Floor, Wall, Stairs by Casting in Place Rev. July 2019Dokument7 Seiten2.8c Risk Assessment - 074 Construction of Substation Floor, Wall, Stairs by Casting in Place Rev. July 2019kamranshamoo1Noch keine Bewertungen

- RA Templates ElectricalDokument17 SeitenRA Templates ElectricalAbid MujtabaNoch keine Bewertungen

- JSA 04 Confined Sapce EntryDokument1 SeiteJSA 04 Confined Sapce EntryalekyaNoch keine Bewertungen

- Ra02 - Container OffloadingDokument3 SeitenRa02 - Container OffloadingSamNoch keine Bewertungen

- JHA Cutting of Asphalt Road For Replacement of Protection SlabsDokument5 SeitenJHA Cutting of Asphalt Road For Replacement of Protection SlabsNasrullah JanNoch keine Bewertungen

- JHA Blowing PressDokument5 SeitenJHA Blowing PressLuqman OsmanNoch keine Bewertungen

- Warehouse Risk Assessment Aldir II IWPPDokument25 SeitenWarehouse Risk Assessment Aldir II IWPPMadhu MohanNoch keine Bewertungen

- Work at Height ProcedureDokument36 SeitenWork at Height ProcedureShams JogNoch keine Bewertungen

- CL-07-02 Crane Lift Study ChecklistDokument7 SeitenCL-07-02 Crane Lift Study Checklisthanes0% (1)

- 11.07.09 Working at Height (TD Repair)Dokument1 Seite11.07.09 Working at Height (TD Repair)Hamdi Rafiek100% (1)

- Near Miss Report: Complete This Form and Email It ToDokument1 SeiteNear Miss Report: Complete This Form and Email It Toloveson709Noch keine Bewertungen

- SS JSP - 013 Foundation and Ground Shuttering Forms and Rebar WorksDokument6 SeitenSS JSP - 013 Foundation and Ground Shuttering Forms and Rebar WorksFarhat SetharNoch keine Bewertungen

- TRA 58 Unloading and Rigging Up Test EquipmentDokument4 SeitenTRA 58 Unloading and Rigging Up Test EquipmentPirlo PoloNoch keine Bewertungen

- Risk Ass - CABLE PULLING LAYING Power Cables, Control Cables & FO CablesMDokument16 SeitenRisk Ass - CABLE PULLING LAYING Power Cables, Control Cables & FO CablesMnsadnanNoch keine Bewertungen

- Contractor Work Method Statement For Fire Hydrant Pipe ReprairDokument8 SeitenContractor Work Method Statement For Fire Hydrant Pipe Reprairnsadnan100% (1)

- Risk Ass. - Installation of Stainless Steel Label On The 10kva Inverter-3210-ELE-003ADokument6 SeitenRisk Ass. - Installation of Stainless Steel Label On The 10kva Inverter-3210-ELE-003AnsadnanNoch keine Bewertungen

- Risk Ass. - TK 4446 - Installation of Cable Tray, Cable Ladder & Scaffolding - PL 1 & PL 2 - Emal FormatDokument6 SeitenRisk Ass. - TK 4446 - Installation of Cable Tray, Cable Ladder & Scaffolding - PL 1 & PL 2 - Emal FormatnsadnanNoch keine Bewertungen

- Risk Ass. - RELOCATION OF 11 KV CABLE FROM EXISTING ROUTE TO NEW LOCATIONDokument6 SeitenRisk Ass. - RELOCATION OF 11 KV CABLE FROM EXISTING ROUTE TO NEW LOCATIONnsadnan100% (1)

- ONVIF Profile - S Specification v1-2Dokument42 SeitenONVIF Profile - S Specification v1-2nsadnan0% (1)

- BSIA Cyber Secure It January 2019Dokument16 SeitenBSIA Cyber Secure It January 2019nsadnanNoch keine Bewertungen

- ONVIF Profile T Specification v1-0Dokument77 SeitenONVIF Profile T Specification v1-0nsadnanNoch keine Bewertungen

- 1 45Dokument3 Seiten1 45nsadnan0% (1)

- ONVIF Profile Feature Overview v2-2Dokument6 SeitenONVIF Profile Feature Overview v2-2nsadnanNoch keine Bewertungen

- Testing and Commissioning Pre-Check List (ID 1506)Dokument1 SeiteTesting and Commissioning Pre-Check List (ID 1506)nsadnan0% (2)

- Peer Communications Protocol Communications Media: Twisted Pair Copper Conductors Ranging From 16 To 24 GageDokument5 SeitenPeer Communications Protocol Communications Media: Twisted Pair Copper Conductors Ranging From 16 To 24 GagensadnanNoch keine Bewertungen

- Checklist For Commissioning of CCTV SystemDokument2 SeitenChecklist For Commissioning of CCTV Systemnsadnan70% (10)

- Excel Intelligent Pdu User InstructionsDokument2 SeitenExcel Intelligent Pdu User InstructionsnsadnanNoch keine Bewertungen

- DDC Systems2Dokument28 SeitenDDC Systems2nsadnan100% (1)

- Checklist For Access Control System InstallationDokument6 SeitenChecklist For Access Control System Installationnsadnan71% (7)

- CCTV Testing and Commissioning Pre-Check List (ID 1506)Dokument1 SeiteCCTV Testing and Commissioning Pre-Check List (ID 1506)nsadnan67% (3)

- Risk Assessment For GIS Preparation For HV Cable TestDokument11 SeitenRisk Assessment For GIS Preparation For HV Cable Testnsadnan100% (3)

- Risk Assessment - Pre-Internal Wiring of Patch PanelDokument3 SeitenRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- RISK ASSESSMENT - TK-4742-Operation Training For Overhead CraneDokument6 SeitenRISK ASSESSMENT - TK-4742-Operation Training For Overhead CranensadnanNoch keine Bewertungen

- Checklist For Pre Commissioning of CCTV SystemDokument1 SeiteChecklist For Pre Commissioning of CCTV Systemnsadnan67% (6)

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Dokument4 SeitenRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanNoch keine Bewertungen

- Risk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)Dokument3 SeitenRisk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)nsadnan100% (2)

- Risk Assessment - Pre-Internal Wiring of Patch PanelDokument3 SeitenRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- Risk Assessment - Installation of Ventilation FanDokument6 SeitenRisk Assessment - Installation of Ventilation Fannsadnan100% (5)

- RISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling FanDokument6 SeitenRISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling Fannsadnan100% (2)

- Risk Assessment - Cable Pulling Laying, Glanding and Termination From RT Bay Outdoor Enclosure To RT Control BuildingDokument14 SeitenRisk Assessment - Cable Pulling Laying, Glanding and Termination From RT Bay Outdoor Enclosure To RT Control Buildingnsadnan91% (82)

- Risk Assessment - Installation and Testing of Motorized Fire & Smoke DamperDokument10 SeitenRisk Assessment - Installation and Testing of Motorized Fire & Smoke Dampernsadnan50% (2)

- Risk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in OmbDokument9 SeitenRisk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in Ombnsadnan100% (1)

- Risk Assessment - Distribution Board (DB) & Junction Box (JB) InstallationDokument6 SeitenRisk Assessment - Distribution Board (DB) & Junction Box (JB) Installationnsadnan91% (11)

- Risk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and TestingDokument12 SeitenRisk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and Testingnsadnan100% (1)

- Risk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)Dokument3 SeitenRisk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)nsadnan0% (1)

- Risk Assessment - Cg-4750-Installation of Lighting Protection Pole, Street Lighting Pole and Light FittingsDokument6 SeitenRisk Assessment - Cg-4750-Installation of Lighting Protection Pole, Street Lighting Pole and Light Fittingsnsadnan86% (21)

- RISK ASSESSMENT - CG-4706-offloading The 40 Feet Container and Offloading The MaterialsDokument6 SeitenRISK ASSESSMENT - CG-4706-offloading The 40 Feet Container and Offloading The Materialsnsadnan100% (5)

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Dokument4 SeitenRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanNoch keine Bewertungen

- Samyu AgreementDokument16 SeitenSamyu AgreementMEENA VEERIAHNoch keine Bewertungen

- De Guia Vs MeralcoDokument3 SeitenDe Guia Vs MeralcoErby Jennifer Sotelo-GesellNoch keine Bewertungen

- 2020 Contract Negotiations - Official CTA Proposal 6-25-21Dokument44 Seiten2020 Contract Negotiations - Official CTA Proposal 6-25-21Chicago Transit Justice CoalitionNoch keine Bewertungen

- Farm Worker: U.S. Department of Labor A. Job Offer InformationDokument14 SeitenFarm Worker: U.S. Department of Labor A. Job Offer InformationJenny GarcíaNoch keine Bewertungen

- LU5 BMAdDokument38 SeitenLU5 BMAdzina minaNoch keine Bewertungen

- Resume Ana Devdariani JobseekerDokument1 SeiteResume Ana Devdariani JobseekerAna DevdarianiNoch keine Bewertungen

- Essay Assignment-Part PayaDokument15 SeitenEssay Assignment-Part PayaJuri JurieNoch keine Bewertungen

- Internship Report FAQsDokument8 SeitenInternship Report FAQsm.saeed1929Noch keine Bewertungen

- Enhanced Cookery NC2 COC2 - POLODokument24 SeitenEnhanced Cookery NC2 COC2 - POLOJennifer J. PascuaNoch keine Bewertungen

- SSSForm EC Medical ReimbursementDokument4 SeitenSSSForm EC Medical Reimbursementmel7sumatraNoch keine Bewertungen

- PHEW!!!!Dokument65 SeitenPHEW!!!!Harshit MaheyNoch keine Bewertungen

- Communist Party of India (Marxist Central Committee OfficeDokument29 SeitenCommunist Party of India (Marxist Central Committee OfficeswoneraNoch keine Bewertungen

- EEM Unit-II-IDokument87 SeitenEEM Unit-II-INishant NNoch keine Bewertungen

- Press V GalitDokument3 SeitenPress V Galitmblopez1Noch keine Bewertungen

- Keyman InsuranceDokument4 SeitenKeyman InsuranceAnonymous gCE3zvINoch keine Bewertungen

- Consultancy Management (Recovered)Dokument30 SeitenConsultancy Management (Recovered)Gilbert G. Asuncion Jr.Noch keine Bewertungen

- Phil Veterans Bank Vs NLRCDokument7 SeitenPhil Veterans Bank Vs NLRCColeen Navarro-RasmussenNoch keine Bewertungen

- HW Reading Assignment - The World of American BusinessDokument8 SeitenHW Reading Assignment - The World of American BusinessAna BasarNoch keine Bewertungen

- Ethics ExamDokument4 SeitenEthics ExamJulius IxohoxiNoch keine Bewertungen

- SPM AssignmentDokument8 SeitenSPM AssignmentKelvin MasekoNoch keine Bewertungen

- Chapter 7 - Strategies For Competing in International Market - Draft1Dokument20 SeitenChapter 7 - Strategies For Competing in International Market - Draft1Milky Umar BawazierNoch keine Bewertungen

- Multiple EmploymentDokument21 SeitenMultiple EmploymentSasha NguNoch keine Bewertungen

- Career Interests Guide Final 092010Dokument6 SeitenCareer Interests Guide Final 092010naba1577Noch keine Bewertungen

- SAP HR Transaction CodesDokument4 SeitenSAP HR Transaction CodesRoberto MartínezNoch keine Bewertungen

- Day Work RatesDokument4 SeitenDay Work RatesFaiz Fitri Noorizan0% (2)

- Human Resource Management VS Human Resource DevelopmentDokument21 SeitenHuman Resource Management VS Human Resource Developmentpriyanka253880% (15)

- Xplore-Tech Services Private Limited: Plot Y9, Block-EP, Sector-V, Salt Lake City, Kolkata-700091Dokument8 SeitenXplore-Tech Services Private Limited: Plot Y9, Block-EP, Sector-V, Salt Lake City, Kolkata-700091Kushal GuptaNoch keine Bewertungen

- Recruitment Theory SheetDokument4 SeitenRecruitment Theory SheetAugust EmpedradNoch keine Bewertungen

- Legal Ethics Cases Canon 12 OnwardsDokument22 SeitenLegal Ethics Cases Canon 12 OnwardsMaria Danice AngelaNoch keine Bewertungen

- Pierre Bourdieu and Abdelmalek SayadDokument43 SeitenPierre Bourdieu and Abdelmalek SayadGabi Maas100% (1)