Beruflich Dokumente

Kultur Dokumente

Risk Assessment For GIS Preparation For HV Cable Test

Hochgeladen von

nsadnanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Risk Assessment For GIS Preparation For HV Cable Test

Hochgeladen von

nsadnanCopyright:

Verfügbare Formate

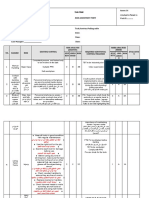

HS.SAF.09.

F12

CONTRACTOR WORK METHOD STATEMENT (EHS)

1. Contractor Name : DANWAY E & M ENGG 3. Trades / Disciplines Involved In Work :

Engineer, Supervisor, Electricians and Helpers.

(TK-4842/ABB)

2. Work Location : GIS Building

Proposed Starting Date :

4. Brief Description Of Work To Be Undertaken : GIS 5. Tools / Substance

PREPARATION FOR HIGH VOLTAGE TEST

Portable Tools

Hand Electrical Pneumatic

Hazardous Substances

Toxic Flammable Corrosive

Harmful Irritant

Environment Impact

Health & Hygiene Effect

Environmental Impact Health & Hygiene

Yes No Yes No

Hazardous waste Significant Dust Generation

Emissions Noise (above 85 DbA)

Discharge to sea or drains Hazardous substances (if yes attach list)

If answer to any of the above is yes, please circulate to If answer to any of the above is yes, please circulate to

Manager, Environmental Affairs Senior Occupational Hygienist

6. Person Completing The Work Method Statement :

Name : Joachim Kuhlmann Position : Joachim Kuhlmann Company : ABB Switzerland

Signature : Date : 30.11.2011

Revision: 0(26-May-2011) Page 1 of 11

HS.SAF.09.F12

7. Approvals

Contractor Site Rep. Name Maan Al-Eshaiker Signature : Date : 30.11.2011

EMAL Contract Admin. Name Signature : Date :

Area Owner Name Signature : Date :

Name Signature: Date:

EMAL EHS Department

The completed Work Method Statement must be submitted at least seven full working days prior to the

commencement of activities.

Where the Work Method Statement indicates the use of Hazardous Substances, a Material Hazard Data

Sheet must be attached.

After the Area Owners approval the Work Method Statement shall be forwarded to EHS department for

approval

The approved Work Method Statement must be attached to the permit(s) to work and all persons involved

in the job instructed in its requirements.

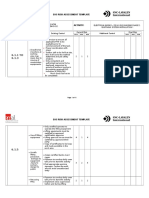

2. RISK ESTIMATOR CHART

The Risk Estimator chart should be used as an assistant for filling out the work

method statement.

Severity

Probability Low x1 Medium x 2 High x3

Low x1 Low Probability x Low LP x MS LP x HS

Severity 1 x 1 = 1 1x2 = 2 1x3 =3

Medium x2 MP x LS MP X MS MP x HS

2x1 =2 2x2 =4

2x3 =6

High x3 HP x LS HP X HS HP x HS

3 x 1 =3 3x2 = 6 3x3=9

Significant Risk = High Risk (6-9) or Medium Risk (3-4) in terms of probability and severity

Tolerable Risk = Risk reduced to an acceptable level = Low Risk (1-2)

Residual Risk = Risk remaining after implementing recommended control actions (usually very minor).

Revision: 0(26-May-2011) Page 2 of 11

HS.SAF.09.F12

8. Safety Analysis

Identified Hazard(s) Persons Precautions and Plan of actions To Be

Individual Activities To Associated With Activity Exposed To Remove / Control Hazards

Complete Work. List In Hazard

Sequence of Activity

1.PREPARATION. Slips, trips and fall at the Emal / SNC Maintain housekeeping around in

same level. rep., Engr., working area.

Supv. Elec.

Helpers

Emal / SNC All workers involve in the activity

rep., Engr., aware of heat stress, supervisor t

Hot weather.

Supv. Elec drinking cold water is available.

Helpers.

Emal / SNC Wear P.P.E.'s at all times (hard h

rep., Engr., safety glass, safety shoes, hand g

Not using P.P.E.'s Supv. dust mask, fire retardant long slee

Elec,Helpers. pants).

Electrical shock, fire and Engr., Supv. Only qualified employees will wor

arc flash. Elec,Helpers on electrical equipment.

Use only proper tools that have a

colour coding.

Failure to interact with Engr., Supv. Depending on the type of activity

each other and absence Elec,Helpers employer shall ascertain that the

of a Job Hazard employees of other employers wo

Assessment. nearby have been adequately ins

with regard to the hazards of eac

tasks and processes to reduce ris

Ensure that adjacent work activa

associated risks are understood.

of non-ABB work areas.

Revision: 0(26-May-2011) Page 3 of 11

HS.SAF.09.F12

Work with hazardous Supv. Complete and document hazard

substances. Elec,Helpers communications training for emp

Follow operation instruction.

Ensure relevant PPE is used.

Avoid skin contact and inhalation

Use of tools Supv. Use proper tools that have been

Elec,Helpers Only qualified and trained emplo

allowed to work.

All tools must be inspected on a

basis and prior to use by the emp

Work with energized Emal / SNC Energized parts within working ar

equipment. rep., Engr., insulated.

Supv. Elec

Helpers Ensure relevant PPE is used.

Prohibit unauthorized entry.

De energized and ground when p

Utilize only qualified and trained

employees.

Follow operation instruction.

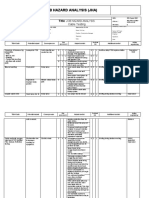

2.INSTALLATION

No specific

Supv,Elect & Supervisor to ensure approved P

available permit. helpers available on site.

Supv,Elect & Check qualifications prior to allow

helpers employee to work on electrical sy

Electrocution

Revision: 0(26-May-2011) Page 4 of 11

HS.SAF.09.F12

Unauthorized and Supv,Elect & Ensure that approval is obtained

untrained staff working helpers management prior to starting wor

in an unsafe manner

Unknown aspects of Supv,Elect & Single line must be available for r

circuits can lead to helpers and use,updates required must b

electrocution reviewed and approved.

Continuous interface with site

management and client.

Encountering energized Supv,Elect & All work planned for the day mus

equipment thought to be helpers reviewed and risks assessed, de

dead. plan must be updated daily.

Ensure that site management an

installation crew interface daily.

Failure to recognize or Supv ,Elect & An assessment of electrical haza

understand risks. helpers relative to ongoing work and adja

must be included in the job hazar

assessment.

Daily tool box talk conducted befo

the work .

Untested tools used Supv ,Elect & Only tools with a current certifica

conducting current. helpers testing will be used for high volta

Only use tools that are appropria

task and have a current certificat

testing.

Revision: 0(26-May-2011) Page 5 of 11

HS.SAF.09.F12

2.1Staging and installing Crush, knock, strike, Supv ,Elect & No transport and lift above perso

equipment shear, etc. helpers

Crane be qualified and a lift plan

All lifting equipment must have a

annual inspection and inspected

Equipment to be secured against

over.

Ensure relevant PPE is used.

Inform personal about working ac

Follow operation instruction.

Defect lifting equipment to be ma

secured against reuse.

Discuss communication between

driver and rigger before lifting act

2.2 Installation of GIS Crush, knock, strike, Supv ,Elect & Only qualified and trained employ

parts shear, etc. helpers allowed to work.

Relevant PPE to be used.

Use the insulated tools when wor

or near energized equipment.

Inform personal about working ac

Follow operation instruction.

Only use approved tools and equ

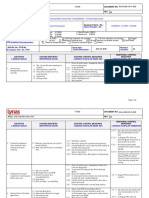

2.3Filling equipment with Release of SF6 gas to Emal / SNC Only qualified and trained employ

SF6 gas the environment rep., Engr., allowed to work.

Supv. Elec

Helpers Relevant PPE to be used.

Use the correct tools.

Use only closed cycle system wit

SF6 gas.

Use recycling equipment to captu

SF6 gas and make sure that all

connections are secure and leaks

occur.

Revision: 0(26-May-2011) Page 6 of 11

HS.SAF.09.F12

Displacement of air by Emal / SNC Only qualified and trained employ

SF6 gas rep., Engr., allowed to work.

Supv. Elec

Helpers Relevant PPE to be used.

Use the correct tools.

Use only closed cycle system wit

SF6 gas.

Generally provide a good air sup

work space.

Ventilate all basement areas to e

a buildup for SF6 in lower areas i

prevented.

Eating, drinking and smoking in t

area are prohibited.

Warn employee by using warning

Follow operation instruction.

Prohibit unauthorized entry.

Exposure to high Emal / SNC Only qualified and trained employ

pressure release rep., Engr., allowed to work.

Supv. Elec

Helpers Relevant PPE to be used.

Use the correct tools.

For filling of equipment follow ope

instruction and gas layout.

Warn workplace by caution label.

Inform personal about working ac

Check the quality of the pressure

Revision: 0(26-May-2011) Page 7 of 11

HS.SAF.09.F12

2.4Evacuate SF6 gas. Release to the Emal / SNC Only qualified and trained employ

environment rep., Engr., allowed to work.

Supv. Elec

Helpers Relevant PPE to be used.

Use the correct tools.

Use recycling equipment to recyc

and ensure that charging operatio

when any leak of SF6 is observe

Follow operation instruction.

Inform personal about working ac

Eliminate air by SF6 gas Emal / SNC Only qualified and trained employ

rep., Engr., allowed to work.

Supv. Elec

Helpers Relevant PPE to be used.

Use the correct tools.

Use only closed cycle system wit

SF6 gas.

Ensure that supply ventilation is u

the work area.

Ventilate cavities and more deep

areas.

Eating, drinking and smoking in t

area are prohibited.

Warning Workplace by caution la

Contaminated objects with SF6 g

separately disposed.

Consider operating instruction.

Follow operation instruction.

Prohibit unauthorized entry.

Revision: 0(26-May-2011) Page 8 of 11

HS.SAF.09.F12

High pressure Emal / SNC Only qualified and trained employ

rep., Engr., allowed to work.

Supv. Elec

Helpers Relevant PPE to be used.

Use the correct tools

Warn workplace by caution label.

Inform personal about working ac

Check the quality of the pressure

2.5Installation of Crush, knock, strike, Emal / SNC Only qualified and trained employ

secondary equipment shear, etc. rep., Engr., allowed to work.

Supv. Elec

Helpers Relevant PPE to be used.

Inform personal about working ac

Follow operation instruction.

Only use approved tools and equ

Electrical shock. Emal / SNC Only qualified and trained employ

rep., Engr., allowed to work.

Supv. Elec

Helpers Relevant PPE to be used.

Use the correct tools.

Follow operation instruction.

2.6Installation of parts Crush, knock, strike, Supv. Elec Only qualified and trained employ

shear, etc. Helpers allowed to work.

Relevant PPE to be used.

Use the correct tools.

Follow operation instruction.

Inform personal about working ac

Revision: 0(26-May-2011) Page 9 of 11

HS.SAF.09.F12

Electrical shock. Supv. Elec Only qualified and trained employ

Helpers allowed to work.

Relevant PPE to be used.

Use the correct tools.

Follow operation instruction.

Inform personal about working ac

This sheet must be properly completed detailing all of the steps required to complete the job along

with the sequence of events and each of the hazards arising. Failure to properly complete the form

will result in non-approval.

(Additional sheets to be used as required)

9. Chemical Analysis (This form to be used as required)

Product Name

MSDS supplied Yes / No

Dangerous Goods Class

Hazardous Material Yes / No

Nature of Hazard Irritation / Carcinogen / Corrosive / Toxic / Other

Form Solid /Liquid / Gas / Dust / Vapour / Mist

Exposure Route Inhalation / Skin / Eye / Ingestion

Number of People Exposed

Duration of Exposure

Frequency of Exposure

Controls to be implemented

Estimate of Exposure Negligible / Marginal / High

Revision: 0(26-May-2011) Page 10 of 11

HS.SAF.09.F12

This sheet must be properly completed detailing all the necessary information. Failure to

properly complete the form will result in non-approval.

Revision: 0(26-May-2011) Page 11 of 11

Das könnte Ihnen auch gefallen

- Jha RebarsDokument7 SeitenJha RebarsJaycee QuinNoch keine Bewertungen

- JSA Electrical Maintenance LCSDokument8 SeitenJSA Electrical Maintenance LCSmohamed yasinNoch keine Bewertungen

- Risk Assessment - Placing of Transformer - TTSDokument6 SeitenRisk Assessment - Placing of Transformer - TTSnsadnan100% (2)

- Risk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and TestingDokument12 SeitenRisk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and Testingnsadnan100% (1)

- 2 - Pulling CablesDokument5 Seiten2 - Pulling CablesAhmed KhaledNoch keine Bewertungen

- Risk Assessment - Pre-Internal Wiring of Patch PanelDokument3 SeitenRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- Risk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)Dokument3 SeitenRisk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)nsadnan0% (1)

- Format for JHA WorksheetDokument4 SeitenFormat for JHA WorksheetWaseem Ahmad100% (1)

- RA Risk Assessment for 33kVA Transformer MaintenanceDokument4 SeitenRA Risk Assessment for 33kVA Transformer MaintenancePandu BirumakovelaNoch keine Bewertungen

- Risk Assessment Form: 1 Biophysical HazardsDokument5 SeitenRisk Assessment Form: 1 Biophysical HazardsGajendran Sriram33% (3)

- RISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling FanDokument6 SeitenRISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling Fannsadnan100% (2)

- Electrical Maintenance & Testing Hazard IdentificationDokument10 SeitenElectrical Maintenance & Testing Hazard IdentificationRavi ValiyaNoch keine Bewertungen

- ACB Panel Maintenance HazardsDokument58 SeitenACB Panel Maintenance HazardsElectrical Team100% (2)

- JSA Cable Glanding & Wiring Termination Works 112Dokument5 SeitenJSA Cable Glanding & Wiring Termination Works 112Francis Enriquez Tan83% (6)

- DOCUMENT Loop Checking Activities JHADokument8 SeitenDOCUMENT Loop Checking Activities JHAFrancis Enriquez Tan83% (6)

- JSA Cable DisconnectedDokument4 SeitenJSA Cable Disconnectedwendypost730% (1)

- JSA FOR Shakthi ElectricalDokument8 SeitenJSA FOR Shakthi Electricalwahyu nugroho100% (1)

- JSA For Electrical TestingDokument5 SeitenJSA For Electrical TestingAchmad Djadjang0% (1)

- 024 - Mobile Scaffold Inspection ChecklistDokument1 Seite024 - Mobile Scaffold Inspection ChecklistFaiez AripiNoch keine Bewertungen

- Risk Generator Risk AssessmentDokument2 SeitenRisk Generator Risk AssessmentBaher MohamedNoch keine Bewertungen

- Transformer Oil Regeneration Issue Based Risk AssessmentDokument2 SeitenTransformer Oil Regeneration Issue Based Risk AssessmentMoses Muchakaviri100% (4)

- Jsa For Cable Tray ErectionDokument2 SeitenJsa For Cable Tray Erectionanko heroNoch keine Bewertungen

- 012 Risk Ass CG 4760 Earthing Sysytem Installation S Rev 1Dokument5 Seiten012 Risk Ass CG 4760 Earthing Sysytem Installation S Rev 1Em Niax50% (2)

- Earthing and Lightning Protection MaintenanceDokument2 SeitenEarthing and Lightning Protection Maintenancemartins7367% (3)

- Cable Laying Safety AnalysisDokument6 SeitenCable Laying Safety AnalysisLuqman Osman100% (6)

- Job Risk Assessment Design and Installation of New Scada SystemDokument17 SeitenJob Risk Assessment Design and Installation of New Scada Systemzee khanNoch keine Bewertungen

- 012 - Risk Ass - CG 4760 - Earthing Sysytem Installation - S - Rev 2Dokument11 Seiten012 - Risk Ass - CG 4760 - Earthing Sysytem Installation - S - Rev 2nsadnanNoch keine Bewertungen

- 004 Annexure D Job Safety SAnalysis JSADokument3 Seiten004 Annexure D Job Safety SAnalysis JSAAvoor Khan75% (4)

- JSP For Electrical and HV TestingDokument4 SeitenJSP For Electrical and HV TestingmohammedNoch keine Bewertungen

- Job Hazard Assessment For Cable TestingDokument4 SeitenJob Hazard Assessment For Cable TestingSamuel Carlos100% (2)

- 5.19 JSP Electrical Power InstallationDokument4 Seiten5.19 JSP Electrical Power InstallationDarius DsouzaNoch keine Bewertungen

- LOTO ProcedureDokument2 SeitenLOTO ProcedureRitesh Dev MaityNoch keine Bewertungen

- Job Hazard Analysis (Jha) Worksheet SPOC-433-CPF-JSA-ELEC-001Dokument2 SeitenJob Hazard Analysis (Jha) Worksheet SPOC-433-CPF-JSA-ELEC-001asteway gonfaNoch keine Bewertungen

- JSA - Electrical Testing - Circuit Breaker Field TestDokument4 SeitenJSA - Electrical Testing - Circuit Breaker Field TestTawfik Mohamed Abu Zaid0% (1)

- 01 JSA CLEANING COMPRESSOR Rev 05 015 BIDokument8 Seiten01 JSA CLEANING COMPRESSOR Rev 05 015 BIMohd Khaidir100% (1)

- Risk Assessment - T&C For Medium Voltage SwitchgearDokument8 SeitenRisk Assessment - T&C For Medium Voltage SwitchgearMuhammad IrfanNoch keine Bewertungen

- Electrical Risk AssessmentDokument6 SeitenElectrical Risk AssessmentEman Fawzy100% (1)

- JSA FOR Fixing of Light FittingsDokument1 SeiteJSA FOR Fixing of Light Fittingswahyu nugroho100% (1)

- Operating A Telescoping Aerial Boom LiftDokument1 SeiteOperating A Telescoping Aerial Boom LiftTFattahNoch keine Bewertungen

- JSA-002-Safety WatchDokument2 SeitenJSA-002-Safety WatchNishad MuhammedNoch keine Bewertungen

- JOB SAFETY ANALYSIS FOR HT & LT PANEL INSTALLATIONDokument1 SeiteJOB SAFETY ANALYSIS FOR HT & LT PANEL INSTALLATIONpushpanath reddy100% (1)

- EHS risk assessment for transformer erectionDokument2 SeitenEHS risk assessment for transformer erectionshamshu123Noch keine Bewertungen

- EEEPL - JSA Light Fitting ErectionDokument6 SeitenEEEPL - JSA Light Fitting ErectionnishanthNoch keine Bewertungen

- JSA For Operation of Jack Hammer, Dimantalling Batching Plant Fountdation Near Waste Water TreatmentDokument4 SeitenJSA For Operation of Jack Hammer, Dimantalling Batching Plant Fountdation Near Waste Water TreatmentMohammed Minhaj100% (1)

- Cable Pulling / Laying, Glanding and Termination SopDokument12 SeitenCable Pulling / Laying, Glanding and Termination SopStansilous Tatenda Nyagomo0% (1)

- JSA For Removal of Broken Bolts and Installation of Switch Pannel On Compressor at Process AraeDokument4 SeitenJSA For Removal of Broken Bolts and Installation of Switch Pannel On Compressor at Process AraeMohammed MinhajNoch keine Bewertungen

- Risk Assessment Switchgear Testing & CommissioningDokument7 SeitenRisk Assessment Switchgear Testing & CommissioningguspriyNoch keine Bewertungen

- Jsa Installation of HV ApparatusDokument6 SeitenJsa Installation of HV ApparatusLuqman OsmanNoch keine Bewertungen

- MV, HV LV Transformer Installation SafetyDokument6 SeitenMV, HV LV Transformer Installation SafetyKiran Bhatt75% (4)

- jsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiDokument6 Seitenjsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiMon Trang NguyễnNoch keine Bewertungen

- 9686-6160-JSA-000-0041 - B1 JSA For UPS & Batteries Pre-Com & CommissioningDokument12 Seiten9686-6160-JSA-000-0041 - B1 JSA For UPS & Batteries Pre-Com & CommissioningKhan Wasim100% (1)

- Electrical Risk AssessmentDokument4 SeitenElectrical Risk AssessmentanisaanNoch keine Bewertungen

- JSA E&I 4.earthing Bonding InstallationDokument3 SeitenJSA E&I 4.earthing Bonding InstallationAmyNoch keine Bewertungen

- Risk Assessment for Installing Switchgear and TransformersDokument16 SeitenRisk Assessment for Installing Switchgear and Transformersamal100% (1)

- Cleaning Risks AssessedDokument6 SeitenCleaning Risks Assessedjulius0% (1)

- Risk Assessment - Installation and Testing of Motorized Fire & Smoke DamperDokument10 SeitenRisk Assessment - Installation and Testing of Motorized Fire & Smoke Dampernsadnan50% (2)

- Job Hazard Analysis: Format For JHA WorksheetDokument3 SeitenJob Hazard Analysis: Format For JHA WorksheetWaseem AhmadNoch keine Bewertungen

- JSA For Blower Cyclone and Duct Installation - Revision 004Dokument8 SeitenJSA For Blower Cyclone and Duct Installation - Revision 004WilsonNoch keine Bewertungen

- Contractor Work Method Statement-GIS Parts, Equipmentand ToolsDokument10 SeitenContractor Work Method Statement-GIS Parts, Equipmentand ToolsnsadnanNoch keine Bewertungen

- Risk Ass - CABLE PULLING LAYING Power Cables, Control Cables & FO CablesMDokument16 SeitenRisk Ass - CABLE PULLING LAYING Power Cables, Control Cables & FO CablesMnsadnanNoch keine Bewertungen

- ONVIF Profile Feature Overview v2-2Dokument6 SeitenONVIF Profile Feature Overview v2-2nsadnanNoch keine Bewertungen

- Exc Installation GuideDokument1 SeiteExc Installation GuidensadnanNoch keine Bewertungen

- ONVIF Profile T Specification v1-0Dokument77 SeitenONVIF Profile T Specification v1-0nsadnanNoch keine Bewertungen

- ONVIF Profile - S Specification v1-2Dokument42 SeitenONVIF Profile - S Specification v1-2nsadnan0% (1)

- Sensor Line Cable InstallationDokument6 SeitenSensor Line Cable InstallationnsadnanNoch keine Bewertungen

- Checklist For Access Control System InstallationDokument6 SeitenChecklist For Access Control System Installationnsadnan71% (7)

- DDC Systems2Dokument28 SeitenDDC Systems2nsadnan100% (1)

- BSIA Cyber Secure It January 2019Dokument16 SeitenBSIA Cyber Secure It January 2019nsadnanNoch keine Bewertungen

- HVAC ManualDokument107 SeitenHVAC ManualWissam JarmakNoch keine Bewertungen

- Testing and Commissioning Pre-Check List (ID 1506)Dokument1 SeiteTesting and Commissioning Pre-Check List (ID 1506)nsadnan0% (2)

- Peer Communications Protocol Communications Media: Twisted Pair Copper Conductors Ranging From 16 To 24 GageDokument5 SeitenPeer Communications Protocol Communications Media: Twisted Pair Copper Conductors Ranging From 16 To 24 GagensadnanNoch keine Bewertungen

- Checklist For Commissioning of CCTV SystemDokument2 SeitenChecklist For Commissioning of CCTV Systemnsadnan70% (10)

- 1 45Dokument3 Seiten1 45nsadnan0% (1)

- Excel Intelligent PduDokument21 SeitenExcel Intelligent PdunsadnanNoch keine Bewertungen

- Exc Fibre Installation GuideDokument38 SeitenExc Fibre Installation GuidensadnanNoch keine Bewertungen

- Excel Intelligent Pdu User InstructionsDokument2 SeitenExcel Intelligent Pdu User InstructionsnsadnanNoch keine Bewertungen

- 109 Installation CCTV Systems PDFDokument60 Seiten109 Installation CCTV Systems PDFRodelDavidNoch keine Bewertungen

- Exc Fibre Installation GuideDokument16 SeitenExc Fibre Installation GuideMohamad FaifNoch keine Bewertungen

- RISK ASSESSMENT - TK-4742-Operation Training For Overhead CraneDokument6 SeitenRISK ASSESSMENT - TK-4742-Operation Training For Overhead CranensadnanNoch keine Bewertungen

- Risk Assessment - Tk-4741-Removal Works For Site Office FacilitiesDokument14 SeitenRisk Assessment - Tk-4741-Removal Works For Site Office FacilitiesnsadnanNoch keine Bewertungen

- Checklist For Pre Commissioning of CCTV SystemDokument1 SeiteChecklist For Pre Commissioning of CCTV Systemnsadnan67% (6)

- CCTV Testing and Commissioning Pre-Check List (ID 1506)Dokument1 SeiteCCTV Testing and Commissioning Pre-Check List (ID 1506)nsadnan67% (3)

- ADDC Electricity Wiring Regulations - Mar.2014Dokument276 SeitenADDC Electricity Wiring Regulations - Mar.2014hajimak89% (18)

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Dokument4 SeitenRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanNoch keine Bewertungen

- Risk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)Dokument3 SeitenRisk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)nsadnan100% (1)

- Risk Assessment - Pre-Internal Wiring of Patch PanelDokument3 SeitenRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- Risk Assessment - Installation of Ventilation FanDokument6 SeitenRisk Assessment - Installation of Ventilation Fannsadnan100% (5)

- Risk Assessment - Pre-Internal Wiring of Patch PanelDokument3 SeitenRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- RISK ASSESSMENT - Load Current Measurement and Cleaning of Oil CoolerDokument5 SeitenRISK ASSESSMENT - Load Current Measurement and Cleaning of Oil CoolernsadnanNoch keine Bewertungen

- RISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling FanDokument6 SeitenRISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling Fannsadnan100% (2)

- Delivery of ConcreteDokument5 SeitenDelivery of Concretesikandar1234Noch keine Bewertungen

- Safety Data Sheet: FOR Floraesters K-20W JojobaDokument6 SeitenSafety Data Sheet: FOR Floraesters K-20W JojobaSiska DNoch keine Bewertungen

- Work Permit for Working at HeightDokument2 SeitenWork Permit for Working at HeightVipul BansalNoch keine Bewertungen

- Shell Unleaded Petrol MSDSDokument13 SeitenShell Unleaded Petrol MSDSuday_khandavilliNoch keine Bewertungen

- DRAFT - HIRARC REGISTER (45637)Dokument6 SeitenDRAFT - HIRARC REGISTER (45637)Leliance Ann BillNoch keine Bewertungen

- Competency Question For UHP ProjectDokument6 SeitenCompetency Question For UHP ProjectAshkar Ahamad100% (1)

- AWS April 2014Dokument44 SeitenAWS April 2014Mohamed FaragNoch keine Bewertungen

- Standard Operating Procedure Concentrated AcidsDokument6 SeitenStandard Operating Procedure Concentrated AcidsDibyendu GhoshNoch keine Bewertungen

- ID Hubungan Faktor Predisposing ReinforcingDokument11 SeitenID Hubungan Faktor Predisposing ReinforcingDeviana Aninda PutriNoch keine Bewertungen

- EN - PSX 60 Part A.SDS - SGS PDFDokument16 SeitenEN - PSX 60 Part A.SDS - SGS PDFnaspauzanNoch keine Bewertungen

- Health and Safety at The WorkplaceDokument24 SeitenHealth and Safety at The Workplaceemma78% (9)

- CBLM - PREPARE APPETIZERS - CKDokument19 SeitenCBLM - PREPARE APPETIZERS - CKkopiko67% (3)

- Unit-Igc3 International Health and Safety Practical ApplicationDokument22 SeitenUnit-Igc3 International Health and Safety Practical Applicationbhupalan s100% (1)

- 9-8 Moem Hirarc Oct 2018Dokument1 Seite9-8 Moem Hirarc Oct 2018PHH9834Noch keine Bewertungen

- John Lane Arc-Flash PaperDokument13 SeitenJohn Lane Arc-Flash Paperkaushikray06100% (1)

- JHA For Plumbing and Piping TradesDokument84 SeitenJHA For Plumbing and Piping TradesKhurram Iqbal100% (2)

- EnDokument234 SeitenEnAliTronic19720% (1)

- MATERIAL SAFETY DATA SHEET FOR TRIETHYLENE GLYCOLDokument7 SeitenMATERIAL SAFETY DATA SHEET FOR TRIETHYLENE GLYCOLRandy Ip100% (1)

- Fg40 User Manual enDokument48 SeitenFg40 User Manual enQ Llanos HenryNoch keine Bewertungen

- TOUAT GAZ Project Job Safety Analysis (Jsa) : Mandatory PPEDokument5 SeitenTOUAT GAZ Project Job Safety Analysis (Jsa) : Mandatory PPEazerNoch keine Bewertungen

- SUNY Brockport Reopening 7.1.20Dokument28 SeitenSUNY Brockport Reopening 7.1.20News 8 WROCNoch keine Bewertungen

- Industrial Training Report on Building Maintenance WorksDokument34 SeitenIndustrial Training Report on Building Maintenance WorksDeeeelaaaaNoch keine Bewertungen

- 51 17 Management of ChangeDokument18 Seiten51 17 Management of Changesarifin100% (1)

- Who 2019 Ncov Ipcppe Use 2020.2 EngDokument7 SeitenWho 2019 Ncov Ipcppe Use 2020.2 EngAnty AuliaNoch keine Bewertungen

- Demolition of Building - SW19-20Dokument38 SeitenDemolition of Building - SW19-20shaolinNoch keine Bewertungen

- Safety Data Sheet GreaseDokument7 SeitenSafety Data Sheet GreaseBurak YILMAZNoch keine Bewertungen

- TM 5-2420-230-24-1Dokument1.398 SeitenTM 5-2420-230-24-1AdvocateNoch keine Bewertungen

- Hira Training 190407052212Dokument44 SeitenHira Training 190407052212Aakanksha GahlautNoch keine Bewertungen

- Bms SystemDokument58 SeitenBms SystemAnandu AshokanNoch keine Bewertungen

- Handling Chlorine: Safety and Functioning of Chlorination SystemsDokument10 SeitenHandling Chlorine: Safety and Functioning of Chlorination SystemsUmairNoch keine Bewertungen