Beruflich Dokumente

Kultur Dokumente

Ball Mill Performance & Efficiency

Hochgeladen von

Vijay BhanCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ball Mill Performance & Efficiency

Hochgeladen von

Vijay BhanCopyright:

Verfügbare Formate

Ball Mill Performance & Efficiency

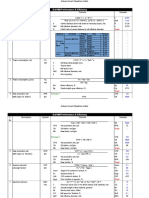

S. Description Symbol Formula Example

No.

1 Arm of gravity a 0.666 * ( 1 - 4 * R2 )1.5 h 0.51

- TAN [ 0.5 / R * (1 - 4*R2)0.5] - [ 2*R * (1 - 4*R2)0.5 ]

-1

Deff 2.9

h Centre Distance (from mill centre to media top layer), mts R 0.176

Deff Mill effective diameter, mts a 0.619

R h/Deff, ratio of centre distance to mill effective diameter Target -

2 Torque factor matrix u - -

Material Grinding Fitting Type Torque

- - -

None Balls 0.73

None Rods 0.55 - -

Coarse/Medium

Danula Balls 0.75 - -

Cement

Sonex Balls 0.66 - -

& Raw

None Balls 0.69

Meal - -

None Cylpebs 0.73

Fine

Danula Balls 0.71 - -

Danula Cylpebs 0.75 - -

Coarse/Medium None Balls /Cylpebs 0.69

Coal - -

Medium Danula Cylpebs 0.71

- -

2 Power consumption, net Pn 0.514 * F * u * n * Deff * a F 79

kW F Grinding media weight, tons u 0.71

u Torque factor n 18.6

n Mill speed, rpm Deff 2.9

Deff Mill effective diameter, mts a 0.578

a Arm of gravity, - Pn 899

Target -

3 Power consumption, gross Pg Pn * 100 * 100 Pn 924

kW Em * Eg Em 95

Em Motor efficiency, % Eg 95

Eg Gearbox/girth gear efficiency, % Pg 1024

Target -

4 New production rate NPB Formula-1(Holderbank) OPB 110

(Mill output Vs. Blaine) tph OPB OB 3450

Exp ( ( NB - OB ) * 0.49 / 1000 ) NB 3350

OPB Old production rate, tph NPB 115.524

OB Old blaine, cm2/gm Target -

NB New blaine, cm2/gm

Formula-2(General) OPB 110

OPB * ( OB / NB )1.3 OB 3450

OPB Old production rate, tph NB 3350

OB Old blaine, cm2/gm NPB 114.288

NB New blaine, cm2/gm Target -

Formula-3(KHD) OPB 110

OPB OB 3450

Exp ( ( NB - OB ) * 0.43 / 1000 ) NB 3350

OPB Old production rate, tph NPB 114.833

OB Old blaine, cm2/gm Target -

NB New blaine, cm2/gm

5 New production rate NPR OPR * ( 2 - log ( OR ) ) OPR 110

(Mill output Vs. Residue) tph ( 2 - log ( NR ) ) OR 11.5

OPR Old production rate, tph NR 9.5

OR Old residue, % NPR 101

NR New residue, % Target -

6 Gypsum set point GSP 21500 * ( Scem - Sclk ) Scem 2.3

(at weigh feeder) tph Pu * ( 100 - Fgyp ) Pu 70

Scem Target SO3 content in cement, % Sclk 1

Pu Gypsum purity, % Fgyp 4.8

Sclk SO3 content in clinker, % GSP 4.19

Fgyp Free moisture in gypsum, % Target -

7(a) Maximum ball size MBS 36 * F0.5 * { ( SG * Wi ) / ( %C * Deff0.5 ) }0.333 F 4

Ball Mill Performance & Efficiency

S. Description Symbol Formula Example

No.

(If feed size is known) mm F Feed size (sieve size in mm which retains 20% material), mm SG 3

SG Specific weight of feed material, gm/cm3 Wi 17

Wi Bond's work index, kWh/t %C 75

%C Mill speed as %critical, % Deff 3

Deff Mill effective diameter, mts MBS 52

Target -

7(b) Maximum feed size F (MBS *{{(%C * (Deff.)0.5 )}/(SG * Wi)}1/3 * 1/36)^2 MBS 52

(If ball size is known) mm MBS Max. Ball Size, mm SG 3

SG Specific weight of feed material, gm/cm3 Wi 17

Wi Bond's work index, kWh/t %C 75

%C Mill speed as %critical, % Deff 3

Deff Mill effective diameter, mts F 4

Target -

8 %Filling %F 112.5 - ( 125 * h / Deff ) h 1.96

% h Free height, mts Deff 2.9

Deff Mill effective diameter, mts %F 28.0

Target -

9 Circulation factor C Formula-1 FF 150

- F+G CR 170

F C 2.13

F Fresh feed rate, tph Target 2-3

G Coarse return, tph

Formula-2 Rg 21.25

Rg - Rf Rf 9.14

Rg - Rm Rm 16.78

Rg Residue of coarse return, % C 2.71

Rf Residue of fines, % Target 2-3

Rm Residue of separator feed, %

10 Circulation load CL ( C - 1 ) * 100 C 2.6

% C Circulation factor, - CL 160

Target -

11 Separator efficiency SE Formula-1 Ro 100

% [log(Ro/Rf) - C * log[{Ro+(C-1)*Rg} / {Rf+(C-1)*Rg}]]*100 Rf 17.68

log(Ro/Rf) - C * log[{Ro+(C-1)*100} / {Rf+(C-1)*100}] C 1.79

Ro Residue of fresh feed, % Rg 83.78

Rf Residue of fines, % SE 80.7

C Circulation factor, - Target 70-80

Rg Residue of coarse return, %

Formula-2 (Fines Efficiency) Rf 17.68

( 100 - Rf ) * 100 Rm 46.91

( 100 - Rm ) * C C 1.79

Rf Residue of fines, % SEf 86.6

Rm Residue of separator feed, % Target 70-80

C Circulation factor, -

Formula-3 (Coarse Efficiency) Rg 83.78

Rg * ( C - 1 ) * 100 C 1.79

C * Rm Rm 46.91

Rg Residue of coarse return, % SEc 78.8

C Circulation factor, - Target 70-80

Rm Residue of separator feed, %

12 Critical speed nc 42.3 / Deff0.5 Deff 2.9

rpm Deff Mill effective diameter, mts Pn 24.8

Target -

Ball Mill Performance & Efficiency

S. Description Symbol Formula Example

No.

Processed by - siddhartha kumar

Ball Mill Performance & Efficiency

S. Description Symbol Formula Example

No.

1 Arm of gravity a 0.666 * ( 1 - 4 * R2 )1.5 h 0.51

- TAN [ 0.5 / R * (1 - 4*R2)0.5] - [ 2*R * (1 - 4*R2)0.5 ]

-1

Deff 2.9

h Centre Distance (from mill centre to media top layer), mts R 0.176

Deff Mill effective diameter, mts a 0.619

R h/Deff, ratio of centre distance to mill effective diameter Target -

2 Torque factor matrix u - -

Material Grinding Fitting Type Torque

- - -

None Balls 0.73

None Rods 0.55 - -

Coars e/Medium

Cem ent

Danula Balls 0.75 - -

Sonex Balls 0.66 - -

& Raw

None Balls 0.69

Meal - -

None Cylpebs 0.73

Fine

Danula Balls 0.71 - -

Danula Cylpebs 0.75 - -

Coars e/Medium None Balls /Cylpebs 0.69

Coal - -

Medium Danula Cylpebs 0.71

- -

2 Power consumption, net Pn 0.514 * F * u * n * Deff * a F 79

kW F Grinding media weight, tons u 0.71

u Torque factor n 18.6

n Mill speed, rpm Deff 2.9

Deff Mill effective diameter, mts a 0.578

a Arm of gravity, - Pn 899

Target -

3 Power consumption, gross Pg Pn * 100 * 100 Pn 924

kW Em * Eg Em 95

Em Motor efficiency, % Eg 95

Eg Gearbox/girth gear efficiency, % Pg 1024

Target -

4 New production rate NPB Formula-1 OPB 110

(Mill output Vs. Blaine) tph OPB OB 3000

Exp ( ( NB - OB ) * 0.49 / 1000 ) NB 3200

OPB Old production rate, tph NPB 100

OB Old blaine, cm2/gm Target -

NB New blaine, cm2/gm

Formula-2 OPB 110

OPB * ( OB / NB )1.3 OB 3000

OPB Old production rate, tph NB 3200

OB Old blaine, cm2/gm NPB 101

NB New blaine, cm2/gm Target -

5 New production rate NPR OPR * ( 2 - log ( OR ) ) OPR 110

(Mill output Vs. Residue) tph ( 2 - log ( NR ) ) OR 11.5

OPR Old production rate, tph NR 9.5

OR Old residue, % NPR 101

NR New residue, % Target -

6 Gypsum set point GSP 21500 * ( Scem - Sclk ) Scem 2.3

(at weigh feeder) tph Pu * ( 100 - Fgyp ) Pu 70

Scem Target SO3 content in cement, % Sclk 1

Pu Gypsum purity, % Fgyp 4.8

Sclk SO3 content in clinker, % GSP 4.19

Fgyp Free moisture in gypsum, % Target -

7(a) Maximum ball size MBS 36 * F0.5 * { ( SG * Wi ) / ( %C * Deff0.5 ) }0.333 F 4.000

(If feed size is known) mm F Feed size (sieve size in mm which retains 20% material), mm SG 3

SG Specific weight of feed material, gm/cm3 Wi 17

Wi Bond's work index, kWh/t %C 75

%C Mill speed as %critical, % Deff 3.24

Deff Mill effective diameter, mts MBS 52.04887

Target -

Ball Mill Performance & Efficiency

S. Description Symbol Formula Example

No.

7(b) Maximum feed size F MBS *{{(%C * (Deff.)0.5 )}/(SG * Wi)}1/3 * 1/36 MBS 52.04887

(If ball size is known) mm MBS Max. Ball Size, mm SG 3

SG Specific weight of feed material, gm/cm3 Wi 17

Wi Bond's work index, kWh/t %C 75

%C Mill speed as %critical, % Deff 3.24

Deff Mill effective diameter, mts F 3.99741

Target -

8 %Filling %F 112.5 - ( 125 * h / Deff ) h 1.96

% h Free height, mts Deff 2.9

Deff Mill effective diameter, mts %F 28.0

Target -

9 Circulation factor C Formula-1 FF 150

- F+G CR 170

F C 2.13

F Fresh feed rate, tph Target 2-3

G Coarse return, tph

Formula-2 Rg 21.25

Rg - Rf Rf 9.14

Rg - Rm Rm 16.78

Rg Residue of coarse return, % C 2.71

Rf Residue of fines, % Target 2-3

Rm Residue of separator feed, %

10 Circulation load CL ( C - 1 ) * 100 C 2.6

% C Circulation factor, - CL 160

Target -

11 Separator efficiency SE Formula-1 Ro 100

% [log(Ro/Rf) - C * log[{Ro+(C-1)*Rg} / {Rf+(C-1)*Rg}]]*100 Rf 17.68

log(Ro/Rf) - C * log[{Ro+(C-1)*100} / {Rf+(C-1)*100}] C 1.79

Ro Residue of fresh feed, % Rg 83.78

Rf Residue of fines, % SE 80.7

C Circulation factor, - Target 70-80

Rg Residue of coarse return, %

Formula-2 (Fines Efficiency) Rf 17.68

( 100 - Rf ) * 100 Rm 46.91

( 100 - Rm ) * C C 1.79

Rf Residue of fines, % SEf 86.6

Rm Residue of separator feed, % Target 70-80

C Circulation factor, -

Formula-3 (Coarse Efficiency) Rg 83.78

Rg * ( C - 1 ) * 100 C 1.79

C * Rm Rm 46.91

Rg Residue of coarse return, % SEc 78.8

C Circulation factor, - Target 70-80

Rm Residue of separator feed, %

12 Critical speed nc 42.3 / Deff0.5 Deff 2.9

rpm Deff Mill effective diameter, mts Pn 24.8

Target -

Processed by - siddhartha kumar

Ball Mill Performance & Efficiency

S. Description Symbol Formula Example

No.

1 Arm of gravity a 0.666 * ( 1 - 4 * R2 )1.5 h 0.51

- TAN [ 0.5 / R * (1 - 4*R2)0.5] - [ 2*R * (1 - 4*R2)0.5 ]

-1

Deff 2.9

h Centre Distance (from mill centre to media top layer), mts R 0.176

Deff Mill effective diameter, mts a 0.619

R h/Deff, ratio of centre distance to mill effective diameter Target -

2 Torque factor matrix u - -

Material Grinding Fitting Type Torque

- - -

None Balls 0.73

None Rods 0.55 - -

Coars e/Medium

Cem ent

Danula Balls 0.75 - -

Sonex Balls 0.66 - -

& Raw

None Balls 0.69

Meal - -

None Cylpebs 0.73

Fine

Danula Balls 0.71 - -

Danula Cylpebs 0.75 - -

Coars e/Medium None Balls /Cylpebs 0.69

Coal - -

Medium Danula Cylpebs 0.71

- -

2 Power consumption, net Pn 0.514 * F * u * n * Deff * a F 79

kW F Grinding media weight, tons u 0.71

u Torque factor n 18.6

n Mill speed, rpm Deff 2.9

Deff Mill effective diameter, mts a 0.578

a Arm of gravity, - Pn 899

Target -

3 Power consumption, gross Pg Pn * 100 * 100 Pn 924

kW Em * Eg Em 95

Em Motor efficiency, % Eg 95

Eg Gearbox/girth gear efficiency, % Pg 1024

Target -

4 New production rate NPB Formula-1 OPB 105

(Mill output Vs. Blaine) tph OPB OB 3550

Exp ( ( NB - OB ) * 0.49 / 1000 ) NB 3350

OPB Old production rate, tph NPB 116

OB Old blaine, cm2/gm Target -

NB New blaine, cm2/gm

Formula-2 OPB 105

OPB * ( OB / NB )1.3 OB 3550

OPB Old production rate, tph NB 3350

OB Old blaine, cm2/gm NPB 113

NB New blaine, cm2/gm Target -

5 New production rate NPR OPR * ( 2 - log ( OR ) ) OPR

(Mill output Vs. Residue) tph ( 2 - log ( NR ) ) OR 11.5

OPR Old production rate, tph NR 9.5

OR Old residue, % NPR 0

NR New residue, % Target -

6 Gypsum set point GSP 21500 * ( Scem - Sclk ) Scem 2.3

(at weigh feeder) tph Pu * ( 100 - Fgyp ) Pu 70

Scem Target SO3 content in cement, % Sclk 1

Pu Gypsum purity, % Fgyp 4.8

Sclk SO3 content in clinker, % GSP 4.19

Fgyp Free moisture in gypsum, % Target -

7 Maximum ball size MBS 36 * F0.5 * { ( SG * Wi ) / ( %C * Deff0.5 ) }0.333 F 1.1

mm F Feed size (sieve size in mm which retains 20% material), mm SG 3

SG Specific weight of feed material, gm/cm3 Wi 17

Wi Bond's work index, kWh/t %C 75

%C Mill speed as %critical, % Deff 5.1

Deff Mill effective diameter, mts MBS 25

Target -

8 %Filling %F 112.5 - ( 125 * h / Deff ) h 1.96

% h Free height, mts Deff 2.9

Ball Mill Performance & Efficiency

S. Description Symbol Formula Example

No.

Deff Mill effective diameter, mts %F 28.0

Target -

9 Circulation factor C Formula-1 FF 150

- F+G CR 170

F C 2.13

F Fresh feed rate, tph Target 2-3

G Coarse return, tph

Formula-2 Rg 60.25

Rg - Rf Rf 6.87

Rg - Rm Rm 37.88

Rg Residue of coarse return, % C 2.39

Rf Residue of fines, % Target 2-3

Rm Residue of separator feed, %

10 Circulation load CL ( C - 1 ) * 100 C 2.39

% C Circulation factor, - CL 139

Target -

11 Separator efficiency SE Formula-1 Ro 37.88

% [log(Ro/Rf) - C * log[{Ro+(C-1)*Rg} / {Rf+(C-1)*Rg}]]*100 Rf 6.87

log(Ro/Rf) - C * log[{Ro+(C-1)*100} / {Rf+(C-1)*100}] C 2.39

Ro Residue of fresh feed, % Rg 60.25

Rf Residue of fines, % SE 80.5

C Circulation factor, - Target 70-80

Rg Residue of coarse return, %

Formula-2 (Fines Efficiency) Rf 17.68

( 100 - Rf ) * 100 Rm 46.91

( 100 - Rm ) * C C 1.79

Rf Residue of fines, % SEf 86.6

Rm Residue of separator feed, % Target 70-80

C Circulation factor, -

Formula-3 (Coarse Efficiency) Rg 83.78

Rg * ( C - 1 ) * 100 C 1.79

C * Rm Rm 46.91

Rg Residue of coarse return, % SEc 78.8

C Circulation factor, - Target 70-80

Rm Residue of separator feed, %

12 Critical speed nc 42.3 / Deff0.5 Deff 2.9

rpm Deff Mill effective diameter, mts Pn 24.8

Target -

Processed by - siddhartha kumar

Das könnte Ihnen auch gefallen

- Wear Rate Grinding Ball PDFDokument12 SeitenWear Rate Grinding Ball PDFLoraNoch keine Bewertungen

- Ball MillDokument3 SeitenBall MillTeeTee PenGen SetiyaNoch keine Bewertungen

- Impact of Process Parameters On QualityDokument25 SeitenImpact of Process Parameters On QualityDineshNoch keine Bewertungen

- Cement Mill Shell LinerDokument7 SeitenCement Mill Shell LinerMahaveer SinghNoch keine Bewertungen

- Cement Mill Ball Mill TestingDokument30 SeitenCement Mill Ball Mill Testingzementhead100% (2)

- User Guide PDFDokument27 SeitenUser Guide PDFbulentbulut100% (1)

- Dokumen - Tips - Vertical Raw Mill Heat Balance SolutionDokument3 SeitenDokumen - Tips - Vertical Raw Mill Heat Balance SolutionRamadhani AhdiyakaNoch keine Bewertungen

- ZeiselDokument98 SeitenZeiselGirne100% (1)

- Factors Influencing The Grinding EfficiencyDokument27 SeitenFactors Influencing The Grinding Efficiencygrameshkreddy2013Noch keine Bewertungen

- Cement Process Engineering Vade-Mecum: 3. QualityDokument22 SeitenCement Process Engineering Vade-Mecum: 3. QualityRaúl Marcelo VelozNoch keine Bewertungen

- Cement raw material gas flow balance sheetDokument4 SeitenCement raw material gas flow balance sheetAli Hüthüt100% (1)

- Flow Calculation SheetDokument24 SeitenFlow Calculation SheetTOULASSI-ANANI Yves Lolo50% (2)

- Precalciner Kiln Systems ExplainedDokument39 SeitenPrecalciner Kiln Systems ExplainedMohamed Saad100% (1)

- K - Constant For Cooler Fan FlowsDokument4 SeitenK - Constant For Cooler Fan FlowsVijay Bhan100% (1)

- Nozzle Ring Area of Raw MillDokument6 SeitenNozzle Ring Area of Raw MillThaigroup CementNoch keine Bewertungen

- Coal Mix Feasibility Aug 2019Dokument13 SeitenCoal Mix Feasibility Aug 2019Junaid Mazhar100% (2)

- Ball Mill GrindingDokument78 SeitenBall Mill GrindingFran jimenezNoch keine Bewertungen

- Ball Mill For Cement GrindingDokument5 SeitenBall Mill For Cement GrindingNkosilozwelo Sibanda100% (1)

- Raw Mill Nozzle Ring Area 8/6/2019 11:02: 4.47 m2 m2 m2 m2 m2 3.57 m2Dokument6 SeitenRaw Mill Nozzle Ring Area 8/6/2019 11:02: 4.47 m2 m2 m2 m2 m2 3.57 m2Bùi Hắc HảiNoch keine Bewertungen

- Heat-Up Schedule As Per RequirementDokument1 SeiteHeat-Up Schedule As Per RequirementVijay BhanNoch keine Bewertungen

- BM TrompcurveDokument1 SeiteBM Trompcurveniladri.jagatyNoch keine Bewertungen

- Review RollerPress OperationsDokument331 SeitenReview RollerPress OperationsAnonymous 3ESYcrKPNoch keine Bewertungen

- Ritschard Case Study Combustion EngineeringDokument6 SeitenRitschard Case Study Combustion Engineeringvikubhardwaj9224Noch keine Bewertungen

- 05 RP - Process Know HowDokument25 Seiten05 RP - Process Know Howaff bear100% (2)

- Atox 45 Raw Mill Critical Interlock SheetDokument6 SeitenAtox 45 Raw Mill Critical Interlock SheetValipireddy NagarjunNoch keine Bewertungen

- Tube Mill OptimisationDokument7 SeitenTube Mill OptimisationJoko DewotoNoch keine Bewertungen

- Tromp Curve Calculations and ResultsDokument3 SeitenTromp Curve Calculations and Resultsrecai100% (2)

- Fan Flow - CementDokument5 SeitenFan Flow - CementharikrushnaNoch keine Bewertungen

- Raw Mix Design SoftwareDokument7 SeitenRaw Mix Design Softwarevvijaybhan100% (9)

- Calculation For CO2 Released During CalcinationDokument4 SeitenCalculation For CO2 Released During CalcinationD N SHARMANoch keine Bewertungen

- Ball Charge in Ball MillDokument11 SeitenBall Charge in Ball MillRanu Yadav0% (1)

- 26 00 Special Cases and Experiences EDokument9 Seiten26 00 Special Cases and Experiences EDiego AlejandroNoch keine Bewertungen

- Cement Grinding Vertical Roller Mills Versus Ball Mills 1654248086Dokument17 SeitenCement Grinding Vertical Roller Mills Versus Ball Mills 1654248086Salah Romdani100% (1)

- Powerpoint VRMDokument14 SeitenPowerpoint VRMAlisa Azizah100% (2)

- Priya Cement Raw MixDokument6 SeitenPriya Cement Raw MixJCS100% (1)

- Calciner Technology in AF Firing PDFDokument22 SeitenCalciner Technology in AF Firing PDFJohn GiannakopoulosNoch keine Bewertungen

- Grinding and Classifying Technology For Slag: Replacement Factors DryingDokument6 SeitenGrinding and Classifying Technology For Slag: Replacement Factors DryingGerman Gabriel Anaya Vega100% (1)

- Mass Balance PDFDokument5 SeitenMass Balance PDFElai MacabitNoch keine Bewertungen

- Kiln Heat Balance 1Dokument33 SeitenKiln Heat Balance 1Bùi Hắc HảiNoch keine Bewertungen

- Ball Top Size Diameter CalculationDokument1 SeiteBall Top Size Diameter Calculationsempatik721100% (1)

- Tips On Kiln OperationDokument1 SeiteTips On Kiln OperationVipan Kumar DograNoch keine Bewertungen

- Precalciner Kilns Systems & OperationDokument58 SeitenPrecalciner Kilns Systems & OperationYhaneNoch keine Bewertungen

- Ball - Mill - Finish Mill Ball Charge CalculationDokument3 SeitenBall - Mill - Finish Mill Ball Charge CalculationVijay Bhan50% (2)

- Ball Filling Degree Mill CalculationDokument2 SeitenBall Filling Degree Mill CalculationBùi Hắc HảiNoch keine Bewertungen

- Raw Mix Design and SamplingDokument26 SeitenRaw Mix Design and SamplingShashwat Omar100% (2)

- Calculating burner parametersDokument3 SeitenCalculating burner parametersIrfan Ahmed100% (1)

- VRM OKoookuuiiiiljjjjyggyyDokument8 SeitenVRM OKoookuuiiiiljjjjyggyyRakaNoch keine Bewertungen

- Ball Mill Understanding OptimisationDokument47 SeitenBall Mill Understanding OptimisationrecaiNoch keine Bewertungen

- Raw Materials Granulometry and Ball Charge DesignDokument11 SeitenRaw Materials Granulometry and Ball Charge DesignKaran_Agarwal_4807100% (2)

- Role of Gypsum in Cement GrindingDokument13 SeitenRole of Gypsum in Cement GrindingMinh Tien LeNoch keine Bewertungen

- Ball Mill Performance & Efficiency: Material Grinding Fitting Type TorqueDokument23 SeitenBall Mill Performance & Efficiency: Material Grinding Fitting Type TorqueSantanu PachhalNoch keine Bewertungen

- Ball Mill CalculationsDokument7 SeitenBall Mill CalculationsSSAC PVT.LTD.100% (1)

- Ball Mill CalculationsDokument7 SeitenBall Mill Calculationszainab alkhafafNoch keine Bewertungen

- Formulase ModDokument17 SeitenFormulase ModribeiroluizrNoch keine Bewertungen

- All - Process - FormulasDokument15 SeitenAll - Process - FormulasMUNNALURU UMAKANTHA RAO100% (1)

- Torque Factor MatrixDokument2 SeitenTorque Factor MatrixVijay BhanNoch keine Bewertungen

- 550 Bar Type I Hydrocarbon Vs Type II TestDokument1 Seite550 Bar Type I Hydrocarbon Vs Type II TestLymeParkNoch keine Bewertungen

- NSK Linear Guide: Miniature PU Series/PE SeriesDokument7 SeitenNSK Linear Guide: Miniature PU Series/PE Seriesjaime cerdaNoch keine Bewertungen

- Model: SE1-12-426-VG: Sidewall Direct Drive Exhaust FanDokument2 SeitenModel: SE1-12-426-VG: Sidewall Direct Drive Exhaust FanDADANoch keine Bewertungen

- "Only Valid For Quotation": Component List Description #Material Hardness Heat Treatment RemarksDokument1 Seite"Only Valid For Quotation": Component List Description #Material Hardness Heat Treatment RemarksMotiram SavargaveNoch keine Bewertungen

- Maximum Ball Size - Grinding Media - CalculationDokument2 SeitenMaximum Ball Size - Grinding Media - CalculationVijay BhanNoch keine Bewertungen

- Specific Stoichiometric - Combustion Air CalculationDokument2 SeitenSpecific Stoichiometric - Combustion Air CalculationVijay BhanNoch keine Bewertungen

- Rotary Kiln - Burning Zone Load CalculationDokument2 SeitenRotary Kiln - Burning Zone Load CalculationVijay BhanNoch keine Bewertungen

- Inching Drive - Mechanism For Process FansDokument1 SeiteInching Drive - Mechanism For Process FansVijay BhanNoch keine Bewertungen

- CORIOLIS PrincipleDokument1 SeiteCORIOLIS PrincipleVijay BhanNoch keine Bewertungen

- Ok Mill Interlock ListDokument1 SeiteOk Mill Interlock ListVijay BhanNoch keine Bewertungen

- Deposit CalculatorDokument2 SeitenDeposit CalculatorVijay Bhan0% (1)

- MMTS Train TimingsDokument15 SeitenMMTS Train TimingsMohan KrishnaNoch keine Bewertungen

- K - Constant For Cooler Fan FlowsDokument4 SeitenK - Constant For Cooler Fan FlowsVijay Bhan100% (1)

- Heat-Up Schedule As Per RequirementDokument1 SeiteHeat-Up Schedule As Per RequirementVijay BhanNoch keine Bewertungen

- Kiln Rotation Procedure Guide for Firing CeramicsDokument1 SeiteKiln Rotation Procedure Guide for Firing CeramicsVijay BhanNoch keine Bewertungen

- Influence of Sulfur in ClinkerDokument1 SeiteInfluence of Sulfur in ClinkerVijay Bhan100% (1)

- Precommissioning Checks in Pyro - Instrumentation SectionDokument1 SeitePrecommissioning Checks in Pyro - Instrumentation SectionVijay BhanNoch keine Bewertungen

- Fan System - System Resistance PDFDokument1 SeiteFan System - System Resistance PDFVijay Bhan0% (1)

- MULTICOR Operating PrincipleDokument1 SeiteMULTICOR Operating PrincipleVijay BhanNoch keine Bewertungen

- Hammer MillDokument1 SeiteHammer MillVijay BhanNoch keine Bewertungen

- Fan System - Curve Operating RangeDokument1 SeiteFan System - Curve Operating RangeVijay BhanNoch keine Bewertungen

- Fan System - System ResistanceDokument1 SeiteFan System - System ResistanceVijay BhanNoch keine Bewertungen

- Pyro-processing system flow overviewDokument1 SeitePyro-processing system flow overviewVijay BhanNoch keine Bewertungen

- B-W Calibration ProcedureDokument4 SeitenB-W Calibration ProcedureVijay Bhan100% (3)

- Pre Commissioning Checks in Pyro - Pre Heater AreaDokument1 SeitePre Commissioning Checks in Pyro - Pre Heater AreaVijay BhanNoch keine Bewertungen

- Weigh Feeder MechanicsDokument1 SeiteWeigh Feeder MechanicsVijay Bhan67% (3)

- Precommissioning Checks in Pyro - Kiln Feed AreaDokument1 SeitePrecommissioning Checks in Pyro - Kiln Feed AreaVijay BhanNoch keine Bewertungen

- Clinker burning reactions and alite formation under 1450°CDokument1 SeiteClinker burning reactions and alite formation under 1450°CVijay BhanNoch keine Bewertungen

- Pre Commissioning Checks in Major Process FansDokument1 SeitePre Commissioning Checks in Major Process FansVijay BhanNoch keine Bewertungen

- Stack MonitoringDokument24 SeitenStack MonitoringVijay BhanNoch keine Bewertungen

- Precommissioning Checks in Raw Mill Feed Bin AreaDokument1 SeitePrecommissioning Checks in Raw Mill Feed Bin AreaVijay BhanNoch keine Bewertungen

- Fan Curves Explained: Power, Speed, Pressure & VolumeDokument1 SeiteFan Curves Explained: Power, Speed, Pressure & VolumeVijay BhanNoch keine Bewertungen

- Building Construction CostDokument3 SeitenBuilding Construction CostVijay BhanNoch keine Bewertungen

- Kiln Audit - Required Measurement ToolsDokument1 SeiteKiln Audit - Required Measurement ToolsVijay BhanNoch keine Bewertungen

- Albert PikeDokument6 SeitenAlbert Pikeapi-302575383Noch keine Bewertungen

- MATH Concepts PDFDokument2 SeitenMATH Concepts PDFs bNoch keine Bewertungen

- Motor Electrico Bojin J4103 - B User ManualDokument6 SeitenMotor Electrico Bojin J4103 - B User ManualJordan BonnettNoch keine Bewertungen

- LTC2410 Datasheet and Product Info - Analog DevicesDokument6 SeitenLTC2410 Datasheet and Product Info - Analog DevicesdonatoNoch keine Bewertungen

- CH 21Dokument70 SeitenCH 21Shakib Ahmed Emon 0389Noch keine Bewertungen

- Asian Games African Games: Beach VolleyballDokument5 SeitenAsian Games African Games: Beach VolleyballJessan Ybañez JoreNoch keine Bewertungen

- Philosophy of Disciple Making PaperDokument5 SeitenPhilosophy of Disciple Making Paperapi-665038631Noch keine Bewertungen

- Amity Online Exam OdlDokument14 SeitenAmity Online Exam OdlAbdullah Holif0% (1)

- Metal Oxides Semiconductor CeramicsDokument14 SeitenMetal Oxides Semiconductor Ceramicsumarasad1100% (1)

- Case Study On Maruti 800Dokument4 SeitenCase Study On Maruti 800Nizar MesaniNoch keine Bewertungen

- Kashmira Karim Charaniya's ResumeDokument3 SeitenKashmira Karim Charaniya's ResumeMegha JainNoch keine Bewertungen

- Vivaldi - Genuis of BaroqueDokument279 SeitenVivaldi - Genuis of Baroqueilcanto100% (4)

- Applied Physics Mini Launcher Lab ReportDokument12 SeitenApplied Physics Mini Launcher Lab ReportTalharashid RamzanNoch keine Bewertungen

- Human Resource Management (MGT 4320) : Kulliyyah of Economics and Management SciencesDokument9 SeitenHuman Resource Management (MGT 4320) : Kulliyyah of Economics and Management SciencesAbuzafar AbdullahNoch keine Bewertungen

- GEd 105 Midterm ReviewerDokument17 SeitenGEd 105 Midterm ReviewerAndryl MedallionNoch keine Bewertungen

- Compabloc Manual NewestDokument36 SeitenCompabloc Manual NewestAnonymous nw5AXJqjdNoch keine Bewertungen

- RISO MZ Servicemanual EnglDokument438 SeitenRISO MZ Servicemanual Englkuvalda2000_8645336367% (3)

- Operation Manual 11-3000psi Shear Ram BopDokument30 SeitenOperation Manual 11-3000psi Shear Ram BopBoedi SyafiqNoch keine Bewertungen

- Questions 32 - 34: Sunny English MqaDokument9 SeitenQuestions 32 - 34: Sunny English MqaHạnh NguyễnNoch keine Bewertungen

- Hong Kong A-Level Chemistry Book 3ADokument69 SeitenHong Kong A-Level Chemistry Book 3AMARENG BERNABENoch keine Bewertungen

- Case Briefing and Case SynthesisDokument3 SeitenCase Briefing and Case SynthesisKai RaguindinNoch keine Bewertungen

- Explore Spanish Lesson Plan - AnimalsDokument8 SeitenExplore Spanish Lesson Plan - Animalsapi-257582917Noch keine Bewertungen

- Agitators: Robert L. Bates, President Chemineer, IncDokument24 SeitenAgitators: Robert L. Bates, President Chemineer, InctenshinomiyukiNoch keine Bewertungen

- Painter CardDokument1 SeitePainter CardPraveen RANANoch keine Bewertungen

- DownloadDokument11 SeitenDownloadAnonymous ffje1rpaNoch keine Bewertungen

- AWS S3 Interview QuestionsDokument4 SeitenAWS S3 Interview QuestionsHarsha KasireddyNoch keine Bewertungen

- Pembahasan Soal UN Bahasa Inggris SMP 2012 (Paket Soal C29) PDFDokument15 SeitenPembahasan Soal UN Bahasa Inggris SMP 2012 (Paket Soal C29) PDFArdi Ansyah YusufNoch keine Bewertungen

- Chime Primary School Brochure TemplateDokument1 SeiteChime Primary School Brochure TemplateNita HanifahNoch keine Bewertungen

- Catalogue MinicenterDokument36 SeitenCatalogue Minicentermohamed mahdiNoch keine Bewertungen

- Jiangsu Changjiang Electronics Technology Co., Ltd. SOT-89-3L Transistor SpecificationsDokument2 SeitenJiangsu Changjiang Electronics Technology Co., Ltd. SOT-89-3L Transistor SpecificationsIsrael AldabaNoch keine Bewertungen