Beruflich Dokumente

Kultur Dokumente

07B Process Risk Analysis Flue Gas Treatment

Hochgeladen von

trung2iCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

07B Process Risk Analysis Flue Gas Treatment

Hochgeladen von

trung2iCopyright:

Verfügbare Formate

LAB GROUPE a

1 SIL classification 29/05/2009 PYK RB PMi

0 First emission 29/04/2009 PYK RB PMi

REV OBJET DATE Auteur Resp. DT CP

PROCESS RISK ANALYSIS

10892 EA 00 401

FLUE GAS TREATMENT

10892 HARLINGEN

25, rue Bossuet

69006 LYON

10892EA00401-1 Harlingen Risk Analysis.doc

Page 1 of 113

LAB GROUPE a

TABLE OF CONTENTS

1. METHODOLOGY IMPLEMENTED 5

1.1. GRAVITY IMPACT ON HEALTH AND SAFETY 6

1.2. TYPE OF CONTROL REQUIRED 7

1.3. SIL CLASSIFICATION 8

1.3.1. ESP 9

1.3.2. Fabric Filter 10

1.3.3. SCR 11

1.3.4. ID FAN 12

1.3.5. Ammonia 13

1.3.6. BICAR 14

1.3.7. Activated Carbon 15

1.3.8. Spent sorbent 16

1.3.9. Heat Exchanger 17

2. ELECTROSTATIC PRECIPITATOR HDE10 18

2.1. DEDUSTING 18

2.1.1. Electrostatic precipitator 18

3. LAB LOOP HTD10 20

3.1. LAB LOOP 20

3.1.1. Analyser 20

3.1.2. LAB loop 22

4. FABRIC FILTER HTE10 24

4.1. DEDUSTING 24

4.1.1. Fabric filter 24

4.2. SPENT SORBENT EXTRACTION 30

4.2.1. Fabric filter hoppers 30

4.3. Preheating system 33

4.3.1. Preheating system 33

5. DENOX SCR HSB10 35

5.1. DIOXINS REMOVAL AND NOX REDUCTION 35

5.1.1. Reactor SCR 35

5.1.2. Gas-Gas Heat exchangers 40

5.1.3. Gas-Steam Heat exchangers 42

5.1.4. Fresh air damper 44

5.1.5. Preheating system 45

6. ID FAN HSC10 46

6.1. GAS EXTRACTION 46

6.1.1. ID Fan 46

7. ANALYSERS HNE10 48

7.1. GAS ANALYSING 48

10892EA00401-1 Harlingen Risk Analysis.doc

Page 2 of 113

LAB GROUPE a

7.1.1. Analyser at the stack inlet 48

8. AMMONIA INJECTION HSJ10 50

8.1. AMMONIA UNLOADING 50

8.1.1. Ammonia unloading 50

8.2. AMMONIA STORAGE 54

8.2.1. Ammonia Tank 54

8.3. AMMONIA INJECTION 58

8.3.1. NH4OH Pumps 58

8.3.2. NH4OH injection circuit 59

9. BICAR TRANSPORT HTJ20 62

9.1. BICAR UNLOADING 62

9.1.1. Bicar unloading 62

9.2. BICAR STORAGE 64

9.2.1. Bicar Silo 64

9.3. BICAR SILO EXTRACTION 66

9.3.1. Silo extraction 66

9.3.2. Buffer tank 68

9.4. BICAR EXTRACTION AND INJECTION 69

9.4.1. Bicar buffer-tank extraction 69

9.4.2. Bicar injection 70

10. ACTIVATED CARBON TRANSPORT HTJ10 71

10.1. ACTIVATED CARBON UNLOADING 71

10.1.1. Activated carbon unloading 71

10.2. ACTIVATED CARBON STORAGE 73

10.2.1. Activated carbon Silo 73

10.3. ACTIVATED CARBON EXTRACTION 76

10.3.1. Silo extraction 76

10.3.2. Buffer tank 78

10.4. ACTIVATED CARBON EXTRACTION AND INJECTION 79

10.4.1. Activated carbon injection 79

11. ESP FLY ASH TRANSPORT AND STORAGE ETH10 82

11.1. ESP FLY ASH TRANSPORT 82

11.1.1. ESP fly ash extraction 82

11.1.2. ESP fly ash transport to big bag 85

11.1.3. ESP fly ash transport to silo 86

11.2. ASH STORAGE SILO 89

11.2.1. Ash storage Silo 89

11.3. ASH SILO EXTRACTION 90

11.3.1. Ash extraction from the silo 90

12. SPENT SORBENT TRANSPORT AND STORAGE HTP50 92

12.1. SPENT SORBENT TRANSPORT 92

10892EA00401-1 Harlingen Risk Analysis.doc

Page 3 of 113

LAB GROUPE a

12.1.1. Spent sorbent transport under fabric filter 92

12.1.2. Spent sorbent transport to big bag 94

12.1.3. Spent sorbent transport to silo 95

12.2. SPENT SORBENT STORAGE SILO 99

12.2.1. Spent sorbent storage Silo 99

12.3. SPENT SORBENT SILO EXTRACTION 101

12.3.1. Spent sorbent extraction from the silo 101

13. HEAT EXCHANGER HSB30 103

13.1. GAS/WATER HEAT EXCHANGER 103

13.1.1. Gas/water heat exchanger (gas side) 103

13.1.2. Gas/water heat exchanger (water side) 105

13.2. CONDENSATE WATER/WATER HEAT EXCHANGER HE4 107

13.2.1. Condensate water-water heat exchanger HE4 (water side) 107

13.2.2. Condensate water-water heat exchanger HE4 (condensate water side) 109

13.3. CIRCULATION WATER PUMPS 110

13.3.1. Circulation Water pumps 110

APPENDIX 1 111

10892EA00401-1 Harlingen Risk Analysis.doc

Page 4 of 113

LAB GROUPE a

1. METHODOLOGY IMPLEMENTED

Risk analysis aims to assess qualitatively if a hazard or an operational problem may arise

when deviations from the normal process design occur. It permits to know in detail

measures taken to control risks (preventive and protective measures) expected by the

designer.

The principle of the method implemented is based on impact on health and safety studies,

similarly to HAZOP (Hazard and Operability Studies).

This method examines and determines all the undesirable events defined during the

functional blocs division. As each undesirable event or deviation is considered its potential

causes and consequences are assessed. Consequences are quantified with a gravity

impact on health and safety, associated with a level control.

Risk analysis document is divided into clearly sections that follow the P&IDs on a line-by-

line basis.

The tables achieved are formed with the following columns:

Undesirable events or deviations: they represent the different situations able to cause

some risks. Product risks, process risks and operating errors risks identification allow to

list them.

Causes: conditions, errors, breakdown or failures that are the cause of the undesirable

event.

Consequences: this column lists every consequence that the undesirable event can lead

to (actions implemented being considered ineffectual or insufficient).

Gravity (G): it is a matter of the gravity of the consequence without considering actions

implemented. The gravity impacts classification is mentioned hereinafter.

Actions: this column lists every preventive and protective measures in order to avoid or

reduce causes and/or limit consequences, thus reducing the gravity of the situation.

Control (C): it is a matter of the control of the event by considering actions implemented.

The control levels classification is mentioned hereinafter.

10892EA00401-1 Harlingen Risk Analysis.doc

Page 5 of 113

LAB GROUPE a

1.1. GRAVITY IMPACT ON HEALTH AND SAFETY

Gravity impact on health and safety (1) Minor effects

Body injuries: light

Environmental risk: none

Equipment deterioration: none

Gravity impact on health and safety (2) Significant effects

Body injuries: corporal injuries with temporary disablement

Environmental risk: limited to the plant

Equipment deterioration: unavailability of the plant limited to one day

Gravity impact on health and safety (3) Critical effects

Body injuries: significant corporal injuries for people inside the site

Environmental risk: minor pollution, limited on the site

Equipment deterioration: unavailability of the plant limited to two weeks

Gravity impact on health and safety (4) Disastrous effects

Body injuries: significant corporal injuries for people inside and outside the site

Environmental risk: major pollution

Equipment deterioration: unavailability of the plant (more than two weeks)

10892EA00401-1 Harlingen Risk Analysis.doc

Page 6 of 113

LAB GROUPE a

1.2. TYPE OF CONTROL REQUIRED

Type of control required (1)

Human control.

Type of control required (2)

Automatic control loop (control system) with alarm and information transmitted to the

control room.

Type of control required (3)

a) 1 sensor connected to a safety system or hardwired cabinet OR

b) 2 sensors (1 on 2) or 2 actuators ( 1 in stand-by) connected to a control system OR

c) 1 sensor connected to the control system and 1 mechanical system (example : safety

valve)

Type of control required (4)

2 sensors (1 on 2) or 3 sensors (2 on 3) connected to a safety system (safety PLC) or

hardwired cabinet

10892EA00401-1 Harlingen Risk Analysis.doc

Page 7 of 113

LAB GROUPE a

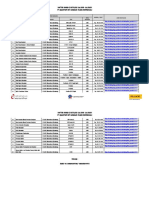

1.3. SIL CLASSIFICATION

For the major risks, a SIL classification has been established, following the project calibration (see

Appendix 1)

10892EA00401-1 Harlingen Risk Analysis.doc

Page 8 of 113

1.3.1. ESP

In i t i a t o r F u rn a c e C O m e a s u re m e n t V e ry h ig h t e m p e ra t u re a t V e ry h ig h t e m p e ra t u re o f V e ry h ig h o il le ve l in H ig h le ve l in E S P h o p p e r ID F a n n o t r u n n i n g o r

t h e fa b r i c fi l t e r i n l e t t r a n s fo r m e r t r a n s fo r m e r LS A H H R 1 H D E 11 C L 30 2 L o w fl u e g a s

te m p e ra tu re

F in a l E le m e n t T r ip h ig h vo lt a g e p r e c ip it a t o r S t o p w a s t e fe e d t o g r a t e S t o p t r a n s fo r m e r S t o p t r a n s fo r m e r S t o p h ig h vo lt a g e p re c ip it a t o r S t o p h ig h vo lt a g e

R 1 H D E 11 G U 0 01 p re c ip it a t o r

S t o p ra p p e rs R 1 H D E 1 1 A T 0 0 1

to A T 0 0 4

F u n c t io n P ro te c t E S P a g a in s t P ro te c t E S P a n d P r e ve n t s h o rt c irc u it in g P re ve n t s h o rt c irc u it in g

e x p lo s io n d o w n s t re a m e q u ip m e n t

a g a in s t e x c e e d a n c e o f

d e s ig n t e m p e ra t u re o f

e q u ip m e n t s

C aus e B a d c o m b u s t io n F a il u r e o f fl u e g a s E x c e s s iv e fly a s h p r o d u c e d i n F u r n a c e t ro u b le s

t e m p e r a t u r e c o n t r o l ( fu r n a c e fu r n a c e L in e s t a rt -u p

s id e ) B rid g in g in E S P

F a ilu re o f c h a in c o n ve y o r (o r

a n y d o w n s t r e a m fa i l u r e )

S c e n a rio E x p lo s io n d u e t o ve ry h ig h E x e e d a n c e o f d e s ig n S h o rt c irc u it in g o f h ig h S h o r t c ir c u it in g o f h ig h S h o r t c ir c u it in g o f h ig h vo lt a g e S h o r t c ir c u it in g o f h ig h

d e s c rip t io n o f F O D C O c o n c e n t ra t io n a n d h ig h t e m p e ra t u re e q u ip m e n t vo lt a g e p re c ip it a t o r vo lt a g e p re c ip it a t o r w h ic h p r e c ip it a t o r w h ic h is p r o t e c t e d vo lt a g e p r e c ip it a t o r

vo lt a g e in t e rn a ls o f E S P le a d in g t o w h ic h is p ro t e c t e d b y a n is p ro t e c t e d b y a n b y a n in d e p e n d e n t e le c t r ic a l w h ic h is p ro t e c t e d b y a n

e q u ip m e n t in t e rn a ls d a m a g e in d e p e n d e n t e le c t ric a l in d e p e n d e n t e le c t r ic a l p ro t e c t io n in d e p e n d e n t e le c t ric a l

a n d e q u ip m e n t a n d d u c t in g p ro t e c t io n p ro t e c t io n p ro t e c t io n

a ft e r E S P w h i c h h a s a

d e s ig n t e m p e ra t u re o f

3 2 0 C ( d u c t i n g m a y b e o v e r

s tre s s e d )

D e m a n d ra te E x p e c t e d d e m a n d ra t e le s s E x p e c t e d d e m a n d r a t e le s s E x p e c te d d e m a n d ra t e E x p e c t e d d e m a n d ra te B a s e d o n e x p e rie n c e : o n c e p e r B a s e d o n e x p e r ie n c e :

th a n o n c e p e r 1 0 y e a rs th a n o n c e p e r 1 0 y e a rs le s s t h a n o n c e p e r 1 0 le s s t h a n o n c e p e r 1 0 y e a r - o n c e p e r 1 0 y e a rs on c e p er y ear - onc e pe r

y e a rs y e a rs 1 0 y e a rs

F = 1 1 1 1 2 2

S a fe t y m in o r in ju r y m a y b e e x p e c te d N o n e ( n o t e t h a t fl u e g a s N o ne N o ne N o ne N one

c o ns eq uen c e s s y s te m o p e ra te s a t s u b

p e o p le a t m . p re s s u re )

S = 1 0 0 0 0 0

T im e ly p re s e n c e

o f p e o p le

T= 1

A vo id a n c e o f

e x p o s u re

A =

S I L s a fe ty = 0 0 0 0 0 0

C ons eq ue nc es m in o r e n vir o n m e n t a l im p a c t N o n e ( n o t e t h a t fl u e g a s N o ne N o ne N o ne N one

e n viro n m e n t s y s te m o p e ra te s a t s u b

a t m . p re s s u re )

E = 1 0 1 1 1 1

A vo id a n c e o f

e x p o s u re

e n viro n m e n t

A =

S IL e n v iro n m e n t = 0 0 0 0 0 0

F in a n c ia l lo s s e s R e p a ir o f d a m a ge d E S P R e p a ir o f d a m a g e d E S P R e p a ir o f d a m a g e d E S P R e p a ir o f d a m a g e d E S P R e s o lvin g s h o rt c irc u it c a u s e R e s o lvin g s h o r t c ir c u it

in t e rn a ls is e x p e c te d to c o s t in t e rn a ls is e x p e c t e d t o in t e rn a ls is e x p e c t e d t o in t e rn a ls is e x p e c t e d t o ( t o o h i g h fl y a s h in E S P c a us e w ill c o s t s b e

100 k D ow n t im e c o s t s a re c o s t 1 0 0 k a n d re p a ir o f c os t 10 0k c os t 10 0k h o p p e r) w ill c o s ts b e 1 0 k - 1 0 k - 1 0 0 k . D o w n t im e

5 d a y s w h ic h e q u a ls 7 00 k . o ve rs t re s s e d d u c t in g 5 k . 1 0 0 k .D o w n t im e c o s t s a re 2 c o s t s a re lo w .

T o t a l fi n a n c i a l d a m a g e is D o w n t im e c o s t s a re 5 d a y s d a y s w h ic h e q u a ls 2 7 0 k .

th u s 8 0 0 k w h ic h e q u a ls 7 0 0 k . T o t a l T o t a l fi n a n c ia l d a m a g e is t h u s

fi n a n c ia l d a m a g e i s t h u s le s s t h a n 10 00 k

80 0k

L= 3 3 3 3 3 2

A vo id a n c e o f G ive n t h a t t h e in c re a s e o f It i s e x p e c t e d t h a t o p e r a t o r

fi n a n c i a l l o s s e s fl u e g a s t e m p e r a t u r e i s a c t io n c a n a vo id t h e d a m a g e

s lo w , it is e x p e c t e d t h a t

o p e ra t o r a c t io n c a n a vo id

th e d a m a g e

A = 1 1 1 1 1 1

S IL fin a n c ia l = a a a a 1 a

S IL to ta l = a a a a 1 a

10892EA00401-1 Harlingen Risk Analysis.doc

Page 9 of 113

1.3.2. Fabric Filter

In i t i a t o r h ig h t e m p e ra t u re F a b ric V e ry lo w t e m p e ra t u re F a b ric V e ry h ig h t e m p e ra t u re F a b ric Low s u c t io n p re s s u re F a b ric V e ry h ig h t e m p e ra t u re F a b ric V e ry h ig h t e m p e ra t u re F a b ric

f i l t e r I n l e t T IS A H fil t e r In l e t f i l t e r In l e t T I S A H H fi l t e r o u t l e t P IS A L L fil t e r P r e h e a t i n g D u c t fi l t e r h o p p e r

R 1 H T A 1 0 C T 9 0 1 (2 o 3 w ith R 1 H T A 1 0 C T 9 0 1 (2 o 3 w it h R 1H T A 2 0 C P 9 0 1 (2 o 3 w it h

C T0 0 1 to C T0 0 3 ) C T0 0 1 to C T0 0 3 ) C P 0 0 1 to C P 0 0 3 )

F in a l E le m e n t S t o p a c t iva t e d c a rb o n O p e n in g b y -p a s s d a m p e r O p e n in g b y -p a s s d a m p e r T rip ID fa n R 1 H S C 1 0 A N 0 0 1 - S t o p p in g h e a t in g b a t t e ry C lo s in g c e ll a n d N 2 in je c t io n

in je c t io n R 1 H T K 1 2 A N 0 0 1 a n d c l o s in g flo w t h r o u g h a n d c l o s i n g fl o w t h r o u g h M 01 /M 0 2

and R 1H TK 17A N 001 f a b r i c fi l t e r fa b r i c fi lt e r R 1

H TA 1 0 /H TA 1 5 A A 0 5 1 a n d R 1

F u n c t io n P r e ve n t p o s t c o m b u s t io n ria k P r e ve n t b a g s d e t r io r a t io n P r e ve n t p o s t c o m b u s t io n r ia k P r e v e n t u n d e r p r e s s u r e i n fl u e P r e ve n t b a g s d e t e r io r a t io n P re ve n t b a g s d e t e r io r a t io n

g a s s y s te m

C ause C o m b u s tio n t ro u b le s C o m b u s t io n t ro u b le s C o m b u s t io n t ro u b le s C lo g g in g i n flu e g a s s t r e a m o r p re h e a t in g T e m p e ra t u re C o m b u s t io n t ro u b le s

L in e s t a rt -u p va lve s b e in g in c lo s e d p o s it io n C o n t ro l lo o p t ro u b le s d u rin g

lin e s t a rt u p

S c e n a rio D e s t r u c t i o n o f f a b r i c fi l t e r D e s t r u c t i o n o f fa b r i c f i l t e r U n d e r p r e s s u r e i n fl u e g a s D e s t r u c t i o n o f fa b r i c f i l t e r D e s t r u c t i o n o f fa b r i c f i l t e r

d e s c rip t io n o f bags bags s y s t e m e x c e e d in g d e s ig n bags bags

FO D p re s s u re . C ra c k a t w e a k e s t

p o in t (p ro b a b ly a d u c t ) le a d in g

t o in g re s s o f a ir

D e m a n d ra t e B a s e d o n e x p e rie n c e : o n c e B a s e d o n e x p e rie n c e : o n c e B a s e d o n e x p e rie n c e : o n c e B a s e d o n e x p e rie n c e : o n c e p e r B a s e d o n e x p e rie n c e : o n c e E x p e c te d d e m a n d ra t e le s s

p e r y e a r - o n c e p e r 1 0 y e a rs per year p e r y e a r - o n c e p e r 1 0 y e a rs y e a r - o n c e p e r 1 0 y e a rs p e r y e a r - o n c e p e r 1 0 y e a rs t h a n o n c e p e r 1 0 y e a rs

F = 2 3 2 2 2 1

S a fe t y N one N one N one M in o r N one N one

cons equenc es

p e o p le

S = 0 0 0 1 0 0

T im e ly p re s e n c e

o f p e o p le

T= 1

A vo id a n c e o f

e x p o s u re

A =

S IL s a fe ty= 0 0 0 0 0 0

C onsequenc es N one N one M in o r M in o r N one N one

e n vir o n m e n t

E = 0 0 1 1 0 0

A vo id a n c e o f

e x p o s u re

e n vir o n m e n t

A =

S IL en viro n m en t = 0 0 a a 0 1

F in a n c ia l lo s s e s R e p a ir o f d a m a g e d b a g s is C o s t fo r r e m p l a c e m e n t o f R e p a ir o f d a m a g e d b a g s is R e p a ir o f lo c a l e q u ip m e n t / d u c t R e s o lvin g s h o r t c irc u it c a u s e R e p a ir o f d a m a g e d b a g s is

e x p e c te d to c o s t 100k s o m e b a g s w ill b e le s s t h a n e x p e c te d to c o s t 100k d a m a g e le a d t o m in im a l d o w n ( t o o h i g h fl y a s h i n E S P e x p e c te d to c o s t 100k

D o w n t im e c o s t s a re 5 d a y s 10 k D o w n tim e c o s t s a re 5 d a y s t im e (b e c a u s e p ro d u c t io n m a y h o p p e r) w ill c o s t s b e 1 0 k - D o w n t im e c o s t s a re 5 d a y s

w h ic h e q u a ls 7 0 0 k . To ta l w h ic h e q u a ls 7 0 0 k . To ta l c o n t in u e t ill n e x t p la n n e d s t o p 1 0 0 k . D o w n t im e c o s t s a re w h ic h e q u a ls 7 0 0 k . To ta l

fi n a n c ia l d a m a g e is t h u s fin a n c i a l d a m a g e is t h u s w it h s o m e t e m p o ra ry re p a irs ). 2 d a y s w h ic h e q u a ls 2 7 0 k . fi n a n c i a l d a m a g e is t h u s

800k 800k T h u s e x p e c t e d d o w n t im e c o s t T o t a l fi n a n c i a l d a m a g e i s 800k

is le s s t h a n 1 0 0 0 k (5 d a y s ) t h u s le s s t h a n 1 0 0 0 k

L= 3 1 3 3 2 3

A vo id a n c e o f It is e x p e c t e d t h a t o p e r a t o r It i s e x p e c t e d t h a t o p e r a t o r It i s e x p e c t e d t h a t o p e r a t o r It i s e x pe c te d th a t o p e ra t o r It i s e x p e c t e d t h a t o p e r a t o r It i s e x p e c t e d t h a t o p e r a t o r

fi n a n c i a l l o s s e s a c t io n c a n a vo id t h e d a m a g e a c t io n c a n a vo id t h e d a m a g e a c t io n c a n a vo id t h e d a m a g e a c t io n ca n a vo id t h e dam age a c t io n c a n a vo id t h e d a m a g e a c t io n c a n a vo id t h e d a m a g e

by bas ed o n va r io u s o th e r P ro d u c t io n c a n n c o n t in u e

p re s s u re m e a s u re m e n ts w it h 7 c e lls o n 8

A = 1 1 1 1 1 1

S IL fi n a n c ia l= 1 a 1 1 a a

S IL to ta l = 1 a 1 1 a a

10892EA00401-1 Harlingen Risk Analysis.doc

Page 10 of 113

1.3.3. SCR

In it ia t o r V e r y lo w t e m pe r a tu r e V e r y L o w te m p e r a tu r e a t V e r y h ig h t e m p e r a t u r e L o w te m p e r a tu r e a t H ig h d i f f e r e n t ia l H ig h d u s t d o w n s t r e a m F a b r i c F ilt e r H ig h C O f r o m b o ile r A m m o n i a d e t e c t io n

F a b r ic f ilt e r In le t T IS A L L in le t D e N O x r e a c to r S C R in le t T IS A H H R 1 o u t le t D e N O x r e a c t o r te m p e r a tu r e o v e r D e N O x Q IS A H H R 1 H T A 2 0 C Q 0 0 1 H ig h C O f r o m s t a c k

R1HTA 10CT9 01 ( 2 o 3 w it h T IS A L L R 1 H S D 1 0CT901 H S D 1 0 C T 9 0 1 ( 1 o 2 w it h r e a c to r H ig h d u s t f r o m s t a c k a n a ly s e r a n a ly s e r

C T 0 0 1 to C T 0 03 ) ( 1 o 2 w it h C T 0 0 1 and C T001 and CT002) Q IS A H H R 1 H S A 5 0 C Q 0 2 0

CT002) F a b r ic f ilt e r b y - p a s s

F in a l E le m e n t O p e n in g b y - p a s s d a m p e r S t o p a m m o n ia in je c t io n : S t e a m f e e d in g s t o p R 1 O p e n in g b y - p a s s O p e n in g b y - p a s s d a m p e r O p e n in g b y - p a s s d a m p e r a n d O p e n in g b y - p a s s C l o s e a m m o n ia s u p p l y

a n d c lo s in g f lo w t h r o u g h c l o s e v a lv e R 1 LBG 21A A 0xx d a m p e r a n d c l o s in g a n d c lo s in g f lo w t h r o u g h c l o s in g f lo w t h r o u g h D e n o x d a m p e r a n d c lo s i n g v a lv e

D e n o x r e a c to r R 1 H T A 3 0 HSK13A A 051 f lo w t h r o u g h D e n o x D e n o x r e a c to r r e a c to r R 1 H T A 3 0 A A 0 5 1 /A A 0 5 2 f lo w t h r o u g h D e n o x

A A 0 5 1 /A A 0 5 2 a n d R 1 r e a c to r a n d R 1 H S A 1 0 /H S A 4 0 A A 0 5 1 r e a c to r

H S A 1 0 /H S A 4 0 A A 0 5 1

F u n c t io n T o p r e v e n t c o r r o s io n r i s k in T o p r e v e n t t o x if ic a t io n o f S C R e q u ip m e n t d a m a g e T o p r e v e n t c o r r o s io n P r e v e n t c o m b u s t io n o f T o p r e v e n t c lo g g in g o f D e N O x P r o t e c t S C R a g a in s t P r e v e n t c o n t in u o u s

DeNO x t h e D e N O x c a t a ly s t r is k r is k in D e N O x c a r b o n in D e N O x a n d c a t a ly s t w i t h d u s t e x p lo s io n r i s k r e le a s e o f A m m o n ia

( A m m o n ia is n o t r e a c t in g p o t e n t i a l e x c e e d in g d e s ig n

w it h N O x ) te m p e r a tu r e o f D e N O x

r e a c to r

Caus e L o w f lu e g a s t e m p e r a t u r e L o w f lu e g a s t e m p e r a t u r e S t e a m c o n t r o l lo o p In g r e s s o f f a ls e a ir V e r y h ig h C O i n f lu e g a s F a ilu r e o f E S P / e x c e s s iv e c a r r y B a d c o m b u s t io n L e a k a g e s a t f la n g e s

( e . g . d u r in g s t a r t - u p a n d ( e . g . d u r in g s t a r t - u p a n d t r o u b le s ( d u e f a ilu r e o f f u r n a c e C O o v e r o f d u s t fro m ES P f le x ib le s

s h u t- d o w n ) s h u t- d o w n ) c o n t r o l)

C o m b u s t io n t r o u b le s C o m b u s t io n t r o u b le s

S c e n a r io C o r r o s io n r is k i n D e N O x T o x if i c a t io n o f t h e D e N O x C o r r o s io n r is k in P o t e n t i a l m e c h a n ic a l C lo g g in g o f D e N O x c a t a ly s t w it h E x p lo s io n d u e t o v e r y P o t e n t ia l e x p o s u r e o f

d e s c r ip t io n o f c a t a ly s t ( A m m o n ia is n o t DeNO x e q u ip m e n t d a m a g e t o d u s t l e a d in g t o r e d u c e d f lu e g a s h ig h C O s ta f f /w o r k e r s to

FO D r e a c t in g w it h N O x ) D e N O x r e a c to r r a te ( a n d d u e to th e f u r n a c e c o n c e n t r a t io n a n d A m m o n ia

A m m o n ia w ill p a s s D e N O x p r e s s u r e c o n t r o l, t h e w a s t e f e e d h ig h t e m p e r a t u r e

a n d le a d t o A m m o n ia r a t e w ill b e r e d u c e d ) a n d

e m is s io n s ( e x c e e d in g in c r e a s e d p r e s s u r e d r o p o v e r

p e r m i t le v e ls ) DeNO x

D e m a n d r a te E x p e c t e d d e m a n d r a t e le s s E x p e c t e d d e m a n d r a t e le s s B a s e d o n e x p e r ie n c e : B a s e d o n e x p e r ie n c e B a s e d o n e x p e r ie n c e B a s e d o n e x p e r ie n c e e x p e c t e d B a s e d o n e x p e r ie n c e B a s e d o n e x p e r ie n c e :

th a n o n c e p e r 1 y e a r th a n o n c e p e r 1 y e a r once per year - onc e per e x p e c te d d e m a n d e x p e c t e d d e m a n d r a t e s is d e m a n d r a t e s i s le s s t h a n o n c e e x p e c te d d e m a n d onc e per year - onc e

1 0 y ea rs r a t e s i s le s s t h a n o n c e le s s t h a n o n c e p e r 1 0 pe r 10 y e ars r a t e s is le s s t h a n per 10 y ears

pe r 1 0 y ea rs y ea rs on c e pe r 10 y e ars

F= 3 3 2 1 1 1 1 2

S a f e ty None None None None None None m in o r in ju r y m a y b e E x p o s u r e c o u ld le a d t o

consequences e x p e c te d a s e r io u s in ju r y

p e o p le S= 0 0 0 0 0 1 2

T im e ly p r e s e n c e A r e a i s a t t e n d e d r a r e ly

o f p e o p le ( < 1 0 - 2 0 % ) p e r s h if t

T= 1 1

A v o id a n c e o f A m m o n i a s m e ll w ill

ex p os u re a la r m s t a f f / w o r k e r s a n d

s u f f ic ie n t ( 2 o r m o r e )

number of escape

r o u t e s a r e p r o v id e d

A = 1

S I L s a fe ty = 0 0 0 0 0 0 0 a

Cons equenc es None E x c e e d a n c e o f p e r m it None None None None m in o r e n v ir o n m e n t a l M in o r e n v ir o n m e n t a l

e n v ir o n m e n t le v e ls f o r a m m o n ia a n d im p a c t im p a c t

N O x ( d u r in g s t a r t - u p / s h u t

d o w n o n ly )

E= 0 1 0 0 0 0 1 1

A v o id a n c e o f

ex p os u re

e n v ir o n m e n t

A =

S I L e n v ir o n m e n t = 0 1 0 0 0 0 0 a

F in a n c i a l lo s s e s L if e t im e w ill b e s h o r t e n e d L i f e t i m e o f D e N O x c a t a ly s t M e c h a n ic a l e q u ip m e n t L if e t im e w il l b e M e c h a n ic a l e q u ip m e n t D u s t c le a n i n g o f c a t a ly s t m a y t a k e M e c h a n ic a l M in o r f in a n c ia l i m p a c t

d u e t o c o r r o s io n . E x p e c t e d w ill b e s h o r t e n e d . d a m a g e to r e a c to r c a n s h o r te n e d d u e to d a m a g e to r e a c to r c a n u p t o 1 d a y . T h is e q u a l s le s s t h a n e q u ip m e n t d a m a g e t o e x p e c te d

d a m a g e is l e s s t h a n 1 0 0 k E x p e c t e d d a m a g e i s le s s l e a d t o lo c a l r e a c t o r c o r r o s io n . Ex p e c te d le a d t o lo c a l r e a c t o r 100k r e a c t o r c a n le a d t o

th a n 1 0 k r e p a ir s a n d d o w n t im e o f d a m a g e is le s s t h a n r e p a ir s a n d d o w n t im e o f a lo c a l r e a c t o r r e p a ir s

a c o u p le o f d a y s 1 0 k c o u p le o f d a y s ( d a m a g e < a n d d o w n t im e o f a

(dam age < 1000k 1000k c o u p le o f d a y s

(d a m a g e < 1 0 0 0 k)

L= 2 1 3 1 3 2 3 1

A v o id a n c e o f It is e x p e c t e d t h a t o p e r a t o r It is e x p e c t e d t h a t It is e x p e c t e d t h a t o p e r a t o r It is e x p e c t e d t h a t o p e r a t o r a c t io n It is e x p e c t e d t h a t

f in a n c ia l lo s s e s a c t io n c a n a v o id t h e o p e r a t o r a c t io n c a n a c t io n c a n a v o id t h e c a n a v o id t h e d a m a g e b y b a s e d o p e r a t o r a c t io n c a n

d a m a g e b y m a n u a ll y a v o id t h e d a m a g e b y d a m a g e d u e to p r e s e n c e o n S C R d e lt a P m e a s u r e m e n t a v o id t h e d a m a g e b y

o p e n in g t h e b y - p a s s m a n u a lly o p e n in g t h e o f d o w n s t r e a m T I' s based on CO

v a lv e s b y - p a s s v a lv e s m eas urem ent

A = 1 0 1 1 1

S IL =

fi n a n c i a l

1 a 1 0 a 1 a 0

S I L to ta l = 1 1 1 0 a 1 a a

10892EA00401-1 Harlingen Risk Analysis.doc

Page 11 of 113

1.3.4. ID FAN

In it ia t o r L o w s u c tio n p re s s u re U p s tre a m H ig h v i b r a t i o n ID F a n b e a r i n g Y IA H H ig h t e m p e r a t u r e ID F a n b e a r i n g H ig h t e m p e r a t u re ID F a n H ig h t e m p e r a t u r e ID F a n

ID F A N P IS A L L R 1 H S C 1 0 C Y 3 0 1 a n d C Y 3 0 2 T IA H R 1 H S C 1 0 C T 0 0 1 a n d C T 0 0 2 m o to r b e a rin g m o to r w i n d in g s T IA H

R 1 H S A 4 0 C P 9 0 1 ( 2 o 3 w it h R 1 H S C 1 0 C T 0 0 3 a n d C T 0 0 4

C P 0 0 1 to C P 0 0 3 ) a n d C T 0 0 5

F in a l E le m e n t T r i p ID fa n R 1 H S C 1 0 A N 0 0 1 - T rip ID fa n R 1 H S C 1 0 A N 0 0 1 -M 0 1 / M 0 2 T r ip ID fa n R 1 H S C 1 0 A N 0 0 1 -M 0 1 /M 0 2 T r ip ID fa n T r i p ID fa n R 1 H S C 1 0 A N 0 0 1 -

M 0 1 /M 0 2 M 0 1 /M 0 2

F u n c t io n P re ve n t u n d e r p re s s u re in fl u e P re ve n t e x c e s s i v e d a m a g e t o ID fa n P re ve n t e x c e s s ive d a m a g e t o ID fa n P re ve n t e x c e s s ive d a m a g e P re ve n t e x c e s s ive d a m a g e

g a s s y s t e m b e a rin g s a n d p o s s ib le ro t o r d a m a g e b e a rin g s a n d p o s s ib le ro to r d a m a g e t o ID fa n b e a r i n g t o ID fa n m o t o r

(n o te th a t m in o r b e a rin g d a m a g e is n o t (n o te th a t m in o r b e a rin g d a m a g e is

p re ve n te d b y t h e t rip ) n o t p re ve n te d b y th e tr ip )

C a u s e C lo g g in g in fl u e g a s s t r e a m o r W e a r a n d te a r to th e b e a rin g , W e a r a n d t e a r t o t h e b e a rin g , W e a r a n d te a r F a ilu re o f m o t o r c o o lin g

va lve s b e in g in c lo s e d p o s it io n c o rro s io n o f ro t o r (lo s s o f b a la n c e o f c o rro s io n o f ro to r (lo s s o f b a la n c e o f

ro to r) ro to r)

S c e n a rio U n d e r p r e s s u r e in flu e g a s E x c e s s iv e d a m a g e t o ID fa n b e a r in g s E x c e s s iv e d a m a g e t o ID fa n b e a r i n g s E x c e s s ive d a m a g e to ID fa n E x c e s s ive d a m a g e to ID fa n

d e s c rip t io n o f s y s t e m e x c e e d in g m in im u m a n d p o s s ib le ro t o r d a m a g e (p o s s ib le a n d p o s s ib le ro t o r d a m a g e (p o s s ib le m o to r b e a rin g m o to r

F O D d e s ig n p re s s u re . P o s s ib le r o t o r d is e n g a g e m e n t ) ro to r d is e n g a g e m e n t)

c ra c k a t w e a k e s t p o in t

(p r o b a b ly a d u c t ) le a d in g t o

in g r e s s o f fa ls e a ir

D e m a n d ra te B a s e d o n e x p e rie n c e : o n c e p e r B a s e d o n e x p e rie n c e t h e t rip is B a s e d o n e x p e rie n c e th e trip is B a s e d o n e x p e rie n c e le s s B a s e d o n e x p e rie n c e le s s

y e a r - o n c e p e r 1 0 y e a rs e x p e c te d o n c e p e r 1 - 1 0 y e a rs e x p e c te d o n c e p e r 1 - 1 0 y e a rs th a n o n c e p e r 1 0 y e a rs th a n o n c e p e r 1 0 y e a rs

F = 2 2 2 1 1

S a fe t y M in o r R o t o r d is e n g a g e m e n t m a y le a d to R o to r d is e n g a g e m e n t m a y le a d t o N o n e N o n e

c o n s e q u e n c e s s e rio u s in ju ry s e rio u s in ju ry

p e o p le

S = 1 2 2

T im e ly p r e s e n c e A re a is a tte n d e d r a re ly (< 1 0 - 2 0 % ) A re a is a tt e n d e d ra re ly (< 1 0 - 2 0 % )

o f p e o p le p e r s h ift p e r s h i ft

T = 1 1 1

A vo id a n c e o f In c a s e o f h ig h v ib r a t io n , it is e x p e c te d In c a s e o f h i g h t e m p e r a t u r e i t is

e x p o s u re t h a t o p e ra t o r s w ill b e a b le t o a vo id e x p e c t e d t h a t o p e ra t o rs w ill b e a b le t o

e x p o s u re a vo id e x p o s u re

A = 1 1

S IL s a f e ty = 0 a a 0 0

C o n s e q u e n c e s M in o r N o n e N o n e N o n e N o n e

e n viro n m e n t

E = 1 0 0 0 0

A vo id a n c e o f

e x p o s u re

e n viro n m e n t

A =

S IL e n v iro n m e n t = a 0 0 0 0

F in a n c ia l lo s s e s R e p a ir o f lo c a l e q u ip m e n t / d u c t E x c e s s iv e d a m a g e t o ID fa n b e a r in g s E x c e s s iv e d a m a g e t o ID fa n b e a r i n g s R e p a ir o f m o t o r b e a rin g m a y R e p a ir o f m o t o r w in d in g s

d a m a g e le a d t o m in im a l d o w n a n d p o s s ib le ro t o r d a m a g e (p o s s ib le a n d p o s s ib le ro t o r d a m a g e (p o s s ib le ta k e m o re th a n a w e e k a n d m a y ta k e m o n th s a n d

t im e (b e c a u s e p ro d u c t io n m a y r o t o r d is e n g a g e m e n t ) re p a ir c a n b e ro to r d is e n g a g e m e n t) re p a ir c a n b e a s s o c ia t e d d o w n t im e c o s t s a s s o c ia t e d d o w n tim e c o s ts

c o n t in u e t ill n e x t p la n n e d s t o p r e a lis e d w it h in 3 d a y s (b e c a u s e s p a r e re a lis e d w it h in 3 d a y s (b e c a u s e s p a re w ill b e lim it e d t o 1 0 0 k m a x w ill e x c e e d 1 0 0 0 k

w it h s o m e t e m p o ra r y r e p a irs ) . p a rt s a re a va ila b le o n s t o c k ) . H o w e ve r p a rt s a re a va ila b le o n s t o c k ). H o w e ve r (d u e to o n s to c k s p a re m o to r C o n s id e r t o m a in t a in a n

T h u s e x p e c t e d d o w n t im e c o s t in c a s e o f th e e x tre m e e ve n t (ro to r in c a s e o f t h e e x t re m e e ve n t (ro t o r b e a rin g ) s p a re (o n s to c k ) m o to r

is le s s t h a n 1 0 0 0 k (5 d a y s ) d is e n g a g e m e n t ) t h e d a m a g e a n d d o w n d is e n g a g e m e n t) t h e d a m a g e a n d

t im e w ill b e s ig n ifi c a n t ly m o r e d o w n t im e w ill b e s ig n ific a n t ly m o r e

L = 3 3 3 2 4

A vo id a n c e o f It i s e x p e c te d th a t o p e ra t o r It is e x p e c t e d t h a t o p e r a t o r a c t io n c a n It is e x p e c t e d t h a t o p e r a t o r a c t io n c a n It is e x p e c t e d t h a t o p e r a t o r O ve rh e a tin g is p ro b a b ly

fin a n c ia l lo s s e s a c t io n c a n a vo id t h e d a m a g e b y a vo id t h e d a m a g e b y b a s e d o n b e a rin g a vo id t h e d a m a g e b y b a s e d o n b e a rin g a c t io n c a n a vo id t h e d a m a g e a vo id e d b y o ve r d im e n s io n in g

b a s e d o n va rio u s o t h e r p re s s u re t e m p e ra tu re vib ra t io n b y b a s e d o n b e a r in g vib ra t io n th e m o to r

m e a s u re m e n ts

A = 1 1 1 1 1

S IL fi n a n c i a l = 1 1 1 0 1

S IL t o t a l = 1 1 1 0 1

10892EA00401-1 Harlingen Risk Analysis.doc

Page 12 of 113

1.3.5. Ammonia

In i t ia t o r A m m o n ia d e t e c t io n A m m o n ia d e t e c t io n Q S A H H A m m o n ia lo o p ve ry h ig h A m m o n ia d e t e c t io n in

R 1 H S J 1 0 C Q 3 0 2 o r C Q 3 0 4 o r p re s s u re in je c t io n a re a

C Q 3 0 6

F in a l E le m e n t S t o p a m m o n ia u n lo a d in g C lo s e " re t e n t io n t o s e w e r" C lo s e a m m o n ia s u p p ly va lve C lo s e a m m o n ia s u p p ly v a lv e

p u m p v a lv e s R 1 in c a s e o f a m m o n ia le a k a g e in c a s e o f a m m o n ia le a k a g e

H S J 3 0 A A 0 5 1 / A A 0 5 2 d e t e c t io n d e t e c t io n

F u n c t io n P re ve n t c o n t in u o u s re le a s e P re ve n t A m m o n ia c a l w a t e r P re ve n t a m m o n ia le a k a g e P re ve n t c o n t in u o u s re le a s e

o f A m m o n ia d is p e rs io n d u e t o t o o h ig h p re s s u re o f A m m o n ia

C a u s e L e a k a g e s a t fla n g e s fle x ib le s L e a k a g e s a t fl a n g e s fl e x i b le s L e a k a g e s a t fla n g e s fle x ib le s L e a k a g e s a t fl a n g e s fl e x i b le s

T a n k o v e r fi l li n g T a n k o v e r fillin g

S c e n a r io P o t e n t ia l e x p o s u re o f P o t e n t ia l p o llu t io n P o t e n t ia l e x p o s u re o f P o t e n t ia l p o llu t io n

d e s c rip t io n o f s t a ff/ w o r k e r s t o A m m o n ia s t a ff/ w o r k e r s t o A m m o n ia

F O D

D e m a n d ra t e B a s e d o n e x p e r ie n c e : o n c e B a s e d o n e x p e rie n c e : o n c e B a s e d o n e x p e rie n c e : o n c e B a s e d o n e x p e rie n c e : o n c e

p e r y e a r - o n c e p e r 1 0 y e a rs p e r y e a r - o n c e p e r 1 0 y e a rs p e r y e a r - o n c e p e r 1 0 y e a rs p e r y e a r - o n c e p e r 1 0 y e a rs

F = 2 2 2 2

S a fe t y E x p o s u r e c o u ld le a d t o a E x p o s u re c o u ld le a d t o a E x p o s u re c o u ld le a d t o a E x p o s u re c o u ld le a d t o a

c o n s e q u e n c e s s e r io u s in ju ry s e rio u s in ju ry s e r io u s in ju ry s e rio u s in ju ry

p e o p le

S = 2 2 2 2

T im e ly p re s e n c e A re a is a t t e n d e d ra re ly (< 1 0 A re a is a t t e n d e d ra re ly (< 1 0 A re a is a t t e n d e d ra re ly (< 1 0 A re a is a t t e n d e d ra re ly (< 1 0

o f p e o p le - 2 0 % ) p e r s h ift - 2 0 % ) p e r s h i ft - 2 0 % ) p e r s h ift - 2 0 % ) p e r s h i ft

T = 1 1 1 1

A v o id a n c e o f A m m o n ia s m e ll w ill a la rm A m m o n ia s m e ll w ill a la rm

e x p o s u re s t a ff/ w o r k e r s a n d s u ffi c ie n t ( 2 s t a ff/ w o r k e r s a n d s u ffic i e n t ( 2

o r m o r e ) n u m b e r o f e s c a p e o r m o r e ) n u m b e r o f e s c a p e

A = ro u t e s a re p ro vid e d 1 1 1 ro u t e s a re p ro vid e d 1

S I L s a f e ty = a a a a

C o n s e q u e n c e s M in o r e n viro n m e n t a l im p a c t t e m p o ra ry e n v ir o n m e n t a l M in o r e n viro n m e n t a l im p a c t M in o r e n viro n m e n t a l im p a c t

e n v ir o n m e n t im p a c t

E = 1 3 1 1

A v o id a n c e o f ra in w a t e r n e t p o llu t io n

e x p o s u re

e n v ir o n m e n t

A =

S I L e n v ir o n m e n t = a 2 a a

F in a n c ia l lo s s e s M in o r fin a n c ia l im p a c t M i n o r fi n a n c ia l i m p a c t M in o r fin a n c ia l im p a c t M i n o r fi n a n c i a l i m p a c t

e x p e c t e d e x p e c t e d e x p e c t e d e x p e c t e d

L = 1 1 1 1

A v o id a n c e o f

fi n a n c ia l l o s s e s

A =

S I L f i n a n c i a l = 0 0 0 0

S I L t o t a l= a 2 a a

10892EA00401-1 Harlingen Risk Analysis.doc

Page 13 of 113

1.3.6. BICAR

In it ia t o r H ig h le ve l in B ic a r S ilo O ve rp re s s u re in B ic a r S ilo V e ry h ig h t e m p e ra t u re fo r t h e

g rin d e r m o t o r

F in a l E le m e n t C lo s in g fillin g va lve C lo s in g fillin g v a lve S t o p p in g m o t o r

F u n c t io n P r e v e n t o v e r fillin g o f t h e P re v e n t re le a s e o f B ic a r t o p re ve n t m o t o r d a m a g e

B ic a r S ilo e n v ir o n m e n t in c a s e o f filt e r

c lo g g in g o r o v e r fillin g

C a u s e O p e ra t o r e rro r O p e ra t o r e rro r

S c e n a rio R e le a s e o f B ic a r t o R e le a s e o f B ic a r t o

d e s c rip t io n o f e n viro n m e n t e n viro n m e n t

F O D

D e m a n d ra t e G iv e n t h a t t h e s ilo is fille d G iv e n t h a t t h e s ilo is fille d B a s e d o n e x p e rie n c e : o n c e

o n ly a c o u p le o f t im e s p e r o n ly a c o u p le o f t im e s p e r p e r y e a r - o n c e p e r 1 0 y e a rs

m o n t h t h e e x p e c t e d d e m a n d m o n t h t h e e x p e c t e d d e m a n d

F = ra t e is ve ry lo w 1 ra t e is ve ry lo w 1 2

S a fe t y E x p o s u re o f o p e ra t o r t o E x p o s u re o f o p e ra t o r t o N o n e

c o n s e q u e n c e s B ic a r B ic a r

p e o p le

S = 1 1 1

T im e ly p re s e n c e O p e ra t o r is a lw a y s p re s e n t O p e ra t o r is a lw a y s p re s e n t

o f p e o p le a t fillin g w h ic h is o u t s id e t h e a t fillin g w h ic h is o u t s id e t h e

b u ild in g . b u ild in g .

T = 1 1 1

A vo id a n c e o f

e x p o s u re

A =

S I L s a f e t y = 0 0 0

C o n s e q u e n c e s T h e re le a s e h a s m in o r T h e re le a s e h a s m in o r N o n e

e n viro n m e n t e n v iro n m e n t a l im p a c t e n viro n m e n t a l im p a c t

E = 1 1 1

A vo id a n c e o f

e x p o s u re

e n viro n m e n t

A =

S I L e n v ir o n m e n t = 0 0 0

F in a n c ia l lo s s e s R e le a s e o f B ic a r w ill re q u ir e R e le a s e o f B ic a r w ill re q u ire E s t im a t e d c o s t s 1 0 - 1 0 0 k

s ig n ific a n t c le a n in g a c t iv it ie s . s ig n ific a n t c le a n in g a c t iv it ie s .

E s t im a t e d c o s t s 1 0 - 1 0 0 k E s t im a t e d c o s t s 1 0 - 1 0 0 k

L = 2 2 2

A vo id a n c e o f D u e t o t h e s t a n d b y lin e , t h e

fin a n c ia l lo s s e s p ro d u c t io n c a n c o n t in u e in

n o m in a l c o n d it io n s

A = 1 1 1

S I L f i n a n c i a l = 0 0 a

S I L t o t a l = 0 0 a

10892EA00401-1 Harlingen Risk Analysis.doc

Page 14 of 113

1.3.7. Activated Carbon

In it ia t o r H ig h le ve l in A c t iva t e d C a rb o n S ilo O ve rp re s s u re in A c t iva t e d C a rb o n H ig h t e m p e ra t u re in A c t iva t e d

S ilo C a rb o n S ilo

F in a l E le m e n t C lo s in g fi l l i n g va lve C lo s in g fi l l i n g va lve R e le a s e o f n it ro g e n

F u n c t io n P r e v e n t o v e r fillin g o f t h e A c t iv a t e d P re ve n t re le a s e o f A c t iva t e d C a rb o n E x t in g u is h a n a c t iva t e d c a rb o n

C a rb o n S ilo w it h a c t iva t e d c a rb o n t o e n v ir o n m e n t in c a s e o f filt e r fir e in t h e s ilo

c lo g g in g o r o v e r fillin g

C a u s e O p e ra to r e rro r O p e ra to r e rro r H o t s p o t in s ilo

S c e n a rio R e le a s e o f a c t iva t e d c a rb o n to R e le a s e o f A c t iva t e d C a rb o n to F ire in s ilo w h ic h m a y a ffe c t th e

d e s c rip t io n o f e n viro n m e n t e n viro n m e n t s ilo in t e g r it y

F O D

D e m a n d ra t e G i v e n t h a t t h e s i l o i s fi l l e d o n l y a G i v e n t h a t t h e s i l o i s fi l l e d o n l y a V e ry ve ry lo w

c o u p le o f t im e s p e r y e a r, t h e c o u p le o f t im e s p e r y e a r, t h e

e x p e c t e d d e m a n d ra t e is ve ry lo w e x p e c t e d d e m a n d ra t e is ve ry lo w

F = 1 1 1

S a fe t y E x p o s u re o f o p e ra to r to a c t iva t e d E x p o s u re o f o p e ra to r to A c t iva t e d P o s s ib le s e rio u s in ju ry

c o n s e q u e n c e s c a rb o n C a rb o n

p e o p le

S = 1 1 2

T im e ly p re s e n c e O p e r a t o r is a lw a y s p r e s e n t a t fillin g O p e ra t o r is a lw a y s p re s e n t a t fillin g S ilo a re a is ra re ly a tt e n d e d

o f p e o p le w h ic h is o u t s id e t h e b u ild in g . T h e w h ic h is o u t s id e t h e b u ild in g .

a c t u a l re le a s e p o in t in c a s e o f

o v e r fillin g is in t h e b u ild in g w h ic h is

r a re ly o c c u p ie d

T = 1 1 1

A vo id a n c e o f P e rs o n s c a n a v o id t h e e x p o s u r e

e x p o s u re b e c a u s e t h e t im e b e tw e e n t h e

in it ia l fir e a n d lo s s o f in t e g rit y o f

t h e s ilo is s u ffic ie n t t o a vo id

e x p o s u re

A = 1

S I L s a fe ty = 0 0 0

C o n s e q u e n c e s T h e r e le a s e h a s m in o r e n viro n m e n t a l T h e r e le a s e h a s m in o r T h e re le a s e h a s m in o r

e n viro n m e n t im p a c t e n viro n m e n t a l im p a c t e n viro n m e n t a l im p a c t

E = 1 1 1

A vo id a n c e o f

e x p o s u re

e n viro n m e n t

A =

S I L e n v ir o n m e n t = 0 0 0

F in a n c ia l lo s s e s R e le a s e o f a c t iv a t e d c a r b o n w ill R e le a s e o f A c t iva t e d C a rb o n w ill R e le a s e o f a c t iva t e d c a rb o n w ill

r e q u ir e s ig n ific a n t c le a n in g a c t iv it ie s . r e q u ir e s ig n ific a n t c le a n in g r e q u ir e s ig n ific a n t c le a n in g

E s t im a t e d c o s t s 1 0 - 1 0 0 k a c t ivit ie s . E s t im a t e d c o s t s 1 0 - a c t ivit ie s a n d s ilo m a y h a ve to

1 0 0 k b e re p la c e d . E s t im a t e d c o s ts

1 0 - 1 0 0 k

L = 2 2 2

A vo id a n c e o f G ive n t h a t t h e t ru c k u n lo a d in g p o in t is G ive n t h a t t h e t ru c k u n lo a d in g p o in t It is e x p e c t e d t h a t if t h e fir e

fin a n c ia l lo s s e s lo c a t e d o u t s id e t h e b u ild in g a n d t h e is lo c a t e d o u t s id e t h e b u ild in g a n d w o u ld o c c u r, t h e o p e ra t o r c a n

s ilo is in s id e t h e b u ild in g , it is t h e s ilo is in s id e t h e b u ild in g , it is n o t a vo id t h e d a m a g e (n o o t h e r

e x p e c te d t h a t t h e fin a n c ia l lo s s e s c a n e x p e c t e d t h a t t h e fin a n c ia l lo s s e s m e a n s fo r d e t e c t io n o f a n

p ro b a b ly n o t b e a vo id e d c a n p ro b a b ly n o t b e a vo id e d i n t e r n a l fi r e a v a i l a b l e )

A = 2 2 2

S I L fi n a n c i a l = 0 0 0

S I L to ta l = 0 0 0

10892EA00401-1 Harlingen Risk Analysis.doc

Page 15 of 113

1.3.8. Spent sorbent

In i t i a t o r H ig h t e m p e ra t u re in S p e n t s o rb e n t

S ilo

F in a l E le m e n t R e le a s e o f n it ro g e n

F u n c tio n E x t i n g u i s h a n s p e n t s io r b e n t fi r e i n

t h e s ilo

Cause H o t s p o t in s ilo

S c e n a rio F i r e i n s i l o w h i c h m a y a ff e c t t h e s i l o

d e s c rip t io n o f in t e g rit y

FO D

D e m a n d ra te V e r y ve r y lo w

F= 1

S a fe t y P o s s ib le s e rio u s in ju ry

consequences

p e o p le

S = 2

T im e ly p re s e n c e S ilo a re a is ra re ly a t t e n d e d

o f p e o p le

T= 1

A vo id a n c e o f P e r s o n s c a n a vo id t h e e x p o s u r e

e x p o s u re b e c a u s e t h e t im e b e t w e e n t h e in it ia l

fi r e a n d l o s s o f i n t e g r i t y o f t h e s i l o i s

s u f fi c i e n t t o a v o i d e x p o s u r e

A = 1

S IL =

s a fe ty 0

Consequences T h e r e le a s e h a s m in o r e n vir o n m e n t a l

e n vir o n m e n t im p a c t

E = 1

A vo id a n c e o f

e x p o s u re

e n vir o n m e n t

A =

S IL en viro n m en t = 0

F in a n c ia l lo s s e s R e le a s e o f s p e n t s o rb e n t w ill re q u ire

s ig n ific a n t c le a n i n g a c t ivi t ie s a n d s il o

m a y h a ve t o b e r e p la c e d . E s t im a t e d

c o s ts 1 0 - 1 0 0 k

L= 2

A vo id a n c e o f It i s e x p e c t e d t h a t i f t h e f i r e w o u l d

fi n a n c i a l l o s s e s o c c u r , t h e o p e r a t o r c a n n o t a vo id t h e

d a m a g e ( n o o t h e r m e a n s fo r d e t e c t i o n

o f a n i n t e r n a l fir e a va i l a b l e )

A = 2

S I L fin a n c ia l 0

S I L to ta l = 0

10892EA00401-1 Harlingen Risk Analysis.doc

Page 16 of 113

1.3.9. Heat Exchanger

In i t i a t o r L o w g a s t e m p e ra t u re G / W L o w w a t e r t e m p e ra t u re G / W H E

H E o u t le t i n l e t T IS A L L R 1 N D A 1 3 C T 0 0 1

F in a l E le m e n t S t o p p in g c irc u la t io n p u m p s S t o p p in g c irc u la t io n p u m p s R 1

N D A 1 1 / N D A 1 2 A P 0 0 1 if 3 w a y s

va l ve n o t i n b y - p a s s ( R 1

N D B 1 0 A A 3 5 1 p o s it io n s w it c h )

F u n c t io n p ro t e c t t h e d o w n s t re a m p ro t e c t t h e H E a n d t h e

e q u ip m e n t s a g a in s t t h e d o w n s t re a m e q u ip m e n t s a g a i n s t

c o rro s io n ris k t h e c o rro s io n ris k

C ause H i g h h e a t r e c o ve r y w i t h l o w w a t e r c o n t r o l l o o p fa i l u r e o r

lo a d a n d n o S C R b y -p a s s fu r n a c e t r o u b l e s o r l i n e s t a r t - u p

S c e n a rio

d e s c ri p t io n o f

FOD

D e m a n d ra t e B a s e d o n e x p e rie n c e : o n c e E x p e c t e d d e m a n d ra t e le s s t h a n

p e r y e a r - o n c e p e r 1 0 y e a rs once per 1 year

F= 2 1

S a fe t y N one None

cons equences

p e o p le

S =

T im e ly p re s e n c e

o f p e o p le

T=

A vo i d a n c e o f

e x p o s u re

A =

S IL s a fe ty = 0 0

C onsequenc es N one None

e n vi r o n m e n t

E =

A vo i d a n c e o f

e x p o s u re

e n vi r o n m e n t

A =

S IL e n v ir o n m e n t = 0 0

F in a n c ia l lo s s e s L i fe t i m e w i l l b e s h o r t e n e d L i fe t i m e w i l l b e s h o r t e n e d d u e t o

d u e t o c o rro s io n . E x p e c t e d c o rro s io n . E x p e c t e d d a m a g e is

d a m a g e is le s s t h a n 1 0 0 k le s s t h a n 1 0 0 k

L= 2 2

A vo i d a n c e o f It i s e x p e c t e d t h a t o p e r a t o r It i s e x p e c t e d t h a t o p e r a t o r

fi n a n c i a l l o s s e s a c t i o n c a n a vo i d t h e d a m a g e a c t i o n c a n a vo i d t h e d a m a g e b y

b y m a n u a l a c t io n m a n u a l a c t io n

A =

S IL fi n a n c i a l= a 1

S IL to ta l = a 1

10892EA00401-1 Harlingen Risk Analysis.doc

Page 17 of 113

LAB GROUPE a

WHAT IF

2. ELECTROSTATIC PRECIPITATOR OPERATION: EQUIPMENT:

HDE10

2.1. DEDUSTING 2.1.1. Electrostatic precipitator

PID 002

Undesirable Events or deviations Causes Consequences G Actions C

2.1.1.1.ESP Explosion Entry of non desired ESP damaged 4 Co measurement (stack and 3

explosive gas furnace) with high and very high

alarm

ESP HV stopped in case of very

high CO alarm in the furnace

2.1.1.2.Very high temperature inlet ESP Fire in the furnace, boiler Internal system 3 3 analogical temperature sensors 3

or in the building deterioration risk at the fabric filter inlet with high

ESP deterioration risk and very high alarm

The fabric filter is automatically

by-passed and the waste

incineration is stopped if very high

temperature alarm is reached

2.1.1.3.Very high temperature of Transformer troubles Dedusting function 2 Internal stop by the HV system 2

transformer troubles

Alarm in control rrom

2.1.1.4.Very high oil level in transformer Transformer troubles Dedusting function 2 Internal stop by the HV system 2

troubles

Alarm in control rrom

10892EA00401-1 Harlingen Risk Analysis.doc

Page 18 of 113

LAB GROUPE a

Undesirable Events or deviations Causes Consequences G Actions C

2.1.1.5.Ashes extraction fault See 11.1.1.1 ESP hopper

blocked

2.1.1.6.Combustion of ashes accumulation of Blazing fire, explosion 2 Level sensors to avoid too many 2

Incandescent ashes in the flue gas incandescent ashes and ashes be concerned by burning

non burned gases

Electrostatic precipitator high

voltage and rappers automatically

stopped if high level in the hopper

is obtained

2.1.1.7.Depression of flue gases Global or partial plugging No consequence on 2 1 pressure sensor downstream 2

increases upstream of ESP ESP ESP with very low alarm

2.1.1.8.Air intake The manholes are not Corrosion 1 Technology choice : double flap 1

correctly closed

Check there is no leak at doors

Air intake through ashes

Operating manual instructions

circuit: evacuation

system

2.1.1.9.Low temperature hopper heating Hopper heating fault Ash plugging risk in the 2 Low temperature switch in the 2

hopper hopper with alarm

Operator checking

2.1.1.10.Electrical troubles with HV (high Operation at too low Disruptive breakdown 2 ID Fan running signal is a 2

voltage system) temperature or at too low of insulator necessary condition to run the HV

gases flowrate

Correct temperature at the ESP

inlet and at the ESP outlet is a

necessary condition to run the HV

10892EA00401-1 Harlingen Risk Analysis.doc

Page 19 of 113

LAB GROUPE a

WHAT IF

3. LAB LOOP HTD10 OPERATION: EQUIPMENT:

PID 003 3.1. LAB LOOP 3.1.1. Analyser

Undesirable Events or deviations Causes Consequences G Actions C

3.1.1.1.Very high HCl/SO2/NOx content Bad quality of waste Risk to obtain 2 1 flue gas analyser at the ESP 2

in flue gas Emission outlet for information and

Bad waste mixing

measurement higher optimisation of reagent injection

than guaranteed

Improve waste mixing to reduce

values

average pollutants contents in flue

gas

1 flue gas analyser at the stack for

emission control and reagent

dosing optimisation

3.1.1.2.Analyser deviation Calibration fault Gas measurements 2 Automatic calibration 2

fault

Analyser frequent maintenance

Operator manual calibration

The bicar injection is corrected by

downstream HCl/SO2

measurements

10892EA00401-1 Harlingen Risk Analysis.doc

Page 20 of 113

LAB GROUPE a

Undesirable Events or deviations Causes Consequences G Actions C

3.1.1.3.Analyser fault Analyser out of order No gas measurements 2 Analyser fault alarm 2

The bicar injection is corrected by

downstream HCl/SO2

measurements

Operator checking

10892EA00401-1 Harlingen Risk Analysis.doc

Page 21 of 113

LAB GROUPE a

WHAT IF

3 LAB LOOP HTD10 OPERATION: EQUIPMENT:

PID 003 3.1 LAB LOOP 3.1.2. LAB loop

Undesirable Events or deviations Causes Consequences G Actions C

3.1.2.1.Very low temperature at the Lab Furnace at the minimum Reagents efficiency 2 1 temperature sensor at the LAB 2

loop inlet load decreasing risk : loop inlet with low alarm

injected quantity of

bicar increases

3.1.2.2.Very high temperature at the Lab Furnace or boiler Activated carbon 2 1 temperature sensor at the LAB 2

loop inlet troubles post-combustion risk loop inlet with very high alarm

in the fabric filter

Activated carbon injection stopped

Damage to filter bags in case of very high temperature

in case of excessive at the fabric filter inlet

temperature

10892EA00401-1 Harlingen Risk Analysis.doc

Page 22 of 113

LAB GROUPE a

Undesirable Events or deviations Causes Consequences G Actions C

3.1.2.3.High pressure drop in lab loop Solid settling Electrical 3 2 Pressure sensors (one inlet and 4

consumption one outlet)

Global or partial plugging

increases

Pressure drop calculated with high

Very low pressure in and very high alarm

the flue gas

3 analogical pressure sensors at

downstream the lab

the fabric filter outlet. Calculated

loop

very low pressure: 2 on 3

Equipments damages detection on very low alarm

risk

Emergency stop required in case

Reduction of furnace of calculated very low pressure in

loading the flue gas

Reagents injection automatically

stops in case of very low flue gas

flowrate

2 Manholes for operator

maintenance for cleaning in case

of plugging

10892EA00401-1 Harlingen Risk Analysis.doc

Page 23 of 113

LAB GROUPE a

WHAT IF

4. FABRIC FILTER HTE10 OPERATION: EQUIPMENT:

PID 004.1 4.1. DEDUSTING 4.1.1. Fabric filter

Undesirable Events or deviations Causes Consequences G Actions C

4.1.1.1.Flue gases very low temperature Furnace at the minimum reagents efficiency 3 3 analogical temperature sensors 4

load decreasing risk and at the fabric filter inlet with low and

injected quantity of bicar very low alarm

increasing

2 temperature sensors in the

Gas temperature lower

fabric filter with low and very low

than the acid dew point :

bags damages risk alarm

Corrosion risk The fabric filter is automatically

by-passed if very low temperature

alarm is reached:

If 2 very low alarms at the fabric

filter inlet are reached (2/3

security)

Preheating system to heat the

fabric filter before receiving flue

gas

Precoating : Bicar injection before

the start up to protect the bags

10892EA00401-1 Harlingen Risk Analysis.doc

Page 24 of 113

LAB GROUPE a

Undesirable Events or deviations Causes Consequences G Actions C

4.1.1.2.Flue gases high temperature Furnace or boiler Activ carbon 3 3 analogical temperature sensors 4

troubles combustion risk at the fabric filter inlet with high

alarm

2 temperature sensors in the

fabric filter with high alarm

Activ carbon injection stop

Operator checking

4.1.1.3.Flue gases very high temperature Furnace or boiler Bags damages risk 3 3 analogical temperature sensors 4

troubles at the fabric filter inlet with very

high alarm

2 temperature sensors in the

fabric filter with very high alarm

The fabric filter is automatically

by-passed if very high

temperature alarm is reached

If 2 very high alarms at the

fabric filter inlet are reached

(2/3 security)

10892EA00401-1 Harlingen Risk Analysis.doc

Page 25 of 113

LAB GROUPE a

Undesirable Events or deviations Causes Consequences G Actions C

4.1.1.4.High pressure drop in the fabric Bags clogging Very low pressure at 2 1 global fabric filter pressure drop 3

filter the bag house outlet: sensor with high and very high

One or several filter cells

are isolated emergency stop risk alarm

ID fan electrical Pressure drop sensor measuring

consumption in 2 cells (cells 1 and 8) with high

increases and very high alarm

Automatic declogging to maintain

pressure drop between two values

Local pressure drop on each cell

to be checked once every shift

Check if cells are isolated

Check compressed air pressure

once every shift

10892EA00401-1 Harlingen Risk Analysis.doc

Page 26 of 113

LAB GROUPE a

Undesirable Events or deviations Causes Consequences G Actions C

4.1.1.5.Declogging fault Compressed air low Bags are not cleaned 2 1 Compressed air pressure sensor 3

pressure with low alarm

Fabric filter pressure

Declogging sequencer fault drop increases 1 global fabric filter pressure drop

sensor with high and very high

alarm

Pressure drop sensor measuring

in 2 cells (cells 1 and 8) with high

and very high alarm

1 local pressure control valve

1 air pressure sensor on each cell

, connected to the declogging

sequencer

Declogging sequencer alarm

Check compressed air pressure

once every shift

4.1.1.6.Low pressure drop in the fabric Bags cleaning troubles Bags damages risk 2 1 global fabric filter pressure drop 2

filter (excess of compressed sensor with low alarm

Flue gas treatment

air)

efficiency decreases Pressure drop sensor measuring

Declogging sequencer in 2 cells (cells 1 and 8) with low

fault alarm

1 local pressure control valve

1 air pressure sensor on each cell

, connected to the declogging

sequencer

10892EA00401-1 Harlingen Risk Analysis.doc

Page 27 of 113

LAB GROUPE a

Undesirable Events or deviations Causes Consequences G Actions C

4.1.1.7.Bags damage Bags cleaning fault Dust leakage 2 1 global fabric filter pressure drop 3

sensor

Incandescent

particulates Pressure drop sensor measuring

in 2 cells (cells 1 and 8)

Hot spot

2 Dust emission sensor at the

fabric filter outlet and at the stack

with alarm

The operator can change or blind

the bags when the corresponding

cell has been isolated.

Operator checking in case of

declogging sequencer fault

Safety relief valve in case of high

pressure

4.1.1.8.Very low pressure at the fabric Fabric filter or upstream Fabric filter damage 4 3 analogical pressure sensors at 4

filter outlet equipment clogging the fabric filter outlet. Calculated

pressure ( 2 on 3 ) with low and

Fabric filter damper fault

very low alarm

Emergency stop in case of

calculated very low alarm

Limit switches on the isolating

dampers

Operator checking

10892EA00401-1 Harlingen Risk Analysis.doc

Page 28 of 113

LAB GROUPE a

Undesirable Events or deviations Causes Consequences G Actions C

4.1.1.9.Bags damage with acid gas Acid gas in contact with Bags damage risk 2 Bicar injection sequence 2

during the start up bags (precoating) available before the

start up to protect the bags ,with

an automatic suggestion for the

operator , at each ID Fan start-up

Operator checking

4.1.1.10.Flue gas is cooled around the Cold air in by-pass duct Duct corrosion around 2 Hot sealing air injected in the by- 2

by-pass dampers during normal the by-pass dampers pass duct

operation

Air temperature sensor at the air

heating battery outlet with low and

very low alarm

Operator checking.

4.1.1.11. Flue gas flow through by-pass By-pass dampers not tight Pollutants level 2 Limit switch on the by-pass 2

duct during normal operation increasing at the stack dampers with discrepancy control

Overpressure in the by-pass duct

with sealing air injection

1 local overpressure sensor to be

checked every shift by the

operator

10892EA00401-1 Harlingen Risk Analysis.doc

Page 29 of 113

LAB GROUPE a

Undesirable Events or deviations Causes Consequences G Actions C

4.1.1.12.Fabric filter inlet or outlet damper fault Underpressure at the 2 Limit switches open / close on 2

damper closed fabric filter outlet dampers

3 analogical pressure sensors at

the fabric filter outlet with

emergency stop in case of very

low underpressure

WHAT IF

4 FABRIC FILTER HTE10 OPERATION: EQUIPMENT:

PID 004.2 4.2. SPENT SORBENT EXTRACTION 4.2.1. Fabric filter hoppers

Undesirable Events or deviations Causes Consequences G Actions C

10892EA00401-1 Harlingen Risk Analysis.doc

Page 30 of 113

LAB GROUPE a

Undesirable Events or deviations Causes Consequences G Actions C

4.2.1.1.Spent sorbent clogging into the Spent sorbent extraction Bags damages risk 2 Hopper equipped with heat tracing 2

hopper equipment stopped with fault alarm

Flue gas treatment

Air tightness fault efficiency decreases 1 High level sensor and 1 very

high level sensor in the hopper

Dust arch in the hopper Risk of hot spot with

with alarm

active carbon

1 temperature sensor in the

hopper with alarms

Low speed detection on the spent

sorbent extraction equipments

with alarm

One cell of the fabric filter can be

isolated for maintenance

Operator checking

10892EA00401-1 Harlingen Risk Analysis.doc

Page 31 of 113

LAB GROUPE a

Undesirable Events or deviations Causes Consequences G Actions C

4.2.1.2.Very high temperature in the Activated carbon auto- Bags damages risk 2 1 temperature sensor (1 2

hopper. ignition condition analogical) in each hopper with

high and very high alarm

The cell is automatically isolated

from flue gas if very high

temperature alarm is reached in

order to stop oxygen feeding

Nitrogen station connected to

each hopper

Automatic Nitrogen injection in the

hopper of the cell if very high

temperature alarm appears after

having isolated the cell

By-pass valve on each Nitrogen

injection automatic valve, for

manual injection

Limit switches on the cells

isolating dampers

4.2.1.3.Low temperature heating hopper Hopper heating fault Spent sorbent plugging 2 Heating Temperature sensor 2

risk in the hopper

Operator checking

10892EA00401-1 Harlingen Risk Analysis.doc

Page 32 of 113

LAB GROUPE a

WHAT IF

4 FABRIC FILTER HTE10 OPERATION: EQUIPMENT:

PID 004.1 4.3. Preheating system 4.3.1. Preheating system

Undesirable Events or deviations Causes Consequences G Actions C

4.3.1.1.High temperature in the electrical Electrical battery fault Bags damage risks 2 1 high temperature sensor (1 3a

battery binary) in the electrical battery

Electrical coils

destruction risk with trip

1 temperature sensor (1

analogical) with high and very high

alarm which stop the battery

4.3.1.2.Preheating dampers discrepancy Preheating dampers fault 2 Limit switch on the preheating 2

dampers

Preheating sequence stopped in

case of dampers discrepancy

Operator checking

10892EA00401-1 Harlingen Risk Analysis.doc

Page 33 of 113

LAB GROUPE a

Undesirable Events or deviations Causes Consequences G Actions C

4.3.1.3.Preheating fan stopped during the Preheating fan fault Electrical battery 2 Electrical battery automatically 2

preheating sequence damage stops if preheating fan running

feed back is lost

1 high temperature sensor (1

binary) in the electrical battery

with alarm

1 temperature sensor (1

analogical) with high and very high

alarm

4.3.1.4.Flue gas is cooled around the Cold air in pre-heating duct Duct corrosion around 2 Hot sealing air injected in the pre- 2

pre-heating dampers during normal the pre-heating heating duct

operation dampers

Air temperature sensor at the air

Battery corrosion heating battery outlet with low and

Pre heating fan very low alarm

corrosion

Operator checking.

4.3.1.5. Flue gas flow through pre- Pre-heating dampers not Pollutants level 2 Limit switch on the pre-heating 2

heating duct during normal operation tight increasing at the stack dampers with discrepancy control

Overpressure in the pre-heating

duct with sealing air injection

1 local overpressure sensor to be

checked every shift by the

operator

10892EA00401-1 Harlingen Risk Analysis.doc

Page 34 of 113

LAB GROUPE a

WHAT IF

5. DENOX SCR HSB10 OPERATION: EQUIPMENT:

PID 005 5.1. DIOXINS REMOVAL AND NOX 5.1.1. Reactor SCR

REDUCTION

Undesirable Events or deviations Causes Consequences G Actions C

5.1.1.1.Very low temperature at the Furnace stopped Gas temperature lower 3 2 temperature sensors in the 3

DeNOx SCR inlet than the acid dew point : fabric filter (DeNOx SCR inlet)

Furnace at the minimum

DeNOx SCR damages with low and very low alarm

load

risk

Fabric filter (and then SCR) by-

Ambiant air entrance

pass in case of Fabric filter

(Manholes open or not

upstream very low temperature

tight)

5.1.1.2.Catalytic reactor pressure drop Catalytic reactor plugging ID fan electrical 2 1 pressure drop sensor with high 2

increases with dust and/or salts consumption increases alarm and very high alarm

Reduction of NOx 1 local pressure drop sensor on

removal efficiency the catalytic reactor layer.

Operator checking

NOx measurement at the stack

10892EA00401-1 Harlingen Risk Analysis.doc

Page 35 of 113

LAB GROUPE a

Undesirable Events or deviations Causes Consequences G Actions C

5.1.1.3.Very low temperature at the Steam not available SCR catalyst clogging 3 2 temperature sensors at the 3

Catalytic reactor inlet (salt deposit) and Catalytic reactor inlet with low and

damages risk very low alarm

Ammonia injection stops in case

of very low temperature

5.1.1.4.Very high temperature at the Furnace or boiler fault SCR equipment 2 2 temperature sensors at the 3

Catalytic reactor inlet damages risk DeNOx SCR reactor inlet with

Steam control loop failure

high and very high alarm

Steam feeding stops in case of

very high temperature

2 temperature sensors at the

DeNOx SCR reactor outlet with

high and very high alarm

Fabric filter (and then SCR) by-

pass in case of Fabric filter

upstream very high temperature

5.1.1.5.Very low temperature at the SCR Steam not available SCR corrosion risk 3 2 temperature sensors at the SCR 3

reactor outlet reactor outlet with low and very

Very low temperature at the

gas-gas Heat exchanger low alarm

SCR is by-passed in case of very

low temperature

10892EA00401-1 Harlingen Risk Analysis.doc

Page 36 of 113

LAB GROUPE a

Undesirable Events or deviations Causes Consequences G Actions C

5.1.1.6.Very high temperature at the Very high temperature at SCR equipment 2 2 temperature sensors at the 3

Catalytic reactor outlet the Catalytic reactor inlet damages risk DeNOx SCR reactor outlet with

high and very high alarm

Steam feeding stops in case of

very high temperature at the

Catalytic reactor inlet

5.1.1.7.Very high delta temperature Catalytic reactor fault SCR catalyst damages 3 2 x 2 temperature sensors 3

across the SCR reactor risk

Delta temperature calculation

across the catalyst with high and

very high alarm

SCR is by-passed in case of very

high delta temperature

5.1.1.8.Very High dust concentration in Fabric filter by-passed SCR catalyst clogging 3 Dust concentration analyser at the 3

the flue gas risk fabric filter outlet with high and

very high alarm.

Dust concentration analyser at the

stack inlet with high and very high

alarm

SCR is by-passed in case of very

high dust concentration during a

time period or in case of fabric

filter by-pass

10892EA00401-1 Harlingen Risk Analysis.doc

Page 37 of 113

LAB GROUPE a

Undesirable Events or deviations Causes Consequences G Actions C

5.1.1.9.Very high CO concentration Combustion fault SCR catalyst 3 CO concentration analyser at the 3

damages risk if very stack inlet and boiler outlet with

high delta high and very high alarm

temperature across

SCR is by-passed in case of very

the SCR reactor

high CO concentration during a

time period

SCR is by-passed in case of very

high delta temperature across the

SCR reactor

5.1.1.10.Very high SO2 concentration Flue gas treatment fault SCR catalyst 2 SO2 concentration analyser at the 2

clogging risk stack inlet with high and very

alarm

SCR is by-passed in case of very

high SO2 concentration

5.1.1.11.SCR damper closed damper fault Underpressure on 3 Limit switches open / close on 3a

the SCR downstream dampers

side

SCR is by-passed if SCR isolating

dampers limit switches open are

lost

3 analogical pressure sensors at

the ID Fan inlet with emergency

stop in case of very low

underpressure

10892EA00401-1 Harlingen Risk Analysis.doc

Page 38 of 113

LAB GROUPE a

Undesirable Events or deviations Causes Consequences G Actions C

5.1.1.12.NH4OH leakage Flange broken or leakage Operator injury by 3 Ammonia detection sensor with 3a

NH4OH high and very high alarm

Ammonia injection stops in case

of very high alarm

Safety shower and eye-washers

Protection clothes

5.1.1.13.Flue gas is cooled around the Cold air in the SCR by-pass Duct corrosion around 2 Hot sealing air injected in the SCR 2

SCR by-pass dampers during normal duct the SCR by-pass by-pass duct

operation dampers

Air temperature sensor at the air

heating battery outlet with low and

very low alarm

Operator checking..

5.1.1.14. Flue gas flow through SCR by- SCR by-pass dampers not Pollutants level 2 Limit switch on the SCR by-pass 2

pass duct during normal operation tight increasing at the stack dampers with discrepancy control

Overpressure in the SCR by-pass

duct with sealing air injection

1 local overpressure sensor to be

checked every shift by the

operator

10892EA00401-1 Harlingen Risk Analysis.doc

Page 39 of 113

LAB GROUPE a

WHAT IF

5 DENOX SCR HSB10 OPERATION: EQUIPMENT:

PID 005 5.1 DIOXINS REMOVAL AND NOX 5.1.2. Gas-Gas Heat exchangers

REDUCTION

Undesirable Events or deviations Causes Consequences G Actions C

5.1.2.1.Gas-Gas heat exchanger clogging High dust concentration Equipments 2 Pressure drop sensors across the 2

in the flue gas damages risks heat exchanger

Fabric filter by-passed Gas-Gas heat Temperature sensors at the inlets

exchanger efficiency and outlets of the heat exchanger

decreases

Dust analyser at the fabric filter

outlet with high and very high

alarm.

Dust analyser at the stack inlet

with high and very high alarm:

DeNOx by passed in case of High

dust concentration at the fabric

filter outlet or at the stack inlet

during a time period

Operator checking

Underpressure sensors at the inlet

ID fan

10892EA00401-1 Harlingen Risk Analysis.doc

Page 40 of 113

LAB GROUPE a

Undesirable Events or deviations Causes Consequences G Actions C

5.1.2.2.Very low temperature at the gas- Very low temperature Gas temperature lower 3 1 temperature sensor at the gas- 3a

gas heat exchanger inlet alarm at the DeNOx SCR than the acid dew point : gas heat exchanger inlet with low

inlet DeNOx SCR damages and very low alarm

risk

Fresh air damper not The DeNOx SCR is automatically

closed by-passed if very low temperature

alarm at the DeNOx SCR inlet is

reached

Limit switches on the isolating

dampers

10892EA00401-1 Harlingen Risk Analysis.doc

Page 41 of 113

LAB GROUPE a

WHAT IF

5 DENOX SCR HSB10 OPERATION: EQUIPMENT:

PID 005 5.1 DIOXINS REMOVAL AND NOX 5.1.3. Gas-Steam Heat exchangers

REDUCTION

Undesirable Events or deviations Causes Consequences G Actions C

5.1.3.1.Steam-Gas heat exchanger High dust concentration Equipments damages 2 Pressure drop sensor across the 2

clogging in the flue gas risks heat exchanger

Fabric filter by-passed Temperature sensor at the inlet

and outlet of the heat exchanger

Dust analyser at the fabric filter

outlet with high and very high

alarm.

Dust analyser at the stack inlet

with high and very high alarm:

DeNOx by passed in case of High

dust concentration at the fabric

filter outlet or at the stack inlet

during a time period

Operator checking

10892EA00401-1 Harlingen Risk Analysis.doc

Page 42 of 113

LAB GROUPE a

Undesirable Events or deviations Causes Consequences G Actions C

5.1.3.2.Lack of steam Automatic valve fault DeNOx SCR 2 1 Temperature sensor at the heat 2

efficiency decreases exchanger inlet

Very low gas 1 Temperature sensor at the heat

temperature risk exchanger outlet

2 Temperature sensors at the

catalytic reactor inlet with low and

very low alarm

Steam automatic valve with

position feedback

10892EA00401-1 Harlingen Risk Analysis.doc

Page 43 of 113

LAB GROUPE a

WHAT IF

5 DENOX SCR HSB10 OPERATION: EQUIPMENT:

PID 005 5.1 DIOXINS REMOVAL AND NOX 5.1.4. Fresh air damper

REDUCTION

Undesirable Events or deviations Causes Consequences G Actions C

5.1.4.1.Flue gas is cooled around the Cold air outside the fresh air Duct corrosion 2 Hot sealing air injected in the fresh 2

fresh air damper during normal operation duct around the fresh air air damper

damper

Air temperature sensor at the air

heating battery outlet with low and

very low alarm

Gas temperature sensor at the

outlet of the fresh air damper with

low and very low alarm

Limit switches on the fresh air

damper

Operator checking..

10892EA00401-1 Harlingen Risk Analysis.doc

Page 44 of 113

LAB GROUPE a

WHAT IF

5 DENOX SCR HSB10 OPERATION: EQUIPMENT:

PID 005 5.1 DIOXINS REMOVAL AND NOX 5.1.5. Preheating system

REDUCTION

Undesirable Events or deviations Causes Consequences G Actions C

5.1.5.1.Flue gas is cooled around the Cold air in pre-heating duct Duct corrosion 2 Hot sealing air injected in the pre-

pre-heating dampers during normal around the pre- heating duct 2

operation heating dampers

Air temperature sensor at the air

Pre heating SCR heating battery outlet with low and

fan corrosion

very low alarm

Operator checking.

5.1.5.2. Flue gas flow through pre- Pre-heating dampers not tight Pollutants level 2 Limit switch on the pre-heating 2

heating duct during normal operation increasing at the dampers with discrepancy control

stack

Overpressure in the pre-heating

duct with sealing air injection

1 local overpressure sensor to be

checked every shift by the

operator

10892EA00401-1 Harlingen Risk Analysis.doc

Page 45 of 113

LAB GROUPE a

WHAT IF

6. ID FAN HSC10 OPERATION: EQUIPMENT:

PID 006 6.1. GAS EXTRACTION 6.1.1. ID Fan

Undesirable Events or deviations Causes Consequences G Actions C

6.1.1.1.very low pressure Upstream ID Upstream equipment Flue gas equipments 3 3 analogical pressure sensors at 4

Fan clogging or obstruction damage the ID Fan inlet. Calculated

pressure ( 2 on 3 ) with low and

very low alarm

Emergency stop in case of

calculated very low alarm

3 analogical pressure sensors at

the fabric filter outlet. Calculated

pressure ( 2 on 3 ) with low and

very low alarm

Emergency stop in case of

calculated very low alarm

: