Beruflich Dokumente

Kultur Dokumente

Sheet CM RD 113 GGG

Hochgeladen von

Ahmet HamamcıoğluOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Sheet CM RD 113 GGG

Hochgeladen von

Ahmet HamamcıoğluCopyright:

Verfügbare Formate

DOCUMENTATION SHEET General

The nodular cast iron RD 113 conical mounting has a static load range from 50 kN to 215 kN.

Conical Mountings The conical design provides high deflection and load capacity combined with long service life.

Type RD 113 Although originally designed for main engine, auxiliary engine and generator installations, the

mountings are particularly versatile and can be equally used for exhaust gas boilers and si-

lencers. For applications like the suspension of deckhouses, accommodation rooms and con-

RD 113

trol cabins, this mounting is an excellent isolator against structure borne vibration and noise,

( p assive isolation ) . The acoustic properties of this type of mounting are excellent. The re-

sults of the measured structure borne vibration and noise transmission are available. In both

vertical and horizontal directions the transfer functions show a decrease of 12 dB/octave in the

low frequency range, an ideal mass-less spring characteristic .

Remark

It is our intention to maintain the excellent standard of our products. Modifications and im-

provements may be made from time to time, therefore we advise to contact us before order-

ing.

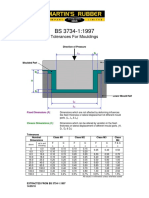

DIMENSIONS

1 CM / RD 113 / AUG 2012

RD 113

Specification

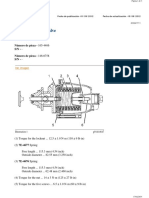

The characteristics of the mounting are provided by a conical rubber element designed to

carry the vertical load in a combination of compression and shear. The rubber elements are

manufactured in three standard rubber mixes: 55NR, 60NR, 65NR, and consequently

cover a wide range of load / deflection requirements. Applicable up to 70C continuous and

90C peak temperatures. Next to that, for the high temperatures applications, there are special

developed compounds for 90C continuous and 110C peak temperature - and 110C continu-

ous and 130C peak temperature available in the above mentioned Shore hardness.

The mounting castings are manufactured in nodular cast iron. They are designed to protect

the rubber element against oil and physical damage. An adjustable central buffer ( s pindle ) ,

manufactured in high tensile steel, controls the mounted equipment displacements due to e.g.

ship movements, both vertically and horizontally within defined limits and so eliminates the

need for separate buffers. The cut out in the bottom casting allows the buffer adjustment to be

checked. All mounting inserts are both individual tested and selected on stiffness by Rubber

Design.

Direction Vertical up Vertical down Radial

Displacement limiter clearance [mm] 6 6 4

CLEARANCE

Rubber Hardness [Sh. A] 55 60 65

Max Marine load [kN] 120 152 175

Max Static load [kN] 142 185 215

Max Static vert. defl. [mm] 15 14 13

CHARACTERISTICS

Max Shockload 360 kN ( all directions )

SHOCKLOAD

Mounting selection

The characteristics table is ideal for initial selection; however, it is advisable to seek expert

advice before finalising an installation design. In practice most installations will be subjected to

both translational and rotational excitations and in consequence an analysis of all six degrees

of freedom will be necessary. We will be pleased to advise on mountings numbers, rubber mix

and mounting positions to ensure a faultless flexible mounted installation. Before we can

commence the design of a mounting system detailed information is required. Vibration calcula-

tions are carried out using our specially developed computer programs to meet new standards

for both crews and passengers.

Rubber Design B.V.

Industrieweg 21

2995BE Heerjansdam

The Netherlands

Phone: +31 ( 0 ) 7 8 677 87 78

Fax: +31 ( 0 ) 78 677 10 38

Email: info@rubberdesign.nl

TYPE APPROVALS

Web: www.rubberdesign.nl

2 CM / RD 113 / AUG 2012

Das könnte Ihnen auch gefallen

- Stainless Steel SpecificationDokument2 SeitenStainless Steel SpecificationmariusdejNoch keine Bewertungen

- CTV WT5556 Rotafrix Catalog enDokument44 SeitenCTV WT5556 Rotafrix Catalog enAhmet HamamcıoğluNoch keine Bewertungen

- Do Kum Turk Standart LariDokument3 SeitenDo Kum Turk Standart LariAhmet HamamcıoğluNoch keine Bewertungen

- Burak Bor Ukata LogDokument26 SeitenBurak Bor Ukata LogmilovanmNoch keine Bewertungen

- CTV WT8344 Good-Vibrations enDokument9 SeitenCTV WT8344 Good-Vibrations enAhmet HamamcıoğluNoch keine Bewertungen

- Im Co Burs Catalog 2019Dokument28 SeitenIm Co Burs Catalog 2019Maquinado RecolsaNoch keine Bewertungen

- En 10025Dokument16 SeitenEn 10025Sorin Radu100% (1)

- International Material Grade Comparison TableDokument9 SeitenInternational Material Grade Comparison Tablenyamuk06100% (4)

- Freudenberg-Cat Rail enDokument64 SeitenFreudenberg-Cat Rail enAhmet HamamcıoğluNoch keine Bewertungen

- Iso 7040Dokument1 SeiteIso 7040serzo75Noch keine Bewertungen

- Kalıp Parlatma ÜrünleriDokument18 SeitenKalıp Parlatma ÜrünleriAhmet HamamcıoğluNoch keine Bewertungen

- Gupilya Split Pins Splint: DIN 94-ISO 1234 A2-A4Dokument108 SeitenGupilya Split Pins Splint: DIN 94-ISO 1234 A2-A4Arif AkbasNoch keine Bewertungen

- Astm d2000 İçeri̇kDokument27 SeitenAstm d2000 İçeri̇kAhmet HamamcıoğluNoch keine Bewertungen

- Astm-D2000 How To ReadDokument3 SeitenAstm-D2000 How To Readmakineci_67Noch keine Bewertungen

- Documentation Exhaust Shock Mountings 1 PDFDokument5 SeitenDocumentation Exhaust Shock Mountings 1 PDFAhmet HamamcıoğluNoch keine Bewertungen

- Documentation Exhaust Shock Mountings 1 PDFDokument5 SeitenDocumentation Exhaust Shock Mountings 1 PDFAhmet HamamcıoğluNoch keine Bewertungen

- Avl PDFDokument52 SeitenAvl PDFAhmet HamamcıoğluNoch keine Bewertungen

- CHEVROLETDokument21 SeitenCHEVROLETAhmet HamamcıoğluNoch keine Bewertungen

- Katalog 3Dokument16 SeitenKatalog 3Ahmet HamamcıoğluNoch keine Bewertungen

- Documentation Exhaust Shock Mountings 1Dokument2 SeitenDocumentation Exhaust Shock Mountings 1Ahmet HamamcıoğluNoch keine Bewertungen

- Technical Documentation Sheet SH2 PDFDokument2 SeitenTechnical Documentation Sheet SH2 PDFAhmet HamamcıoğluNoch keine Bewertungen

- Documentation Exhaust Shock Mountings 1 PDFDokument5 SeitenDocumentation Exhaust Shock Mountings 1 PDFAhmet HamamcıoğluNoch keine Bewertungen

- G Y in Propeller Shaft Installations: Rubber DesignDokument6 SeitenG Y in Propeller Shaft Installations: Rubber DesignAhmet HamamcıoğluNoch keine Bewertungen

- Sae J200 PDFDokument62 SeitenSae J200 PDFAhmet Hamamcıoğlu100% (3)

- Documentation Sheet Steel Spring Isolator GeneralDokument2 SeitenDocumentation Sheet Steel Spring Isolator GeneralAhmet HamamcıoğluNoch keine Bewertungen

- Technical Documentation Sheet LSDokument2 SeitenTechnical Documentation Sheet LSAhmet HamamcıoğluNoch keine Bewertungen

- Documentation Sheet Steel Spring Isolator GeneralDokument2 SeitenDocumentation Sheet Steel Spring Isolator GeneralAhmet HamamcıoğluNoch keine Bewertungen

- Technical Documentation Sheet LSDokument2 SeitenTechnical Documentation Sheet LSAhmet HamamcıoğluNoch keine Bewertungen

- Documentation Sheet Steel Spring Isolator GeneralDokument2 SeitenDocumentation Sheet Steel Spring Isolator GeneralAhmet HamamcıoğluNoch keine Bewertungen

- Tolerances For MouldingsDokument1 SeiteTolerances For MouldingsAhmet HamamcıoğluNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Rakesh ReportDokument81 SeitenRakesh ReportRakesh SharmaNoch keine Bewertungen

- 5 Tool HoldersDokument40 Seiten5 Tool Holdersraks_mechnadNoch keine Bewertungen

- 2701 MSDSDokument5 Seiten2701 MSDSAhmed Emad AhmedNoch keine Bewertungen

- Hollow Bars (ISO2938)Dokument8 SeitenHollow Bars (ISO2938)suku maranNoch keine Bewertungen

- SUFIXOS FAG - SKF GrandesDokument4 SeitenSUFIXOS FAG - SKF GrandesWaldir Bento De Portugal BeserraNoch keine Bewertungen

- Instruction: Check The Circle That Corresponds To Your AnswerDokument2 SeitenInstruction: Check The Circle That Corresponds To Your AnswerXyrile InguilloNoch keine Bewertungen

- Electrical Maintenance VRM Shutdown Activities PlanDokument1 SeiteElectrical Maintenance VRM Shutdown Activities Planabay firewNoch keine Bewertungen

- Weft MasterDokument20 SeitenWeft MasterZulfikar Ari PrkzNoch keine Bewertungen

- Synthesis and Application of Zinc Oxide Nanoparticles On Nylon Fabric by Layer by Layer Technique As Antimicrobial PropertyDokument8 SeitenSynthesis and Application of Zinc Oxide Nanoparticles On Nylon Fabric by Layer by Layer Technique As Antimicrobial PropertyÖzkan YaparNoch keine Bewertungen

- TL - 52337 (2015)Dokument8 SeitenTL - 52337 (2015)Chloe ReyesNoch keine Bewertungen

- Difference Between Static Relays and Electromagnetic RelaysDokument2 SeitenDifference Between Static Relays and Electromagnetic Relayskriitka86% (7)

- YALE (C878) GDP155VX LIFT TRUCK Service Repair Manual PDFDokument20 SeitenYALE (C878) GDP155VX LIFT TRUCK Service Repair Manual PDFfjskekdmmemNoch keine Bewertungen

- 2016 EXPT BluDokument1 Seite2016 EXPT BluToto MidgleyNoch keine Bewertungen

- Tata Steel en 15804 Verified EPD ProgrammeDokument16 SeitenTata Steel en 15804 Verified EPD Programmeashutosh mishraNoch keine Bewertungen

- Cromato AmarilloDokument3 SeitenCromato Amarillohumbertotorresr100% (1)

- P 07Dokument1 SeiteP 07Kamarul NizamNoch keine Bewertungen

- CWWS ULTRA-SEP Brochure (2008)Dokument12 SeitenCWWS ULTRA-SEP Brochure (2008)Steve OsuohaNoch keine Bewertungen

- RoboticsDokument30 SeitenRoboticsSarvesh Naik100% (1)

- Materials 16 01374 v2Dokument11 SeitenMaterials 16 01374 v2Feyisa GuyeNoch keine Bewertungen

- Fa 4 STS (Ged104) Subsec 2Dokument2 SeitenFa 4 STS (Ged104) Subsec 2Elmoe VillanuevaNoch keine Bewertungen

- Dhir 1988Dokument11 SeitenDhir 1988AhmadrazatahirNoch keine Bewertungen

- CMT Lab ReportDokument3 SeitenCMT Lab ReportJohn Emerald GoloNoch keine Bewertungen

- Power Systems, Inc.: Owner's ManualDokument64 SeitenPower Systems, Inc.: Owner's ManualAndrew67% (3)

- Aisi 3215Dokument1 SeiteAisi 3215luis_dominguezeNoch keine Bewertungen

- Optimal Bracing System For Steel TowersDokument4 SeitenOptimal Bracing System For Steel TowersSaravanan Silamban100% (1)

- Dedicated Outdoor Air SystemsDokument5 SeitenDedicated Outdoor Air SystemseduardofemecNoch keine Bewertungen

- RS 017 August 2014 (Welder Test Run Sheet Yudistira)Dokument1 SeiteRS 017 August 2014 (Welder Test Run Sheet Yudistira)Muhammad Fitransyah Syamsuar PutraNoch keine Bewertungen

- Exhaust Bypass ValveDokument3 SeitenExhaust Bypass ValveHugo CiprianiNoch keine Bewertungen

- Songsorb CS 326 TDSDokument2 SeitenSongsorb CS 326 TDSdipen royNoch keine Bewertungen

- Notes On Sprockets and ChainsDokument6 SeitenNotes On Sprockets and Chainsjjoohhnn90Noch keine Bewertungen