Beruflich Dokumente

Kultur Dokumente

Tutorial - 4 and Solution Feb 2 2017 Final

Hochgeladen von

Rounak MajumdarOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Tutorial - 4 and Solution Feb 2 2017 Final

Hochgeladen von

Rounak MajumdarCopyright:

Verfügbare Formate

TUTORIAL 4

Design of Machine Elements

ME 351 (02/02/17)

NOTE: STEP MARKS ARE SHOWN AGAINST EACH STEP MM:35

Q1. A 25 mm diameter solid round bar has a groove 2.5 mm deep with a 2.5 mm radius machined into it. The bar is

made of AISI 1018 CD steel and is subjected to a purely reversing torque of 200 N-m. For the S-N curve of this material,

let f = 0.9.

(a). Estimate the number of cycles to failure.

(b). If the bar is also placed in an environment with a temperature of 450 F, estimate the number of cycles to failure.

Sol. 1. D = 25 mm, d = 20 mm, T = 200 N-m, f = 0.9, and from Table A-20: Sy = 370 MPa = 54 kpsi, Sut = 440 MPa =

64 kpsi (AISI 1018, CD).

r 2.5 D 25

(a). Fig. A-15-15: 0.125 , 1.25 , K ts 1.40 [1]

d 20 d 20

Get the notch sensitivity either from Fig. 6.21, or from the curve fit Eqs. (6.34) and (6.35b). We will use the equations.

a 0.190 2.5110 3 S ut 1.3510 5 S ut2 2.6710 8 S ut3 0.077 , q s

1 1

0.803 . [1]

a 1 0.077

1

r 0.3136

Eq. (6-32): K fs 1 q s K ts 1 1.32 . For a purely reversing torque of T = 200 N-m,

Tr 16T 16200

a K fs K fs 3 1.32 168.21 MPa. [2]

J d 20 10 3

3

Eq. (6-8): S e 0.5440 220 MPa. [1]

Eq. (6-19): k a 4.51440

0.265

0.898 . [1]

Eq. (6-20): k b 1.2420

0.107

0.899 . [1]

Eq. (6-26): k c 0.59 . [1]

Eq. (6-18): (labeling for shear) S se 0.898(0.899)(0.59)(220) 104.89 MPa. [1]

For purely reversing torsion, use Eq. (6-54) for the ultimate strength in shear.

Eq. (6-54): S su 0.67Sut 294.8 MPa. [1]

Adjusting the fatigue strength equations for shear,

fS su 2 1 fS

Eq. (6-14): a 671.128MPa. Eq. (6-15): b log su 0.134 [2]

S se 3 S se

1

b

Eq. (6-16): N a 30.54(103 ) cycles. [1]

a

Ans .

(b). For an operating temperature of 450 F, the temperature modification factor,

k d 0.975 0.432 103 TF 0.115 105 TF2 0.104 108 TF3 0.595 1012 TF4 1.006 . [1]

S se 0.898(0.899)(0.59)1.006(220) 105.52 MPa. [1]

fS su 2

a 667.12 MPa. [1]

S se

1 fS

b log su 0.133 . [2]

3 S se

1

b

N a 31.54(103 ) cycles. [2]

a

Ans.

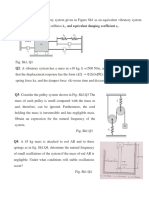

Q2. The rotating shaft shown below (all the dimensions are in mm) is machined from AISI 1020 CD steel. It is subjected

to a force of F = 10 kN. Find the minimum factor of safety for fatigue based on infinite life. If the life is not infinite,

estimate the number of cycles. Be sure to check of yielding.

1000

350

50 D 70 D 6R 100 D 50 D

40 40

40 360 560 40

Sol. 2. Left bearing reaction force: 3.5 kN, right bearing reaction: 6.5 kN. [1]

The critical location will be at the shoulder fillet between the 70 mm and the 100 mm diameters, where the bending

moment is large, the diameter is smaller, and the stress concentration exists. The bending moment at this point is

M 3.5400 1400kN-mm. With a rotating shaft, the bending stress will be completely reversed.

rev

Mc 1400 2

70

0.0415 kN/mm2 = 41.5MPa.

I

704

64

This stress is far below the yield strength of 390MPa, so yielding is not predicted. Find the stress concentration factor

for the fatigue analysis. [2]

r 6 D 100

Fig. A-15-9: 0.086 , 1.43 , K t 1.7 . [1]

d 70 d 70

Get the notch sensitivity either from Fig. 6.21, or from the curve fit Eqs. (6.34) and (6.35a). We will use the equations

with Sut = 470 MPa = 68.2 kpsi and r = 6 mm = 0.236 in.

a 0.246 3.0810 3 S ut 1.5110 5 S ut2 2.6710 8 S ut3 0.0977 , q

1 1

0.832 . [1]

a 1 0.0977

1

r 0.236

Eq. (6-32): K f 1 qK t 1 1.582 . [1]

Eq. (6-8): S e 0.5S ut 0.5(470) 235 MPa. [1]

0.265

Eq. (6-19): k a aS 4.51(470)

b

ut 0.88 . (a and b from Table 6.2) [1]

0.157 0.107

Eq. (6-20): k b 1.51d 1.24(70) 0.774 . [1]

Eq. (6-26): k c 1. [1]

Eq. (6-18): S e k a k b k c S e 0.880.7741235 160.26 MPa. [1]

Se 160.26

nf 2.441. Infinite life is predicted. [4]

K f rev 1.58241.5

Ans.

Das könnte Ihnen auch gefallen

- Tutorial QuestionsDokument6 SeitenTutorial QuestionsLadnilrebNoch keine Bewertungen

- Cyclic Plasticity of Engineering Materials: Experiments and ModelsVon EverandCyclic Plasticity of Engineering Materials: Experiments and ModelsNoch keine Bewertungen

- MCQ in Machine Design Part 6 ME Board ExamDokument20 SeitenMCQ in Machine Design Part 6 ME Board ExamJade Carlo AntonioNoch keine Bewertungen

- Dke672 ch4Dokument43 SeitenDke672 ch4Khaled SolimanNoch keine Bewertungen

- Modeling in The Frequency DomainDokument71 SeitenModeling in The Frequency DomainAbril de VeraNoch keine Bewertungen

- Hw5 SolutionDokument1 SeiteHw5 SolutionUmair AbbasNoch keine Bewertungen

- Pages 64-71 From 0849302579 Fundamentals of Kinematics and Dynamics VinogradovDokument8 SeitenPages 64-71 From 0849302579 Fundamentals of Kinematics and Dynamics VinogradovAmadeo ErebaraNoch keine Bewertungen

- Machine Design Assignment-1Dokument2 SeitenMachine Design Assignment-1RAJAT RAJNoch keine Bewertungen

- Bearing ProblemsDokument16 SeitenBearing ProblemsRohit GhulanavarNoch keine Bewertungen

- MCQ in Machine Design Part 5 ME Board ExamDokument19 SeitenMCQ in Machine Design Part 5 ME Board ExamJade Carlo AntonioNoch keine Bewertungen

- Mech 325 Tutorials (Questions Only)Dokument54 SeitenMech 325 Tutorials (Questions Only)Shahriar Norouzi ZadehNoch keine Bewertungen

- Design of Machinery: Chapter 7 - Acceleration AnalysisDokument44 SeitenDesign of Machinery: Chapter 7 - Acceleration AnalysisKen Vu100% (1)

- Mechanical Advantage of Inclined PlaneDokument4 SeitenMechanical Advantage of Inclined PlaneShuja MarwatNoch keine Bewertungen

- UNIT-1: What Is The Difference Between Refrigeration & Air Conditioning?Dokument8 SeitenUNIT-1: What Is The Difference Between Refrigeration & Air Conditioning?Udit NarayanNoch keine Bewertungen

- Design of ShaftsDokument2 SeitenDesign of ShaftsÖzgür AtaseverNoch keine Bewertungen

- Ball BRG Chapeter-JBK DasDokument26 SeitenBall BRG Chapeter-JBK DasNaresh Kini50% (2)

- Lect 5 Reduction of Multiple Subsystems1Dokument53 SeitenLect 5 Reduction of Multiple Subsystems1SśēmǾǿ ŔämáďañNoch keine Bewertungen

- Modeling in Time DomainDokument30 SeitenModeling in Time Domainfarouq_razzaz2574Noch keine Bewertungen

- Lec 02 Shaft DesignDokument0 SeitenLec 02 Shaft DesignamdevaNoch keine Bewertungen

- Chapter 3-BreakDokument37 SeitenChapter 3-Breakkibromgidey12Noch keine Bewertungen

- Solutions Mechanical Engineering Design Shigley 7th EditionDokument21 SeitenSolutions Mechanical Engineering Design Shigley 7th Editiondorifutospez100% (1)

- A Textbook of Machine Design by R.S.KHURMI AND J.K.GUPTA - 216Dokument1 SeiteA Textbook of Machine Design by R.S.KHURMI AND J.K.GUPTA - 216Vivek MishraNoch keine Bewertungen

- Design of Fluid Thermal Systems: William S. Janna 9781285859651 Fourth Edition Errata For First PrintingDokument1 SeiteDesign of Fluid Thermal Systems: William S. Janna 9781285859651 Fourth Edition Errata For First PrintingAhsan Habib Tanim0% (1)

- RAC Assignments 24062016 091508AMDokument37 SeitenRAC Assignments 24062016 091508AMsakalidhasavasanNoch keine Bewertungen

- DTS Unit 5Dokument20 SeitenDTS Unit 5Muthuvel MNoch keine Bewertungen

- CH 14Dokument11 SeitenCH 14hirenpatel_universalNoch keine Bewertungen

- AUTO400 Homework Assignment 1 SOLUTIONDokument16 SeitenAUTO400 Homework Assignment 1 SOLUTIONVinoliaEdwin100% (1)

- Tom-I Question Bank UpdatedDokument174 SeitenTom-I Question Bank Updatedkiran_wakchaureNoch keine Bewertungen

- Lecture No.3 The Ideal Reheat Rankine CycleDokument12 SeitenLecture No.3 The Ideal Reheat Rankine Cycledanielalejandro133Noch keine Bewertungen

- Design of Shaft PDFDokument5 SeitenDesign of Shaft PDFAnonymous oTrMzaNoch keine Bewertungen

- Bell Crank Lever Dt. 14-07-2021Dokument4 SeitenBell Crank Lever Dt. 14-07-2021AK kunduNoch keine Bewertungen

- Multipressure SystemDokument21 SeitenMultipressure SystemRocky RuleNoch keine Bewertungen

- Chapter 8: Designing For Heating and CoolingDokument11 SeitenChapter 8: Designing For Heating and CoolingmegaspiceNoch keine Bewertungen

- Problem Set 9-Chapter 14 - Rolling Element BearingDokument25 SeitenProblem Set 9-Chapter 14 - Rolling Element BearingPaulNoch keine Bewertungen

- Mod-3. Spur GearDokument18 SeitenMod-3. Spur GearSharthak GhoshNoch keine Bewertungen

- Lecture in Machine ElementsDokument30 SeitenLecture in Machine ElementsMark Angelo PagadorNoch keine Bewertungen

- Solution Manual Shigleys Mechanical Engineering Design 10th Edition by Budynas PDFDokument23 SeitenSolution Manual Shigleys Mechanical Engineering Design 10th Edition by Budynas PDFAbhinash KumarNoch keine Bewertungen

- Belt Drive Types Material Applications Advantages Disadvantages PPT 1Dokument19 SeitenBelt Drive Types Material Applications Advantages Disadvantages PPT 1Sandesh yadavNoch keine Bewertungen

- Viva Voce Questions: CNC MachinesDokument4 SeitenViva Voce Questions: CNC MachinesguruNoch keine Bewertungen

- Ifp MCQS - 2Dokument2 SeitenIfp MCQS - 2yuvarajballalNoch keine Bewertungen

- Question Bank For Unit II of MechaDokument3 SeitenQuestion Bank For Unit II of MechaSainand Jadhav100% (1)

- NalsDokument148 SeitenNalsKartik BhararaNoch keine Bewertungen

- Problem 4.1: Solutions To Chapter 4 Exercise ProblemsDokument23 SeitenProblem 4.1: Solutions To Chapter 4 Exercise ProblemsValeria S HernándezNoch keine Bewertungen

- CH 19Dokument21 SeitenCH 19Sanjay Kumar100% (1)

- ME 6505 - Dynamics of Machines: Fifth Semester Mechanical Engineering (RegulationsDokument18 SeitenME 6505 - Dynamics of Machines: Fifth Semester Mechanical Engineering (RegulationsshivendrakumarNoch keine Bewertungen

- Vib Prob - Print NalangsDokument16 SeitenVib Prob - Print NalangsNicole YacubNoch keine Bewertungen

- Chapter 9 Spur Gear DesignDokument31 SeitenChapter 9 Spur Gear DesignRamesh Martha100% (1)

- Threlkeld 5 AnswersDokument11 SeitenThrelkeld 5 AnswersJaycob Clavel100% (2)

- HMT Tut1Dokument2 SeitenHMT Tut1Meet ShahNoch keine Bewertungen

- MCQ On Air Standarad CyclesDokument6 SeitenMCQ On Air Standarad Cyclessatish448100% (1)

- Lecture 1Dokument41 SeitenLecture 1norhaslina_aa33% (3)

- Airy PointsDokument13 SeitenAiry PointsDirajen PMNoch keine Bewertungen

- Tutorial 6 AM1100Dokument2 SeitenTutorial 6 AM1100Sanchit GuptaNoch keine Bewertungen

- Test No. 13Dokument51 SeitenTest No. 13Krishna BelelaNoch keine Bewertungen

- Tutorial - 6 and Solution Feb 16 2017 FinalDokument2 SeitenTutorial - 6 and Solution Feb 16 2017 FinalRounak Majumdar100% (1)

- Tutorial - 5 and Solution Feb 9 2017 FinalDokument2 SeitenTutorial - 5 and Solution Feb 9 2017 FinalRounak Majumdar100% (1)

- Tutorial - 2 and Solution Jan 19 2017 FinalDokument2 SeitenTutorial - 2 and Solution Jan 19 2017 FinalRounak Majumdar100% (1)

- 2022.05.15 Đáp Án Final Exam Machine Elements PDFDokument7 Seiten2022.05.15 Đáp Án Final Exam Machine Elements PDFHoàng QuânNoch keine Bewertungen

- HK212Dokument7 SeitenHK212Minh HuyNoch keine Bewertungen

- Analysis of Badminton-Playing Robot: Team Members (B2)Dokument1 SeiteAnalysis of Badminton-Playing Robot: Team Members (B2)Rounak MajumdarNoch keine Bewertungen

- Solution Tutorial - 1Dokument2 SeitenSolution Tutorial - 1Akash FuryNoch keine Bewertungen

- Tutorial - 2 and Solution Jan 19 2017 FinalDokument2 SeitenTutorial - 2 and Solution Jan 19 2017 FinalRounak Majumdar100% (1)

- Raoji Bazaar: A Lot Can Happen Over Coffee... Well Certainly That Is, If She Ever ShowsDokument5 SeitenRaoji Bazaar: A Lot Can Happen Over Coffee... Well Certainly That Is, If She Ever ShowsRounak MajumdarNoch keine Bewertungen

- Structural Analysis of 10 KW Horizontal - Axis Wind Turbine (HAWT)Dokument2 SeitenStructural Analysis of 10 KW Horizontal - Axis Wind Turbine (HAWT)Rounak MajumdarNoch keine Bewertungen

- Tutorial - 5 and Solution Feb 9 2017 FinalDokument2 SeitenTutorial - 5 and Solution Feb 9 2017 FinalRounak Majumdar100% (1)

- Solution Tutorial - 1Dokument2 SeitenSolution Tutorial - 1Akash FuryNoch keine Bewertungen

- Home Assignment-8 - (Assignment Problems) (Chapter-9)Dokument3 SeitenHome Assignment-8 - (Assignment Problems) (Chapter-9)Rounak MajumdarNoch keine Bewertungen

- Home Assignment-8 - (Practice Problems) (Chapter-9)Dokument3 SeitenHome Assignment-8 - (Practice Problems) (Chapter-9)Rounak MajumdarNoch keine Bewertungen

- Project Groups (ME351A) PDFDokument7 SeitenProject Groups (ME351A) PDFRounak MajumdarNoch keine Bewertungen

- Home Assignment - 1: Chapter-1Dokument4 SeitenHome Assignment - 1: Chapter-1Akash FuryNoch keine Bewertungen

- Tutorial - 6 and Solution Feb 16 2017 FinalDokument2 SeitenTutorial - 6 and Solution Feb 16 2017 FinalRounak Majumdar100% (1)

- Home Assignment-8 - (Assignment Problems) (Chapter-9)Dokument3 SeitenHome Assignment-8 - (Assignment Problems) (Chapter-9)Rounak MajumdarNoch keine Bewertungen

- Home Assignment-6 (Practice Problem) Chapter-7Dokument2 SeitenHome Assignment-6 (Practice Problem) Chapter-7Rounak MajumdarNoch keine Bewertungen

- Home Assignment-8 - (Practice Problems) (Chapter-9)Dokument3 SeitenHome Assignment-8 - (Practice Problems) (Chapter-9)Rounak MajumdarNoch keine Bewertungen

- Home Assignment-4 - (Assignment Problems) HMTDokument2 SeitenHome Assignment-4 - (Assignment Problems) HMTRounak MajumdarNoch keine Bewertungen

- Home Assignment-5 (Practice Problem) Chapter-6Dokument2 SeitenHome Assignment-5 (Practice Problem) Chapter-6Rounak MajumdarNoch keine Bewertungen

- Home Assignment-7 - (Assignment Problems)Dokument2 SeitenHome Assignment-7 - (Assignment Problems)Rounak MajumdarNoch keine Bewertungen

- Home Assignment-6 - (Assignment Problems) Chapter-7Dokument2 SeitenHome Assignment-6 - (Assignment Problems) Chapter-7Rounak MajumdarNoch keine Bewertungen

- Home Assignment - 2Dokument6 SeitenHome Assignment - 2Rounak MajumdarNoch keine Bewertungen

- (Intelligent Robotics and Autonomous Agents Series) Choset H., Et Al.-Principles of Robot Motion - Theory, Algorithms, and Implementations-MIT (2005)Dokument616 Seiten(Intelligent Robotics and Autonomous Agents Series) Choset H., Et Al.-Principles of Robot Motion - Theory, Algorithms, and Implementations-MIT (2005)Rounak Majumdar100% (1)

- Home Assignment-5 - (Assignment Problems) Chapter-6Dokument2 SeitenHome Assignment-5 - (Assignment Problems) Chapter-6Rounak MajumdarNoch keine Bewertungen

- Original Cu Keystone VSMDokument18 SeitenOriginal Cu Keystone VSMRounak MajumdarNoch keine Bewertungen

- Business Club: An: Presented By: Gaurav Dawrani Srishti Agarwal Rounak MajumdarDokument11 SeitenBusiness Club: An: Presented By: Gaurav Dawrani Srishti Agarwal Rounak MajumdarRounak MajumdarNoch keine Bewertungen

- Application Template - Tech Summers 2017Dokument5 SeitenApplication Template - Tech Summers 2017Rounak MajumdarNoch keine Bewertungen

- Group Discussion Points: 20 Explanation:: ST ND ST NDDokument2 SeitenGroup Discussion Points: 20 Explanation:: ST ND ST NDRounak MajumdarNoch keine Bewertungen

- 2-Deg of Indeterminacy and Deg of Freedom - PSD - FinalDokument10 Seiten2-Deg of Indeterminacy and Deg of Freedom - PSD - FinalSteven KuaNoch keine Bewertungen

- DME1Dokument3 SeitenDME1Ganesh RamNoch keine Bewertungen

- Final Exam Engineering MechanicsDokument9 SeitenFinal Exam Engineering MechanicsjohnjabarajNoch keine Bewertungen

- KIneTic THeory of GassEsDokument14 SeitenKIneTic THeory of GassEsVail LunorNoch keine Bewertungen

- Bouncy ChudinovDokument8 SeitenBouncy Chudinovthefallenghost6108Noch keine Bewertungen

- Partial DerivativesDokument3 SeitenPartial DerivativesS M AkashNoch keine Bewertungen

- Column Interaction Diagram Lecture21Dokument58 SeitenColumn Interaction Diagram Lecture21kzlondon50% (2)

- Fluid-Mechanics-Ace Text Book SolutionDokument45 SeitenFluid-Mechanics-Ace Text Book SolutionShazeb LaluNoch keine Bewertungen

- Mitosek1993 Article OscillatoryLiquidFlowInElasticDokument15 SeitenMitosek1993 Article OscillatoryLiquidFlowInElasticbaja2014Noch keine Bewertungen

- Work Energy Power Chap 6 Giancoli PhysicsDokument32 SeitenWork Energy Power Chap 6 Giancoli PhysicsPurwojatmiko HandokoNoch keine Bewertungen

- CIDECT Design Guide 01Dokument69 SeitenCIDECT Design Guide 01Karl PacalaNoch keine Bewertungen

- Kinematics Problems With SolutionDokument17 SeitenKinematics Problems With SolutionApril ClaireNoch keine Bewertungen

- Footing Design Joseph Sent To BentleyDokument15 SeitenFooting Design Joseph Sent To BentleyfarrukhNoch keine Bewertungen

- Assessment 1 Circular MotionDokument6 SeitenAssessment 1 Circular Motionhadia nasirNoch keine Bewertungen

- Science 6.5Dokument6 SeitenScience 6.5Nestlee ArnaizNoch keine Bewertungen

- Transport Phenomena III: Mass Transfer Chapter 28: Convective Mass TransferDokument23 SeitenTransport Phenomena III: Mass Transfer Chapter 28: Convective Mass Transferنزار الدهاميNoch keine Bewertungen

- Discussion - Yield Line Analysis of Bolted Hanging ConnectionsDokument1 SeiteDiscussion - Yield Line Analysis of Bolted Hanging ConnectionsRob TamaccioNoch keine Bewertungen

- Cylinder/ Spherical Vessel Thick Cylinder: - ThinDokument44 SeitenCylinder/ Spherical Vessel Thick Cylinder: - ThinVikas RathodNoch keine Bewertungen

- Agitator Design 11 PDF FreeDokument9 SeitenAgitator Design 11 PDF FreeMeisam MomeniNoch keine Bewertungen

- Rotational Equilibrium and Rotational DynamicsDokument12 SeitenRotational Equilibrium and Rotational DynamicsCG AmonNoch keine Bewertungen

- Aashto Guide Specifications For Seismic Isolation Design 3rd Ed July 2010 PDFDokument62 SeitenAashto Guide Specifications For Seismic Isolation Design 3rd Ed July 2010 PDFAlma Rasyid100% (1)

- Magnetic CircuitDokument64 SeitenMagnetic CircuitheroNoch keine Bewertungen

- Semester 2 Answer 2019 Chung Ling ButterworthDokument3 SeitenSemester 2 Answer 2019 Chung Ling ButterworthKhang Ni 康妮 FooNoch keine Bewertungen

- BOW Guru Antra Goal: Anand PrakashDokument10 SeitenBOW Guru Antra Goal: Anand PrakashThe Innocent TuberNoch keine Bewertungen

- Prediction of Residual Stress and Distortion From PDFDokument60 SeitenPrediction of Residual Stress and Distortion From PDF임학진Noch keine Bewertungen

- Magnetism Separate With AnswersDokument67 SeitenMagnetism Separate With AnswersThanh DinhNoch keine Bewertungen

- Flow Around A Sphere - Fluent AnalysisDokument4 SeitenFlow Around A Sphere - Fluent AnalysisRamon SilvérioNoch keine Bewertungen

- Reciprocity Mechanical, Acoustical, Interconnected Systems : ElectromagneticDokument23 SeitenReciprocity Mechanical, Acoustical, Interconnected Systems : ElectromagneticJumpster TwangNoch keine Bewertungen

- Sheet1 اهتزازاتDokument2 SeitenSheet1 اهتزازاتاحمد الربيعيNoch keine Bewertungen

- Experiment No.6 Stefan Boltzmann'S Apparatus: Heat Transfer Laboratory (MECH3123)Dokument6 SeitenExperiment No.6 Stefan Boltzmann'S Apparatus: Heat Transfer Laboratory (MECH3123)Raj PratyushNoch keine Bewertungen

- AP Physics 1 Premium, 2024: 4 Practice Tests + Comprehensive Review + Online PracticeVon EverandAP Physics 1 Premium, 2024: 4 Practice Tests + Comprehensive Review + Online PracticeNoch keine Bewertungen

- The LearnCurious Companion to the Digital SAT: VerbalVon EverandThe LearnCurious Companion to the Digital SAT: VerbalNoch keine Bewertungen

- AP English Language and Composition Premium, 2024: 8 Practice Tests + Comprehensive Review + Online PracticeVon EverandAP English Language and Composition Premium, 2024: 8 Practice Tests + Comprehensive Review + Online PracticeNoch keine Bewertungen

- AP World History: Modern Premium, 2024: Comprehensive Review with 5 Practice Tests + an Online Timed Test OptionVon EverandAP World History: Modern Premium, 2024: Comprehensive Review with 5 Practice Tests + an Online Timed Test OptionBewertung: 5 von 5 Sternen5/5 (1)

- AP Computer Science A Premium, 2024: 6 Practice Tests + Comprehensive Review + Online PracticeVon EverandAP Computer Science A Premium, 2024: 6 Practice Tests + Comprehensive Review + Online PracticeNoch keine Bewertungen

- AP Microeconomics/Macroeconomics Premium, 2024: 4 Practice Tests + Comprehensive Review + Online PracticeVon EverandAP Microeconomics/Macroeconomics Premium, 2024: 4 Practice Tests + Comprehensive Review + Online PracticeNoch keine Bewertungen

- AP Calculus Premium, 2024: 12 Practice Tests + Comprehensive Review + Online PracticeVon EverandAP Calculus Premium, 2024: 12 Practice Tests + Comprehensive Review + Online PracticeNoch keine Bewertungen

- To Engineer Is Human: The Role of Failure in Successful DesignVon EverandTo Engineer Is Human: The Role of Failure in Successful DesignBewertung: 4 von 5 Sternen4/5 (138)

- GMAT Prep 2024/2025 For Dummies with Online Practice (GMAT Focus Edition)Von EverandGMAT Prep 2024/2025 For Dummies with Online Practice (GMAT Focus Edition)Noch keine Bewertungen

- Fire Protection Engineering in Building DesignVon EverandFire Protection Engineering in Building DesignBewertung: 4.5 von 5 Sternen4.5/5 (5)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresVon EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresBewertung: 1 von 5 Sternen1/5 (2)

- How to Be a High School Superstar: A Revolutionary Plan to Get into College by Standing Out (Without Burning Out)Von EverandHow to Be a High School Superstar: A Revolutionary Plan to Get into College by Standing Out (Without Burning Out)Bewertung: 4.5 von 5 Sternen4.5/5 (11)

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemVon EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNoch keine Bewertungen

- AP U.S. History Premium, 2024: Comprehensive Review With 5 Practice Tests + an Online Timed Test OptionVon EverandAP U.S. History Premium, 2024: Comprehensive Review With 5 Practice Tests + an Online Timed Test OptionNoch keine Bewertungen

- AP Biology Premium, 2024: Comprehensive Review With 5 Practice Tests + an Online Timed Test OptionVon EverandAP Biology Premium, 2024: Comprehensive Review With 5 Practice Tests + an Online Timed Test OptionNoch keine Bewertungen

- AP Chemistry Flashcards, Fourth Edition: Up-to-Date Review and PracticeVon EverandAP Chemistry Flashcards, Fourth Edition: Up-to-Date Review and PracticeNoch keine Bewertungen

- Oxford LSAT Logical Reasoing Workbook: Complete Guide and Workbook to Ace the Logic Reasoning Section | 1,200+ Practice Drills | LSAT Logical Reasoning Prep 2024 | LSAT Logical Reasoning WorkbookVon EverandOxford LSAT Logical Reasoing Workbook: Complete Guide and Workbook to Ace the Logic Reasoning Section | 1,200+ Practice Drills | LSAT Logical Reasoning Prep 2024 | LSAT Logical Reasoning WorkbookNoch keine Bewertungen

- AP Physics 2 Premium, 2024: 4 Practice Tests + Comprehensive Review + Online PracticeVon EverandAP Physics 2 Premium, 2024: 4 Practice Tests + Comprehensive Review + Online PracticeNoch keine Bewertungen

- AP Computer Science Principles Premium, 2024: 6 Practice Tests + Comprehensive Review + Online PracticeVon EverandAP Computer Science Principles Premium, 2024: 6 Practice Tests + Comprehensive Review + Online PracticeNoch keine Bewertungen

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisVon EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisBewertung: 5 von 5 Sternen5/5 (1)

- Digital SAT Preview: What to Expect + Tips and StrategiesVon EverandDigital SAT Preview: What to Expect + Tips and StrategiesBewertung: 5 von 5 Sternen5/5 (3)

- AP Human Geography Premium, 2024: 6 Practice Tests + Comprehensive Review + Online PracticeVon EverandAP Human Geography Premium, 2024: 6 Practice Tests + Comprehensive Review + Online PracticeNoch keine Bewertungen

- GMAT Foundations of Math: Start Your GMAT Prep with Online Starter Kit and 900+ Practice ProblemsVon EverandGMAT Foundations of Math: Start Your GMAT Prep with Online Starter Kit and 900+ Practice ProblemsBewertung: 4 von 5 Sternen4/5 (7)

- Digital SAT Prep 2024 For Dummies: Book + 4 Practice Tests Online, Updated for the NEW Digital FormatVon EverandDigital SAT Prep 2024 For Dummies: Book + 4 Practice Tests Online, Updated for the NEW Digital FormatNoch keine Bewertungen

- Electrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70EVon EverandElectrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70EBewertung: 3 von 5 Sternen3/5 (6)

- AP Environmental Science Premium, 2024: 5 Practice Tests + Comprehensive Review + Online PracticeVon EverandAP Environmental Science Premium, 2024: 5 Practice Tests + Comprehensive Review + Online PracticeNoch keine Bewertungen