Beruflich Dokumente

Kultur Dokumente

WoodyFarrow Vacuum PDF

Hochgeladen von

Carla Míriam FerreiraOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

WoodyFarrow Vacuum PDF

Hochgeladen von

Carla Míriam FerreiraCopyright:

Verfügbare Formate

SGR FOCUS FEATURE

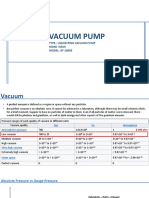

described: rough, medium, high, and ultra-high

vacuum (See Figure 2.). The boundary of each

region cannot be rigidly defined, but these

terms are useful when discussing the actions of

molecules inside the vacuum system.

Ultra-high Vacuum: Below 1x10-8 millibar

(1x10-9 milliTORR)

High Vacuum: 1x10-5 millibar (1x10- 6

TORR) to 1x10-8 millibar (1x10-9 TORR)

Medium Vacuum: 0.1 millibar (75 milliTORR)

to 1x10-5 millibar (1x10-6 TORR)

Rough Vacuum: Atmospheric pressure to 0.1

millibar (75 milliTORR)

Terms and Definitions (See also Table 1)

1.2 Volume: The most common units are liters

and cubic feet, to convert from cubic feet to liters

multiply by 28.3.

Basic vacuum principles 1.3 Temperature: I dont think I need

to do much explanation, but its important

to remember that a rise in temperature

and measurement

in the chamber or piping can result in a

pressure rise.

1.4 Outgassing: Is the gas load created

by the evolution of gases from O-Rings,

chamber surfaces, or piping surfaces. The

Vacuum: a space that is relatively empty of matter, especially evolution of gases creates a gas load that

must be removed by the pump from the

when that void has been created through artificial means. vacuum systems, in order to reach the

T

desired vacuum level.

he earths atmosphere exerts a pressure This article revisits the basics of vacuum 1.5 Conductance: Is the amount of gas that

upon us (known as the atmospheric technology; i.e., what is a vacuum and how is it can travel through a particular device per unit

pressure), which can be measured in measured? Once the basics are understood, the of time. The conductance through any device

a number of ways. At sea level the standard more sophisticated aspects of the technology varies with pressure. I have always tried to

pressure is described in different units as: can be better understood. explain conductance by using the analogy of

101,300 Pascals water being conducted through a hose. Both

1,103 millibar How is a Vacuum Created? water through a hose and gases through

760 TORR The creation of a vacuum typically requires a vacuum piping system are fluids through

760 mm of HG a chamber, piping, and a pump (or pumps). restrictive devices.

29.92 of Hg The simplified sketches nearby can help you In vacuum piping design, its best to use

14.7 psia understand how the pump reduces the number the straightest, shortest, and largest diameter

The foregoing is the dictionary definition of of molecules inside a vacuum chamber. possible piping, so gas molecules can easily

vacuum. Not bad. Its simple and to the point... As the number of molecules in the chamber move to the inlet of the vacuum pump and be

and pretty appropriate even for high tech (Figure 1.) is decreased, it becomes more removed from the system. As the pressure

applications. How to get there (achieve a space difficult for the molecules to reach the vacuum decreases in the vacuum chamber or piping,

that is relatively empty of matter), is not so pump and therefore to be removed from the gas flow is restricted to a much larger degree

simple. As a matter of fact, getting there is one chamber. (not quite exponentially) by small diameter

of the most critical operations in the production Generally, four regions of vacuum are piping, bends, elbows, and the length of the

of specialty and medical gases. What kind of piping Consider which will get you wetter.(See

equipment is used and when? What is the best Q&A Table p40.)

practice as far as technique and process are Low-pressure Region

concerned? Measurement Gauge Considerations and

Without knowing the answers to these Selection

questions, its impossible to create pure Pump When measuring a vacuum you need to

or mixed gases with any guarantee that the gas determine what type of gauge and in what range

purity of the gas you put into the cylinder will to use: thermocouple Piriani, Penning, or

remain that way for any length of time. Without High-pressure Region capacitance manometer and their construction,

that guarantee its impossible to be in the operation, and characteristics.

specialty or medical gas business. Figure 1. The pump reduces the number of There is no universal vacuum gauge one

The term vacuum is used to describe the molecules inside the vacuum chamber. that will respond accurately throughout the range

zone of pressure below atmospheric pressure. from atmospheric pressure to 1x10-11 Pascals

38 Specialty Gas Report Second Quarter 2009 www.specialtygasreport.com

SGR FOCUS FEATURE Second Quarter 2009

(1x10-13 TORR). Materials of construction, Table 1. Terms and Definitions

method of measurement (both direct and

indirect), and electronics all contribute to the

limitation of each type of gauge. 1.1 Pressure the measurement of the number of molecules hitting a given surface

All electronic gauges are subject to shifts in 1.1.1 Millibar the international standard (Pascals are also permitted)

reading due to the drift inherent in electronic 1.1.2 MilliTORR the more commonly used unit of measure in the USA

controllers. Both electronic gain (span) and the 1.1.3 Conversion Chart

zero set point are adjustable, so care must be 101,300 Pascals = 1,103 millibar = 760 TORR = 760 mmHg

taken whenever gauge heads or electronic 100,000 Pascals = 1,100 millibar = 750 TORR = 750 mmHg

controllers are replaced, to verify both the span 1,000 Pascals = 10 millibar = 7.5 TORR

and zero of the new combination. 100 Pascals = 1 millibar = 750 milliTORR

Direct gauges measure the pressure 10 Pascals = 0.1 millibar = 75 milliTORR

independently of the composition of the gas 1 Pascals = 1 x 10-2 millibar = 7.5 milliTORR

being measured. Indirect gauges are dependent 0.1 Pascals = 1 x 10-3 millibar = 0.75 milliTORR

on the composition of the gas being measure,

such as the thermal conductivity, electrical

conductivity, or ionization capability.

Manufacturers offer combination gauges to

mask the limitations of some of the technologies. Typical Vacuum Pump Operating Ranges

For instance, a combination Pirani-Penning

gauge can operate from atmosphere to 1x10-11 Pressure (Torr)

Pascals (1x10-13 TORR). (See Figure 3.) 10 -13

10 -11

10 -9

10-7 10-5 10-3 10-1 101 103

Pirani and Thermocouple Gauges

Dual Stage Rotary Vane Pump

Thermocouple and Pirani gauges are classified

as indirect gauges that typically operate from Dry Mechanical Pumps, All Types

atmosphere to 1x10-2 Pascals (1x10-3 TORR). Roots Booster Pumps

Thermocouples and Pirani gauges differ a small

Molecular Drag Pumps

amount depending on the manufacturer, but

fundamentally they function in the same manner. Turbomolecular Pumps

Piriani gauges have a slightly wider range

Turbomolecular Pumps

and provide better resolution than thermocouple

Ion Pumps

gauges. The basic theory of operation is the

measurement of heat lost from a wire, at

pressures below 1x10-2 Pascals (1x10-4 TORR) 10-11 10-9 10-7 10-5 10-3 10-1 101 103 105

there is so little gas present that the gauge Pressure (Pa)

cannot provide an accurate reading.

One of the thin wire filaments of a standard Figure 2. Comparison Pump Range Chart

Wheatstone bridge circuit is placed inside the

vacuum system and the other side in a reference

gas. The gauge electronics measure the

temperature loss of the wire inside the vacuum

system and compares it to that of the reference

Pressure (Torr)

wire, and then it displays the vacuum reading. 10 -13

10 -11

10 -9

10-7 10-5 10-3 10-1 101 103

When large amounts of gas are present near

the wire, a large amount of heat is removed

from the wire, and a large amount of current

is consequently required to maintain the

temperature of the wire. The current required to

maintain the temperature is directly proportional

to the heat being conducted away by the

gas present near the wire inside the vacuum

system. As the amount of gas near the wire

decreases, less heat is removed from the wire,

and the electronics measure and report the 10-11 10-9 10-7 10-5 10-3 10-1 101 103 105

lower amount of current required to maintain the Pressure (Pa)

temperature of the wire.

The composition of the gas significantly

affects the reading (accuracy) of these gauges. Figure 3. Chart indicates the different types of gauges used to measure vacuum and the

Typically the gauges are calibrated for air (78 ranges in which they operate.

percent nitrogen) and a factor must be applied

Second Quarter 2009 Specialty Gas Report 39

second Quarter 2009 SGR FOCUS FEATURE

Questions Answers

A 5-ft long, 1-in. dia. hose with 30 psig pressure or a The shorter hose conducts water flow better than the longer one.

50-ft-long, 1-in. diameter hose with 30 psig pressure?

A 50-ft long, 1-in. dia. hose with 30 psig pressure or a The larger diameter hose conducts water flow better than the smaller diameter

50-ft long 4-in. dia. hose with 30 psig pressure? hose.

A 50-ft long 4-in. dia. hose with 30 psig pressure or a This answer is more complex than the first two. The effect of increasing the

25-ft long 1-in. dia. hose with 30 psig pressure? diameter of the hose is raised by the power of 2 (squared), while the effect of length

is linear.

A 50-ft long, 4-in. dia. hose with 15 psig pressure or a Now were really getting complex, weve added a pressure differential to the mix. In

25-ft long, 1-in. dia. hose with 45 psig pressure? this case, even though the pressure of the smaller diameter hose is 3 times that of

the larger diameter hose, but the smaller diameter is still too much of a restriction.

The larger diameter hose conducts more water flow.

to the gauges reading for argon, helium, or semiconductor systems is limited because discharge. The combination of a strong magnetic

hydrogen. Argon absorbs heat much faster than hot wires and reactive gases are generally field and the high voltage applied to the

nitrogen, while nitrogen is much faster than not compatible. electrodes creates a directed plasma discharge

helium or hydrogen. As the pressure decreases of electrons. Ions are formed by the electron

the offset due to the gas composition decreases Penning and Ion Gauges Operation bombardment of the gases inside the confined

as well. Penning (cold cathode) and ion (hot cathode) cathode. The ions are accelerated by the

gauges are classified as indirect gauges that magnetic field towards the charged cathode. The

typically operate from one Pascal (1x10-2 TORR) impact of the ions with the cathode is measured

to 1x10-10 Pascals (1x10-12 TORR). Penning and reported by the gauges electronics.

(cold cathode) and Ion (hot cathode) gauges Penning and ion gauges are significantly

differ only a small amount, depending on the affected by the gas composition in the vacuum

manufacturer, but fundamentally they function system and cannot be used with reactive gases.

in the same manner. Some ion gauges are constructed from glass

Penning and ion gauges operate by ionizing and once the gauges glow discharge starts, the

gas within a magnetically confined cathode heat can cause the gauge to become very brittle

(and fragile). The glow discharge that is required

for the gauge to operate is also the reason

that these gauges cannot operate at pressures

above one Pascal (1x10-2 TORR).

Capacitance Manometer

This direct pressure gauge typically

operates from atmosphere to 1x10-2 Pascals

(1x10-4 TORR). The gauge contains a small

metal diaphragm (disk) with one side of the

diaphragm exposed to the vacuum chamber

and a known pressure on the backside.

The pressure in the vacuum chamber either

compresses or allows the expansion of the metal

diaphragm. The gauges electronics measures

the movement of the metal diaphragm as a

function of capacitance of the metal diaphragm

Figure 4. Wheatstone Bridge and with a fixed parallel electrode.

Pirani gauges When the metal disk and the housing are

constructed from stainless steel, this type of

gauge is very resistant to corrosive or reactive

Application of Pirani and Thermocouples gases. The range of the gauge can be changed

Thermocouples and Pirani gauges are to a degree by the changing trapped pressure.

inexpensive and are used primarily for A very small trapped volume and pressure

measuring the vacuum in non-corrosive Figure 5. Penning and Ion gauges. allows the gauge to measure small differences in

and non-reactive chambers. Their use in chamber pressure. The small gap between the

40 Specialty Gas Report Second Quarter 2009 www.specialtygasreport.com

SGR FOCUS FEATURE Second Quarter 2009

Built Right

for the Rigors of Shipping

Specd Right

for the Rigors of Code

Figure 6. Capacitance manometer.

metal diaphragm and the fixed electrode makes

this type of gauge especially susceptible to

vibration, temperature, and any electrical

field changes.

Most operators are unaware of the fact

that the zero and span of the electronics

must be reset every time the sensor head is

changed, bumped, or otherwise moved.

Summary

Vacuum technology provides controlled

environment for scientific experiments and

production lines. It is the bases for almost all

areas of science and technology, materials, Certified Weldship Tube ISO-Containers

semiconductor, and display production,

surface analysis, space study, and in most Certified by the American Bureau Manufactured for maximum

R&D equipment. As science and technology of Shipping (ABS), Weldship ISO- stacking, racking and other

developed, the importance of good vacuum Containers are manufactured for the shipboard procedures

technology has increased dramatically. In the optimal weight-to-payload efficiency, All common sizes, configurations

processes where each unwanted molecules can providing the lowest shipping cost and capacities as well as

ruin the whole process, the precise control of the for your compressed and liquefied Ultra-High Purity Containers

environment, processing gases, materials and gases, and specialty chemicals.

surface treatments producing little particles and Weldship will engineer Certified

gases from all the moving parts are crucial. All specs in accordance with US Tube ISO-Containers for virtually

A basic understanding of what a vacuum and international requirements any product or project.

is, how it is measured, and where each type

With over 50 years experience, Weldship is a world leader in the manufacture

of measurement is applied is essential to

of gas storage and transport equipment. Contact Weldship for quality

understanding how and when each can be

ISO-Containers as well as any capacity tube trailers, ground storage

applied most effectively and economically. SGR

modules, CO2 transports, and retest/rehab requirements.

Woodrow D Farrow

Woodrow D Farrow,

originally trained as an w w w. w e l d s h i p . c o m

analytical chemist, has more

than 30 years experience 225 West Second St. Bethlehem, PA 18015 P610 861 7330

in specialty gases and 75 East Main Street West boro, MA 01581 P508 898 0100

industrial processes. During

his long career, he has

managed analytical labs,

production facilities, and sales/marketing programs.

He is currently a consultant in the field.

For more information contact Woodrow D Farrow,

email: woodrowdfarrow@yahoo.com

Second Quarter 2009 Specialty Gas Report 41

Das könnte Ihnen auch gefallen

- PSD CEU 194dec12 PDFDokument22 SeitenPSD CEU 194dec12 PDFCesar Muñoz OssesNoch keine Bewertungen

- Effects of Altitude On Vacuum Systems PDFDokument8 SeitenEffects of Altitude On Vacuum Systems PDFAbhishek JainNoch keine Bewertungen

- Cadplans CatalogDokument40 SeitenCadplans CatalogCarla Míriam Ferreira100% (3)

- Vacuum Techniques and Thin Film Deposition: Experiment 3 (October 2001)Dokument10 SeitenVacuum Techniques and Thin Film Deposition: Experiment 3 (October 2001)Nezar Gassem ElfadillNoch keine Bewertungen

- FAN AND SYSTEM CHARACTERISTICS - Kruger VentilationDokument4 SeitenFAN AND SYSTEM CHARACTERISTICS - Kruger VentilationPRASHANT GOURNoch keine Bewertungen

- Crude Unit Startup Consequences of High Liquid LevelDokument4 SeitenCrude Unit Startup Consequences of High Liquid LevelAlessio ScarabelliNoch keine Bewertungen

- Basic Vacuum Technology PrinciplesDokument54 SeitenBasic Vacuum Technology PrinciplesChiranjeev SahooNoch keine Bewertungen

- Unit 1Dokument27 SeitenUnit 1shmanviarmaNoch keine Bewertungen

- Mechanical Vacuum SystemsDokument17 SeitenMechanical Vacuum Systemsصلاح الواديNoch keine Bewertungen

- Mesh BlanketsDokument13 SeitenMesh BlanketsmodestyNoch keine Bewertungen

- Falling Head Permeability TestDokument9 SeitenFalling Head Permeability TestPasindu MalithNoch keine Bewertungen

- Surface Science Experimentals V4 KIDokument140 SeitenSurface Science Experimentals V4 KIDadang RamadhanNoch keine Bewertungen

- Lecture 11 - CE 433Dokument31 SeitenLecture 11 - CE 433MathumalarNoch keine Bewertungen

- UHV Seminar HandbookDokument136 SeitenUHV Seminar HandbookiordacheNoch keine Bewertungen

- PSD CEU 194dec12 PDFDokument22 SeitenPSD CEU 194dec12 PDFRama RameshNoch keine Bewertungen

- How Wicks and Orientation: Affect Heat Pipe PerformanceDokument6 SeitenHow Wicks and Orientation: Affect Heat Pipe Performancejames mayNoch keine Bewertungen

- III. Vacuum Fundamentals & Technology: Why We Need Vacuum?Dokument15 SeitenIII. Vacuum Fundamentals & Technology: Why We Need Vacuum?solanki8950Noch keine Bewertungen

- Unidad II Termo I PDFDokument60 SeitenUnidad II Termo I PDFRoutine Of Nepal BandaNoch keine Bewertungen

- Vacuum Leak TestingDokument14 SeitenVacuum Leak TestingDilipNoch keine Bewertungen

- Iiche Online Internship - 2020 Petroleum Refinery Engineering - Batch 1 Assignment 1 - White Paper 1Dokument3 SeitenIiche Online Internship - 2020 Petroleum Refinery Engineering - Batch 1 Assignment 1 - White Paper 1Shivam Kumar RaiNoch keine Bewertungen

- Process DesignDokument6 SeitenProcess DesignDaniel Andres Canro CalderónNoch keine Bewertungen

- A Vacuum Primer: by Gary NavrotskiDokument19 SeitenA Vacuum Primer: by Gary NavrotskiProcess EngineerNoch keine Bewertungen

- Vacuum Technology and Its Requirement: (Latin: Horror Vacui) - Therefore, An Atmosphere With A Pressure Below AmbientDokument9 SeitenVacuum Technology and Its Requirement: (Latin: Horror Vacui) - Therefore, An Atmosphere With A Pressure Below AmbientSheikh SohailNoch keine Bewertungen

- Calculos de Filtros y Pulse JetDokument18 SeitenCalculos de Filtros y Pulse JetJose Alfredo Rodriguez ColladoNoch keine Bewertungen

- Special Topics in Unit Operations: Md. Mominur Rahman Department of Chemical Engineering (Dche), BuetDokument38 SeitenSpecial Topics in Unit Operations: Md. Mominur Rahman Department of Chemical Engineering (Dche), BuetMd Abid AfridiNoch keine Bewertungen

- Falling Head PermeabilityDokument13 SeitenFalling Head PermeabilitySitiNoch keine Bewertungen

- Lecture 17-18: Illustrations - 1: Nozzles, Diffusers, Turbines, CompressorsDokument24 SeitenLecture 17-18: Illustrations - 1: Nozzles, Diffusers, Turbines, Compressorsmanish_aspiringNoch keine Bewertungen

- KJLC Ed09 Sec07 Web200910Dokument16 SeitenKJLC Ed09 Sec07 Web200910NickMoloNoch keine Bewertungen

- Fundamentals of Vacuum - Short CourseDokument37 SeitenFundamentals of Vacuum - Short CoursechipulinoNoch keine Bewertungen

- EnE 250 Air Quality Management and Pollution Control Lecture 02 - 2 APC Stationary Sources Aug 13 2015Dokument152 SeitenEnE 250 Air Quality Management and Pollution Control Lecture 02 - 2 APC Stationary Sources Aug 13 2015Alexis Bryan RiveraNoch keine Bewertungen

- Chemical Engineering ThermodynamicsDokument13 SeitenChemical Engineering ThermodynamicsHope PescadorNoch keine Bewertungen

- CycloneDokument25 SeitenCycloneAna Marie AllamNoch keine Bewertungen

- Rocket Engine Sim PDFDokument8 SeitenRocket Engine Sim PDFVidushee GeetamNoch keine Bewertungen

- Unit 3 - Air & Noise Pollution and Control - Control TechnologiesDokument143 SeitenUnit 3 - Air & Noise Pollution and Control - Control TechnologiesYash PednekarNoch keine Bewertungen

- Fundamental Principles of Diaphragm Meters: Robert Bennett American Meter CompanyDokument5 SeitenFundamental Principles of Diaphragm Meters: Robert Bennett American Meter Companymyself_riteshNoch keine Bewertungen

- Steam Blowing BASICSDokument14 SeitenSteam Blowing BASICSadarsh_gangradeNoch keine Bewertungen

- Figure 1. Ejector System For Soybean Oil DeodorizerDokument11 SeitenFigure 1. Ejector System For Soybean Oil DeodorizerjarofidzNoch keine Bewertungen

- PHM - 06-Lecture 6 (Gas Solid Separations)Dokument9 SeitenPHM - 06-Lecture 6 (Gas Solid Separations)Ritvi BartiyaNoch keine Bewertungen

- Goepfert2010 Article CharacterizationOfASystemGenerDokument14 SeitenGoepfert2010 Article CharacterizationOfASystemGenerGhazanfarNoch keine Bewertungen

- Practical Guild Airflow MeasurementDokument20 SeitenPractical Guild Airflow MeasurementJason NguyenNoch keine Bewertungen

- 1008 2294 PDFDokument17 Seiten1008 2294 PDFالاسمر الجنوبيNoch keine Bewertungen

- Lecture 5 Vacuum Systems: Z Introduction of VacuumDokument16 SeitenLecture 5 Vacuum Systems: Z Introduction of VacuumAlok BaralNoch keine Bewertungen

- Cleaning Force RatioDokument1 SeiteCleaning Force Ratioahmad isnaidiNoch keine Bewertungen

- Vacuum Pump: Type: Liquid Ring Vacuum Pump Make: Nash MODEL: AT-1006EDokument46 SeitenVacuum Pump: Type: Liquid Ring Vacuum Pump Make: Nash MODEL: AT-1006EAmit Balot100% (2)

- Chapter 05 Part 1Dokument25 SeitenChapter 05 Part 1Abdulmajeed AlqNoch keine Bewertungen

- Darcy'S Law Apparatus: Chemical Engineering GroupDokument6 SeitenDarcy'S Law Apparatus: Chemical Engineering GroupNoNameNoch keine Bewertungen

- Difusion Pryde PDFDokument5 SeitenDifusion Pryde PDFadrianaNoch keine Bewertungen

- H H T T A Al K Ty Permeabili: 3.0 TheoryDokument9 SeitenH H T T A Al K Ty Permeabili: 3.0 TheorycrizelNoch keine Bewertungen

- Radon Reduced LaboratoryDokument9 SeitenRadon Reduced LaboratoryMichael BowlesNoch keine Bewertungen

- C-Series Claw: Technologies For All Vacuum and Pressure ApplicationsDokument6 SeitenC-Series Claw: Technologies For All Vacuum and Pressure ApplicationsKrzysztof WrzeszczNoch keine Bewertungen

- Free-Water Knockouts (Fwko)Dokument17 SeitenFree-Water Knockouts (Fwko)aciNoch keine Bewertungen

- DSH CatalogueDokument20 SeitenDSH Catalogueनिखिल बायवारNoch keine Bewertungen

- High Vacuum Techniques-1Dokument15 SeitenHigh Vacuum Techniques-1Nicholas MorganNoch keine Bewertungen

- Zelimir Schmidt, Severe Slugging in Offshore Pipeline Riser-Pipe SystemsDokument12 SeitenZelimir Schmidt, Severe Slugging in Offshore Pipeline Riser-Pipe SystemsTrần Vũ HạNoch keine Bewertungen

- Falling Head Permeability Test Lab ReportDokument11 SeitenFalling Head Permeability Test Lab ReportLee Z QiNoch keine Bewertungen

- Rough Vacuum Webinar 2016Dokument30 SeitenRough Vacuum Webinar 2016sw lNoch keine Bewertungen

- Thermodynamics Chapter 1 Basic ConceptsDokument7 SeitenThermodynamics Chapter 1 Basic ConceptsKamaruz DanialNoch keine Bewertungen

- Chapter7 Internal FlowsDokument31 SeitenChapter7 Internal FlowsMithun PNoch keine Bewertungen

- Transport Process (Fluidization Beds)Dokument6 SeitenTransport Process (Fluidization Beds)zujishorok7Noch keine Bewertungen

- Mold o Rama Service Repair Manual PDFDokument34 SeitenMold o Rama Service Repair Manual PDFCarla Míriam FerreiraNoch keine Bewertungen

- METRICSectionA PDFDokument137 SeitenMETRICSectionA PDFCarla Míriam FerreiraNoch keine Bewertungen

- Layer Compression and Enhanced Optical Properties of Few-Layer Graphene Nanosheets Induced by Ion IrradiationDokument18 SeitenLayer Compression and Enhanced Optical Properties of Few-Layer Graphene Nanosheets Induced by Ion IrradiationCarla Míriam FerreiraNoch keine Bewertungen

- METRICSectionA PDFDokument137 SeitenMETRICSectionA PDFCarla Míriam FerreiraNoch keine Bewertungen

- Military 14 Bolt Axle ManualDokument29 SeitenMilitary 14 Bolt Axle ManualCAP History Library67% (6)

- Creaform Metrology Services en 13052014Dokument5 SeitenCreaform Metrology Services en 13052014Carla Míriam FerreiraNoch keine Bewertungen

- Synthetic Sapphire Extreme Performer WP en GBDokument3 SeitenSynthetic Sapphire Extreme Performer WP en GBCarla Míriam FerreiraNoch keine Bewertungen

- Thorlabs OEM BrochureDokument16 SeitenThorlabs OEM BrochureCarla Míriam FerreiraNoch keine Bewertungen

- Baterias de Filme Fino de Papel: Dia Mundial Dos Materiais 2009 2. Menção Honrosa SPMDokument15 SeitenBaterias de Filme Fino de Papel: Dia Mundial Dos Materiais 2009 2. Menção Honrosa SPMCarla Míriam FerreiraNoch keine Bewertungen

- GEARWRENCH 81 Series Air Impact Wrench Brochure SP-188-EnDokument3 SeitenGEARWRENCH 81 Series Air Impact Wrench Brochure SP-188-EnCarla Míriam FerreiraNoch keine Bewertungen

- Vacuum Assessment 2006Dokument2 SeitenVacuum Assessment 2006Carla Míriam FerreiraNoch keine Bewertungen

- PLL Loss of Lock ChecklistDokument3 SeitenPLL Loss of Lock ChecklistLeslie WrightNoch keine Bewertungen

- Arduino Based Underground Cable Fault Distance LocatorDokument60 SeitenArduino Based Underground Cable Fault Distance Locatornabil tijjani100% (3)

- Getting StartedDokument46 SeitenGetting StartedThenappan SNoch keine Bewertungen

- Micro Electro Mechanical Systems (MEMS)Dokument44 SeitenMicro Electro Mechanical Systems (MEMS)Neethu Krishna KNoch keine Bewertungen

- HCC4538B HCF4538B: Dual Monostable MultivibratorDokument14 SeitenHCC4538B HCF4538B: Dual Monostable MultivibratorDavid ReyesNoch keine Bewertungen

- SVPumps LowaraDokument64 SeitenSVPumps LowaraIsakov IgorNoch keine Bewertungen

- LM117HVDokument28 SeitenLM117HVEnrique MirazoNoch keine Bewertungen

- High Volteage EngineeringDokument5 SeitenHigh Volteage EngineeringSenthil NathanNoch keine Bewertungen

- Stun Gun Circuit: by Kenyon SmithDokument10 SeitenStun Gun Circuit: by Kenyon SmithReginald SimpsonNoch keine Bewertungen

- LN004 - PWM DRIVER For ASYMMETRIC MOTORS (V5.1) PDFDokument40 SeitenLN004 - PWM DRIVER For ASYMMETRIC MOTORS (V5.1) PDFsinergicusNoch keine Bewertungen

- Bergquist Sil Pad TSP 1600s-EnDokument2 SeitenBergquist Sil Pad TSP 1600s-EnKim WayneNoch keine Bewertungen

- Op-Amp Comparator and The Op-Amp Comparator CircuitDokument15 SeitenOp-Amp Comparator and The Op-Amp Comparator Circuitpwnkumar63Noch keine Bewertungen

- Inspection Data Sheet (I.D.S.) : Company Job. Country RevisionDokument2 SeitenInspection Data Sheet (I.D.S.) : Company Job. Country Revisionbrome2014Noch keine Bewertungen

- TV TOSHIBA 19a30Dokument11 SeitenTV TOSHIBA 19a30Eibar016Noch keine Bewertungen

- TFR PDFDokument9 SeitenTFR PDFgameel alabsiNoch keine Bewertungen

- Saloni Rana ResumeDokument3 SeitenSaloni Rana ResumeArtis HashNoch keine Bewertungen

- Resistor Sizes and PackagesDokument3 SeitenResistor Sizes and PackagesВладимир МалићNoch keine Bewertungen

- SMD Type IC SMD Type Transistors: Complementary MOSFET Half-Bridge (N-And P-Channel) KI4501DYDokument2 SeitenSMD Type IC SMD Type Transistors: Complementary MOSFET Half-Bridge (N-And P-Channel) KI4501DYVeronicaGonzalezNoch keine Bewertungen

- 18 - Ground GridDokument27 Seiten18 - Ground GridleoarcangelNoch keine Bewertungen

- 200 Basic Electronic Terms FinalDokument8 Seiten200 Basic Electronic Terms FinalShairyl Ü TablanteNoch keine Bewertungen

- MOS Mismatch Pelgrom1998Dokument4 SeitenMOS Mismatch Pelgrom1998dick freebirdNoch keine Bewertungen

- Camera Link Repeaters - Splitters, Repeaters, Mux: What Is The Weightage of in GATE Exam? 9 1.22Dokument5 SeitenCamera Link Repeaters - Splitters, Repeaters, Mux: What Is The Weightage of in GATE Exam? 9 1.22Sri ShandilyaNoch keine Bewertungen

- Resistive Transducers: Instructor: DR Alivelu M ParimiDokument28 SeitenResistive Transducers: Instructor: DR Alivelu M ParimiSaketh DahagamNoch keine Bewertungen

- Astm D 2132Dokument6 SeitenAstm D 2132IngJGM100% (1)

- Buk9222 55aDokument13 SeitenBuk9222 55aAnthony AndreyNoch keine Bewertungen

- Ah211 PDFDokument11 SeitenAh211 PDFAldo TonatoNoch keine Bewertungen

- Chapter 4 - DC MachineDokument82 SeitenChapter 4 - DC Machinepsksiva13Noch keine Bewertungen

- Soldering and DesolderingDokument24 SeitenSoldering and DesolderingMedley CharlesNoch keine Bewertungen

- TH-46PZ85E Service Manual PDFDokument154 SeitenTH-46PZ85E Service Manual PDFAngela SmithNoch keine Bewertungen