Beruflich Dokumente

Kultur Dokumente

Construction Stage Analysis of Segmental Cantilever Bridge

Hochgeladen von

IAEME PublicationOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Construction Stage Analysis of Segmental Cantilever Bridge

Hochgeladen von

IAEME PublicationCopyright:

Verfügbare Formate

International Journal of Civil Engineering and Technology (IJCIET)

Volume 8, Issue 2, February 2017, pp. 373382 Article ID: IJCIET_08_02_040

Available online at http://www.iaeme.com/IJCIET/issues.asp?JType=IJCIET&VType=8&IType=2

ISSN Print: 0976-6308 and ISSN Online: 0976-6316

IAEME Publication Scopus Indexed

CONSTRUCTION STAGE ANALYSIS OF SEGMENTAL

CANTILEVER BRIDGE

Suhas S Vokunnaya

Department of Civil Engineering, Manipal Institute of Technology, Manipal, India

Ravindranatha

Department of Civil Engineering, Manipal Institute of Technology, Manipal, India

Tanaji.Thite

Design Manager-Structures, C V Kand Consultants Pvt Ltd, Pune, India

ABSTRACT

Bridge is a structure which is usually built over several obstructions or depressions like rail

lines, water bodies, highways, pipelines, canals and also urban roads for decreasing the traffic

congestion and directing the traffic to desired destination. Cantilever construction is a method of

progressive construction of a cantilever in segments and stitching them to segments previously

casted by prestressing. Failure analysis of the bridge during construction phase is very essential,

in balanced cantilever construction of continuous bridge, Bending Moment in the bridge increases

with addition of the new segment during construction. Once the cantilever segments are added in

to both side of pier, the bending moment arise in the pier is negative and increases with the addition

of each new segment. When the key blocks are added, the bridge is converted from cantilever form

to a continuous form and the negative bending moments on the pier decreases and there arises a

positive moment.

If the design of the bridge is carried out using the final construction stage structural factors

only, it may fail during the intermediate stage. For this operation a bridge model is created and

analysed to observe the rate of change of bending moment, reactions and deflection at different

stages of construction including the time dependent effects in the construction sequence.

The final stage results of the Segmentally constructed bridge is compared with the results

obtained considering the bridge as a single structure neglecting the stage wise increments and the

difference is noted to prove the importance of Construction Stage Analysis in a Segmental

Cantilever Bridge .

Key words: Balanced Cantilever, Cast in-Situ, Construction Stage, Form Traveller, Segmental

Construction.

Cite this Article: Suhas S Vokunnaya, Ravindranatha and Tanaji.Thite, Construction Stage

Analysis of Segmental Cantilever Bridge. International Journal of Civil Engineering and

Technology, 8(2), 2017, pp. 373382.

http://www.iaeme.com/IJCIET/issues.asp?JType=IJCIET&VType=8&IType=2

http://www.iaeme.com/IJCIET/index.asp 373 editor@iaeme.com

Construction Stage Analysis of Segmental Cantilever Bridge

1. INTRODUCTION

Transportation facilities and related infrastructural developments play a key role in the overall progress of

a country. In a developing country like India, land transport especially-Road and Rail network play a major

role in this regard. Bridges are one of the most important engineering structures which are commonly used

for interplant and intercity transportation. Bridge is a structure which is usually built over several

obstructions or depressions like railways, rivers, highways, pipelines, canals and also urban roads for

decreasing the traffic jam and directing the traffic to desired destination. Main goal of constructing the

bridge refers to enhancing safety, ease of mobility, reducing time and cost, decreasing the traffic jam and

congestion that has significant impact on the environment as well as socio-economic situation of the society.

Strategic decision is to be made on the type of bridge to be constructed and is to be analysed for better

decision making in this field such as importance of the bridge, length of the bridge, span of the bridge, the

nature of the terrain, and the material used to make it, safety of drivers, pedestrians, traffic, quality of work,

user costs and impacts on the business and society.

1.1. Segmental Cantilever Bridge

A Segmental Bridge is built in short segments, that is one piece at a time, combined to span a bridge. The

bridge is either cast-in-place or precast. Where site conditions at the bridge site prohibit the erection of

scaffolding and centering on river bed and long spans are to be constructed to compensate for the high cost

of tall piers and deep foundations, cantilever construction is elegantly convenient and competitive. The

cantilevering segments are erected from pier outwards, one on either side, and stitched back simultaneously.

The insitu construction is done by a pair of travelling gantries also called form traveller each weighing

around 400-800KN .After constructing the pier head unit, a pair of gantry systems is erected on top, one on

either side of pier. The gantries project beyond the pier head to support the hanging shuttering required for

casting the next segment on either side. The external shuttering of the box section deck is supported directly

from the gantry system. The internal shuttering is supported on a gantry girder running inside the box along

the length of the bridge which in turn is supported at its forward end by previously completed decking.

Each travelling gantry is supported when it is moving from completed section to forward section. The

gantry systems proceed in a systematic manner from section to section on either side of the pier after the

prestressing of segments last cast, they also support a suspended scaffolding for constructional convenience

and labour safety. Segmental type of bridge has several advantages in comparison with conventional bridge

construction methods such as faster construction, additionally it can be used for irregular and long span

lengths with few repetitions, most advantageous part of using this method especially in urban areas refers

to its construction technology that it does not need any temporary shoring without any disruption to traffic

over water channels and in deep gorges which is very dangerous for construction workers.

1.2. Construction Stage Analysis

The construction of bridges is the most complex and challenging operations in bridge design. Different

methods and techniques are adopted for the construction of bridge superstructure. To achieve a safe and

structurally sound economical strategy planning and implementation of the construction operations, the

effects of the chosen erection methods needs to be considered [1].

http://www.iaeme.com/IJCIET/index.asp 374 editor@iaeme.com

Suhas S Vokunnaya, Ravindranatha and Tanaji.Thite

Figure 1 Typical construction of a Cantilever Bridge

These effects are seen at early age due to the time dependent effects for which construction stage (CS)

analysis has to be performed on the structure. In balanced cantilever construction of continuous bridge,

bending moment (BM) in the bridge increases with addition of the new segment during construction. Once

the cantilever segments are added in to both side of pier, the bending moment arise in the pier is negative

and increases with the addition of each new segment. When the key blocks are added the bridge converted

from cantilever form to a continuous form and the negative bending moments on the pier decreases and

arise a positive moment. So, if the design of the bridge is carried out using the service period structural

factors only, it may fail during the construction stage. It is seen that displacements have an increasing trend

towards to the middle of the bridge deck. But, bending moments have a decreasing trend. Because of the

fact that the bridge system is statically indeterminate and the cantilever length is much long, the minimum

and maximum bending moments are obtained in the middle of the bridge deck and on the bridge column,

respectively [3]. Both displacements and bending moments are obtained symmetrically according to the

middle point of the bridge deck.

2. PROJECT METHODOLOGY

2.1. Segmental Cantilever Bridge

The bridge analysed is segmentally constructed prestressed continuous box Girder Bridge consisting of

three spans with a total length of 200 m (55.5m+89m+55.5 m). The cross section height of the

superstructure is 5 m at the pier support and 3 m at the midspan section which varies following a second

order curve (Parabolically). The cantilever consist of 12 segment each 3 m long and where the two adjacent

cantilever meet they are joined with the key segments of 2 m length to close the structure and the end

segments are 2.5m long. Bridge width is 12m. The segments are constructed with the Form Traveller

(Gantry) at an interval of 14 days each. Grade of concrete used in construction of segments is M-50. In a

FCM bridge construction, the sections at the piers are deeper than those at the mid spans to resist high

moments and shear forces for cantilevers.

Prestressing cables are provided in the upper flange as they are necessary in the construction stage, the

cables in the bottom flange are post-tensioned after the completion of the superstructure when the centre

segment is cast. 15.2mm-7 ply strands are used throughout. Duct size of 0.15 m is provided. The RCC Pier

chosen is a solid rectangular one of dimension 2.5m x 7.5 m ,the Pier is constructed using M-40 concrete.

Each support has 2 rectangular piers at a spacing of 4.5m c/c of the pier.

http://www.iaeme.com/IJCIET/index.asp 375 editor@iaeme.com

Construction Stage Analysis of Segmental Cantilever Bridge

12m 36m 15m 36m 2m 36m 15m 36m 12m

15m

200m

Figure 3 Layout of the Bridge Model

The segmental bridge is modelled using the MIDAS Civil-2016 where the structure is modelled using

free cantilever method known as balanced cantilever method. During modelling, the bridge is divided into

the segments from Construction Stage 1 to Construction Stage 16, with a construction period of 14 days for

the 12 segments of length 3m each out of which first 7 days is assigned for installation of formwork,

reinforcement bars, ducts etc and next 7 days for pouring of concrete and post tensioning of tendons, curing

and 30 days is assigned for the construction of end segments and key segments each, At each construction

stage the elements are activated. In segmental bridge construction process the construction is started from

both the piers simultaneously with the help of Form Traveller (Gantry) hence time dependent effects are

important to be considered in construction stage analysis. The weight of the form traveller applied is 500kN,

which includes the formwork and its support devices is internally converted into a vertical force and a

moment, which is then applied at the end of the cantilever segment.The loads applied on the bridge structure

are generally on higher side than the vehicle loads for which it is designed, hence in construction stage

highest deflection occurs during the construction, the two cantilevers undergo different creep, shrinkage

and tendon losses, resulting in different stresses and deflections at the time of erecting the Key Segment,

such differences need to be reflected in preparing the construction stages for analysis.

Data Considered in the modelling and analysis:

1. Pier Section - 2 nos RCC pier 2.5m x7.5m at 4.5 m c/c

2. Grade of Concrete used - M-40 for Pier and M-50 Superstructure

3. Pier Table - 15m wide at top and 10 m wide at bottom, height of 15m from the

ground level

4. Superstructure - 12 segments of 3m length each, key segments of 2m length, 4nos

of end segments of 2.5 m length each

5.Form Traveller - Weight of gantry is taken as 500 kN.

6. Creep/Shrinkage - Start of loading at 10 days and end at 10000 days (As per

IRC:112-2011

http://www.iaeme.com/IJCIET/index.asp 376 editor@iaeme.com

Suhas S Vokunnaya, Ravindranatha and Tanaji.Thite

Construction of the Substructure, Gantry Fabrication and Assembling

Erection of Pier Table formwork and Installation of Form Traveller (Gantry)

Erection of formwork, Fabrication of Reinforcement, Ducts etc.,(7 day Duration)

Casting of concrete segments, curing and post tensioning of tendons (7 day duration)

Form Traveller is moved and installed to the next segment to be casted

On Completion of one span of casting, Form Traveller (gantry) is moved to another pier

Erection of scaffoldings, formwork for end spans (Full Support Zones)

Construction of key segments linking the adjacent cantilevers

Erection of scaffoldings, formwork for end spans (Full Support Zones)

Construction of key segments linking the adjacent cantilevers

Installation of bearings, post tensioning of bottom tendons

Bridge surface construction

Figure 4 Construction procedures involved

2.2. Time Dependent Material Properties

In the construction stage analysis of highway bridges, time dependent material properties such as elasticity

modulus, creep and shrinkage for concrete and relaxation for the pre stressed steel are considered. For

example, strength of the concrete increase continuously at 7th, 28th and 1000th days of concreting. If these

properties are not considered in the analysis, it may effect the analysis results. There are several material

properties and phenomena that have some effect on the response of the structure, the evolution of material

parameters such as elastic modulus, creep, shrinkage,, and relaxation has been described according to the

methods in the design code IRC 112-2011.

Creep phenomenon may be defined as the property of concrete by which it continues to deform with

time under sustained loads at unit stresses within the acceptable elastic range. Shrinkage is the property of

concrete to change in volume independent of the load it sustains. It is essentially due to evaporation of

water from concrete and hydration of its components with time, which occurs without any external stress

to the concrete.

Shrinkage is usually expressed as a dimensionless strain under steady condition of relative humidity

and temperature. The development of compressive strength of concrete depends on the type of cement,

curing conditions and maturity of concrete.

http://www.iaeme.com/IJCIET/index.asp 377 editor@iaeme.com

Construction Stage Analysis of Segmental Cantilever Bridge

Figure 5 Definition of Creep and Shrinkage

2.3. Loads and Load Cases

In the analyses of the bridge, the following load cases are considered;

Dead Load: Weight of all elements is considered, it is calculated directly from the software for the model

input.

Additional Load: Weight of the pavement, crash barriers, footpath kerb is added as additional loads and is

considered to be 30 kN/m distributed throughout.

Gantry: Load of the form traveller. This load is implemented to previous one before the construction of

one segment and slide to next one after construction of the segment this load is considered as 500

kN. After the construction of the bridge, this load is removed wholly.

Pre stress: Post-tension cables are fixed according to the load charecteristics by the software itself. Post-

tension loads are considered as strain.

Time dependent Loads: Creep, Shrinkage and Compressive strength gain charecteristics is evaluated at

each stage of construction and age of concrete, which corresponds to the Modulus of Elasticity at the

specified period of construction.

The final stage results of the Segmentally constructed bridge is compared with the results obtained

considering the bridge as a single structure neglecting the stage wise increments and the difference is noted

to prove the importance of Construction Stage Analysis.

3. ANALYSIS AND RESULTS

3.1. Maximum Bending Moments (Cantilever Moments)

The Bending moments induced due to the Dead load, Prestress tendons, Erection loads, Creep, Shrinkage

of concrete are tabulated as below considering a point at which maximum moment occurs (Pier Table)

according to the stages of construction in the segmental bridge construction.

The maximum bending moment at the final stage analysis without the construction stage analysis effect

is found to be -141173.1 kN-m

The graphical representation of variation of Bending moments according to the stages of construction

at a point in the pier table is considered and shown below in Fig.6.

http://www.iaeme.com/IJCIET/index.asp 378 editor@iaeme.com

Suhas S Vokunnaya, Ravindranatha and Tanaji.Thite

Bending Moments in (kN-m)

Construction

Dead Erection Prestress

Stage Creep Summation

Load Load Tendon

CS-1 -7343.63 -2500 8809.861 287.7247 -1033.772

CS-2 -15459 -4000 14570.25 -539.391 -4889.535

CS-3 -26745.2 -5500 21265.83 -2193.96 -10979.37

CS-4 -41075 -7000 29044.04 -4581.26 -19030.97

CS-5 -58353.6 -8500 37227.14 -7832.7 -29626.46

CS-6 -78490.7 -10000 45121.14 -12113.6 -43369.53

CS-7 -101443 -11500 60152.18 -15655 -52790.72

CS-8 -127345 -13000 74993.41 -19911.2 -65351.9

CS-9 -156149 -14500 89604.19 -24977.1 -81044.93

CS-10 -187918 -16000 104127.6 -30879.9 -99790.6

CS-11 -222748 -17500 119399.1 -37478.4 -120848.5

CS-12 -260730 -19000 129133.3 -45963.4 -150596.8

CS-13 -273530 -20500 139785.5 -54613.1 -154244.6

CS-14 -283598 -13267.8 150766.8 -56269.4 -144390.1

CS-15 -287114 -13267.8 150145.1 -61254.1 -146301.4

CS-16 -294760 -12381.8 144210.1 -123229 -150297.1

Figure 6 Variation of Bending Moment with Construction stages and load cases

http://www.iaeme.com/IJCIET/index.asp 379 editor@iaeme.com

Construction Stage Analysis of Segmental Cantilever Bridge

3.2. Behaviour of RCC Pier

The variation of vertical reaction and the bending moments with the Construction Stages at the base of the

Pier is as tabulated below:

Fz (kN) My (kN-m)

Construction

Stage Erection Erection

Dead Load Summation Dead Load Summation

Load Load

CS-1 10926.8 500 11433.37 -800.515 -218.344 -919.55

CS-2 12087.63 500 12597.29 -1399.53 -298.377 -1508.8

CS-3 13216.71 500 13729.04 -2148.99 -376.782 -2189.5

CS-4 14321.49 500 14836.42 -3040.65 -453.966 -2947.4

CS-5 15405.41 500 15922.76 -4064.99 -529.928 -3813.8

CS-6 16475.67 500 16995.14 -5211.59 -604.82 -4817.6

CS-7 17531.21 500 18053.95 -6483.02 -678.944 -5685.3

CS-8 18590.68 500 19116.5 -7872.03 -751.613 -6675.1

CS-9 19645.52 500 20174.19 -9373.4 -823 -7781.8

CS-10 20699.16 500 21230.47 -10988.9 -893.249 -9001.5

CS-11 21755.04 500 22288.92 -12721.7 -962.477 -10298

CS-12 22826.34 500 23362 -14564.6 -1030.65 -11869

CS-13 25897.94 500 26454.74 -13424.5 -1098.33 -10515

CS-14 28544.68 2789.26 28332.25 -12638.7 874.3043 -8982.7

CS-15 26584.1 2789.26 25859.22 -14113.7 874.3043 -10618

CS-16 26909.44 3274.28 19003.57 -13901.6 613.6935 -29955

70000

60000

50000

40000

Fx(kN) Summation

30000 Fx(kN) Erection Load

20000 Fx(kN) Dead Load

10000

0

CS-1

CS-2

CS-3

CS-4

CS-5

CS-6

CS-7

CS-8

CS-9

CS-10

CS-11

CS-12

CS-13

CS-14

CS-15

CS-16

Figure 7 Variation of Moments (Reaction) with different Construction Stages

3.3. Displacement of the Box Girder

The displacement of the top girder obtained for the last stage of construction which is maximum, the

maximum displacement is found to be 30.04 mm (<allowable deflection i.e 185mm), the displacements of

various segments is as shown in the deformed shape.

http://www.iaeme.com/IJCIET/index.asp 380 editor@iaeme.com

Suhas S Vokunnaya, Ravindranatha and Tanaji.Thite

Figure 8 Displacements at CS-16 (Maximum)

4. CONCLUSIONS

Large difference is observed between the results with and without the construction stages, a difference of

13071 kN-m (10 % deviation) . It can be stated that the analysis without construction stages cannot give the

reliable solutions.

The bending moment increases as the new segment is added till a key segment is constructed (CS-13).

The variation in the Reaction parameters offered by the pier (column) has to be considered and incorporated

in the design.

Maximum Bending moments occur on the Pier Table.

REFERENCES

[1] Richard Malm, Hakan Sundquist (2010) Time-dependent analyses of segmentally constructed balanced

cantilever bridges Elsevier journal of Engineering Structures 32(2010).

[2] Ahmet Can Altunisik, Alemdar Bayraktar, Bar Sevim, Sleyman Adanu and Arman Domani. (2010)

Construction stage analysis of Komura Highway Bridge using time dependent material properties-

Structural Engineering and Mechanics, Vol. 36, No. 2 ,Page no 207-223

[3] Parag D Patil, Dr.B.S Karkare, G.R.Chillal. (2010) Construction Stage Analysis of Balanced Cantilever

Bridge International Journal of Advance Foundation and Research In Science & Engineering, Volume

2.

[4] Adanur, S. and Gunayd M. (2010), Construction stage analysis of bosporus suspension bridge,

Proceeding of 9th International Congress on Advances in Civil Engineering, Trabzon, September.

[5] Altun k, A.C., Bayraktar, A., Sevim, B., Domani, A. and Adanur, S. (2009), Construction stage

analysis of bridges using time dependent material properties, Proceeding of International Symposium

on Earthquake, Sakarya, September.

[6] JN Mahto and SC Roy, Experimental Analysis of Propagation of Crack In Brass Cantilever Beam Under

Forced Vibration. International Journal of Mechanical Engineering and Technology, 7(5), 2016, pp. 316

320

[7] IRC: 112 2011, Code of Practice for Concrete Road Bridges, India Road Congress, New Delhi.

[8] IRC: 18 2010, Design Criteria for Prestressed Concrete Road Bridges, India Road Congress, New

Delhi.

http://www.iaeme.com/IJCIET/index.asp 381 editor@iaeme.com

Construction Stage Analysis of Segmental Cantilever Bridge

[9] ER. Hassan Mohamed Abdulnabi and Dr. V. C. Agarwal, Claims in Construction Projects "Design Errors

and Change Orders". International Journal of Civil Engineering and Technology, 7(6), 2016, pp.123

130.

[10] Sumesh Sudheer Babu and Dr. B. Sudhakar, Construction Project Management During Economic Crisis.

International Journal of Management, 7(7), 2016, pp. 371381

[11] IRC SP: 65 2005, Guidelines for Design and Construction of Segmental Bridges, India Road

Congress, New Delhi.

[12] IS: 456 2000, Plain and Reinforced Concrete Code of Practice, Bureau of Indian Standards, New

Delhi.

[13] IS: 1343 2012, Prestressed Concrete Code of Practice, Bureau of Indian Standards, New Delhi.

[14] Raina.V.K, Rainas Concrete Bridge Practice-Analysis,Design and Economics, 2007.

http://www.iaeme.com/IJCIET/index.asp 382 editor@iaeme.com

Das könnte Ihnen auch gefallen

- Strukturas MSS PresentationDokument52 SeitenStrukturas MSS PresentationumutakinNoch keine Bewertungen

- Is 1343-Prestress-Flexure and ShearDokument134 SeitenIs 1343-Prestress-Flexure and Sheargrkvani10100% (1)

- Pain Audit ToolsDokument10 SeitenPain Audit ToolsIrmela CoricNoch keine Bewertungen

- Course On Balance Cantilever BridgeDokument43 SeitenCourse On Balance Cantilever BridgeNandeesha Ramesh100% (1)

- Cable Supported Bridges: Concept and DesignVon EverandCable Supported Bridges: Concept and DesignBewertung: 5 von 5 Sternen5/5 (1)

- Toyota Auris Corolla 2007 2013 Electrical Wiring DiagramDokument22 SeitenToyota Auris Corolla 2007 2013 Electrical Wiring Diagrampriscillasalas040195ori100% (125)

- Manual On Power System ProtectionDokument393 SeitenManual On Power System ProtectionSakthi Murugan88% (17)

- NDA For Consultants Template-1Dokument4 SeitenNDA For Consultants Template-1David Jay Mor100% (1)

- Akashi Kaikyo BridgeDokument110 SeitenAkashi Kaikyo Bridgekhawaja AliNoch keine Bewertungen

- MB Concrete Footbridges July2012Dokument8 SeitenMB Concrete Footbridges July2012Yasonsky CaptainNoch keine Bewertungen

- Introduction To The Bridge EngineeringDokument153 SeitenIntroduction To The Bridge EngineeringyasirjurabaNoch keine Bewertungen

- Analysis and Design of Prestressed Concrete Box Girder BridgeDokument14 SeitenAnalysis and Design of Prestressed Concrete Box Girder BridgeCETNoch keine Bewertungen

- Bridges: Prepared By: DIA Baboye Lhmaime Mohamed Ajouaou Farid Yazid HamzaDokument34 SeitenBridges: Prepared By: DIA Baboye Lhmaime Mohamed Ajouaou Farid Yazid HamzaSaid Mrf100% (1)

- BRIDGES - PPT by VASUMATHIDokument48 SeitenBRIDGES - PPT by VASUMATHIVASUMATHINoch keine Bewertungen

- MIDAS Civil 2013 Analysis ReferenceDokument400 SeitenMIDAS Civil 2013 Analysis ReferenceFernando Viloria0% (1)

- Design and Analysis of Pre Stressed I Girders by Midas Civil SoftwareDokument7 SeitenDesign and Analysis of Pre Stressed I Girders by Midas Civil SoftwareEditor IJTSRDNoch keine Bewertungen

- Www.sefindia.orgDokument372 SeitenWww.sefindia.orgRahul KolateNoch keine Bewertungen

- The New Balanced Cantilever Bridge Over Acheloos RiverDokument9 SeitenThe New Balanced Cantilever Bridge Over Acheloos Riverhugojameswood100% (1)

- Gaurav Jhalani SeminarDokument47 SeitenGaurav Jhalani SeminarrezarazaqaNoch keine Bewertungen

- E-Payment (Telecom Operatoers)Dokument12 SeitenE-Payment (Telecom Operatoers)Ahmed SelimNoch keine Bewertungen

- CVH CFST Arch BridgeDokument71 SeitenCVH CFST Arch BridgeTùng NguyễnNoch keine Bewertungen

- PowerPoint Cable Stay BridgeDokument76 SeitenPowerPoint Cable Stay BridgeNONGTHON100% (1)

- Method Statement For Backfilling WorksDokument3 SeitenMethod Statement For Backfilling WorksCrazyBookWorm86% (7)

- Precast Segmental Bridge ConstructionDokument16 SeitenPrecast Segmental Bridge ConstructionAhmedNoch keine Bewertungen

- COWIs International Bridge ProjectsDokument45 SeitenCOWIs International Bridge ProjectsSteel_catNoch keine Bewertungen

- Review On Reinforced Concrete Skew SlabDokument4 SeitenReview On Reinforced Concrete Skew SlabAscanio MarchionneNoch keine Bewertungen

- PC Cable-Stayed Bridge Part I PDFDokument28 SeitenPC Cable-Stayed Bridge Part I PDFEncik BadrulNoch keine Bewertungen

- A Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiDokument16 SeitenA Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiIAEME PublicationNoch keine Bewertungen

- Balanced Cantilever Bridge Analysis Day 3Dokument15 SeitenBalanced Cantilever Bridge Analysis Day 3Isidro P. BuquironNoch keine Bewertungen

- Chapter 3 Direct Displacement Based DesignDokument68 SeitenChapter 3 Direct Displacement Based DesignMuhammadNomanKNoch keine Bewertungen

- Balanced Cantilever StabilityDokument12 SeitenBalanced Cantilever StabilityTeo Peng KeatNoch keine Bewertungen

- 4.3 - K F Tam, Gammon - PDFDokument11 Seiten4.3 - K F Tam, Gammon - PDFsouthchayNoch keine Bewertungen

- Detail Design of Bridge Abutment 1Dokument4 SeitenDetail Design of Bridge Abutment 1mohammad azimNoch keine Bewertungen

- Bridge Bearing DesignDokument2 SeitenBridge Bearing DesignYoshua Yang100% (1)

- Phu My BridgeDokument7 SeitenPhu My BridgetecanasioNoch keine Bewertungen

- GDN-206 - Guidelines On Safety Management System in Petroleum IndustryDokument49 SeitenGDN-206 - Guidelines On Safety Management System in Petroleum IndustrykarpanaiNoch keine Bewertungen

- WhenBalancedCantileverBridgeConstruction A MoreFeasibleOptionDokument66 SeitenWhenBalancedCantileverBridgeConstruction A MoreFeasibleOptionSathyanarayanan DhandapaniNoch keine Bewertungen

- 4 Design of Slab Bridges PDFDokument6 Seiten4 Design of Slab Bridges PDFsohanpmeharwadeNoch keine Bewertungen

- Framework For Durable ConcreteDokument8 SeitenFramework For Durable ConcreteDai ThanhNoch keine Bewertungen

- Transverse Post-Tensioning Design and Detailing of Precast Prestressed Concrete Adjacent-Box-Girder Bridges PDFDokument15 SeitenTransverse Post-Tensioning Design and Detailing of Precast Prestressed Concrete Adjacent-Box-Girder Bridges PDFSanti CheewabantherngNoch keine Bewertungen

- Welcome To Mandovi Bridge Project Site GoaDokument132 SeitenWelcome To Mandovi Bridge Project Site GoaVenkatesh RavvaNoch keine Bewertungen

- Cable Stayed BridgesDokument33 SeitenCable Stayed Bridgesmaged salama100% (1)

- Construction Stage Analysis of Segmental BridgesDokument19 SeitenConstruction Stage Analysis of Segmental BridgesSHRADDHA KADAMNoch keine Bewertungen

- Bridge Construction: Dr. Ahmed Abdel-Atty Gab-AllahDokument32 SeitenBridge Construction: Dr. Ahmed Abdel-Atty Gab-Allahselva_651950Noch keine Bewertungen

- Seismic Design Requirements and Construction Challenges of Lifeline Essential and Critical BridgesDokument44 SeitenSeismic Design Requirements and Construction Challenges of Lifeline Essential and Critical BridgesJack JackNoch keine Bewertungen

- Comparative Study of Waffle Slab With Bracing System and Conventional Slabs Without Bracing SystemDokument8 SeitenComparative Study of Waffle Slab With Bracing System and Conventional Slabs Without Bracing SystemIJRASETPublicationsNoch keine Bewertungen

- Segmental Bridge Construction in Florida-A Review and PerspectiveDokument42 SeitenSegmental Bridge Construction in Florida-A Review and PerspectiveTan Duy LeNoch keine Bewertungen

- Balanced Cantilever Bridges 1Dokument6 SeitenBalanced Cantilever Bridges 1roshanNoch keine Bewertungen

- PC Cable-Stayed Bridge Part IDokument30 SeitenPC Cable-Stayed Bridge Part Inandi_scrNoch keine Bewertungen

- Construction Control of The Yamen Cable-Stayed Bridge: Han Dajian Su ChengDokument6 SeitenConstruction Control of The Yamen Cable-Stayed Bridge: Han Dajian Su Chengarindam1508Noch keine Bewertungen

- ANSYS and Cable Stayed BridgeDokument22 SeitenANSYS and Cable Stayed BridgeZain SaeedNoch keine Bewertungen

- Pre Tensioning and Post TensioningDokument13 SeitenPre Tensioning and Post TensioningBal Krishna Rajput100% (1)

- Chapter 2 Literature ReviewDokument10 SeitenChapter 2 Literature ReviewSharan BvpNoch keine Bewertungen

- Design of Pier Segments in Segmental Hollow Box Girder Bridges 3898739929 PDFDokument1 SeiteDesign of Pier Segments in Segmental Hollow Box Girder Bridges 3898739929 PDFVarun VermaNoch keine Bewertungen

- Arch Bridge ConstructionDokument8 SeitenArch Bridge Constructionjim1893Noch keine Bewertungen

- PCM For Waterproofing WorksDokument23 SeitenPCM For Waterproofing WorksChris AdaminovicNoch keine Bewertungen

- Comparative Study of RCC T-Beam Bridge By12Dokument32 SeitenComparative Study of RCC T-Beam Bridge By12Pranay ReddyNoch keine Bewertungen

- CD-Bridge Engineering-2008May16Dokument482 SeitenCD-Bridge Engineering-2008May16dingwen1974100% (1)

- RCC Slab Culvert Widening 1X3.0Dokument1 SeiteRCC Slab Culvert Widening 1X3.0Shivam SharmaNoch keine Bewertungen

- Gustave Magnel LectureDokument4 SeitenGustave Magnel LectureRachel BushNoch keine Bewertungen

- Bridge Construction PDFDokument74 SeitenBridge Construction PDFsanusi69Noch keine Bewertungen

- Computerised Design of Box Girder Bridge Using Balanced Cantilever MethodDokument14 SeitenComputerised Design of Box Girder Bridge Using Balanced Cantilever MethodTeo Peng KeatNoch keine Bewertungen

- Paper Bridge Construction MethodDokument10 SeitenPaper Bridge Construction MethodAsep ArdiantoNoch keine Bewertungen

- The Books On The BottomDokument53 SeitenThe Books On The BottomJr BongabongNoch keine Bewertungen

- Design of High Level Bridge Across River: Rathod Chiranjeevi Sabbineni RamyakalaDokument11 SeitenDesign of High Level Bridge Across River: Rathod Chiranjeevi Sabbineni RamyakalaimamtaNoch keine Bewertungen

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionVon EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNoch keine Bewertungen

- Impact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesDokument10 SeitenImpact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesIAEME PublicationNoch keine Bewertungen

- A Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurDokument7 SeitenA Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurIAEME PublicationNoch keine Bewertungen

- Modeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyDokument14 SeitenModeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyIAEME PublicationNoch keine Bewertungen

- Broad Unexposed Skills of Transgender EntrepreneursDokument8 SeitenBroad Unexposed Skills of Transgender EntrepreneursIAEME PublicationNoch keine Bewertungen

- Voice Based Atm For Visually Impaired Using ArduinoDokument7 SeitenVoice Based Atm For Visually Impaired Using ArduinoIAEME PublicationNoch keine Bewertungen

- A Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaDokument9 SeitenA Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaIAEME PublicationNoch keine Bewertungen

- Dealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsDokument8 SeitenDealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsIAEME PublicationNoch keine Bewertungen

- Influence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiDokument16 SeitenInfluence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiIAEME PublicationNoch keine Bewertungen

- Attrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesDokument15 SeitenAttrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesIAEME PublicationNoch keine Bewertungen

- Role of Social Entrepreneurship in Rural Development of India - Problems and ChallengesDokument18 SeitenRole of Social Entrepreneurship in Rural Development of India - Problems and ChallengesIAEME PublicationNoch keine Bewertungen

- A Multiple - Channel Queuing Models On Fuzzy EnvironmentDokument13 SeitenA Multiple - Channel Queuing Models On Fuzzy EnvironmentIAEME PublicationNoch keine Bewertungen

- EXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESDokument9 SeitenEXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESIAEME PublicationNoch keine Bewertungen

- Application of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDDokument19 SeitenApplication of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDIAEME PublicationNoch keine Bewertungen

- Various Fuzzy Numbers and Their Various Ranking ApproachesDokument10 SeitenVarious Fuzzy Numbers and Their Various Ranking ApproachesIAEME PublicationNoch keine Bewertungen

- A Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksDokument10 SeitenA Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksIAEME PublicationNoch keine Bewertungen

- Optimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsDokument13 SeitenOptimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsIAEME PublicationNoch keine Bewertungen

- Knowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentDokument8 SeitenKnowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentIAEME PublicationNoch keine Bewertungen

- Quality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceDokument7 SeitenQuality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceIAEME PublicationNoch keine Bewertungen

- Analysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsDokument13 SeitenAnalysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsIAEME PublicationNoch keine Bewertungen

- A Overview of The Rankin Cycle-Based Heat Exchanger Used in Internal Combustion Engines To Enhance Engine PerformanceDokument5 SeitenA Overview of The Rankin Cycle-Based Heat Exchanger Used in Internal Combustion Engines To Enhance Engine PerformanceIAEME PublicationNoch keine Bewertungen

- Sentiment Analysis Approach in Natural Language Processing For Data ExtractionDokument6 SeitenSentiment Analysis Approach in Natural Language Processing For Data ExtractionIAEME PublicationNoch keine Bewertungen

- Prediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsDokument13 SeitenPrediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsIAEME PublicationNoch keine Bewertungen

- Financial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelDokument9 SeitenFinancial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelIAEME PublicationNoch keine Bewertungen

- Moderating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorDokument7 SeitenModerating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorIAEME PublicationNoch keine Bewertungen

- Formulation of The Problem of Mathematical Analysis of Cellular Communication Basic Stations in Residential Areas For Students of It-PreparationDokument7 SeitenFormulation of The Problem of Mathematical Analysis of Cellular Communication Basic Stations in Residential Areas For Students of It-PreparationIAEME PublicationNoch keine Bewertungen

- Ion Beams' Hydrodynamic Approach To The Generation of Surface PatternsDokument10 SeitenIon Beams' Hydrodynamic Approach To The Generation of Surface PatternsIAEME PublicationNoch keine Bewertungen

- Analysis On Machine Cell Recognition and Detaching From Neural SystemsDokument9 SeitenAnalysis On Machine Cell Recognition and Detaching From Neural SystemsIAEME PublicationNoch keine Bewertungen

- A Review of Particle Swarm Optimization (Pso) AlgorithmDokument26 SeitenA Review of Particle Swarm Optimization (Pso) AlgorithmIAEME PublicationNoch keine Bewertungen

- Evaluation of The Concept of Human Resource Management Regarding The Employee's Performance For Obtaining Aim of EnterprisesDokument6 SeitenEvaluation of The Concept of Human Resource Management Regarding The Employee's Performance For Obtaining Aim of EnterprisesIAEME PublicationNoch keine Bewertungen

- Aaa0030imb02 FDokument30 SeitenAaa0030imb02 FJvr Omar EspinozaNoch keine Bewertungen

- Arvind Textiles Internship ReportDokument107 SeitenArvind Textiles Internship ReportDipan SahooNoch keine Bewertungen

- Application For Leave - EODokument1 SeiteApplication For Leave - EOcomelec carmenNoch keine Bewertungen

- Objectives in DraftingDokument1 SeiteObjectives in Draftingshannejanoras03Noch keine Bewertungen

- Asme 1417 WordDokument12 SeitenAsme 1417 WordERIKA RUBIONoch keine Bewertungen

- BR186 - Design Pr¡nciples For Smoke Ventilation in Enclosed Shopping CentresDokument40 SeitenBR186 - Design Pr¡nciples For Smoke Ventilation in Enclosed Shopping CentresTrung VanNoch keine Bewertungen

- Gorlov Wind TurbineDokument3 SeitenGorlov Wind TurbineDwayneNoch keine Bewertungen

- Outline - Essay and Argumentative EssayDokument2 SeitenOutline - Essay and Argumentative EssayGabbo GómezNoch keine Bewertungen

- 1 Conflict in NG - Report - 28FEB2018Dokument46 Seiten1 Conflict in NG - Report - 28FEB2018KrishnaNoch keine Bewertungen

- DRPL Data Record Output SDP Version 4.17Dokument143 SeitenDRPL Data Record Output SDP Version 4.17rickebvNoch keine Bewertungen

- Wind Flow ProfileDokument5 SeitenWind Flow ProfileAhamed HussanNoch keine Bewertungen

- Indian Institute of Technology (Indian School of Mines) DhabadDokument23 SeitenIndian Institute of Technology (Indian School of Mines) DhabadAmit KumarNoch keine Bewertungen

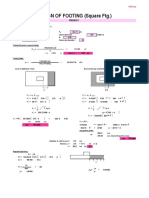

- Design of Footing (Square FTG.) : M Say, L 3.75Dokument2 SeitenDesign of Footing (Square FTG.) : M Say, L 3.75victoriaNoch keine Bewertungen

- Raport de Incercare TL 82 Engleza 2015 MasticDokument3 SeitenRaport de Incercare TL 82 Engleza 2015 MasticRoxana IoanaNoch keine Bewertungen

- Long Term Growth Fund Fact SheetDokument2 SeitenLong Term Growth Fund Fact SheetmaxamsterNoch keine Bewertungen

- 73-87 Chevy Truck 09 WebDokument132 Seiten73-87 Chevy Truck 09 WebBlaster Web Services100% (2)

- Assignment Mid Nescafe 111173001Dokument5 SeitenAssignment Mid Nescafe 111173001afnan huqNoch keine Bewertungen

- 450-11 Schmalensee RebuttalDokument11 Seiten450-11 Schmalensee RebuttalFlorian MuellerNoch keine Bewertungen

- Buffett Wisdom On CorrectionsDokument2 SeitenBuffett Wisdom On CorrectionsChrisNoch keine Bewertungen

- 2017 Directory WO Member PagesDokument112 Seiten2017 Directory WO Member PagessberkowitzNoch keine Bewertungen

- Electric Baseboard StelproDokument4 SeitenElectric Baseboard StelprojrodNoch keine Bewertungen