Beruflich Dokumente

Kultur Dokumente

Degasifier 18-02-2017 Sheet 1

Hochgeladen von

Abu SuraisyCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Degasifier 18-02-2017 Sheet 1

Hochgeladen von

Abu SuraisyCopyright:

Verfügbare Formate

1 2 3 4 5 6 7 8 9 10

KEY PLAN

DESIGN DATA PN TN

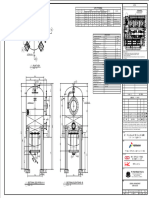

Tag No. C20201

Service Degassifier Tank Tower

A A

Manufacturer PT Golden Multiindah Glasstech

Quantity 1 Unit

Vessel Orientation Horizontal Vertical

Design Code ASME RTP-1, ASTM D-4097+D3299

Fluid Content De-cation Water

0 Fluid Density 998 kg/cm 4WW- 20102-BB1

,5

Design Pressure Full Liquid kg/cm 20WW- 20101-BB1

22,

337

Operating Pressure Atmospheric kg/cm

5 Design Temperatur 70 C

B Operating Temperatur 40 - 70 C C

B

Hydrostatic Full Water kg/cm

Test Pressure

Pneumatic N/A kg/cm

Shell

N8 0-0.3m Height 16.4 mm 8"

6"

8"

6"

3"

2"

2"

Nominal Wall Thickness 0.3-4.6m Height 10.0 mm

3"

5 Top Head 10.0 mm

31 N4

45 Bottom Head 11.4 mm

Internal No

Painting / Coating

External Yes

0

SG SG 6PA-20202-BB1

315

315

45

45

M1 M1

24" N4 24"

1"

90 270 90

N1 N1

8" 1" 8"

N4

135

135

225

225

180 180

C

0 0

SG

315

315

45

45

ASCE 7-10

M1 M1

24" N4 24"

1"

Wind Code Design

NP

90 N2 270 90

8"

N1 N1

8" 1" 8"

N4 0

N4

6"

45

315

135

135

225

225

N1

6"

180 180 M1

20"

270 90

N5

1"

135

225

N3

0 3"

180

SG SG

315

315

45

45

M1 M1

24" N4 24"

1"

90 270 90 N4

6"

45

315

N1 N1

8" 1" 8"

N4 N1

6"

M1

20"

270 90

135

135

225

225

N5

1"

Seismic Code Design ASCE 7

180

225

135

N3

3"

180

0 0

SG SG

315

315

45

45

0

N4

6"

M1 M1

315

45

24" N4 24"

1"

N1

6"

270 90 270 90 M1

20"

90

N12

N1 N1

8" 1" 8"

N5

N4 1"

225

135

135

135

N3

3"

225 180

225

180 180

0

N4

0 0 6"

45

315

SG SG

315

315

Join Efficiency 100/100

45

45

N1

6"

M1

20"

M1 M1 270 90

24" N4 24"

1"

N5

NP 1"

270 90 N2 270

8"

225

135

N3

3"

N1 N1 180

8" 1" 8"

N4

135

135

LIFTING LUG

225

225

180 180

0

N4

6"

315

45

N1

6"

M1

0 270 90

20"

SG SG

315

N5

45

45

1"

225

M1 135

24" N3

3"

180

NP

270 90 N2 270

8"

N1 N1

1" 8"

N4

Radiography N/A

135

225

225

180 180

X

Y

Inside Diameter of Shell 2300 mm

Height 4600 mm

Corrosion Barrier 3 mm

N1

5

MATERIAL SPECIFICATION

67,

,

292

M2 PART DESCRIPTION MATERIAL SPEC & GRADE NOZZLE LIST

5

D

M3 Shell FRP, Isophtalic + Roving Mark Qty Size

FLANGE PROJECTION Operate

D

Head FRP, Isophtalic + Roving

BASEPLATE Vessel Support Pipe A53 b, FRP Coated

Rating Facing Type Elevation Orientation

N.1 1 8" #150 FF WN +9.420 135 Water InputInlet

Flange ( Nozzle, Shell, ana Cover ) FRP, Isophtalic + Roving -

N.2 1 520x352 - - +5.905 270 Air Input

Nozzles FRP, Isophtalic + Roving

N.3 1 520x352 - - - +5.905 90 Air Input

Manhole FRP, Isophtalic + Roving

N.4 1 10" #150 FF WN +4.726 45 Over Flow

Stud bolts and nuts SS A193 B8 & A194 Gr.8

Lifthing Lug & Tailing Lug A36 N.5 1 12" #150 FF WN +0.736 270 Water Output

Name Plate & Bracket SS 304 & A36 N.6 1 2" #150 FF WN +5.070 192 Level Gauge

Stiddener Ring FRP, Isophtalic + Roving N.7 1 2" #150 FF WN +0.520 192 Level Gauge

E N5 N2 Joint Overlay FRP, Isophtalic + Roving N.8 1 4" #150 FF WN +0.575 45 Drain E

LIFTING LUG Internal bolts & nuts

Earthing Lugs

A193-B7 GALV.

N/A

N.9 1 2" #150 FF WN +5.241 146 Radar

N.10 1 2" #150 FF WN +0.900 146 Level Transmitter

Baffle N/A N.11 1 2" #150 FF WN +5.370 135 Venting

Foundation bolt & nuts A 307 Gr. B GALV. 2" FF Venting

N.12 1 #150 WN +5.370 315

270 Gasket PTFE #4mm

TO 1 24" - - - +5.170 Center Line Top Opening

90 Demister

Internal Ladder

N/A

A53 + Lining FRP M.1 1 24" #150 FF WN +6.320 225 Manhole

LIFTING LUG External Ladder A53 + Painted M.2 1 24" #150 FF WN +8.200 135 Manhole

M.3 1 24" #150 FF WN +10.190 45 Manhole

N3 DESIGN DATA

M.4 1 24" #150 FF WN +5.490 180 Manhole

NP.1 1 - - - - +2.000 270 Name Plate

Tag No. T20203 NP.2 1 - - - - +6.820 270 Name Plate

F F

Service Degassifier Water Tank NOTE :

ALL DIMENSION DRAWING ARE IN MILIMETER UNLESS OTHERWISE SPECIFIED

Manufacturer PT Golden Multiindah Glasstech

NP1 NP2 Quantity 1 Unit

5 FOR APPROVAL OJA DKY DDY RMT 10/02/17

5 FOR APPROVAL ATP DKY DDY RMT 11/01/17

Vessel Orientation Horizontal Vertical

4 FOR APPROVAL ATP DKY DDY RMT 22/12/16

Design Code ASME RTP-1, ASTM D4097 & D3299

3 FOR APPROVAL ATP DKY DDY RMT 24/10/16

Fluid Content Deggased Water

2 FOR APPROVAL ATP DKY DDY RMT 30/08/16

247

,5

Fluid Density 998 kg/cm 1 FOR APPROVAL ATP DKY DDY RMT 02/06/16

297420

M1 Design Pressure Full Liquid kg/cm

112

0 FOR APPROVAL ATP DKY DDY RMT 25/05/16

,5

Operating Pressure Atmospheric kg/cm

N11 REV DESCRIPTION DESIGN CHEKD APPRD AUTHD DATE

A3

Design Temperatur 70 C

PROJECT NAME :

Operating Temperatur 40 - 70 C G

AMMONIA - UREA II PROJECT

M4 Test Pressure

Hydrostatic Full Water kg/cm

Pneumatic N/A kg/cm 2000 MTPD AMMONIA AND 1725 MTPD UREA

Shell GRESIK, EAST JAVA, INDONESIA

N9 0-0.3m Height 30.5 mm

815 0.3-1.59m Height 21.0 mm CLIENT NAME :

R407

Nominal Wall Thickness 1.59-3.18m Height 15.5 mm

PETROKIMIA

610

3.18-4.77m Height 10.0 mm

Top Head 15.0 mm

5 Bottom Head 12.5 mm GRESIK

13

H

N10 Painting / Coating

Internal

External

No

Yes

Wind Code Design ASCE 7-10 CONTRACTOR :

Seismic Code Design ASCE 7

210 6 Join Efficiency N/A

14 Radiography N/A

PT. ADHI KARYA (Persero) Tbk

Inside Diameter of Shell 6750 mm BEYOND CONSTRUCTION

,5 Height 4770 mm

157 Corrosion Barrier 3 mm VENDOR :

MATERIAL SPECIFICATION I

N6 192

BUANAHDIIPT.PAANAUAJUB

HIJAU

PADI

PT.

PART DESCRIPTION MATERIAL SPEC & GRADE PT. PADI HIJAU BUANA

180 PT

. PA D

I H I JA U BU

A NA

WITHOUT

REPRODUCED

BE

SHALL

DOCUMENT

THIS

OF

PART

BUANANO

HIJAU

PADI

PT.

OF

PROPERTY

THE

AND

ARECONFIDENTIAL

IN,

THERE

CONTAINED

INFORMATION

AND

DOCUMENT

RESERVEDTHIS

RIGHTS

OWNER:DATEDESCRIPTIONAPPROVEDCHECKEDDRAWNALL

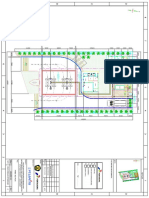

NO.SHEETS:1234567891011121314151612345678910111213141516ACDEFGHIJKACDEFGHIJK00NTS01

NO.DRAWING

NO.PROJECT

BY:SCALE:DATE:APPROVED:REVISION

BY:CHECKED

TITLE:DRAWN

:DRAWING

NOTES:PROJECT:Contractor

:GENERAL

Contractor

PROJECTMain

II

UREA

GRESIKAMMONIA

PETROKIMIA

TbkPT.

(Persero)

KARYA

ADHI

BalancePT.

DemineralizationWater

and

Water

)Filtered

6

x

10

BUANABB(

HIJAU

PADI

PT.

OF

PERMISSION

WRITTEN

PERIOR

THE

Shell FRP, Isophtalic + Roving

Head FRP, Isophtalic + Roving

N7 Vessel Support N/A

MANUFACTURE :

Flange ( Nozzle, Shell, ana Cover ) FRP, Isophtalic + Roving

Nozzles FRP, Isophtalic + Roving

Manhole FRP, Isophtalic + Roving

Stud bolts and nuts SS A193 B8 & A194 Gr.8 PT. GOLDEN MULTI INDAH GLASSTECH

Lifthing Lug & Tailing Lug A36 + COATED FRP

Name Plate & Bracket SS 304 & FRP

Stiddener Ring FRP, Isophtalic + Roving

TOP VIEW Joint Overlay

Internal bolts & nuts

Earthing Lugs

FRP, Isophtalic + Roving

A193-B7 GALV.

N/A

DRAWING NAME :

Baffle N/A

Foundation bolt & nuts A 307 Gr. B GALV.

Gasket PTFE #4mm J

Demister N/A

SIGNATURE

Internal Ladder A53 + Lining FRP SCALE : DRAWING NO : REV.

SPECI

External Ladder A53 + Painted

Handrail A53 + Painted DOCUMENT NO : SHEET. OF

1 2 3 4 5 6 7 8 9 10

Das könnte Ihnen auch gefallen

- MB 11 BrochureDokument7 SeitenMB 11 BrochurePhliip StaintonNoch keine Bewertungen

- Flint WTP O-M Manual With SOPs 553219 7Dokument83 SeitenFlint WTP O-M Manual With SOPs 553219 7Omkar BharankarNoch keine Bewertungen

- 04 Sec. 3 Sewage Characteristics and Effluent Discharge Requirements PDFDokument8 Seiten04 Sec. 3 Sewage Characteristics and Effluent Discharge Requirements PDFVic KeyNoch keine Bewertungen

- Sanitary Engineer II: Passbooks Study GuideVon EverandSanitary Engineer II: Passbooks Study GuideNoch keine Bewertungen

- Summary Report: RO System Flow DiagramDokument3 SeitenSummary Report: RO System Flow Diagramjugal ranaNoch keine Bewertungen

- 225 H Engg DataDokument8 Seiten225 H Engg DataPravin BoteNoch keine Bewertungen

- Troubleshooting STP's IssuesDokument34 SeitenTroubleshooting STP's IssuesAshish A ArbaleNoch keine Bewertungen

- 04 - STP Boq - 1080 (3x360) KLD STP MBBR - Sec-35Dokument12 Seiten04 - STP Boq - 1080 (3x360) KLD STP MBBR - Sec-35kunal singhNoch keine Bewertungen

- Brushbond TGPDokument2 SeitenBrushbond TGPBalasubramanian AnanthNoch keine Bewertungen

- M13 - L17 Grit ChamberDokument6 SeitenM13 - L17 Grit ChamberBerliana Cahya Ningtias0% (1)

- Aquachem Enviro Engineers Pvt. LTD: Civil Unitlist (BY Client) Section-IvDokument5 SeitenAquachem Enviro Engineers Pvt. LTD: Civil Unitlist (BY Client) Section-IvNitin GajmalNoch keine Bewertungen

- 12 m3hr. WTP OFFER For Bore Well Water - BOQDokument18 Seiten12 m3hr. WTP OFFER For Bore Well Water - BOQt m murshedNoch keine Bewertungen

- Uf 500 LPHDokument6 SeitenUf 500 LPHSimbu ArasanNoch keine Bewertungen

- Tulsion A-27 MPDokument2 SeitenTulsion A-27 MPPT Deltapuro IndonesiaNoch keine Bewertungen

- Techno-Commercial Offer For 600 KLD STP MBBRDokument9 SeitenTechno-Commercial Offer For 600 KLD STP MBBRTech MongerNoch keine Bewertungen

- Air Reverse OsmosisDokument12 SeitenAir Reverse Osmosisirdawan100% (2)

- Water Purifier Home in DubaiDokument33 SeitenWater Purifier Home in DubaiaquaproNoch keine Bewertungen

- SEKO Solenoid Dosing Pumps Kompact SeriesDokument3 SeitenSEKO Solenoid Dosing Pumps Kompact SeriesmauiraNoch keine Bewertungen

- WTP Boq-FinalDokument3 SeitenWTP Boq-FinalT M Murshed Mukul100% (1)

- 50 KLD Biological & Tertiary Treatment Plant - RLS FinalDokument19 Seiten50 KLD Biological & Tertiary Treatment Plant - RLS FinalkezaihrajNoch keine Bewertungen

- Waste Water Treatment PlantDokument1 SeiteWaste Water Treatment PlantdimasNoch keine Bewertungen

- Presentation of WTPDokument75 SeitenPresentation of WTPsiddhartha pandaNoch keine Bewertungen

- Reference Simulation: Project Information: Case-Specific: System DetailsDokument17 SeitenReference Simulation: Project Information: Case-Specific: System Detailssoe0303Noch keine Bewertungen

- Hydraulic Design of Sewage Treatment PlantDokument9 SeitenHydraulic Design of Sewage Treatment PlantSCR_010101Noch keine Bewertungen

- Ate Huber-1Dokument47 SeitenAte Huber-1Ravena RemaditaNoch keine Bewertungen

- Filtration Process DescriptionDokument4 SeitenFiltration Process DescriptionJoy Das MahapatraNoch keine Bewertungen

- Today'S Topic "Cooling Water Treatement" "Condenser Leak Detection" "Chlorination Plant" AND "Effluent Treatment"Dokument57 SeitenToday'S Topic "Cooling Water Treatement" "Condenser Leak Detection" "Chlorination Plant" AND "Effluent Treatment"saravan1891Noch keine Bewertungen

- 02.12.21 90m3hr Euroclean-DHV MaithonDokument16 Seiten02.12.21 90m3hr Euroclean-DHV MaithonSagnik DasNoch keine Bewertungen

- Simple Sewage: Treatment SolutionsDokument10 SeitenSimple Sewage: Treatment SolutionsAnonymous oUoJ4A8xNoch keine Bewertungen

- Process Flow Diagram Hospital E.T.P: EP Bio CompositesDokument2 SeitenProcess Flow Diagram Hospital E.T.P: EP Bio CompositesRohan Chaugule100% (1)

- WaterSoftner - Opened by M.gh.Dokument4 SeitenWaterSoftner - Opened by M.gh.Hamdy AdelNoch keine Bewertungen

- 40 KLD MBR QuoteDokument15 Seiten40 KLD MBR QuoteV Narasimha RajuNoch keine Bewertungen

- Pre-Feasibility Report For Proposed Construction Project of "Santnagari" atDokument12 SeitenPre-Feasibility Report For Proposed Construction Project of "Santnagari" atMohammedNoch keine Bewertungen

- DesignDokument3 SeitenDesigntata_77Noch keine Bewertungen

- 2021 BinNova Microfiltration General PresentationDokument19 Seiten2021 BinNova Microfiltration General PresentationФейсал УджхихNoch keine Bewertungen

- Workbook Contents: Find More Excel Spreadsheets For Engineering atDokument34 SeitenWorkbook Contents: Find More Excel Spreadsheets For Engineering atGabrielito Pachacama100% (1)

- Prensentation Slides For Industry BriefingDokument40 SeitenPrensentation Slides For Industry BriefingkunalkhubaniNoch keine Bewertungen

- PH Balancing Dosing CalculationDokument1 SeitePH Balancing Dosing Calculationkamod.rai528100% (1)

- Bike Wash ETP OfferDokument11 SeitenBike Wash ETP OfferMuhammadHanifaNoch keine Bewertungen

- Batching of Dosing Chemicals For BoilersDokument4 SeitenBatching of Dosing Chemicals For BoilersDavid Muñoz CastroNoch keine Bewertungen

- WWTP Budgeting SaddamDokument11 SeitenWWTP Budgeting SaddamAQUAMART INDONESIANoch keine Bewertungen

- Trehan STPDokument2 SeitenTrehan STPsoma_sharadNoch keine Bewertungen

- I Electro Mechanical Equipments II STP Panel III Statutory Approval ChargeDokument11 SeitenI Electro Mechanical Equipments II STP Panel III Statutory Approval ChargeSajeshKumarNoch keine Bewertungen

- Exp 3Dokument15 SeitenExp 3mjunaidNoch keine Bewertungen

- Design Basis: M/S Space Combine Kind Attn: Mr. Arun VishwakarmaDokument6 SeitenDesign Basis: M/S Space Combine Kind Attn: Mr. Arun Vishwakarmabyajaytyagi2266Noch keine Bewertungen

- ACO Passavant - Technical Handbook and Product CatalogueDokument24 SeitenACO Passavant - Technical Handbook and Product CatalogueACO PassavantNoch keine Bewertungen

- DM PlantDokument9 SeitenDM Plantsohag97Noch keine Bewertungen

- Ultra Pure WaterDokument6 SeitenUltra Pure Watergauravgarg115Noch keine Bewertungen

- Filter Ion ExchangeDokument10 SeitenFilter Ion Exchangemanjunath hrNoch keine Bewertungen

- Optimization of A2O BNR Processes Using PDFDokument16 SeitenOptimization of A2O BNR Processes Using PDFPhạm LinhNoch keine Bewertungen

- 2010 SMR ClarifierDokument60 Seiten2010 SMR ClarifierRohan KakdeNoch keine Bewertungen

- Sedron Services Sumner Washington - ST 6267 - Draft O&M Manual - Emailed 1-26-21Dokument31 SeitenSedron Services Sumner Washington - ST 6267 - Draft O&M Manual - Emailed 1-26-21Vishal shuklaNoch keine Bewertungen

- Aqua Engineers-250 KLD MBR Membrane System Design Summary: Influent FlowsDokument2 SeitenAqua Engineers-250 KLD MBR Membrane System Design Summary: Influent FlowsNithin BharathiNoch keine Bewertungen

- 04 Manifold HydraulicsDokument29 Seiten04 Manifold HydraulicsVeena NageshNoch keine Bewertungen

- 1295 - Offer 50 KLD Package Type STP 27.08.2022 - RemovedDokument11 Seiten1295 - Offer 50 KLD Package Type STP 27.08.2022 - RemovedsanjeevNoch keine Bewertungen

- A3S Enviro Consultants - ProfileDokument7 SeitenA3S Enviro Consultants - ProfileA3S Enviro Private LimitedNoch keine Bewertungen

- PFD FileDokument11 SeitenPFD FileNaveen MahawarNoch keine Bewertungen

- Httpcpe Czasopisma Pan Plimagesdatacpewydaniano3201202propertiesofactivecarbonwithvariousparticlDokument10 SeitenHttpcpe Czasopisma Pan Plimagesdatacpewydaniano3201202propertiesofactivecarbonwithvariousparticlAbu SuraisyNoch keine Bewertungen

- Naocl Tank RWTPDokument2 SeitenNaocl Tank RWTPAbu SuraisyNoch keine Bewertungen

- Coagulant Tank-RwtpDokument3 SeitenCoagulant Tank-RwtpAbu SuraisyNoch keine Bewertungen

- 0083 - 2 - PHB (Tangki WWTP) - RevDokument4 Seiten0083 - 2 - PHB (Tangki WWTP) - RevAbu SuraisyNoch keine Bewertungen

- WWTP Feed PumpDokument2 SeitenWWTP Feed PumpAbu SuraisyNoch keine Bewertungen

- Sand Filter-RwtpDokument6 SeitenSand Filter-RwtpAbu SuraisyNoch keine Bewertungen

- Determination of Wheel-Rail Contact Characteristics by Creating A Special Program For CalculationDokument12 SeitenDetermination of Wheel-Rail Contact Characteristics by Creating A Special Program For CalculationAbu SuraisyNoch keine Bewertungen

- Applied Sciences: Carbon Dioxide Adsorption On Porous and Functionalized Activated Carbon FibersDokument15 SeitenApplied Sciences: Carbon Dioxide Adsorption On Porous and Functionalized Activated Carbon FibersAbu SuraisyNoch keine Bewertungen

- Captureof CO2 From AutomobileexhaustDokument2 SeitenCaptureof CO2 From AutomobileexhaustAbu SuraisyNoch keine Bewertungen

- Tugas SolarDokument5 SeitenTugas SolarAbu SuraisyNoch keine Bewertungen

- Excel Take Home UASDokument21 SeitenExcel Take Home UASAbu SuraisyNoch keine Bewertungen

- Pipe Stress & Flexibility Analysis of Steam Line 4ms-20201-Ed1-HDokument11 SeitenPipe Stress & Flexibility Analysis of Steam Line 4ms-20201-Ed1-HAbu SuraisyNoch keine Bewertungen

- PHB Strength Calculation - Softener Pressure Vessel 09.09.19Dokument7 SeitenPHB Strength Calculation - Softener Pressure Vessel 09.09.19Abu SuraisyNoch keine Bewertungen

- Integrity Analysis of Bed StrainerDokument6 SeitenIntegrity Analysis of Bed StrainerAbu SuraisyNoch keine Bewertungen

- Cross SectDokument1 SeiteCross SectAbu SuraisyNoch keine Bewertungen

- Tugas Mata Kuliah Metodologi Penelitian (AE6000)Dokument2 SeitenTugas Mata Kuliah Metodologi Penelitian (AE6000)Abu SuraisyNoch keine Bewertungen

- Product Handbook Structureal Steel PDFDokument175 SeitenProduct Handbook Structureal Steel PDFRanu JanuarNoch keine Bewertungen

- Datasheet Steam Trap03022017Dokument4 SeitenDatasheet Steam Trap03022017Abu SuraisyNoch keine Bewertungen

- Ultra Filtration: 201485 Mechanical Data Sheet REV 2 201485-Z20212-01 Ammonia-Urea Ii Project Proj NoDokument2 SeitenUltra Filtration: 201485 Mechanical Data Sheet REV 2 201485-Z20212-01 Ammonia-Urea Ii Project Proj NoAbu SuraisyNoch keine Bewertungen

- Natural Gas Technology - Small Scale LNG - Receiving TerminalDokument7 SeitenNatural Gas Technology - Small Scale LNG - Receiving TerminalAbu SuraisyNoch keine Bewertungen

- Medium SteamDokument139 SeitenMedium SteamAbu SuraisyNoch keine Bewertungen

- Ansi b36.10 Pipe SizeDokument9 SeitenAnsi b36.10 Pipe SizeSpoonful BurnsideNoch keine Bewertungen

- 201485-37000-MC04 - PI Spec Piping Stress AnalysisDokument14 Seiten201485-37000-MC04 - PI Spec Piping Stress AnalysisAbu SuraisyNoch keine Bewertungen

- SOP 2 KaustDokument3 SeitenSOP 2 KaustAbu Suraisy100% (1)

- WindDokument6 SeitenWindAbu SuraisyNoch keine Bewertungen

- Dago Engineering Consultant Employees Monthly Time ReportDokument1 SeiteDago Engineering Consultant Employees Monthly Time ReportAbu SuraisyNoch keine Bewertungen

- Composites OverviewDokument15 SeitenComposites OverviewSantosh OjhaNoch keine Bewertungen

- BGR1 SPBGDokument1 SeiteBGR1 SPBGAbu SuraisyNoch keine Bewertungen

- Straightforward Material Section: Xlpe vs. FRPDokument2 SeitenStraightforward Material Section: Xlpe vs. FRPAbu SuraisyNoch keine Bewertungen

- Drill Bit Classifier 2004 PDFDokument15 SeitenDrill Bit Classifier 2004 PDFgustavoemir0% (2)

- GCG Damri SurabayaDokument11 SeitenGCG Damri SurabayaEndang SusilawatiNoch keine Bewertungen

- H I Ôn Thi Aptis & Vstep - Tài Liệu - Anna MaiDokument4 SeitenH I Ôn Thi Aptis & Vstep - Tài Liệu - Anna Maihanh.mt2022Noch keine Bewertungen

- Rise of Al JazeeraDokument1 SeiteRise of Al Jazeeraইlish ProductionsNoch keine Bewertungen

- Reviewer For Bookkeeping NCIIIDokument18 SeitenReviewer For Bookkeeping NCIIIAngelica Faye95% (20)

- CV Old NicDokument4 SeitenCV Old NicTensonNoch keine Bewertungen

- 7094 Bangladesh Studies: MARK SCHEME For The May/June 2011 Question Paper For The Guidance of TeachersDokument11 Seiten7094 Bangladesh Studies: MARK SCHEME For The May/June 2011 Question Paper For The Guidance of Teachersmstudy123456Noch keine Bewertungen

- Lesson Plan Wid Awt Method 2Dokument7 SeitenLesson Plan Wid Awt Method 2Yan LianNoch keine Bewertungen

- Data Analyst Chapter 3Dokument20 SeitenData Analyst Chapter 3Andi Annisa DianputriNoch keine Bewertungen

- Business English ExerciseDokument11 SeitenBusiness English ExerciseAdeline KwanNoch keine Bewertungen

- VRF Mv6R: Heat Recovery Outdoor UnitsDokument10 SeitenVRF Mv6R: Heat Recovery Outdoor UnitsTony NguyenNoch keine Bewertungen

- What On Earth Is A MainframeDokument132 SeitenWhat On Earth Is A MainframeCarlos DantasNoch keine Bewertungen

- Hotel Voucher: Itinerary ID Hotel Santika Taman Mini Indonesia IndahDokument2 SeitenHotel Voucher: Itinerary ID Hotel Santika Taman Mini Indonesia IndahSyukron PribadiNoch keine Bewertungen

- Fbla Scavenger Hunt 1Dokument3 SeitenFbla Scavenger Hunt 1api-472648158Noch keine Bewertungen

- Electric Valve Actuator Type Car: For 2 & 3-Way Valves Type G/L/M/S 2Fm-T & G/L/M/S 3Fm-T Page 1 of 4 0-4.11.08-HDokument4 SeitenElectric Valve Actuator Type Car: For 2 & 3-Way Valves Type G/L/M/S 2Fm-T & G/L/M/S 3Fm-T Page 1 of 4 0-4.11.08-HMuhd Khir RazaniNoch keine Bewertungen

- Astm D2265-00 PDFDokument5 SeitenAstm D2265-00 PDFOGINoch keine Bewertungen

- Test Cases: Project Name: Virtual ClassroomDokument5 SeitenTest Cases: Project Name: Virtual ClassroomTina HernandezNoch keine Bewertungen

- FE 208 Lab #4 - Profile Leveling: CrewDokument4 SeitenFE 208 Lab #4 - Profile Leveling: CrewJefferson Himson0% (1)

- SalerioDokument28 SeitenSalerioRizqaFebrilianyNoch keine Bewertungen

- Buy Wholesale China Popular Outdoor Football Boot For Teenagers Casual High Quality Soccer Shoes FG Ag Graffiti Style & FootballDokument1 SeiteBuy Wholesale China Popular Outdoor Football Boot For Teenagers Casual High Quality Soccer Shoes FG Ag Graffiti Style & Footballjcdc9chh8dNoch keine Bewertungen

- Intermediate Programming (Java) 1: Course Title: Getting Started With Java LanguageDokument11 SeitenIntermediate Programming (Java) 1: Course Title: Getting Started With Java LanguageRickCy Perucho PccbsitNoch keine Bewertungen

- Perfect Picture SummaryDokument3 SeitenPerfect Picture SummaryReiaNoch keine Bewertungen

- CS1 Entity Level Controls SolutionsDokument16 SeitenCS1 Entity Level Controls SolutionsPakistan Breaking News100% (6)

- Damask: by ChenoneDokument17 SeitenDamask: by ChenoneYasir IjazNoch keine Bewertungen

- ProposalDokument17 SeitenProposalKhairul AkmalNoch keine Bewertungen

- Ijrpr2741 Study On Investor Perception Towards Stock Market InvestmentDokument19 SeitenIjrpr2741 Study On Investor Perception Towards Stock Market InvestmentAbhay RanaNoch keine Bewertungen

- Kobelco CK1100G Spec BookDokument38 SeitenKobelco CK1100G Spec BookEjeantengNoch keine Bewertungen

- SET UP Computer ServerDokument3 SeitenSET UP Computer ServerRicHArdNoch keine Bewertungen

- Neuroscience Core ConceptsDokument2 SeitenNeuroscience Core Conceptseglantina alishollariNoch keine Bewertungen

- Ken Holt 06 The Secret of Hangman's InnDokument216 SeitenKen Holt 06 The Secret of Hangman's InnPastPresentFuture100% (2)